Colors play a key role in our lives: our clothes, our cars, and the furniture in our houses come with a wide range of choices when it comes to hues, inks, and paints. Since the accidental synthesis of the first synthetic aniline dye, mauveine, by William Perkin in 1856, the range of dye molecules available has widened and entered not only the textile, food, and cosmetic fields but also the pharmaceutical, plastics, ink, and packaging industries. As consumers, we mainly see them as a way of expressing our personal taste, mood, or personality and usually pay little attention to their origin and production process. As scientists, we are fascinated by the chemical processes behind them and, at the same time, mindful of the hazards they pose to the environment. This research highlights the importance not only of biotechnological approaches but also of a sustainable leadership to achieve a future-proof fashion industry. Science has been producing sustainable alternatives to counter the issue of dyes, but this is not enough. A change in the business attitude and leadership approach of the organizations that operate in the industry is needed. Only through the successful combination of new technologies and forward-looking decision-making will it be possible to alter the status quo and deal with the multiple environmental challenges that businesses are and will be facing.

- biotechnological innovation

- leadership

- sustainability

- sustainable leadership

1. Traditional Knowledge and Modern Biotechnologies

2. Colorants and Biotech-Assisted Sustainability

3. The Leadership Perspective

Today more than ever, organizations are interconnected and exercise a reciprocal influence in a constant process of exchange and cross-pollination. The advances in biotech and science are therefore only one of many factors that should be considered when addressing sustainability issues. Novel technological solutions and processes cannot be effective without the engagement of all the people involved and an overarching change in strategy that is consistent and supported by all stakeholders. Over the last few decades, many industries, like the fashion and furniture sectors, have pursued growth strategies aimed at achieving high financial returns by producing significant volumes of products and attracting a wider customer base. Unfortunately, this often resulted in high-volume, low-quality products that come with a significant negative impact on the environment [32].

The ongoing COVID-19 pandemic and conflict in the Ukraine have also exacerbated a few of the already-existing issues related to supply chain and raw material sourcing, highlighting the importance of developing reliable and efficient relationships with all parties involved in the production process [33][34]. This is also an increasingly important factor in the ability to attract new customers and retain existing ones. Consumers from newer generations are much more aware than in the past of the use of natural products and compliance with environmental protection regulations when it comes to choosing a product based on factors like carbon footprint [35][36].

References

- Agbahoungbata, M. Elements of Flair and Fashion. Chem. Int. 2019, 41, 29–33.

- Hu, R.; Li, T.; Qin, Y.; Liu, Y.; Huang, Y. Ethnobotanical study on plants used to dye traditional costumes by the Baiku Yao nationality of China. J. Ethnobio. Ethnomed. 2022, 18, 2.

- Teron, R.; Borthakur, S.K. Traditional Knowledge on Herbal Dyes and Cultural Significance of Colors among the Karbis, an Ethnic Tribe in Northeast India. Ethnobot. Res. Appl. 2012, 10, 593–603.

- Raza, A.; Iqbal, N.; Mahmood, S.; Parvee, S.; Azeem, M.; Nawaz, M.; Jarved, M.T.; Noman, A. Harnessing Natural Colorants for Sustainable Textile Dyeing an Eco-Friendly Approach Using Sweet Cane (Saccharum Bengalense Retz.) Inflorescence. Env. Sci. Braz. Arch. Biol. Tech. 2018, 61.

- Liman, M.L.R.; Islama, M.T.; Repon, M.R.; Hossain, M.M.; Sarker, P.A. Comparative dyeing behavior and UV protective characteristics of cotton fabric treated with polyphenols enriched banana and watermelon biowaste. Sustain. Chem. Pharm. 2021, 21, 100417.

- De Luca, E.; Redaelli, M.; Zaffino, C.; Bruni, S. A SERS and HPLC study of traditional dyes from native Chinese plants. Vib. Spectrosc. 2018, 95, 62–67.

- Lesellier, E.; West., C. Supercritical fluid chromatography for the analysis of natural dyes: From carotenoids to flavonoids. J. Sep. Sci. 2021, 45, 382–393.

- Angelini, L.G.; Tozzi, S.; Bracci, S.; Quercioli, F.; Radicati, B.; Picollo, M. Characterization of Traditional Dyes of The Mediterranean Area by Non-Invasive UV-Vis-NIR Reflectance Spectroscopy. Stud. Cons. 2013, 55 (Suppl. 2), 184–189.

- Ma, Y.; Rosson, L.; Wang, X.; Byrne, N. Upcycling of waste textiles into regenerated cellulose fibres: Impact of pretreatments. J. Tex. Inst. 2020, 111, 630–638.

- Kandasamy, N.; Kaliappan, K.; Palanisamy, T. Upcycling sawdust into colorant: Ecofriendly natural dyeing of fabrics with ultrasound assisted dye extract of Pterocarpus indicus Willd. Ind. Crops Prod. 2021, 171, 113969.

- Scarano, P.; Naviglio, D.; Prigioniero, A.; Tartaglia, M.; Postiglione, A.; Sciarrillo, R.; Guarino, C. Sustainability: Obtaining Natural Dyes from Waste Matrices Using the Prickly Pear Peels of Opuntia ficus-indica (L.) Miller. Agronomy 2020, 10, 528.

- Botteri, L.; Miljković, A.; Glogar, M.I. Influence of Cotton Pre-Treatment on Dyeing with Onion and Pomegranate Peel Extracts. Molecules 2022, 27, 4547.

- Adeel, S.; Ahmad, T.; ur-Rehman, F.; Kamran, M.; Sultan, M.; Amin, M.; Hassan, A. Recent Advances in Developing Ecofriendly Cost-Effective Textile Processing. In Textile Dyes and Pigments: A Green Chemistry Approach; Pandit, P., Singha, K., Maity, S., Ahmed, S., Eds.; Wiley: Hoboken, NJ, USA, 2022; Chapter 18.

- Islam, M.T.; Repon, M.R.; Rahman, M.L.; Hossain, M.M.; AlMamun, M.A. Functional modification of cellulose by chitosan and gamma radiation for higher grafting of UV protective natural chromophores. Rad. Phys. Chem. 2021, 183, 109426.

- Lara, L.; Cabral, I.; Cunha, J. Ecological Approaches to Textile Dyeing: A Review. Sustainability 2022, 14, 8353.

- Shukla, C.A.; Kute, M.S.; Kulkami, A.A. Towards sustainable continuous production of azo dyes: Possibilities and techno-economic analysis. Green Chem. 2021, 23, 6614–6624.

- Baaka, N.; El Ksibi, I.; Mhenni, M.F. Optimisation of the recovery of carotenoids from tomato processing wastes: Application on textile dyeing and assessment of its antioxidant activity. Nat. Prod. Res. 2017, 31, 196–203.

- Parshetti, G.; Saraale, G.; Telke, A.; Govindwar, S. Biodegradation of hazardous triphenylmethane dye methyl violet by Rhizobium radiobacter (MTCC 8161). J. Basic Microb. 2009, 49, S36–S42.

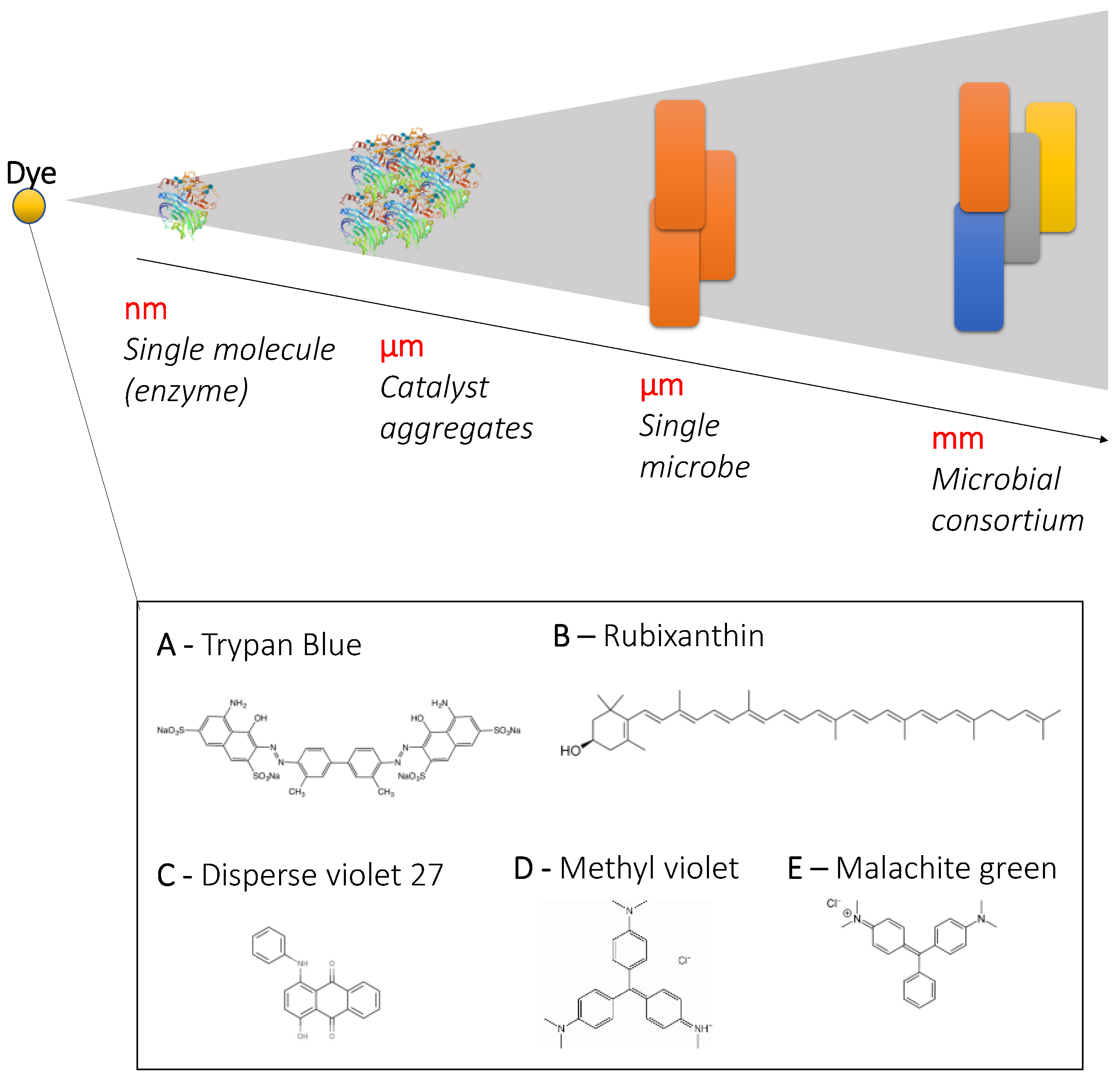

- Madhuri, R.J.; Vijayalakshmi, G. Biodegradation of diazodye, trypan blue by Aspergillus species from dye contaminated sites. Semant. Sch. 2014, 19092983.

- Jamee, R.; Siddique, R. Biodegradation of Synthetic Dyes of Textile Effluent by Microorganisms: An Environmentally and Economically Sustainable Approach. Eur. J. Microb. Imm. 2019, 9, 114–118.

- Roy, D.C.; Biswas, S.K.; Saha, A.K.; Sikdar, B.; Rahman, M.; Roy, A.K.; Prodhan, Z.H.; Tang, S.S. Biodegradation of Crystal Violet dye by bacteria isolated from textile industry effluents. PeerJ 2018, 6, e5015.

- Morsy, S.A.G.Z.; Tajudin, A.A.; Ali, M.S.M.; Shariff, F.M. Current Development in Decolorization of Synthetic Dyes by Immobilized Laccases. Front. Microbiol. 2020, 11, 572309.

- Bello-Gil, D.; Roig-Molina, E.; Fonseca, J.; Sarmiento-Ferrández, M.D.; Ferrándiz, M.; Franco, E.; Mira, E.; Maestro, B.; Sanz, J.M. An enzymatic system for decolorization of wastewater dyes using immobilized CueO laccase-like multicopper oxidase on poly-3-hydroxybutyrate. Microbiol. Biotech. 2018, 11, 881–892.

- Svetozarevića, M.; Šekuljica, N.; Onjia, A.; Barać, N.; Mihajlović, M.; Knežević-Jugović, Z.; Mijin, D. Biodegradation of synthetic dyes by free and cross-linked peroxidase in microfluidic reactor. Environ. Technol. Innov. 2022, 26, 102373.

- Kamarudin, W.F.W.; Rahman, M.N.A.; Rahamat, N.B.; Irwan, Z.; Yaafar, M.R. Microbial degradation of food dye by Pseudomonas aeruginosa. AIP Conf. Proc. 2022, 2454, 050029.

- Sarnaik, S.; Kanebar, P. Bioremediation of color of methyl violet and phenol from a dye-industry waste effluent using Pseudomonas spp. isolated from factory soil. J. Appl. Bacteriol. 1995, 79, 459–469.

- Gudelj, I.; Hrenović, J.; Hrenović, J.; Landeka, T.; Dragičević, F.; Šoljan, V.; Gudelj, H. Azo dyes, their environmental effects, and defining a strategy for their biodegradation and detoxification. Arh. Hig. Rada. Toksikol. 2011, 62, 91–101.

- Lade, H.; Kadam, A.; Paul, D.; Govindwar, S. A Low-Cost Wheat Bran Medium for Biodegradation of the Benzidine-Based Carcinogenic Dye Trypan Blue Using a Microbial Consortium. Int. J. Environ. Res. Public Health 2015, 12, 3480–3505.

- Sosa-Martínez, J.D.; Balagurusamy, N.; Montañez, J.; Peralta, R.A.; de Fátima Peralta Muniz Moreira, R.; Bracht, A.; Peralta, R.M.; Morales-Oyervides, L. Synthetic dyes biodegradation by fungal ligninolytic enzymes: Process optimization, metabolites evaluation and toxicity assessment. J. Haz. Mat. 2020, 400, 123254.

- Garg, V.K.; Amita, M.; Kumar, R.; Gupta, R. Basic dye (methylene blue) removal from simulated wastewater by adsorption using Indian Rosewood sawdust: A timber industry waste. Dyes Pigm. 2004, 63, 243–250.

- Hameed, B.H. Equilibrium and kinetic studies of methyl violet sorption by agricultural waste. J. Haz. Mat. 2004, 154, 204–212.

- UN. Putting the Brakes on Fast Fashion. 2018. Available online: https://www.unep.org/news-and-stories/story/putting-brakes-fast-fashion (accessed on 23 November 2022).

- KPMG. Russia-Ukraine War Impact on Supply Chains and Inflation. Econ. Anal. 2022. Available online: https://www.kpmg.us/insights/2022/russia-ukraine-war-impact-supply-chains-inflation.html (accessed on 23 November 2022).

- Kilpatrick, J. Supply chain implications of the Russia-Ukraine Conflict. Deloitte 2022. Available online: https://www2.deloitte.com/xe/en/insights/focus/supply-chain/supply-chain-war-russia-ukraine.html (accessed on 23 November 2022).

- Lee, K. Opportunities for green marketing: Young consumers. Mark. Intell. Plan. 2008, 26, 573–586.

- Vătămănescu, E.M.; Dabija, D.C.; Gazzola, P.; Cegarro-Navarro, J.G.; Buzzi, T. Before and after the outbreak of COVID-19: Linking fashion companies’ corporate social responsibility approach to consumers’ demand for sustainable products. J. Clean. Prod. 2021, 321, 128945.