You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Tuyen Le and Version 2 by Sirius Huang.

Safety-critical sounds at job sites play an essential role in construction safety, but hearing capability is often declined due to the use of hearing protection and the complicated nature of construction noise. Thus, preserving or augmenting the auditory situational awareness of construction workers has become a critical need.

- auditory signal processing

- hazard detection

- auditory situational awareness

- construction safety

- AI

1. Introduction

The recognition of auditory safety cues at job sites plays a vital role in preventing injuries and deaths for construction workers [1]. Research has found a significant correlation between a lack of auditory signal awareness and an increase in unsafe actions leading to fatalities due to the failure to stay vigilant in hazardous situations [2][3][2,3]. Inadequate auditory situation awareness is often caused by declining hearing capability due to the use of hearing protection and the complex nature of construction noise [3]. Therefore, the development of wearable devices capable of automated detection of acoustic safety signals has received increasing attention from the research community.

Despite the critical need for augmenting the hearing of safety cues for construction workers, research in this area is still lagging. Previous studies on wearable safety devices have been focused on employing real-time data analytics to continuously measure a wide variety of safety performance metrics [4] other than auditory signals. Typical functions of existing wearable safety devices include physiological monitoring, environmental sensing, proximity detection, and location tracking of construction hazards [5]. Adopting computer vision algorithms to detect hazards is among the most popular approaches for extracting information from images or videos [6][7][8][6,7,8]. This approach still involves various challenges, such as limited field of view, illuminations, and occlusions of digital cameras that could harm the widespread use of this method at complicated construction sites. Others employed kinematic sensors, such as gyroscopes and accelerometers, to record the kinematic signals of the equipment and to detect its activities [9][10][9,10]. However, using kinematic sensors fails to detect hazards in such situations when sensors cannot be directly attached to the body of the machine that vibrates during operation, such as jackhammers, concrete pumps, and concrete truck mixers. It is also expensive and complex to deploy sensing devices on every piece of construction equipment.

Audio-based hazard detection has emerged as a supplement technique that can augment workers in effectively monitoring the work environment. Processing audio signals for automated detection has meaningful implications because hazardous situations usually cause strong acoustic emissions. A variety of hazard detection models employing advanced machine learning techniques for signal processing have been developed in many other workplace environments other than construction sites [11][12][13][14][15][11,12,13,14,15]. They possess great potential to enable workers to quickly detect auditory safety cues that are important for their safety. These computing advances have been implemented in many different environments, including indoor and public environments [16][17][18][19][20][21][22][23][24][25][26][16,17,18,19,20,21,22,23,24,25,26], medical and health care systems [27][28][27,28], and working environments [29][30][31][32][33][29,30,31,32,33]. However, current research does not sufficiently address automated auditory surveillance for construction safety.

2. Audio Signal Processing Applications and Methods

2.1. Application Contexts of Auditory Surveillance

Auditory surveillance has been applied to detect abnormal events in various contexts. As shown in Table 13, the literature shows the implementations of sound-based technology in the following areas: home security [23], public environments [16][17][18][19][20][21][22][24][25][26][16,17,18,19,20,21,22,24,25,26], office [29], medical and health care facilities [27][28][27,28], and in industrial plants [31][32][31,32].Table 13.

Applications of sound surveillance.

| Application | References |

|---|---|

| Home security | [23] |

| Detection of critical situations in a railway system | [24] |

| General surveillance in public areas | [16]16[17][19][,1720,19],20[21],21[22][,22] |

| Detection of crimes in elevators | [25] |

| Detection of human emotions in public spaces | [18][26][18,26] |

| Office surveillance | [29] |

| Medical and health care facilities | |

| Surveillance of the elderly, the convalescent, or pregnant women | [27] |

| Automatic fall detection to improve the quality of life for independent older adults | [28] |

| Industrial plants | |

| Fault diagnosis of an induction motor | [31] |

| Detection of abnormality or failure of equipment | [32] |

2.2. Principles of Audio-Based Hazard Detection

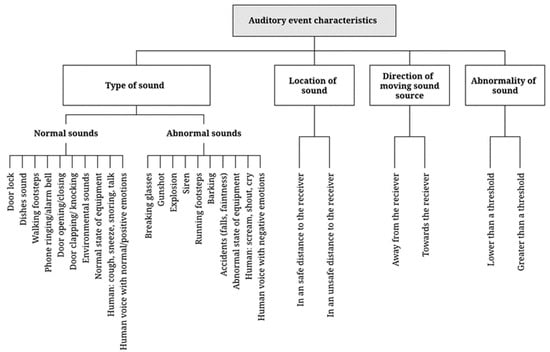

The detection of hazards using acoustic data is typically based on the extraction of the following four types of information: type of sound, location of the sound, the direction of moving sound sources, and the abnormality of sound (see Figure 17). These auditory event characteristics are used as input for detecting hazardous situations. The type of sound is the most common indicator used for detecting hazardous events and differentiating abnormal sounds from normal sound events. The occurrence of abnormal sounds, such as a gunshot or an explosion, is an important indicator of a dangerous situation requiring a quick safety response. Additionally, sound localization cues, such as the location and the direction of a moving sound source, are also essential for detecting potential abnormal events. They could inform receivers whether or not they are at an unsafe distance from the hazard. Moreover, measuring the abnormality of ambient sound has been used for evaluating hazardous situations, such as a scenario where a machine is operated and any abnormal sound that occurs in the parts or in the assembly process is often regarded as an abnormal sound and will require the attention of maintenance officers. Given the fact that onwe may not be able to classify all the unknown abnormal sound events that occur during equipment operational noise inspection, the anomaly would be useful in cases where researchers are developing the abnormal noise inspection device to automate the process.

Figure 17.

Indicators of hazardous events.

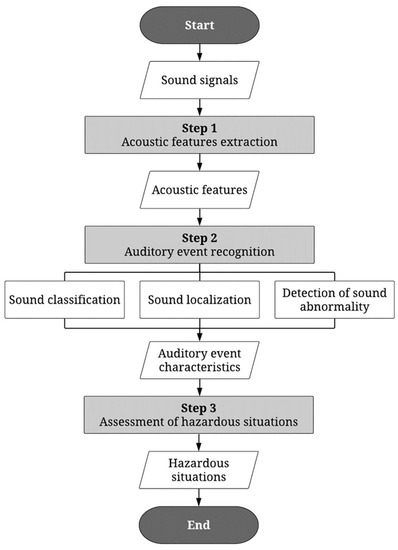

Figure 28.

Overall architecture of auditory signal processing to detect hazardous situations.

2.3. Sound Localization

Sound localization refers to the ability to identify acoustic sources in terms of direction and distance. It is one of the essential acoustic parameters that enables the ability to recognize and locate hazardous events. When dangerous objects or equipment are within an unsafe distance of a construction worker, detecting the location of acoustic sources can enable them to make appropriate preventive responses. Methods to localize sound events are mainly based on calculating the difference in the arrival times of the signal. Then, the similarity measure of the signal at different times is examined in either time or frequency domain for sound localization. For the time domain, the acoustic impulses reach the microphones at varying Times of Arrival (TOA) when they are spatially distant from one another. The signal’s Direction of Arrival (DOA) is determined from the recorded time delays using the given array geometry. Each pair of microphones in the array has a projected time delay. Then, using time delays and geometry, the best estimate of the DOA is determined, while the frequency domain is the difference between the time sound pressure reaching the array geometry and is mostly used to localize higher frequency sounds. Table 27 lists the methods for sound localization, of which the details are provided below.Table 27.

Summary of methods for sound localization.

| Methods | References |

|---|---|

| 1. Maximum-Likelihood Generalized Cross Correlation (GCC) | [17] |

| 2. Linear-correction least-square localization algorithm | [17] |

| 3. Similarity measure based on the Euclidean Distance (EUD) in the time domain | [34][78] |

| 4. Similarity measure based on Normalized Cross Correlation (NCC) in the frequency domain | [35][79] |

| 5. Similarity measure based on the Euclidean Distance (EUD) in the frequency domain | [36][80] |

| 6. Fast Fourier Transform (FFT) | [36][80] |

| 7. Fingerprinting algorithm | [37][81] |

2.4. Sound Abnormality Detection

Measuring sound abnormality is another challenging issue, given that preparing all labeled sound data related to hazardous situations is unrealistic. If a surveillance system is trained using the data of specific sounds, such as explosions or gunshots, it cannot be applied to detect other auditory events. A method for detecting unknown abnormal sound events is required to develop an automated auditory surveillance system that is useful in more general cases. To address this issue, Ref. [39][71] developed a method that models the abnormality of sounds without using any samples of labeled sounds. The technique can detect those sounds that rarely occur in a normal situation. It first processes sound in the usual situation and trains a statistical model of the normal sounds. After training the model, the system continues to process sounds and calculates the likelihood of the sound. If the likelihood value goes beyond a predefined threshold, that sound is considered abnormal. Lu et al. [40][83] used another approach to detect abnormal sounds using the case-based identification algorithm. In this method, it is necessary to first convert the sound data into feature representation vectors and then to apply an establishment distribution of a supervised learning model. This supervised learning requires a small training dataset of sample elements of abnormality. In the construction industry, sound equipment abnormality will affect the model performance since mobile equipment sound varies between different types of equipment. This could be because the acoustic characteristic of one sound is more difficult to train than that of another. Other equipment characteristics that may affect sound abnormality measurement are the models, brands, age, and maintenance programs. Obtaining different model metadata for the audio dataset would help us understand how they affect the detection capability. Collecting such data requires a significant effort in terms of time, cost, and human resources.3. Audio-Based Surveillance in Construction

3.1. Feasibility of Implementing Audio-Based Hazard Detection in Construction

The potential auditory indicators of hazards in construction are provided in Table 38. As shown, one of the most important types of sounds is the sound source of moving heavy equipment or machinery, which can cause collision hazards [30][33][41][30,33,36]. Furthermore, the detection of screams, shouts, or cry sounds is also supportive for acoustic surveillance and monitoring of negative situations, since human emotions are somehow delivered in sound events [17][18][19][20][23][24][25][26][27][28][42][43][44][45][46][17,18,19,20,23,24,25,26,27,28,61,62,68,76,77]. Other sounds released by people can also help detect abnormal situations. Detecting ground ambient sound (i.e., a group of people) allows workers to be aware of violent events, natural disasters, riots, or chaotic acts in crowds [26]. Some types of safety-critical sounds which lead to dangerous situations, such as alarms of fire, earthquakes, explosions, and gunshots, could improve the situational awareness of hazards [23][25][45][46][23,25,76,77]. For example, the detection of an explosion allows workers to stay away from the hazardous source [16] and gunshot detection allows workers to stay away from a gun attack [16][17][19][20][25][42][43][16,17,19,20,25,61,62].Table 38.

Summary of auditory event characteristics in the construction field.

| Code | Auditory Event Characteristics | References | |

|---|---|---|---|

| A | Abnormality of sound | ||

Table 49.

List of hazardous situations and required auditory event characteristics (see

Table 3 for the auditory event notations).

8 for the auditory event notations).

| No. | Hazardous Situations | Combination of Auditory Event Characteristics | |||

|---|---|---|---|---|---|

| 1 | Heavy equipment/machine is at an unsafe distance | A.1 + B | |||

| Greater than the threshold? | [ | ||||

| 2 | Heavy equipment/machine is approaching | 39][71] | |||

| A.1 + B + C | B | Direction of moving sound source | |||

| Towards the worker? | [34][35][36][78 | ||||

| 3 | Heavy equipment/machine is operating in an abnormal condition | [,7937,80],81] | |||

| C | Location of sound | ||||

| Less than a safe distance to the worker? | [34][35][36][37][78,79,80,81] | ||||

| A.1 + D | |||||

| 4 | There is someone screaming/shouting/crying | A.2a | |||

| 5 | There is a crowd approaching | A.2b + C | |||

| 6 | There is an abnormal crowd approaching | A.2b + C + D | D | ||

| 7 | Type of sound | ||||

| There is an alert alarm | A.3 | D.1 | Alert alarm (fire/earthquake) | [23][25][45][46][23,25,76,77] | |

| 8 | There is an explosion | A.4 | D.2 | Explosion | |

| 9 | [ | 19] | |||

| There is a gunshot | A.5 | D.3 | Gunshot | [16][17][19][20][25][42][43][16,17,19,20,25 | |

| 10 | There is an abnormal sound | ,61,62] | |||

| D | D.4 | Human | a. Announcement | [23] | |

| b. Crowd ambient sound | [26] | ||||

| c. Scream/shout/cry | [17][17[18][19][20][23]27,18,19],20[24][25][26][[28,23][42,24][43,25],26[,2744][45][46,28],61,62,68,76,77] | ||||

| D.5 | Moving heavy equipment/machine | [30][33][41][30,33,36] | |||