1. Introduction

Resources and the climate crises are major societal problems worldwide

[1]. The effects are intensifying, as can be seen, for example, in extreme weather conditions or bottlenecks in supply chains

[2]. Renewable energy technologies are playing an important role in tackling the climate crisis

[3,4][3][4]. However, the materials that will make up these regenerative systems will have to be mined and manufactured and the energy transition will not be realized without significant material and energy costs

[5]. For example, to limit global warming to less than 2 °C, 60 TW of photovoltaic systems need to be installed by 2050, which will require a large amount of aluminum (480 million tons) but aluminum has high global warming potential

[6]. Even so, currently photovoltaic systems as well as wind energy plants have difficulties in the end-of-life phase; recycling of materials is mostly not possible, so the materials have to be disposed of

[7]. These technologies run through a linear economy.

The linear economy is the most concerning problem in context of the resource crisis

[8] and is also often referred to as the “take, make and waste” economy

[9]. The idea of the circular economy offers solutions to that issue. The circular economy has been highlighted by the Ellen MacArthur Foundation, among others, and is already being applied in industries as a policy objective, in particular within the EU Green Deal and Circular Economy Action Plan

[10,11][10][11]. With this concept, products are made to last to be reparable, remanufacturable and recyclable

[12]. Essential in this context are design principles, because at least 70% of the environmental impact of a product is already predetermined in the design phase of a product

[13].

A promising technology which can potentially be made from non-toxic materials and with low energy demand in the production process is dye-sensitized solar cells (DSSC)

[14]. DSSCs could not only replace conventional photovoltaic technology but supplement it. Possible applications include transparent versions in windows of buildings or in vehicles and indoor applications, e.g., for Internet of Things devices, as they also work in diffuse-light conditions in the evening or morning hours as well as indoors

[15,16,17,18][15][16][17][18]. Since DSSCs can also be used for aesthetic purposes, the design of colored facades in architecture could also be a niche for this technology

[19].

The operating principle of a DSSC is briefly explained as follows: a DSSC consists of two conductive glass plates; usually, fluorine-doped tin oxide (FTO) is applied on the surface of the glass to enable conductivity. On the front electrode, a layer of semiconductor material is applied, generally titanium dioxide (TiO

2). On the porous layer of TiO

2, the photoactive material, in

ouresearcher

s' case natural dye, is incorporated. On the counter electrode, a catalyst is applied, typically graphite or platinum. Finally, front and counter electrodes are connected by an electrolyte, also described as the redox couple, and iodide/triiodide (I

−/I

3−) is often used. If light excites electrons in the photoactive material, the dye and the electrons pass the semiconductor layer and enter an external circuit. Here, the electrical energy can be used. The electrons enter the DSSC through the counter electrode and the catalyst layer. The electrolyte transports the electrons to the dye molecules and complete the circuit

[20].

This technology has not yet reached the stage of large-scale industrial manufacturing, and therefore approaches to circular design need to be explored to minimize the environmental impact of this technology from the outset. Of course, the processes for the circular economy, such as remanufacturing or recycling, need to be flexible and adaptable in the initial phase, as DSSC technology is expected to undergo several transformations before reaching an industrial scale.

So far, a main focus in research was to improve PCE as well as its long-term stability

[21]. These aspects are fundamental, but a technology for renewable energies with high efficiency, which causes strong environmental impacts, is not suitable to cope with the acute crises.

Work in the area of sustainable DSSCs ranges from life cycle assessment (LCA) to eco-design approaches and the 12 principles of Green Chemistry

[22,23,24][22][23][24].

LCAs can be used to analyze the environmental impact and energy balance of products. Several LCAs for DSSC describe that the cumulative energy demand (CED) for DSSCs is comparable with amorphous, silicon-based photovoltaics (a-Si PV)—760.21 MJ/m

2 for a-Si PV and 863.2 MJ/m

2 for DSSC modules

[22,25,26][22][25][26]. Since a-Si PV already is produced on industrial scale, in contrast to DSSC modules, big improvements in energy efficiency can be expected in DSSC production

[26]. The energy payback time for DSSCs is between 0.6 and 3.3 years, and for crystalline silicon photovoltaics (c-Si PV) between 0.6 and 1.5 years

[22,27][22][27]. However, the niche application at lower light intensity is not considered. This setup would give the DSSC technology advantages over c-Si PV in the LCA.

Mustafa et al. investigated a window-integrated DSSC system without the end-of-life stage due to a lack of appropriate information. In their case, the production phase caused most of the greenhouse gas (GHG) emissions due to the Malaysian energy mix, which consists of over 80% coal and gas

[28]. That is why they emphasize improving the production process with, for example, low-temperature approaches

[28].

De Wild-Scholten et al. pointed out that the main environmental impact is due to energy consumption during the manufacturing process, in particular the production of the glass substrate

[29]. This was also confirmed by Parisi et al. adding that glass, silver and ruthenium are causing around 90% of the global impact during a DSSC life time

[22].

To mend this issue, they suggest using thin-glass, metal or polymer substrates. They mention that recycling could improve the environmental impact, but no practical experiments have been conducted so far

[29]. In previous work,

wresearche

rs investigated the recycling and remanufacturing potential of non-toxic DSSCs and found promising opportunities to use FTO-glass longer and integrate DSSCs in a glass recycling process

[21,30,31][21][30][31].

Ansanelli et al. stated that for c-Si PV recycling, two sequential steps of recycling have to be realized. First, the recovery plant to separate and recover raw materials such as aluminum, copper, glass, silver and silicon from the c-Si PV modules. Secondly, the glass reuse line for the use of the recovered glass in construction elements is needed. In their LCA, they describe a downcycling scenario, where only building materials such as predalles slabs are manufactured

[32]. Nevertheless, they found that the process is environmentally friendly, even taking into account the environmental impact resulting from the implementation of recycling treatments

[33,34][33][34]. Challenges of c-Si module recycling are the variety of modules and cell structures and the separation of cells from the glass

[35]. The electricity consumed for heat treatment can be considered as the largest load and thus causes the largest environmental impact

[32]. For this reason, the energy used significantly determines the price and carbon emissions of the recycling process. If it is green energy, the carbon footprint is low; if the energy for heating and transportation comes from fossil sources, it is high. An LCA study has shown that the production of c-Si cells from recycled material has a 58% lower environmental impact than c-Si modules produced from virgin material, mainly due to energy savings, as the energy-intensive processing of raw silicon is not required

[36]. In Germany, for every kWh saved, 0.42 kg of CO

2 and EUR 0.17–0.23 could be saved

[37,38][37][38].

Anctil et al., stated that in the case of thin-film technologies, such as CdTe and CIGS, a-Si/thin-film Si, the use of abundant material could lead to a waste problem in the future

[39,40][39][40]. Reasons for that are that the manufacturer has no incentive to take back end-of-life modules and that abundant material has little recovery value. Possible solutions they describe are on the one hand political incentives and on the other hand that the costs for end-of-life management should be included in the PV module price

[39].

If non-toxic DSSCs are used, they can potentially be used for conventional glass recycling

[30]. When recycled cullet from DSSCs is used, indirect energy savings can be achieved because the extraction, mining, processing and transportation of raw materials are not required. Direct energy savings can be achieved during the melting process in glass furnaces, as the cullet melts at lower temperatures than the pure raw materials..

Every kg of raw materials replaced by DSSC cullet could save between 1.9–2.35 MJ

[41].

A calculation of these direct energy savings, costs and CO

2 savings from the recycling process is presented below:

Natural gas causes 0.201 tCO

2/MWh emissions

[42]. The following calculates how much CO

2 can be saved if one ton of raw material is replaced by cullet:

In total, 0.13 tCO

2 can be saved per ton of cullet, replacing the raw material. Glass production mainly uses natural gas. The gas price now is 129.80 EUR/MWh (3 November 2022), and the highest price was 339.00 EUR/MWh (26 August 2022)

[43]. The cost savings of using one ton of cullet are calculated as follows:

A total of EUR 84.80 per ton of cullet could therefore be saved in a recycling process for the energy costs of the glass furnace alone.

In summary, energy savings can be achieved both from glass furnaces (direct savings) and in the supply chain and processing of raw materials (indirect savings). Most importantly, fossil fuels and energy, and thus CO

2 emissions, are reduced through the use of DSSC cullet

[41]. In addition, waste can be reduced and scarce resources are not required for production.

2. Circular DSSC—Investigation Inspired by the Circo Method

2.1. Identification of Opportunities in the Value Chain of Building-Integrated DSSCs

Since DSSC production has not yet reached an industrial scale, the value chain of a DSSC is based on laboratory processes and data and is published by companies that manufacture DSSC panels as well as previous research and LCAs in this field

[26,83][26][44].

LCA is an instrument to measure the environmental impact of a product along its life cycle, including raw material extraction, processing, manufacturing, use phase and end-of-life phase.

The key data of an LCA are explained below:

-

Cumulative energy demand (CED) describes the primary energy demand for producing materials, manufacturing of the DSSC system, transport, operation and end-of-life management. However, this can vary according to the scope of the LCA, cradle-to-gate or cradle-to-grave, for instance.

-

Energy payback time (EPBT) is a figure that describes the time required until the DSSC system has produced as much energy as was required for the life cycle of the DSSC to produce a return on investment in energy.

-

The greenhouse gas (GHG) emission rate is given in CO2-equivalents/kWh. To obtain this key figure, the total electricity generated by the PV system over its entire life divides all GHG emissions of the PV system life cycle.

To visualize the status quo of the environmental impact of DSSCs, several results of LCAs are given in

Table 1. At the end of the list, there is also a c-Si PV and a perovskite example provided for comparison purposes.

Table 1.

Overview of LCAs and key data.

105][63][64]. After all, what was actually implemented, design changes or business models are not described; only in one case some design hints are given. Therefore, the further estimation of the economic and ecologic benefits is based on previous research rather than C2C-certified products:

-

Refilling DSSCs: DSSCs can be refilled manually or in the future by humidity, morning dew or rain

[51,97][53][54]. If refilling is done manually, a hybrid business model could be applied. A high-quality DSSC can be sold, and electrolyte refill packs could be sold on a regular basis; if the customer is willing to buy the refill packs, this represents an economic value. This already works with razor blades or coffee pads. The question is, if the customer is willing to invest in constant refilling for this technology, which is unlikely, since the c-Si technology functions without refilling. When coupled with the second case “design element”, refilling could be used for changing the color of the DSSC or an upgrade can be sold with a better performing or more stable electrolyte. From an environmental point of view, resources must be invested in packaging, since the electrolyte is likely to be supplied in small quantities and without a lot of packaging.

-

Design element: When DSSCs are used not only for power generation but also as art and design elements, the product can be sold for a higher price. For the ecologic advantages, it can be expected that product attachment and trust will influence the customer to use this product longer. Refilling can be used here because it allows the product to be adapted to changing customer requirements. Figure 62 shows a student project by Malin Melzer from the University of Art and Design Halle, in which a concept for a DSSC design element is described and a prototype is manufactured.

| |

Assumptions |

Results |

| Publication Year and Reference |

Setup and Scope |

Location (kWh/(m | 2 | Year)) |

Active Area (%) |

Lifetime (Years) |

PCE (%) |

CED |

EPBT (Years) |

GHG Emission Rate (gCO | 2 | -eq/kWh) |

| 2011 [84] | 2011 [45] |

DSSC/Cradle to gate |

Southern Europe 1117 |

75 |

20 |

8 |

277.4 MJ/m | 2 |

1.58 |

22.38 |

| 2014 [57] | 2014 [46] |

. DSSCs show shorter EPBT, mainly reached by a simple structure, low cost and eco-compatibility

[87][49].

Mustafa et al., explains the much higher CED in their study with the energy mix of Malaysia, which consists of over 80% coal and gas

[28].

Other environmental impacts, for instance human toxicity, eco-toxicity and resource depletion, are predominantly caused by ruthenium, silver and consumed electricity

[22].

The performed LCA studies describe many different future scenarios for DSSCs, but the general value chain described is similar.

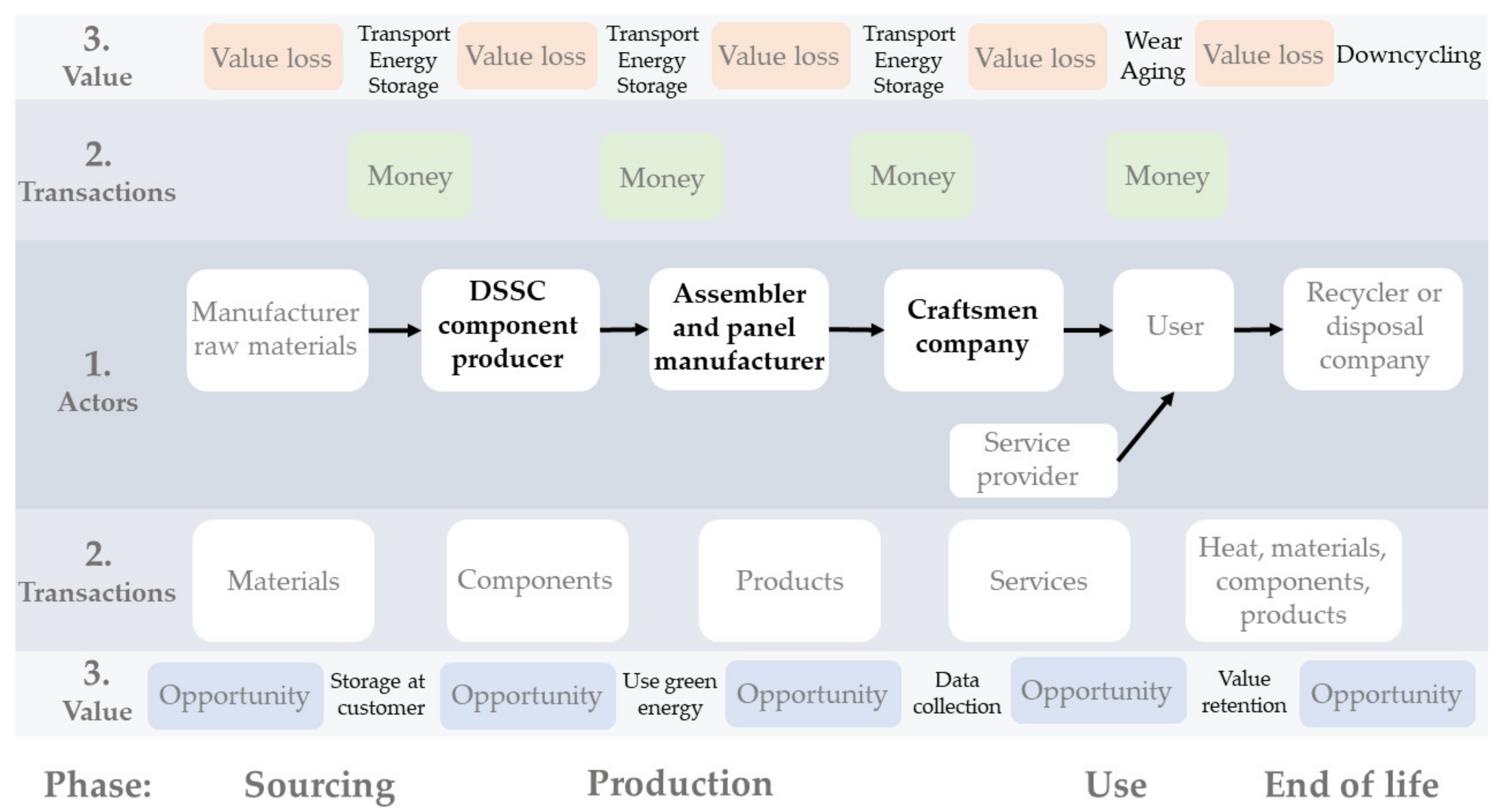

Figure 51 illustrates the value chain of a DSSC module as it is described in several LCA studies

[22,25,28][22][25][28].

Figure 51.

The value chain of a DSSC module.

In contrast to Figure 4, tThis figure specifically shows typical DSSC stakeholders, for instance, the DSSC component producer, assembler and panel manufacturer and a trade company, which mounts the modules; all differences are highlighted in bold. Raw materials are obtained from manufacturers and processed into components for DSSCs. The panels are assembled, sold and installed on or in the user’s building. Materials flow from left to right. If a recycling process takes place at the end of life, material, heat or components can be returned to the system or to production processes in other industries. Money usually flows from right to left when material or components are purchased. In the step from user to recycler or disposer, the user may have to pay for appropriate disposal of the scrap material. Typical value losses that occur in almost every value chain are costs for energy, transport and storage. During the use phase, the value of the product usually decreases due to aging, but with a maintenance and repair service, value retention can be realized. That also is the first opportunity. During the end-of-life phase, modules could be refurbished, remanufactured or recycled. Since the company keeps ownership of the products during the use-phase, it is often explained as an advantage, whereby the storage of the company is in the customer’s building. Regardless, the material (the assets) would be bound there for around 20 years anyway. Another advantage of service models is that information and data can be collected during the use phase of a product, enabling the product to be improved and adapted to customers’ needs. Green energy could be used for production instead of the general energy mix for green marketing of the company or brand.

During the sourcing phase, the following materials are obtained and processed for the production of DSSCs:

-

Substrates: FTO glass or plastic;

-

Semiconductor materials: titanium dioxide;

-

Dyes: ruthenium (N719

[28], Z907

[22]), organic

[59][50], natural

[88][51];

-

Catalyst layers: platinum or graphite;

-

Electrolyte: iodine

-

For enhancing conductivity: silver

[28], carbon solutions

[89][52];

-

For sealing: ethylene vinyl acetate copolymer

[28], polyethylene, low density resin

[28];

-

Other process chemicals: deionized water, ethanol, soap

[28]; organic solvents

[22].

| 1 |

| Southern Europe 1.700 |

75 |

20 |

At the sourcing material stage, major environmental and social problems are caused by exploitation and pollution. Value losses and emissions are caused by transportation, refining processes, labor, storage and energy costs. However, these steps are necessary to deliver the necessary components and raw material for further processing and they cannot be designed out completely, unless one refrains from using the product at all (refuse in the 9R strategy). In addition, waste is generated during the extraction and refinement of raw materials.

The greatest environmental impact is in the categories of human toxicity, ecotoxicity and resource depletion, which can be traced back to silver, ruthenium, platinum and electricity, with decreasing relevance in this listing

[22].

Over 90% of the embodied energy can be traced back to FTO glass (734.10 MJ/m

2 = 73.09%) and the metallization paste (190.15 MJ/m

2 = 18.93%)

[28].

For conventional DSSCs, the following component production and assembling process steps have to be applied

[57][46]:

-

Glass preparation (Laser-scribing and cleaning);

-

Printing and drying of silver paste;

-

TiO2 screen printing on a glass substrate;

-

Sintering in a furnace at 500 °C;

-

Printing Platinum (Pt) on a counter electrode substrate;

-

Sintering platinum in a furnace at 450 °C;

-

Dye dipping;

-

Assembling the thermoplastic (PE);

-

Drying for curing in a convection oven;

-

Electrolyte injection;

-

Patch sealing;

-

Ultrasonic soldering;

-

Panel assembly.

An advantage of DSSC in the production process is that they do not need highly energy intensive processes as c-Si PV do

[57][46]. The industrial production process can be compared to other thin-film technologies and has the advantage of not assembling a module from single cells, but from direct fabrication of a DSSC module

[57][46].

2.2. Investigating Possible Changes to the Design and Business Model

In the next step, the identified opportunities, further called cases, will be matched with one or several business models and design strategies.

Table 32 shows an overview of the cases matched with the strategies and business models.

Table 32.

Overview of cases, design strategies and business models.

| Cases |

Design Strategies |

Business Models |

Reference |

| 1. Refilling DSSCs |

Upgradability, ease of maintenance and repair |

Hybrid |

[51,97] | [53][54] |

| 2. DSSCs as design element |

Attachment and Trust, Durability |

Classic long life

Gap exploiter |

[98] | [55] |

| 3. Long-life DSSC |

Durability |

To proceed with the Circo method, the economic and ecologic benefits from each objective are estimated. However, investigating the sustainability of a product is complicated, especially when it comes to electronics that are made of a mixture of different materials, each of which occurs in only a small quantity. As an indicator for a state-of-the-art status, the Cradle to Cradle (C2C) certified registry was investigated. At the moment (19.08.2022), 13 out of 759 products from the C2C product registry are electronic products, comprising around 1.7% of the total.

The products range from relatively simple products such as switches and sockets up to PV modules. Of these 13 products, five are sockets or switches, which are of comparatively low complexity. Only one product, Beosound Level, was certified with the new version 4.0, which is much more difficult to obtain compared to the older version, 3.1. Three glass–glass c-Si modules can be found in the product registry. For c-Si modules, entire series are certified so a variety of applications are possible, for example, roof- mounted or building-integrated.

Table 43 gives an overview of the more complex, to-date (19 August 2022) C2C-certified electronic devices.

Table 43.

C2C-certified products in context of electronics without sockets and switches.

| Manufacturer |

Product Description |

Standard Version |

Level |

Expiration Date |

| Solitek (Vilnius, Lithuania) |

Glass–glass solar modules |

3.1 |

Silver |

12 December 2022 |

| Solarwatt GmbH (Dresden, Germany) |

Panel vision H series and Vision 60/EasyIn series |

3.1 |

Silver |

| 2019 [28] |

DSSC/Cradle-to-gate | 1 |

Malaysia 1402.82 |

75 |

20 |

5.00 |

18.75 GJ/kWh |

2.42 |

Classic long life |

[ | 70.52 |

| 22 | , | 56 | ] | [22][56] |

2020 [22] |

DSSC/Cradle-to-grave | 1 |

Italy 1700 |

78 |

5 |

3.91 |

6.7 MJ/kWh |

3.28 |

380 |

| 4. Short life time for consumables |

Dis- and re-assembly |

Gap exploiter and access |

[99] | [57] |

2020 [22] |

DSSC/Cradle-to-grave | 1,2 |

Italy 1700 |

88 |

20 |

7.20 |

0.9 MJ/kWh |

| 5. DSSC can be used in glass recycling | 0.61 |

50 |

| Design for recycling |

Gap exploiter |

[ | 30] |

2021 [85] | 2021 [47] |

c-Si PV/Cradle-to-grave |

Chengdu 888.2 |

85 |

25 |

20 |

| 6. Remanufacturing of used DSSCs |

Standardization and compatibility |

Gap exploiter | 2.19 MJ/kWh |

13.8 |

164.41 |

| [ | 31 | ] |

| 7. Using recycled material |

Dis- and reassembly |

Gap exploiter |

[100,101] | [58][59] |

| 8. DSSC in a performance contract |

Ease of maintenance and repair, upgradability and adaptability |

Performance |

Fenoplastica Lights & Electrics (Barcelona, Spain) |

Industrial Ventilation Systems |

3.1 |

Bronze |

29 November 2023 |

| Bang & Olufsen A/S (Struer, Denmark) |

Beosound Level |

4.0 |

Bronze |

1 September 2023 |

Only for the Beosound Level, some sustainable design hints are given: modular design, high quality materials, built to last, replaceable battery, upgradeable, recirculated material

[103][62]. What must be implemented to obtain the certificate is described in the Cradle to Cradle Certified

® Product Standard

[104,

Figure 62.

DSSC as a design element—student project by Malin Melzer, industrial design, University of Art and Design Halle.

- 3.

-

Long life DSSC: Has a higher ecological value since the product does not need to be replaced. Even though the product with a long life can be sold for more, the competition with c-Si PV still limits the price and thus the economic value. For all commercially available c-Si PV, the price for one Watt peak is below EUR 0.35

[106][65].

-

- 4.

-

Short life for consumables: The lifetime of the DSSC should be at least as long as that of the consumable upgraded with the DSSC. The recycling process could be more complex. That is why the ecological challenges are high. From an economic point of view, it is attractive to upgrade tents or clothing with electricity generation, as the products can be sold at a higher cost. An example is the “Gratzel Solar Backpack 2” from GCell, a backpack with an integrated DSSC for charging a phone

[99][57].

-

- 5.

-

Glass recycling: FTO glass production causes has great environmental impact on DSSC production. That is why it has a lot of advantages both ecologically and economically for recycling FTO glass

[30].

-

- 6.

-

Remanufacturing: has an even higher value retention, is less energy intensive and therefore offers higher benefits than recycling. The required reverse logistics, however, are more complicated and reduce the economic benefit

[31].

-

- 7.

-

Using recycled material: Re-using a TCO substrate from smart phones, for example, reduces the necessary energy during the production process and reduces resource depletion

[100,101][58][59]. Again, the logistics and the quality of the material is a problem and reduces the economic benefit.

-

- 8.

-

Performance contract: The classic disadvantage of a service-based model is the high initial investment since the product is not sold but the company retains ownership. In the long term, the company has a great interest in using durable, easy-to-maintain and efficient DSSCs, which are ecologic benefits. During the use phase, information about the product can be collected for improving the product. At the end of the contract the product can be taken back for reuse, remanufacturing or recycling. In general, service-oriented business models are the goal of the circular economy, as they bring major benefits both economically and ecologically

[107][66]. On top of that, to acquire new customers is at least five times more expensive than customer retention

[108,109][67][68].

-

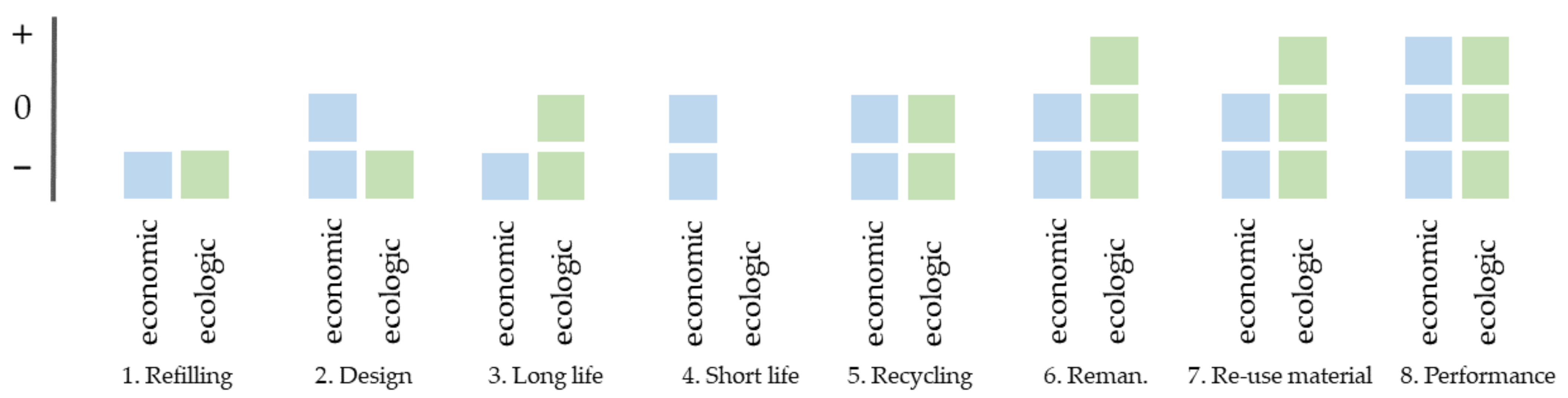

In

Figure 73, the economic and ecologic benefits are summarized.

Figure 73.

Estimation of the economic and ecologic benefits from the eight described cases.

The estimation of the economic and ecologic value is based on research results and the assumptions listed in the enumeration above, i.e., cases 1 to 8. This is only a qualitative assessment and experiments and prototypes are needed to support the statements with evidence. Usually, in the Circo track, a qualitative assessment is made by experts in the same way.

In Section 3.3, tThe most promising cases, 6, 7 and 8, will be used to build a circular business model around them.

In the next phase of the Circo method, the changes the company has to make in several categories is estimated and described. Therefore, the fictitious business model from this publication must first be explained. In

ouresearcher

s' scenario, the standard DSSC modules are manufactured by the module manufacturer

, as described in Section 3.1. The module is then sold to a craftsman who installs the system on the user’s roof. So far, there is no direct contact from module manufacturer to the user. At the end of its life cycle, the DSSC module is fed into similar recycling streams as the c-Si PV modules, with a comparably high recycling rate and the same downcycling; and so, the material cannot be reused for photovoltaic applications.

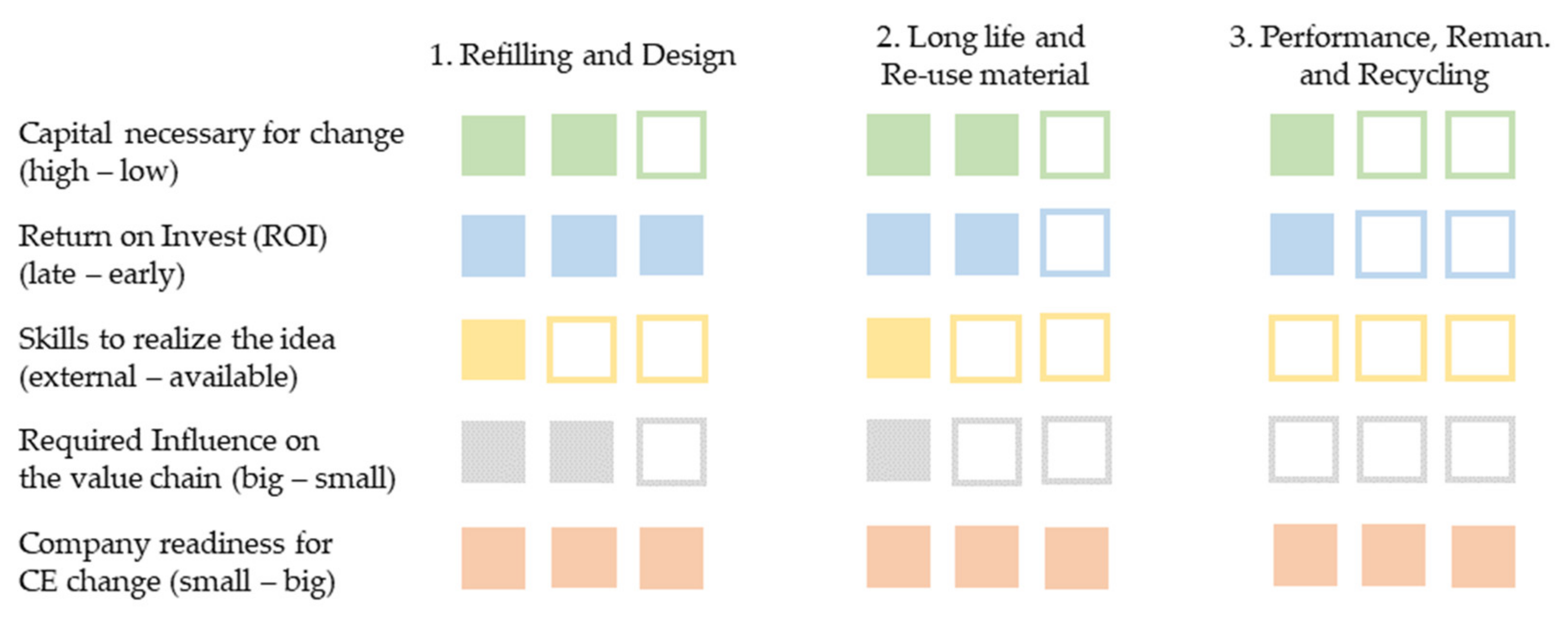

In further investigations, the number of the design cases is reduced to three by fusing them together as follows:

-

Refilling and design: The design of the product must be adapted so that the DSSC can be easily refilled and customized to meet the needs of customers. New employees, likely designers, are required. They can improve the aesthetics of the product. The return on investment can be achieved comparatively quickly as the product continues to be sold and a new revenue stream, the refill packs, generate an additional revenue stream. The new business model of selling refilling packages makes it necessary to build a new branch and to get in contact with the user; so far, the product is only sold to the trade company. That is why more people need to be hired for service and product management. The impact on the value chain for this design change does not pose major challenges, as only contact with the user has to be established.

-

Long life and using recycled material: By re-using old material, energy and costs can be reduced. Even so, new supply channels for the material need to be established, as well as good relationships with partners along the value chain. The longer life of the product is coupled to new technology, such as solid-state or gel-electrolytes, which reach better long-term stability to the price of lower PCEs. When using recycled material, the production cost can be reduced. For example, when using cullet in glass production, 2–3% of energy can be saved for every 10% increase in used cullet

[110][69]. Due to the long service life, the product can be sold at a higher price, but is limited by the cheap alternative c-Si PV module. New skills are required for implementing the new technology into the production line and quality investigations of the reused conductive substrate. In addition, the legal requirements and warranty issues must be clarified. The required influence on the value chain focuses on building up the connection with the recycling companies to acquire the used devices or components, flat screen TVs or mobile phones, for instance, for DSSC manufacturing.

-

Performance, remanufacturing and recycling: In this model, the largest investment costs will be incurred at the beginning of the changeover, as the products are no longer sold but remain the property of the company. Revenue is earned over time as customers pay their monthly fee for the service provided; the return on investment for this model is lengthy. On the positive side, the material is returned to the company at the end of the contract. Then, the real advantage comes: the old DSSC can be upgraded in a remanufacturing process and be reused as new products. Many new capabilities need to be integrated into this business model, such as service to the customer, compliance management, quality control for used modules, remanufacturing and recycling partners and the development of an upgradable product. The service-oriented model extends the influence on the value chain to new areas, such as direct contact with the user, logistics partners for take-back, craftsmen, etc.

-

Table 54 summarizes the merged models and presents the core elements.

Table 54.

Overview of the fused cases, design strategies and business models.

Return on investment (ROI) describes how quickly the money invested can be earned back by adapting the new business model. Three blue squares represent a very fast ROI, whereas no blue square indicates a long time to ROI.

-

-

Skills to realize the idea stands for the capability of the company and employees. Three yellow squares indicate that employees are able to make all necessary changes independently. No yellow square means that external partners must be engaged, employees must be trained or new people with appropriate skills must be hired.

-

Required influence on the value chain stands for the dependency on the value chain. Three gray squares indicate that the company can implement the new business model on its own. No gray square means that the necessary changes depend strongly on the partners along the supply chain.

-

The willingness and readiness of companies to change in the area of the circular economy was assessed as high for all business models. It describes how receptive the corporate culture, the knowledge of the employees and the readiness for change are. Change management in the company often plays an important role, as it is difficult to change a corporate culture from selling products to a service-oriented culture. It is a difficult task to anchor the idea of the circular economy in the minds and hearts of all employees.

| Cases |

Design Strategies |

Business Models |

| 1. Refilling and design |

Upgradability, ease of maintenance and repair, attachment and trust, durability |

Hybrid, Classic long life, Gap exploiter |

| 2. Long life and using recycled materials |

Durability, Dis- and re-assembly |

Classic long life, Gap exploiter |

| 3. Performance, remanufacturing and recycling |

Ease of maintenance and repair, upgradability and adaptability, design for recycling, standardization and compatibility |

Performance, Gap exploiter |

| [ |

| 80 |

| ] |

| [ |

| 60 | ] |

The following cases from

Table 3 are explained in more detail.

| Maxeon Solar Technologies, Ltd. (Singapore) |

| Maxeon Solar Panels |

3.1 |

Silver |

30 June 2024 |

| Whitecroft Lighting Limited (Ashton-under-Lyne, UK) |

Selene 2 |

3.1 |

Bronze |

30 June 2024 |

| Tridonic GmbH & Co KG (Dornbirn, Austria) |

CLE, LLE and QLE LEDModules |

3.1 |

Bronze |

30 June 2024 |

| Brandbase BV (Amsterdam, The Netherlands) |

Remote control cars |

| 2016 [86] | 2016 [48] |

Perovskite/Cradle-to-gate |

Not given 1.700 |

65 |

5 |

15 |

504 MJ/m | 2 |

1.54 |

147 |

Figure 73.Estimation of the economic and ecologic benefits from the eight described cases.

Figure 73.Estimation of the economic and ecologic benefits from the eight described cases. Figure 84.Overview of the business scope.

Figure 84.Overview of the business scope.