InSolid this manuscript, an effort is made to comprehensively State Transformer (SST) is considered to be the most suitable andel

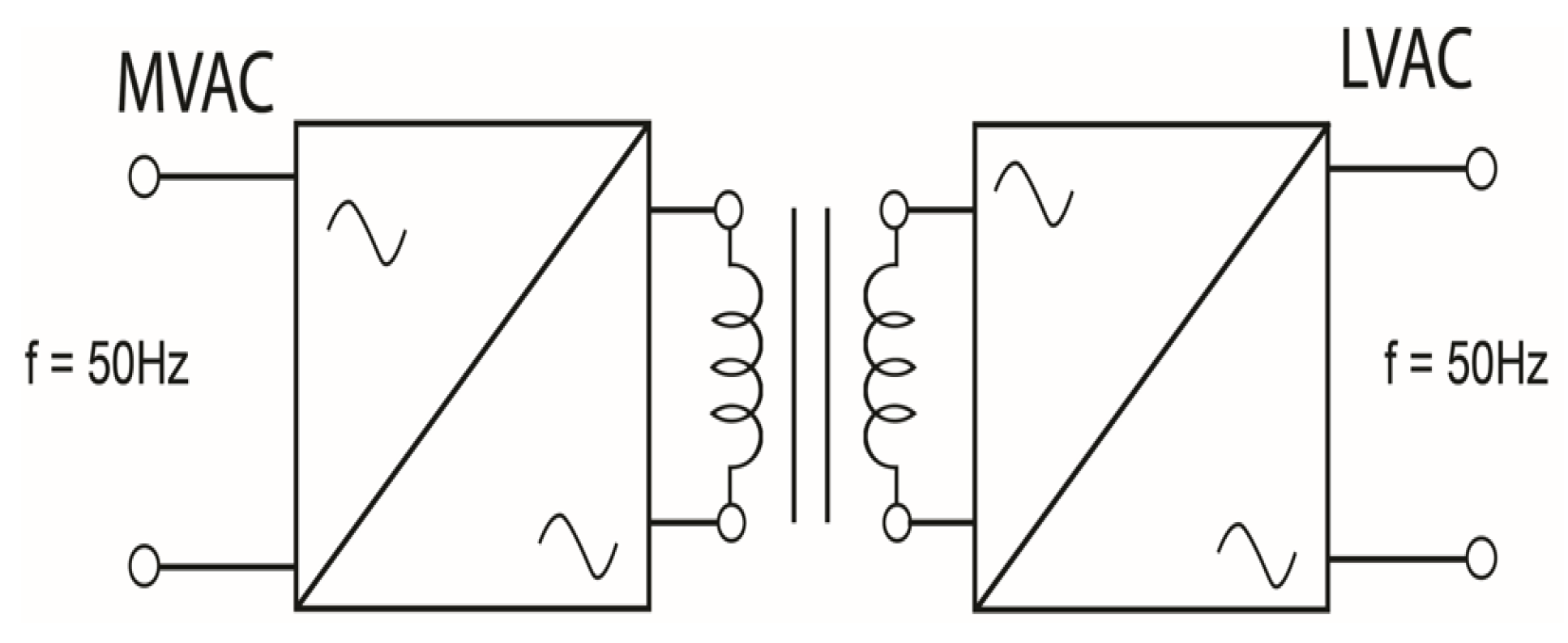

appropriberate/review the issues with the ee conversion device to replace the traditional prevailing

transformerg. In this dence of a high-voltage and hvice, the weight/volume savings, extensive

efficigency enh-power SST and related state-ancement and above all, the cost economization are taken

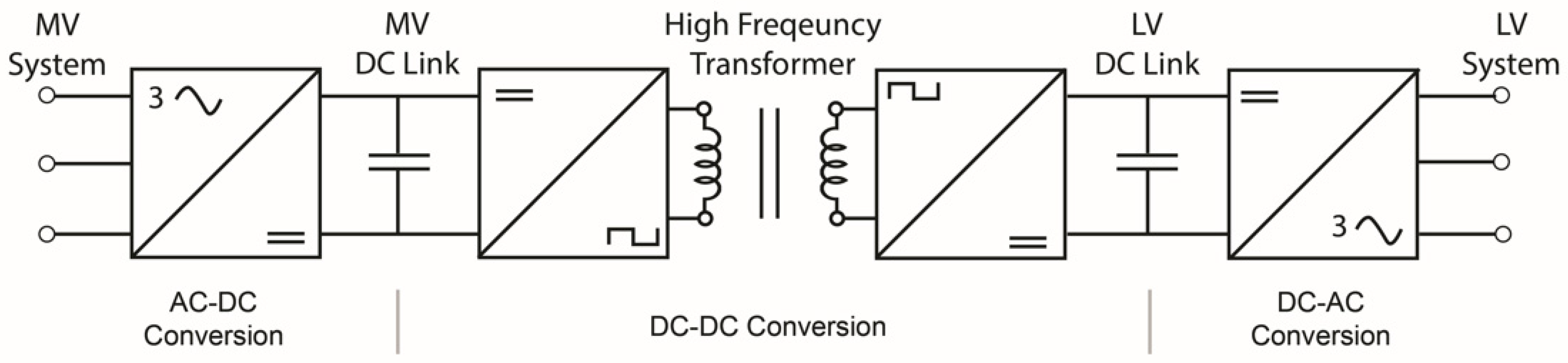

tof- be the-art investigations, mainly focusing on high-voltage hallmarks. SST configuration comprises of three main stages

(i.e., powea r devices, high-power and high-frequencyectifier, isolation through the HF transformers, A and finally the

DC-AC tcopologies, and the application of SSTs in distribution systemsnverter to reproduce line frequency AC).

- SST

- AC-AC converter

- distribution transformer

- DC-DC converter

1. Introduction

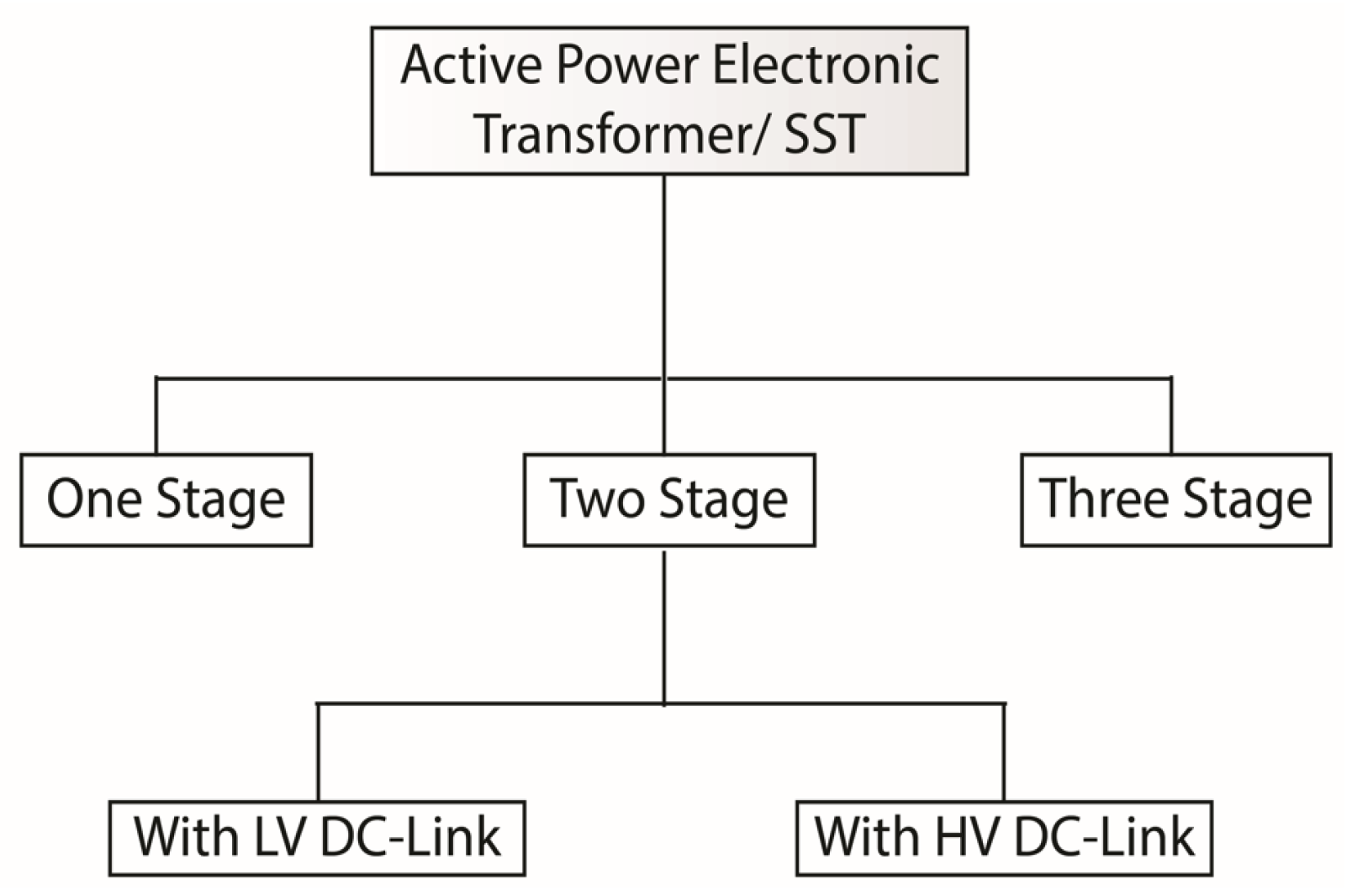

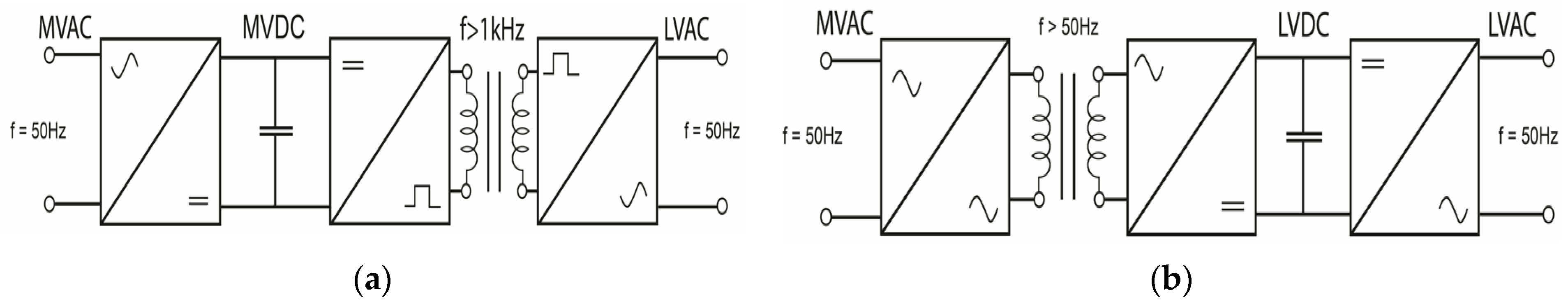

1.1. Single-Stage SST

1.2. Two-Stage SST

1.3. Three-Stage SST

2. Three Topologies and SST Applications

2.1. Solid State Transformer Architecture

2.2. Transformer-Isolated DC-DC Converter

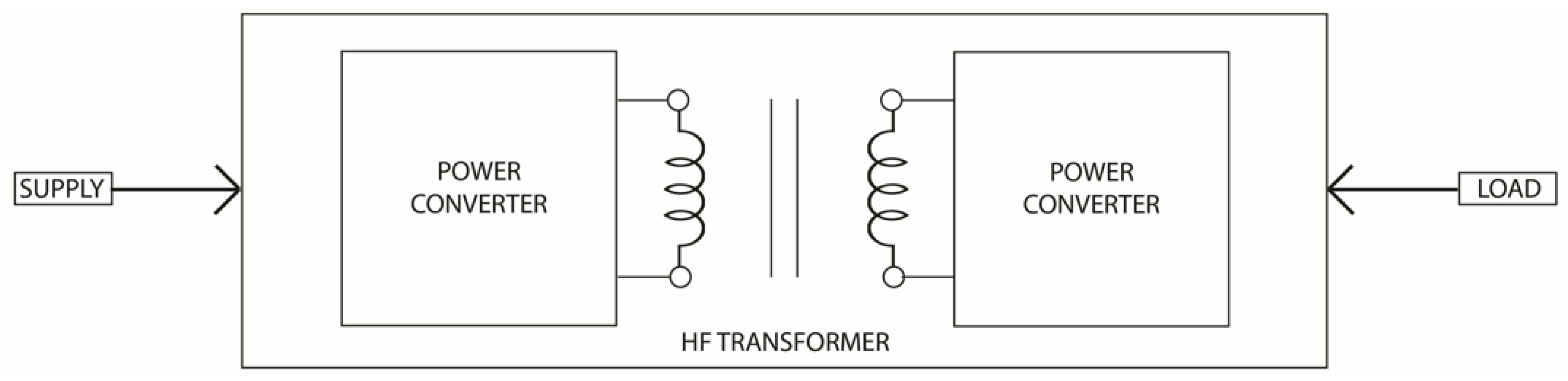

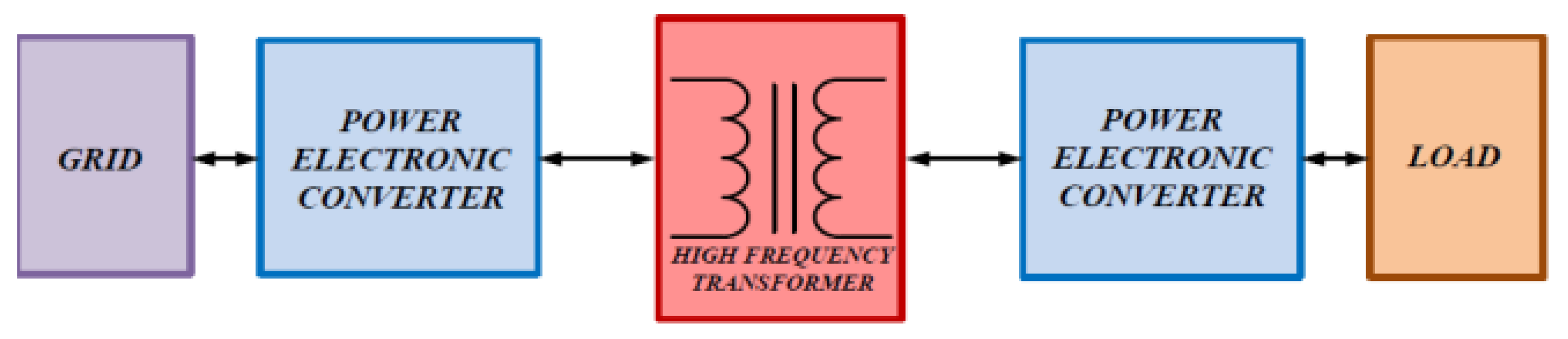

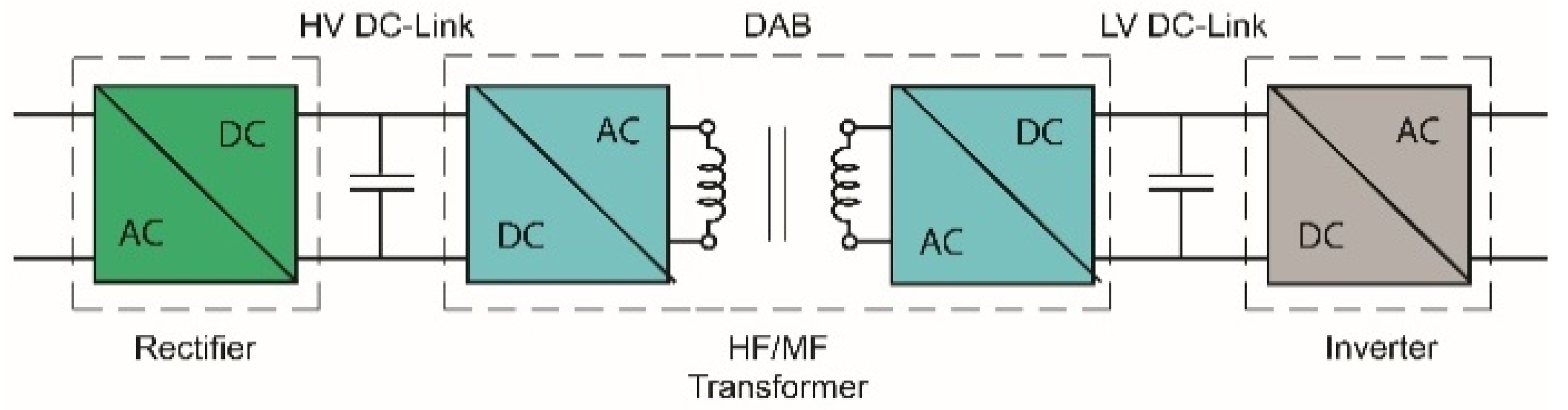

The transformer-isolated DC-DC converter as an entity and the SST as a scheme; both of these arrangements make use of HF inverter at the input side of the MPHF transformer in order to produce AC voltage. Transformer-isolated converters are incorporated primarily for the establishment of galvanic isolation, to enhance safety, to raise noise immunity and to avoid the transmission of voltage transients to the output. With fragmentary technological progression in power electronics, exploration in this arena is very vigorous and rationalized, and numerous research manuscripts are circulated [33][34][35][36]. Power conversion using high-frequency inverters are achieving improved consideration in scheming high-frequency power distribution arrangements. Researchers (academic/industrial) and investigators are carrying out extensive research on the design of HF inverters in different configurations/topologies. In a bridge arrangement, the vital structures proposed are the full bridge (FB) and half bridge (HB) inverter in step down mode and step up mode; performance concerning efficiency and total harmonic distortion (THD) were deliberated through experimental results [37][38].2.3. High Frequency DC-AC Inverter

The literature survey emphasizes the importance of HB configuration in terms of output voltage, number of bridges, number of switches, etc. The advantages of the HB arrangement are as follows: (1) the output voltage is halved compared to the full bridge (FB) voltage requirement (i.e., step down), (2) the number of bridges required is halved as compared to the FB topology (3) the sufficient simplification of a power scheme layout, (4) the reduction in the complexity of control and protection circuitry, coupled with the reduced converter price [39][40][41][42][43]. A number of researchers have worked on the design of inverter in the FB configuration, whereas very few have based their studies on HB topology [44][45][46].2.4. Embryonic Development—HFHP Isolated DC-DC Module

A transformer-isolated DC-DC converter stage in high frequency perspective is considered to be the most significant and vital element of the SST system [47][48][49]. Conventionally, the frequently used practical devices in practice are the high voltage IGBTs, based upon three-level NPC topology; however, the 1.7 kV IGBT with low cost can also be incorporated for certain applications [50][51][52][53]. With the emergence of wide-band gap devices, the DC-DC stage working frequency is escalating, even up to 50 kHz. The DAB converter undergoes the most frequently used topology with high performance [54][55][56][57]. The LLC unregulated resonant converter (DCX) is already in practice by ABB. System efficiency has improved gradually. From the magnetic aspect, the nano-crystalline and MnZn ferrite are the most tremendous and frequently used core materials, because of their enlarged working frequency [58][59][60]. The transformer structures most commonly adopted are still the UU core shape and EE core shape [61][62][63]. Litz wire is used in almost all the transformer windings, in order to reduce the frequency current conduction loss. Most transformers use dry-type insulation; whereas ABB is already switching to oil-immersed insulation owing to its 15 kV medium voltage application [64][65][66][67].3. Transformer as Galvanic Isolator of the DAB/DHB

In comparison to conventional transformers, the SST incorporates power electronic converters using a HF transformer. Power switches such as MOSFET, IGBT, etc., are widely used [68][69][70][71]. The HF transformer plays a vital role in design and functionality. It deals mainly with the efficiency aspect, depending on the operating condition, and wire/core selection [72]. Although the high operating frequency contributes to the compactness and density of the transformer, there are many more limitations/restrictions which must be taken into consideration, such as insulation, power loss and costs [73][74][75][76]. There are two kinds of losses which contribute to total transformer losses; these include the core losses (no load loss) and the winding/copper losses (load loss) [77][78][79][80]. HF transformers in SSTs primarily cater to the performance and overall efficiency; that is why the selection of suitable materials, along with the optimization of the design, is imperative in meeting all of the requirements for the operating conditions [79][80][81]. Various types of core material characteristics are also momentarily abridged [82][83][84][85]:-

Nano-crystalline (FT-3M): Possesses saturation flux density, Bmax,1.23 (T), Curie temperature Tc 570 (°C) and maximum operation temperature.150 (°C).

-

Ferrite (3F3): Possesses saturation flux density, Bmax, 0.45 (T), Curie temperature Tc 200 (°C) and maximum operation temperature. 120 (°C).

-

Super-alloy: Possesses saturation flux density, Bmax 0.79~0.87 (T), Curie temperature Tc 430 (°C) and maximum operation temperature. 125 (°C).

-

Amorphous (2605SA): Possesses saturation flux density, Bmax 1.57(T), Curie temperature Tc 392 (°C) and maximum operation temperature. 150 (°C).