You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by Pilar De Tiedra.

Resistance spot welding (RSW) is a process characterized by its high speed and adaptability for automation that renders it suitable for mass production.

- welding processes

- competitiveness

- nondestructive testing

1. Introduction

Resistance spot welding (RSW) is a process characterized by its high speed and adaptability for automation that renders it suitable for mass production [1,2][1][2]. Therefore, resistance spot welding (RSW) is a key joining technology in the automotive industry [3[3][4],4], where competitiveness is increasing with each passing day [5]. This highly competitive industrial environment leads not only to the fact that, in recent times, the process has undergone numerous and significant advances in aspects such as quality control and the development of new strategies to improve weld quality, but also in the fact that interesting alternatives, such as (i) friction stir spot welding (which, as a solid-state process, is suitable for joining alloys with microstructures sensitive to high temperatures [6,7][6][7] or for joining dissimilar materials [8]), (ii) ultrasonic spot welding (which, as it is also a solid-state process, is an interesting option for joining aluminum alloys, where it also provides short welding times [9]), and (iii) laser spot welding (which, like RSW, is a fusion welding process, and it has the characteristics of fast welding speed, low heat input, and small deformation [10]), may be considered.

2. Quality Control

The trend to reduce the number of RSW joints per vehicle is a logical consequence of (i) the high number of RSW joints per vehicle (typically between 4000 and 7000 [11]) and (ii) the aforementioned high competitiveness in the automotive industry. This trend leads to the optimization of quality control systems and decision support tools [12] because the fewer the spot welds per vehicle, the stronger the requirements for each of them [13]. The weld nugget is formed from the solidification of the molten metal after a heating by the Joule effect [14], and the weld nugget size, especially the nugget diameter, is used as an indicator of weld quality [15]. On the other hand, and given that, according to Özyürek [16], structures using RSW joints are typically designed so that these joints are loaded in shear when the parts are exposed to tension or compression loading, the tensile–shear strength of the spot weld, and particularly its tensile–shear load-bearing capacity (TSLBC), which is the peak load value obtained during the tensile–shear test, is also a common quality estimation criterion [17]. In fact, both Hasanbaşoğlu and Kaçar [18] and Kong et al. [19] indicated that the most important factor affecting TSLBC is the size of weld nugget, and the standard JIS Z 3140 [20] establishes as acceptance criteria for RSW joints both the weld nugget diameter and the TSBLC. As pointed out by Zhou and Yao [15], the study of the effects of different aspects of the welding process on RSW joint quality can be approached from (i) the use of auxiliary measuring signals from external sensors, or (ii) the use of intrinsic process variables. In addition, this restudyearch may be assisted by the use of models based on mathematical tools.2.1. Use of Auxiliary Measuring Signals from External Sensors

Since destructive testing is not suitable for routine production monitoring, a range of nondestructive testing (NDT) methods have been developed for assessing weld quality in RSW [21]. Ultrasonic nondestructive testing is a promising technique for the quality control of RSW joints in the automotive industry [22], which allows for the possibility of reducing costs, but which requires human operators with some degree of qualification [23], especially when the complex material microstructure disturbs the ultrasonic wave propagation and makes it difficult to interpret the results obtained [24]. Since these results depend heavily on the human operator’s experience [25], and the efficiency of the latter may be negatively affected by the task of repeatedly interpreting ultrasonic oscillograms for a long period of time [26], the tools that could help the human operator with the interpretation and classification of ultrasonic oscillograms can contribute to improving the evaluation by the ultrasonic nondestructive testing of RSW joints. The ultrasonic oscillogram obtained by the A-scan technique is a plot of wave amplitude versus time [27], where the ultrasonic beam is reflected when it reaches an interface, causing a series of echoes whose positions indicate the location of the reflecting interface and whose heights are a function of the sound attenuation, i.e., of the microstructure of the weld nugget [28]. Martín et al. [12] obtained a ten-component vector from each ultrasonic oscillogram and used a back-propagation multilayer feedforward artificial neural network (ANN) trained with the Levenberg–Marquardt algorithm to classify it, i.e., each ultrasonic oscillogram and its corresponding RSW joint, into four possible quality levels [29]: (i) good weld, (ii) undersize weld, (iii) stick weld, and (iv) no weld. Afterwards, and in light of the fact that ANNs are “black boxes” and do not have explanatory capacity, Martín et al. [13] proposed classification and regression tree (CART) and random forest techniques as pattern recognition models for the classification of ultrasonic oscillograms obtained from RSW joints, and they demonstrated that CARTs gave rise to an acceptable error rate with high interpretability, whereas random forests, compared with CARTs, reduced the error rate at the cost of reducing decision interpretability. With the aim of saving time, Hua et al. [30] developed an in situ ultrasonic detection system consisting of an electrode with an embedded probe, which made it possible to rapidly obtain the ultrasonic testing signal from the RSW joint. Wang et al. [31] proposed a particle swarm optimization support vector machine (PSO-SVM) to classify the maximum tensile–shear strength (MTSS) of RSW joints. Signal processing and mathematical statistics methods were used to extract the features of ultrasonic detection signals as input variables, and the MTSSs of the RSW joints were employed as output variables. Wavelet packet analysis was used by Qiuyue et al. [32] for the ultrasonic nondestructive evaluation of porosity size and location in stainless steel RSW joints and by Liu et al. [33] for the automatic identification and classification of ultrasonic echo signals obtained from stainless steel RSW joints by additionally using back-propagation neural network models. Moghanizadeh [34] studied, in the light of the effect of heat input on two microstructural features (grain size and phase content), the relationship between the attenuation coefficient of ultrasonic testing in low carbon steel RSW joints and the microhardness and, in turn, between the microhardness and the welding quality. Amiri et al. [35] investigated the relationship between the results of ultrasonic testing with the tensile strength and fatigue life of three-sheet RSW joints using a single and dual-objective neural network. According to Lindner and Deike [36], radiographic inspection is a reliable nondestructive testing method for the inaccessible intermediate sheet area, which is usable in the large-scale automotive industry. Consequently, the above-mentioned authors [36] used radiographic inspection for analyzing the liquid metal embrittlement (LME) crack characteristic, in relation to the surrounding conditions and welding parameters, inside the intermediate sheet area of dissimilar RSW joints, where the base metals were austenitic stainless steel, on the one hand, and microalloyed galvanized steel, on the other. The LME phenomenon can occur when, during the welding process, the liquid zinc penetrates into the grain boundaries of the austenitic stainless steel microstructure. Finally, regarding radiographic inspection, it should be mentioned that due to the fact that X-rays are harmful to the human body, the application of radiographic inspection to welding control quality in actual production is limited [37]. Another method for the nondestructive inspection of RSW joints is the magnetic technique, which, although when compared with the ultrasonic and radiographic techniques, it does not offer good morphology information, is, indeed, convenient and low-cost [38,39][38][39]. As indicated by Tsukada et al. [39], there are two main methods for carrying out magnetic based testing: (i) the magnetic flux leakage test (MFL), which employs the magnetic flux leakage from the sample surface when a low frequency magnetic flux is induced, and (ii) the eddy current test (ECT), which employs high frequency electromagnetic induction in conductive materials. Tsukada et al. [40] developed an MFL system using a magnetoresistive sensor for the nondestructive testing of RSW joints. Song et al. [41] applied an imaging method for analyzing the internal structure of RSW joints based on the phase of a magnetic field by using a wide range of frequencies from high to low. Vértesy and Tomáš [38] presented the magnetic adaptive testing (MAT) method, which is based on the systematic measurement and evaluation of magnetic minor hysteresis loops, as an alternative for characterizing quality in RSW, finding a good correlation between the welding current value and the magnetic descriptors. Regarding the ECT, Harada et al. [42] used it for the evaluation of RSW joints whose internal microstructure could be visualized by using multiple frequencies, and also for obtaining a good correlation between the measured magnetic field strength and the tensile–shear load. Additionally, cameras or infrared (IR) thermography can be used to study the process of and assess the quality in RSW.2.2. Use of Intrinsic Process Variables

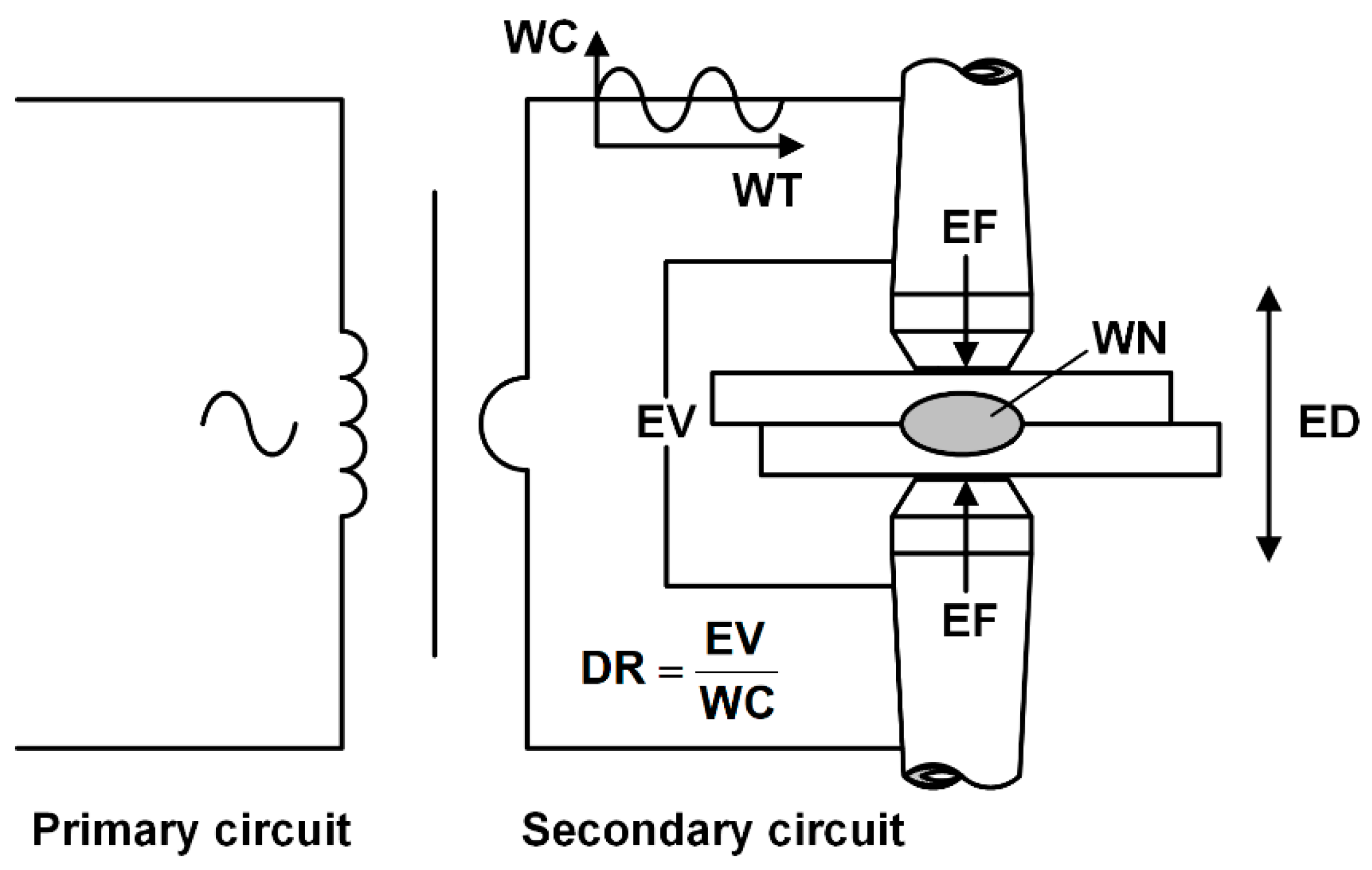

As reported by Gedeon et al. [47][43], two of the most popular inputs for assessing the quality in RSW are dynamic resistance and electrode displacement. Xing et al. [48][44] employed a random forest model for classifying RSW from dynamic resistance signals. This model adequately distinguished good welds from the other unacceptable welds such as cold welds and expulsions; in addition, the implementation of random forest based on the combination of welding parameters and dynamic resistance signals improved the accuracy of classification (by reducing the misclassification error between good welds and cold welds). Luo et al. [49][45] monitored in real-time the change of welding current and electrode voltage in the secondary circuit in the RSW process, and thus the dynamic resistance was analyzed to characterize the weld nugget growth. The results showed that (i) the whole process of nugget growth is composed of an initial stage, a growing stage, and a stable stage, (ii) different types of nugget growth show diverse curves of dynamic resistance, which is a way to assess the weld nugget growth and weld nugget quality, and (iii) welding current and electrode force can affect the nugget growth—a larger welding current and a larger electrode force improve the rate of nugget growth. Zhang et al. [50][46] developed a method for evaluating the quality in RSW based on the extraction of nine time domain statistical features from the electrode displacement signal. These nine features were sketched as a Chernoff face which classified the welding quality in four levels (poor, good, excellent, and expulsion) through the different facial expressions, which made the diagnostic procedure for welding quality easily understood and interpreted. Xing et al. [51][47] studied the shunting effect in RSW (which, due to the presence of an adjacent and previous spot weld, gives rise to the reduction in the welding current flowing to the new spot weld, with a consequent decrease in its size and strength) from the electrode displacement signals; the results showed that the weld spacing and nugget diameter were polynomial-correlated, with a minimum weld spacing of approximately 20 mm. Zhang et al. [52][48] proposed a method for quality assessment in RSW by converting the electrode displacement waveform into binary image and then, by using binary matrices according to different weld qualities to train a probabilistic neural network, they created a quality classifier. In addition to the two aforementioned inputs (dynamic resistance and electrode displacement), the quality in RSW can be directly assessed from the welding parameters, the most important of which are welding current, welding time, and electrode force [53,54][49][50] (Figure 1). Separately, the effect of welding current [55][51] and of welding time [56][52] on the tensile–peel strength and tensile–shear strength of RSW joints of microalloyed steel sheets with a 1.2 mm thickness was studied. Kianersi et al. [57][53] investigated the effect of both welding current and welding time on the macroscopic aspects (weld nugget diameter, welded penetration, width and thickness of heat affected zone (HAZ), and indentation depth of the electrode), mechanical properties (tensile–shear strength and failure energy, peak load, and failure mode), and metallurgical properties (formed phases in the welded nugget and HAZ) of the RSW joints of AISI 316L austenitic stainless steel.

Figure 1. RSW process diagram that shows: (i) the weld nugget (WN) formation after heating by the Joule effect, (ii) the principal welding parameters (welding current (WC), welding time (WT), and electrode force (EF)) [53[49][50],54], and (iii) two of the most popular inputs for assessing the quality in RSW (dynamic resistance (DR) [48,49][44][45] and electrode displacement (ED) [50,51,52][46][47][48]).

References

- Martín, Ó.; López, M.; De Tiedra, P.; Juan, M.S. Prediction of Magnetic Interference from Resistance Spot Welding Processes on Implantable Cardioverter-Defibrillators. J. Mater. Process. Technol. 2008, 206, 256–262.

- Jou, M. Real Time Monitoring Weld Quality of Resistance Spot Welding for the Fabrication of Sheet Metal Assemblies. J. Mater. Process. Technol. 2003, 132, 102–113.

- Pouranvari, M.; Aghajani, H.; Ghasemi, A. Enhanced Mechanical Properties of Martensitic Stainless Steels Resistance Spot Welds Enabled by in Situ Rapid Tempering. Sci. Technol. Weld. Join. 2020, 25, 119–126.

- Ertas, A.H.; Akbulut, M. Experimental Study on Fatigue Performance of Resistance Spot-Welded Sheet Metals. Int. J. Adv. Manuf. Technol. 2021, 114, 1205–1218.

- Mousavizade, S.M.; Pouranvari, M. Projection Friction Stir Spot Welding: A Pathway to Produce Strong Keyhole-Free Welds. Sci. Technol. Weld. Join. 2019, 24, 256–262.

- Skowrońska, B.; Chmielewski, T.; Pachla, W.; Kulczyk, M.; Skiba, J.; Presz, W. Friction Weldability of UFG 316L Stainless Steel. Arch. Metall. Mater. 2019, 64, 1051–1058.

- Skowrońska, B.; Chmielewski, T.; Kulczyk, M.; Skiba, J.; Przybysz, S. Microstructural Investigation of a Friction-Welded 316L Stainless Steel with Ultrafine-Grained Structure Obtained by Hydrostatic Extrusion. Materials 2021, 14, 1537.

- Shen, Z.; Ding, Y.; Gerlich, A.P. Advances in Friction Stir Spot Welding. Crit. Rev. Solid State Mater. Sci. 2020, 45, 457–534.

- Ni, Z.L.; Ye, F.X. Ultrasonic Spot Welding of Aluminum Alloys: A Review. J. Manuf. Process. 2018, 35, 580–594.

- Tian, J.; Tao, W.; Yang, S. Investigation on Microhardness and Fatigue Life in Spot Welding of Quenching and Partitioning 1180 Steel. J. Mater. Res. Technol. 2022, 19, 3145–3159.

- Xia, Y.J.; Zhou, L.; Shen, Y.; Wegner, D.M.; Haselhuhn, A.S.; Li, Y.B.; Carlson, B.E. Online Measurement of Weld Penetration in Robotic Resistance Spot Welding Using Electrode Displacement Signals. Meas. J. Int. Meas. Confed. 2021, 168, 108397.

- Martín, Ó.; López, M.; Martín, F. Artificial Neural Networks for Quality Control by Ultrasonic Testing in Resistance Spot Welding. J. Mater. Process. Technol. 2007, 183, 226–233.

- Martín, Ó.; Pereda, M.; Santos, J.I.; Galán, J.M. Assessment of Resistance Spot Welding Quality Based on Ultrasonic Testing and Tree-Based Techniques. J. Mater. Process. Technol. 2014, 214, 2478–2487.

- Raoelison, R.; Fuentes, A.; Rogeon, P.; Carré, P.; Loulou, T.; Carron, D.; Dechalotte, F. Contact Conditions on Nugget Development during Resistance Spot Welding of Zn Coated Steel Sheets Using Rounded Tip Electrodes. J. Mater. Process. Technol. 2012, 212, 1663–1669.

- Zhou, K.; Yao, P. Overview of Recent Advances of Process Analysis and Quality Control in Resistance Spot Welding. Mech. Syst. Signal Process. 2019, 124, 170–198.

- Özyürek, D. An Effect of Weld Current and Weld Atmosphere on the Resistance Spot Weldability of 304L Austenitic Stainless Steel. Mater. Des. 2008, 29, 597–603.

- Martín, Ó.; De Tiedra, P.; López, M.; San-Juan, M.; García, C.; Martín, F.; Blanco, Y. Quality Prediction of Resistance Spot Welding Joints of 304 Austenitic Stainless Steel. Mater. Des. 2009, 30, 68–77.

- Hasanbasoglu, A.; Kacar, R. Resistance Spot Weldability of Dissimilar Materials (AISI 316L-DIN EN 10130-99 Steels). Mater. Des. 2007, 28, 1794–1800.

- Kong, J.P.; Han, T.K.; Chin, K.G.; Park, B.G.; Kang, C.Y. Effect of Boron Content and Welding Current on the Mechanical Properties of Electrical Resistance Spot Welds in Complex-Phase Steels. Mater. Des. 2014, 54, 598–609.

- JIS Z 3140; Japanese Industrial Standard Method of Inspection for Spot Weld. Japanese Standards Association: Tokyo, Japan, 1989.

- Hao, M.; Osman, K.A.; Boomer, D.R.; Newton, C.J. Developments in Characterization of Resistance Spot Welding of Aluminum. Weld. J. 1996, 75, 1S–8S.

- Chen, Z.; Shi, Y.; Jiao, B.; Zhao, H. Ultrasonic Nondestructive Evaluation of Spot Welds for Zinc-Coated High Strength Steel Sheet Based on Wavelet Packet Analysis. J. Mater. Process. Technol. 2009, 209, 2329–2337.

- Spinella, D.J.; Brockenbrough, J.R.; Fridy, J.M. Trends in Aluminum Resistancespot Welding for the Auto Industry. Weld. J. 2005, 84, 34–40.

- Rupin, F.; Blatman, G.; Lacaze, S.; Fouquet, T.; Chassignole, B. Probabilistic Approaches to Compute Uncertainty Intervals and Sensitivity Factors of Ultrasonic Simulations of a Weld Inspection. Ultrasonics 2014, 54, 1037–1046.

- Thornton, M.; Han, L.; Shergold, M. Progress in NDT of Resistance Spot Welding of Aluminium Using Ultrasonic C-Scan. NDT E Int. 2012, 48, 30–38.

- Barrera Cardiel, G.; de los Fabián Alvarez, M.; Vélez Martínez, M.; Villaseñor, L. Inteligencias Artificiales y Ensayos Ultrasónicos Para La Detección de Defectos. Rev. Metal. 2001, 37, 403–411.

- Zhang, H. Evaluation and Quality Control of Resistance-Welded Joints. In Welding Fundamentals and Processes, ASM Handbook, vol. 6A; Lienert, T., Siewert, T., Babu, S., Acoff, V., Eds.; ASM international: Materials Park, OH, USA, 2011; pp. 486–504.

- Mansour, T. Ultrasonic Testing of Spot Welds in Thin Gage Steel. In Nondestructive Testing Handbook. Vol. 7: Ultrasonic Testing; McIntire, P., Ed.; American Society for Nondestructive Testing: Metals Park, OH, USA, 1991; pp. 557–568.

- Krautkrämer, J.; Krautkrämer, H. Welded Joints. In Ultrasonic Testing of Materials; Krautkrämer, J., Krautkrämer, H., Eds.; Springer: Berlin, Germany, 1990; pp. 431–465.

- Hua, L.; Wang, B.; Wang, X.; He, X.; Guan, S. In-Situ Ultrasonic Detection of Resistance Spot Welding Quality Using Embedded Probe. J. Mater. Process. Technol. 2019, 267, 205–214.

- Wang, X.; Guan, S.; Hua, L.; Wang, B.; He, X. Classification of Spot-Welded Joint Strength Using Ultrasonic Signal Time-Frequency Features and PSO-SVM Method. Ultrasonics 2019, 91, 161–169.

- Qiuyue, F.; Guocheng, X.; Xiaopeng, G. Ultrasonic Nondestructive Evaluation of Porosity Size and Location of Spot Welding Based on Wavelet Packet Analysis. J. Nondestruct. Eval. 2020, 39, 7.

- Liu, J.; Xu, G.; Ren, L.; Qian, Z.; Ren, L. Defect Intelligent Identification in Resistance Spot Welding Ultrasonic Detection Based on Wavelet Packet and Neural Network. Int. J. Adv. Manuf. Technol. 2017, 90, 2581–2588.

- Moghanizadeh, A. Evaluation of the Physical Properties of Spot Welding Using Ultrasonic Testing. Int. J. Adv. Manuf. Technol. 2016, 85, 535–545.

- Amiri, N.; Farrahi, G.H.; Kashyzadeh, K.R.; Chizari, M. Applications of Ultrasonic Testing and Machine Learning Methods to Predict the Static & Fatigue Behavior of Spot-Welded Joints. J. Manuf. Process. 2020, 52, 26–34.

- Lindner, S.; Deike, R. Detection Method for Liquid Metal Embrittlement Cracks Inside the Intermediate Sheet Zone of Dissimilar Resistance Spot Welds. Steel Res. Int. 2020, 91, 2000044.

- Ma, N.; Gao, X.; Tian, M.; Wang, C.; Zhang, Y.; Gao, P.P. Magneto-Optical Imaging of Arbitrarily Distributed Defects in Welds under Combined Magnetic Field. Metals 2022, 12, 1055.

- Vértesy, G.; Tomáš, I. Nondestructive Magnetic Inspection of Spot Welding. NDT E Int. 2018, 98, 95–100.

- Tsukada, K.; Miyake, K.; Harada, D.; Sakai, K.; Kiwa, T. Magnetic Nondestructive Test for Resistance Spot Welds Using Magnetic Flux Penetration and Eddy Current Methods. J. Nondestruct. Eval. 2013, 32, 286–293.

- Tsukada, K.; Yoshioka, M.; Kiwa, T.; Hirano, Y. A Magnetic Flux Leakage Method Using a Magnetoresistive Sensor for Nondestructive Evaluation of Spot Welds. NDT E Int. 2011, 44, 101–105.

- Song, N.; Shiga, K.; Sakai, K.; Kiwa, T.; Tsukada, K. Development of a Magnetic Phase Map for Analysis of the Internal Structure of a Spot Weld. Electromagn. Nondestruct. Eval. 2016, 41, 302.

- Harada, D.; Sakai, K.; Kiwa, T.; Tsukada, K. Analysis of the Internal Structure of a Spot-Weld by Magnetic Measurement. In Proceedings of the Singapore International NDT Conference & Exhibition, Singapore, 19–20 July 2013.

- Gedeon, S.A.; Sorensen, C.D.; Ulrich, K.T.; Eagar, T.W. Measurement of Dynamic Electrical and Mechanical Properties of Resistance Spot Welds Displacement Curves and Dynamic Resistance Provide Significant Data for Evaluating Nugget Quality. Weld. J. 1987, 66, 378S–385S.

- Xing, B.; Xiao, Y.; Qin, Q.H.; Cui, H. Quality Assessment of Resistance Spot Welding Process Based on Dynamic Resistance Signal and Random Forest Based. Int. J. Adv. Manuf. Technol. 2018, 94, 327–339.

- Luo, Y.; Rui, W.; Xie, X.; Zhu, Y. Study on the Nugget Growth in Single-Phase AC Resistance Spot Welding Based on the Calculation of Dynamic Resistance. J. Mater. Process. Technol. 2016, 229, 492–500.

- Zhang, H.; Wang, F.; Xi, T.; Zhao, J.; Wang, L.; Gao, W. A Novel Quality Evaluation Method for Resistance Spot Welding Based on the Electrode Displacement Signal and the Chernoff Faces Technique. Mech. Syst. Signal Process. 2015, 62–63, 431–443.

- Xing, B.; Xiao, Y.; Qin, Q.H. Characteristics of Shunting Effect in Resistance Spot Welding in Mild Steel Based on Electrode Displacement. Measurement 2018, 115, 233–242.

- Zhang, H.J.; Wang, F.J.; Gao, W.G.; Hou, Y.Y. Quality Assessment for Resistance Spot Welding Based on Binary Image of Electrode Displacement Signal and Probabilistic Neural Network. Sci. Technol. Weld. Join. 2014, 19, 242–249.

- Oliveira, J.P.; Ponder, K.; Brizes, E.; Abke, T.; Edwards, P.; Ramirez, A.J. Combining Resistance Spot Welding and Friction Element Welding for Dissimilar Joining of Aluminum to High Strength Steels. J. Mater. Process. Technol. 2019, 273, 116192.

- Wen, J.; De Jia, H.; Wang, C.S. Quality Estimation System for Resistance Spot Welding of Stainless Steel. ISIJ Int. 2019, 59, 2073–2076.

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E.; Demir, Z. Effect of Welding Current on Mechanical Properties of Galvanized Chromided Steel Sheets in Electrical Resistance Spot Welding. Mater. Des. 2007, 28, 2–7.

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E. Welding Time Effect on Mechanical Properties of Automotive Sheets in Electrical Resistance Spot Welding. Mater. Des. 2008, 29, 1427–1431.

- Kianersi, D.; Mostafaei, A.; Mohammadi, J. Effect of Welding Current and Time on the Microstructure, Mechanical Characterizations, and Fracture Studies of Resistance Spot Welding Joints of AISI 316L Austenitic Stainless Steel. Metall. Mater. Trans. A 2014, 45, 4423–4442.

More