Hydrogen is acknowledged as a potential and appealing energy carrier for decarbonizing the sectors that contribute to global warming, such as power generation, industries, and transportation. Many people are interested in employing low-carbon sources of energy to produce hydrogen by using water electrolysis. Additionally, the intermittency of renewable energy supplies, such as wind and solar, makes electricity generation less predictable, potentially leading to power network incompatibilities. Hence, hydrogen generation and storage can offer a solution by enhancing system flexibility. Hydrogen saved as compressed gas could be turned back into energy or utilized as a feedstock for manufacturing, building heating, and automobile fuel.

- hybrid microgrid

- bidirectional AC-DC converter

- hydrogen energy

- wind energy

- energy management

1. Introduction

2. Literature Work

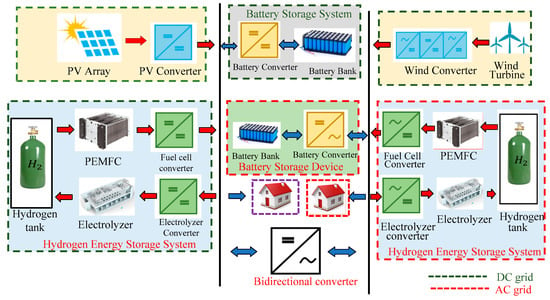

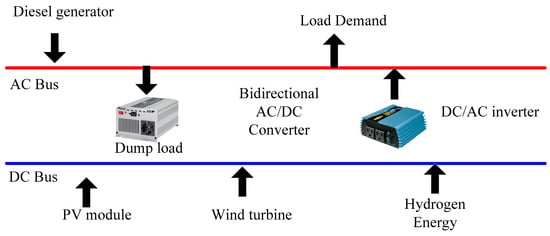

The fundamental issue of combining hydrogen energy storage devices with solar and wind power generation is the subject of a very small number of studies. Herein, the operational issues with hydrogen energy systems are described. The linkages between research on hydrogen system operation and the related electrical markets, agreements, renewable energy resources, storage, energy management in HMG, and the possibilities of hydrogen energy globally can be evaluated. Yue et al. [27][31] provided a summary of current advancements in hydrogen technologies and their utilization in power systems for the creation, storage, and re-electrification of hydrogen. Dawood et al. [28][32] evaluated these pathways as well in order to evaluate how different pathways for producing hydrogen interacted with one other and with other phases of the hydrogen square. Najjar [29][33] assessed the safety of hydrogen during its production, transfer, and use, but did not examine the many drawbacks of the various methods used to produce hydrogen. Their analysis indicates that safety concerns about the usage of hydrogen are mostly highlighted in reference to its ignition and burning characteristics, including its lower ionization energy, quick diffusion, relatively high flame velocities, and wide combustibility range explosions. Parra et al. [30][34] provided the cost-based evaluation of the evolution of hydrogen generation, but lacked a thorough analysis of the numerous trends in the advancement of the various technologies. Recently, Mengdi and Wang [31][35] provided a summary of the technologies used to produce hydrogen, which covers both sustainable and non-renewable resources. Additionally, they contrasted the environmental effect assessments for each technology’s life cycle. Lane et al. [32][36] discussed the prediction for renewable hydrogen technologies production shareholdings. This work indicates that in the early markets, biomass gasifiers are the dominant technology. The chemical energy of a fuel and oxidizer agent is turned into electrical energy through electrochemical reaction FCs, which are electromechanical devices. The reagents are continually supplied, unlike batteries. Transportation, portable, and stationary industries can all benefit from the utilization of FCs [33][37]. The main technical obstacles of this technology are still the price, performance, and endurance. Platinum is the most expensive component in terms of the potential cost. One of the key obstacles to overcoming the technical hurdles and improving FC’s effectiveness, durability, and price is the development of materials that reduce the degradation mechanisms in FCs [34][38]. Furthermore, the cost of hydrogen must be equivalent to that of current fuels and technology. Edathil et al. [35][39] looked at the best fuel alternatives while analyzing the practicality of HMG systems. An ant colony algorithm was used in the study to design multi-objective economic operations for three separate Egyptian island communities. Abo-Elyousr et al. [36][40] used several optimization strategies to find the hybrid PV/wind/diesel microgrid system’s ideal size while taking the battery banks into account as energy storage systems. The techno-economic viability of preserving energy in biomass-fired industrial boilers was examined by Diab et al. [37][41]. The cycle tempo program was used to determine how ecofriendly rice husk is as a fuel. Arévalo et al. [38][42], used HOMER software to examine the effects of five various storage technologies incorporated into hydrokinetics, a diesel generator, PV, and hybrid RES. Mahani et al. [39][43] presented the HSS-based integrated transport network. The authors established HSS’s viability and its potential in Germany. Using HOMER software, Cai et al. [40][44] studied the techno-economic analysis of fuel cells for a vehicle system, hydrogen generation, and wind energy limitation. The excess wind power restriction was, however, best stored by the hydrogen fuel cell generator. El-Taweel et al. [41][45] planned privately owned hydrogen storage facilities and topologies. The PV battery hydrogen systems had an identity of higher than 54%, according to Coppitters et al. [42][46], who looked into the optimal design and stochastic performance of an on-grid PV system. These findings indicate that the generated system was less vulnerable to real-world uncertainties. A proposed interface converter-based adaptive virtual inertia control approach for HMG is discussed by Luo et al. [43][47]. By reducing the rate of variation in AC frequency and DC voltage and increasing the variation in AC frequency and DC voltage, this control strategy dynamically modifies the system’s virtual momentum when the performance differs from the nominal voltage. Xia et al., [23] proposed an HMG configuration for a grid-connected microgrid with a DC link at back-to-back converters. An additional DC bus connection can make it easier to use the DC microsources than a back-to-back connection between two AC systems, which might provide a dependable, isolated, and effective coupling. In order to guarantee voltage stability and power equilibration between the AC and DC grids, a BAC is required for HMGs. Majumder [44][48] created a flexible detection method that validates reaction time while taking into account detection performance. However, the grid voltage magnitude was impacted by the effectiveness of the detecting system. The identification impact is highly consistent, there are no complex matrix modifications needed. Based on the study of harmonic identification, the appropriate control method is required to perform the power transfer between the AC and DC sub microgrid [45][49]. Toghani et al. [46][50] implies a more effective droop control (DRC) strategy that puts BAC in a shutdown state and stops power electrical device activities. The DRC methods mentioned above are predicated on perfect conditions. NL loads in a grid are not taken into account. A NL load can generate further power outages and conflicts with equipment linked to the grid when it alters the current. A harmonic rectification system of integrated converters is described by Tian et al. [47][51] using the NL control approach. The instantaneous depiction of the harmonic component on the PWM signal greatly reduces the influence of bandwidth management on harmonic voltage minimization. The above approach does not have a high compensating harmonic accuracy. Liu et al. [48][52] present the parallel functioning transformer with a mutual filter. This method provides a high attenuation capacity, a reduced resonance risk, and enhanced filtering performance. The aim of the multi-mode control scheme for combining interface converters is to address unbalanced power quality (PQ) problems in a targeted manner and within a limited area of application, as stated by Senthil Kumar et al. [49][53]. When a microgrid is cut off from the main grid and running autonomously with small sources and loads, it is referred to as being in island mode [50][54]. Power to the PCC is abruptly interrupted while switching from grid-connected mode to islanded mode. If this electricity goes to the microgrid before the changeover, there will be a power shortage in the microgrid after the system switches to island mode. The island mode HMG system is shown in Figure 2, where the DC bus is interconnected to the PV, wind turbine, and HSS. A hydrogen storage tank, an electrolyzer, and a FC make up the HSS. It is being examined if the HMG system can optimize each power source in accordance with the levelized cost of energy. Therefore, a load profile is a tool to aid in pointing the direction of HSS growth. Active and reactive power changes are effectively suppressed while current distortion is decreased when a percentage resonant controller is integrated with the BAC.

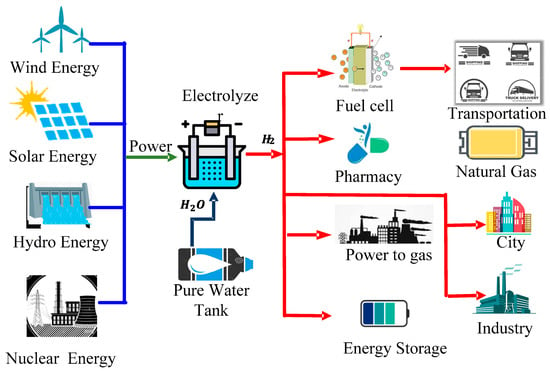

3. Hydrogen Production

Numerous feedstocks, including fossil and sustainable energy, can be used to create hydrogen. Hydrogen can be produced using a variety of process methods, including catalytic, biologic, electrochemical, photochemical, and thermo-chemical [55][59]. A thorough overview of several hydrogen generating processes is provided in [56][60]3.1. Coal and Other Hydrocarbon Gasification

The “gasification” method makes hydrogen from a diversity of hydrocarbon fuels, including lignite, heavy residue lubricants, and limited refining output [57][61]. Hydrogen generation is handled mostly by the condensing of fossil fuels and heavy oil, as well as the burning of coal, petroleum, and diesel oil [58][62].3.2. Steam Reforming

The chemical method of making hydrogen from a combination of water and a hydrocarbon substrate, typically a fossil fuel, is known as steam reforming. Natural gas, usually methane, is the most prevalent substrate [59][63]. A chemical reaction takes place when steam and propane are mixed at a higher temperature and pressure, converting them to carbon monoxide and hydrogen. The calorific value of the hydrogen generated is really larger than that of the natural gas used, but because the reformer requires a significant amount of energy to function, the net conversion efficiency is often only approximately 65–70%. The environmental factor is also a key problem, since converting natural gas to hydrogen creates the same number of pollutants and CO2 as immediately burning natural gas. The technique of producing hydrogen from natural gas is well developed [60][64].3.3. Electrolysis

Electrolysis is the process of sending a current over water to separate specific molecules into oxygen and hydrogen [61][65]. As it is a precise method and water is available, electrolysis garnered great interest while accounting for just a small proportion of modern hydrogen generation. However, at the moment, the process is only employed in small facilities at a cost of 2.40–3.60 USD/kg of gases produced. Electrolysis is now conducted at rates ranging from several kW to 2000 kW of each electrolysis cell. As a consequence of the electrolysis procedure, molecular oxygen and pure hydrogen are produced [62][66]. Although the benefits of generating highly pure hydrocarbons via electrolysis of water were known for nearly two centuries [63][67], its implementations are still restricted to simple scale and unique situations. A massive scale hydrocarbon processing facility is not feasible or cost-effective, such as for marine, rockets, spaceships, industrial application, farming industry, and healthcare. Water electrolysis now accounts for just 4% of global producing hydrogen [64][68].3.4. Solar Hydrogen

The solar hydrogen paradigm proposes creating electricity directly from sunlight utilizing PVs, electrolyzing water to create hydrogen, and replacing this hydrogen for petrol as well as other fossil fuels now in usage [65][69]. The terminology is increasingly used much more generally to cover electrolysis relying on various renewable energy sources, such as wind. This concept is attracting a lot of interest, owing to the ecological benefits of using hydrogen rather than fossil fuels. It also tackles two impediments to the eventual realization of massive solar power use. Solar electricity cannot be immediately used for quasi purposes, such as internal combustion, and electricity is complicated and expensive to retain.3.5. Thermochemical Process

Heat is used to divide hydrogen from water. The most basic type of such a process is thermal transformation, which involves boiling water to extreme temperatures, approximately 3400 K. Direct heat conversions, though, are still impracticable beyond the study due to the extreme heat necessary [66][70]. Chemical processes can be used to minimize the needed temperature. Several alternatives were investigated, generally including intricate multistep procedures.3.6. Nuclear Energy

Hydrogen may well be generated using a variety of nuclear energy-based systems. This includes nuclear heat conversion of water utilizing specific chemical techniques, including the sodium-iodine cycle and nuclear power hydrolysis of water. Moreover, high-temperature electrolytic employs nuclear excess heat to reduce the amount of power needed for electrolysis [67][71]. Though the use of nuclear energy for hydrogen generation is appealing from a carbon reduction standpoint, it poses additional severe environmental and health problems connected to uranium extraction and smelting, the possibility of accidents, and the administration and disposal of hazardous waste.3.7. Biomass

There are two types of conversion of biomass techniques: thermochemical and biological processes. Thermochemical operations are less costly because they can be run at higher temperatures and therefore produce quicker response rates. Biomass combustion is recognized as a potential technique for producing renewable hydrogen. It is advantageous to leverage biomass resources in order to build an extremely efficient clean method for massive production of hydrogen. Adhesives, carbon black, activated charcoal, polymers, fertilizers, ethanol, different acids, Friedel diesel, paraffin, and methanol can all be produced using many of the techniques available to produce hydrogen from biomass [68][72].3.8. Off-Gas Cleanup

After steam generation, the cleaning of commercial off-gases is currently the most prevalent source of hydrogen. Many industries emit significant levels of hydrogen in their solid waste, including refineries, steel plants, and some chemical facilities. Most off-gas hydrogen is utilized by the industry that generates it [69][73]. However, it is doubtful that off-gas cleaning could be extended sufficiently to meet the increasing demand that would come from the extensive utilization of hydrogen as a fuel. During the early stages of infrastructure development, biomass combustion is used in small, decentralized facilities, and later in larger centralized units. Steam reformation and electrolyzers can also be downscaled and installed on site at fueling stations, but coal gasification or nuclear energy is only for large-scale, centralized production and is hence limited to later stages with significant hydrogen consumption [70][74]. Natural gas combustion, coal liquefaction, and water electrolysis are established methods for hydrogen generation that are already used on a large scale across the world. Natural gas hydrogen production is the most widely utilized method in the petrochemical and chemical sectors. It is now the least expensive technique of generation and emits the least CO2 of any fossil fuel-producing route. Electrolysis, on the other hand, is more costly and only viable if high-purity hydrogen is desired. With natural gas prices predicted to rise, coal gasification is expected to become the most cost-effective alternative around 2030 [71][75]. A comparison of various hydrogen production methods and observations is shown in Table 1. It shows the possible ways to produce hydrogen, and the steam reforming method is a simple way to produce hydrogen.|

Authors |

Publication Year |

Method |

Observations |

|---|---|---|---|

|

2022 |

Gasification |

How to use biomass, water, and fossil fuels to transform solid material into hydrogen and carbon monoxide after reacting with carbonaceous oxygen and steam was considered. |

|

|

2022 |

Steam reforming |

The process of producing hydrogen and gaseous or liquid fuels using biofuels and fossil fuels was considered. |

|

|

2022 |

Electrolysis |

It was explored how to break down water and steam using electrical and thermal energy to drive electrochemical processes that separate the materials into oxygen and hydrogen. |

|

|

2022 |

Nuclear energy |

It was discussed how to operate a nuclear reactor utilizing the water splitting technique. The cooling methods for reactors, including gas cooling, liquid metal cooling, and molten salt cooling, were compared. |

|

|

2022 |

Biomass |

Biochemical and photonic energy played in the process of extracting hydrogen from biodegradable materials using biological energy was examined. |

4. Hydrogen Storage Technologies

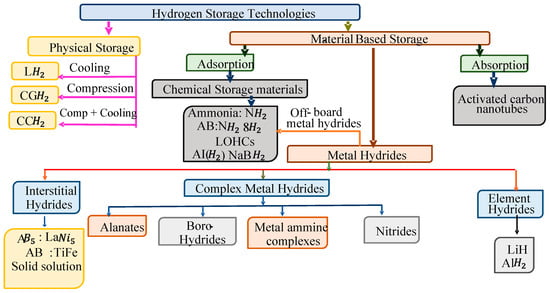

Storage and transmission of hydrogen energy are ongoing and evolving concerns. Operations involving transportation and storage are at minimum as crucial as those involving manufacturing [72][76]. The hydrogen economy benefits greatly from these processes. The objective of conserving hydrogen energy is to make it safe, effective, and available at all times. Hydrogen has a lower volume power density and a large specific gravity energy density when it is purified [73][77]. There are two techniques for storing hydrogen. Physical storage methods include pressurized storage, and material-based hydrogen storage [74][78]. The various storage methods and their categorizations are shown in Figure 3. The most popular strategies are pressurized gas and liquid hydrogen preservation. The solid-state storage technology is in progress and anticipates increased application in the next decades. Hydrogen can be compressed to 700 bar in appropriate buildings and kept as a gas in cylinders, containers, and subterranean cavities.5. Hydrogen Based HMG

Integration of storage energy systems into grid-connected and standalone energy systems emerged as a promising research area. For both static and mobile applications, the use of hydrogen as a fuel for fuel cell technologies presents a significant difficulty [76][96]. Numerous studies concentrated on identifying the ideal size and design of HMG systems for practical energy management purposes, as well as conducting techno-economic analyzes in these areas. Utilizing renewable energy efficiently may be achieved by combining local load, hydrogen energy storage, PV, wind power generation, and HMG. The HMG may, however, also include alternative energy sources. Even still, the power’s properties are greatly worsened by its high reactive power under non-linear loads. Figure 4 depicts the HMG, which comprises a DC grid, an AC grid, and an AC/DC power flow regulator, as well as stores hydrogen and batteries [77][97]. An AC/DC hybrid microgrid with hydrogen storage and battery storage was used to clarify the control approach. Both the AC sub grid and the DC sub grid consist of five components: PV, WT, HSS, battery ESS, and loads. Bidirectional converters are used to transfer power between the DC and AC sub grids and ensure steady operation of two sub grids. A DC/DC boost converter connects PV panels to the DC bus. A capacitor is used to reduce the high frequency voltage ripples from solar panels. In order to replicate AC sources, an AC bus is linked to a permanent magnet synchronous generator in a wind turbine. DC/DC converters are used to connect hydrogen tanks and fuel cells to both DC and AC buses. In order to ensure excellent PQ, HMG should offer voltage stability and power balancing. PQ is substantially impacted by harmonics and unbalanced load currents that arise when NL loads are present in the system. The identification and rectification of harmonic currents must be effective as a consequence [78][98].