Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Dean Liu and Version 1 by Julian Suer.

Using the life cycle assessment (LCA) methodology, the impacts of the primary steel production via the blast furnace route and the scrap-based secondary steel production via the electric arc furance (EAF) route are assessed. Methodological as well as technical differences are analysed and their impacts on the results.

- life cycle assessment

- recycling

- Electric arc furnace

- Blast Furnace

- Steel Production

1. LCA Overview of the Primary Blast Furnace-Related Steel Production Route

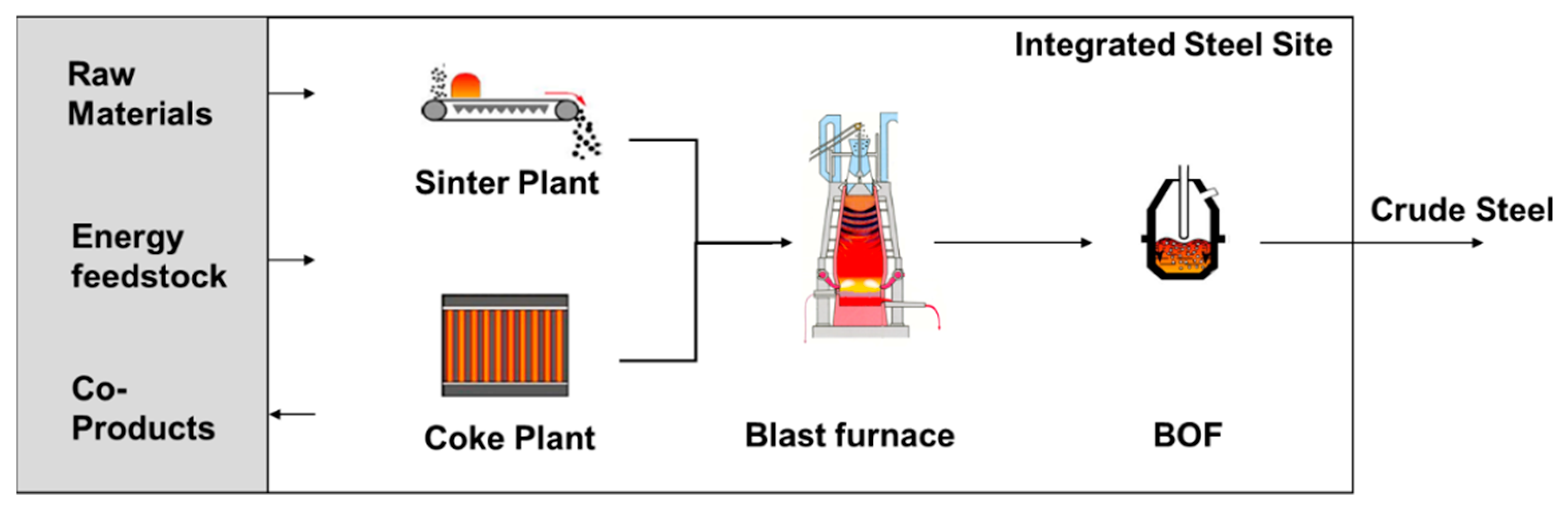

The blast furnace - basic oxygen furnace (BF–BOF) route is the world’s most dominant steel production route with a share of 73% in 2020 [1]. A simplified chart is presented in Figure 1. The iron oxides are reduced and melted by pulverized coal and coke in a blast furnace. As supporting processes, fine iron ores are pelletized and sintered, respectively, to be used in the blast furnace. The feedstock for the blast furnace must not be too fine to ensure sufficient gas permeability in the shaft furnace. Another supporting process is the pyrolysis of coal to coke in a coke plant. Besides serving as a reducing agent and energy supplier, coke serves as a supporting matrix, also to ensure gas permeability in the blast furnace.

Figure 1. System boundary of an integrated steel site.

An overview of environmental LCA studies of the products steel produced over the BF–BOF route is presented in the following. Some studies consider the flat steel product hot-rolled coil, which is produced from steel slabs in a hot-rolling mill. The main messages and results are afterwards summarized in Table 1.

Norgate et al. (2007) [2] reported an LCA about the metals nickel, copper, lead, zinc, aluminum, titanium, and steel from the BF–BOF route, and stainless steel from the scrap-based EAF route. Assessing the system from cradle-to-gate, Norgate et al. (2007) included the processes from raw material mining, sinter plant, blast furnace, and basic oxygen furnace (BOF) in case of the metal steel. There is no information on whether steel scrap has an environmental burden and how the co-products like the blast furnace slag and BOF slag are evaluated. They investigated the environmental impact categories of global warming potential (GWP) and acidification potential (AP).

Neugebauer and Finkbeiner (2012) [3] presented a multirecycling approach of steel. Primarily produced hot-rolled coil is five times recycled within an EAF and the environmental burdens are shared equally over the life cycles. Losses during the use phase and the recycling process are considered. Credits for the co-products blast furnace slag, BOF slag, electricity, benzene, sulphur, and tar are given. The results of the study presented in Table 1 prove that the choice, whether the recycling potential is taken into account or not, has crucial effect on the LCA results. The data are based on the German industry.

Burchart-Korol (2013) [4] presented an LCA of the steel production in Poland considering both the BF–BOF route and the EAF route. The data are averaged from existing steel plants in Poland. A cradle-to-gate system is used. An environmental burden of scrap is not mentioned and is most likely not considered according to the results, which are presented. Comparably high credits for blast furnace and BOF slag are given, e.g., the GWP presented without credits for the slag is 2.5 kg CO2eq/kg steel and the GWP including the slag credit is 1.7 kg CO2eq/kg steel, see Table 1.

Within an Italian LCA study special attention is given to the human toxicity aspects of single processes from an integrated site [5]. This LCA uses the cradle-to-gate system, including the processes from raw material mining up to the product steel slab. The data have different sources: industry, literature, and commercial LCA databases. The GWP presented of 1.6 kg CO2eq per kg of steel is quite low in comparison to the other results from literature, see Table 1. The results from the LCI reveal that a coal input is composed of 0.58 kg/kg steel into the coke plant and 0.16 kg/kg steel as pulverized coal into the blast furnace. Considering an emission factor of about 3.0 kg CO2/kg coal [6], the coal input would lead to 2.2 kg CO2/kg steel. Parts of environmental impacts are allocated to the by-products blast furnace gas, Coke plant gas, BOF gas, and blast furnace slag, amongst others. An allocation method considering both the mass and economic value was assessed. A consideration of an environmental burden of scrap is not mentioned.

Chisalita et al. (2019) [7] assessed the environmental impact of an integrated steel site and evaluated the potential of CO2 capture and storage using the LCA methodology. The data are based on a report of the IEA [8]. Emissions from the manufacture of purchased pellets, burnt dolomites, and scrap are not included. Despite an amount of probably 0.57 kg coal per kg of hot-rolled coil (Within the LCI 568.69 t coal/t HRC is presented. The authors of this paper assume that it was a mistake, and it should have been kg coal instead of tonnes coal per tonne hot-rolled coil presented within the LCI), the abiotic depletion potential of fossils (ADPf) is only 5.3 MJ/kg hot-rolled coil, see Table 1. Considering a lower heating value (LHV) of 32 MJ per kg of coal [6], this ADPf is questionable. The use of a biomass-based coal is not mentioned. Credits for co-products are not included.

Backes et al. (2021) [9] reported an LCA about a primary German BF–BOF route. A cradle-to-gate approach is used including the processes from raw material supply up to the product hot-rolled coil. The data are based on the German industry. Credits for co-products are given. An environmental burden for scrap is not given following the recycled content approach.

The results of the aforementioned LCA studies are summarized in Table 1.

Table 1. Overview of life cycle assessments (LCA) studies for a blast furnace related steel and hot-rolled coil production.

| Study | Year | Product | Methodology | Impact Categories | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | Scrap | Co-Products | Impact Method | GWP kg CO | 2 | eq | AP kg SO | 2 | eq | ADPf MJ |

CED MJ |

||

| [2] | 2007 | Steel | n. s. | n. s. | n. s. | 2.3 | 0.020 | n. a. | 23 | ||||

| [3] | 2012 | HRC | MRA | SE | CML 16 | 1.0 | 3.0 × 10 | −3 | 12 | 15 | |||

| [3] | 2012 | HRC | RC | SE | CML 16 | 1.7 | 4.0 × 10 | −3 | 24 | 24 | |||

| [4] | 2013 | Steel | n. s. | SE | Recipe Midpoint | 1.7 | 5.0 × 10 | −3 | n. a. | 25 | |||

| [5] | 2016 | Steel | n. s. | Allocation | ILCD | 1.6 | n. a. | n. a. | 23 | ||||

| [7] | 2019 | HRC | RC | n. s. | CML 16 | 2.1 | 1.6 × 10 | −4 | 5.3 | n. a. | |||

| [9] | 2021 | HRC | RC | SE | CML 16 | 2.1 | 4.8 × 10 | −3 | 21 | n. a. | |||

Abbreviations: HRC (Hot-rolled coil); MRA (Multi Recycling Approach); SE (System Expansion); RC (Recycled Content); GWP (Global Warming Potential); AP (Acidification Potential); ADPf (Abiotic Depletion Potential for fossil resources); CED (Cumulative Energy Demand); CML (Centrum for Milieukunde); n. s. (not specified); n. a. (not available).

The LCA results for steel can differ significantly depending on the underlying methodologies and assumptions. The choice of whether the recycling potential of steel is evaluated has a crucial effect. In the cases in which the scrap methodology is not specified, the authors of this paper assume that the scrap is not evaluated following the recycled content approach[10]. In addition, the methodologies and databases chosen for evaluating the co-products, which are in particular the blast furnace slag, the BOF slag, the process off-gases, and surplus electricity from integrated power plants have significant impact on the results. In general, the chosen life cycle impact assessments (LCIA) methods might also lead to differences in case study results, as Bach and Finkbeiner (2017) demonstrated at the example of the impact categories AP and eutrophication potential (EP) comparing the CML (Centrum for Milieukunde) method, the ReCiPe method, and the method of accumulated exceedance [11]. In case of steel, the differences between the CML method and the ReCiPe method are quite moderate for the impact categories GWP, AP, and ozone depletion potential (ODP) [3].

Besides methodological differences, the results of case studies depend on the process control, which shall be explained in the example of the impact category of climate change. The amount of scrap used in the BOF has a significant environmental impact, in particular, if the scrap is not evaluated with an environmental burden. Scrap replaces hot metal in the BOF. Since the production processes until hot metal are the most GWP-intensive ones, a replacement of hot metal has a high impact on GWP reductions. In the BF the iron feedstock graded sinter, iron ore pellets, and lump ore can be used. The upstream environmental impacts of these input materials differ significantly and thus have influence on the carbon footprint of the resulting hot metal and steel.

The production step from steel to hot-rolled coil requires fuel consumption between 1.3 and 1.4 MJ/kg hot-rolled coil [12][13]. Regarding the direct and indirect GHG emissions from natural gas and electricity consumption Kahlid et al. (2021) report 0.11 kg CO2 eq/kg hot-rolled coil due to hot rolling [12]. An increased steel production due to losses within the hot-rolling process is not considered. However, this gives a range of the difference caused by the two various products listed in Table 1. In addition, different assumptions regarding to the use of alloying elements have an impact on the results.

Steel is made from natural raw materials, which differ in their quality. The better the quality of the feedstock, the higher the metallurgical advantages, e.g., for every 1% increase in iron (FE) content of the iron ores, there is a 1–3% increase in productivity and a similar decrease in coke rate. The ash, sulphur, and phosphorous contents are important for the used coal. The ash is the inorganic residue after burning and consists of refractory oxides as SiO2, Al2O3, Fe2O3, and CaO, amongst others. To transfer the ash, the sulphur, and the phosphorous of the coke into the slag within the blast furnace process, energy in the form of coke and coal and slag building components are required. For a 1% increasing of ash, there is a productivity decrease of 2–3% and a coke rate increase of 1–2% [14].

2. LCA Overview of the Secondary Scrap-Based Steel Production Route

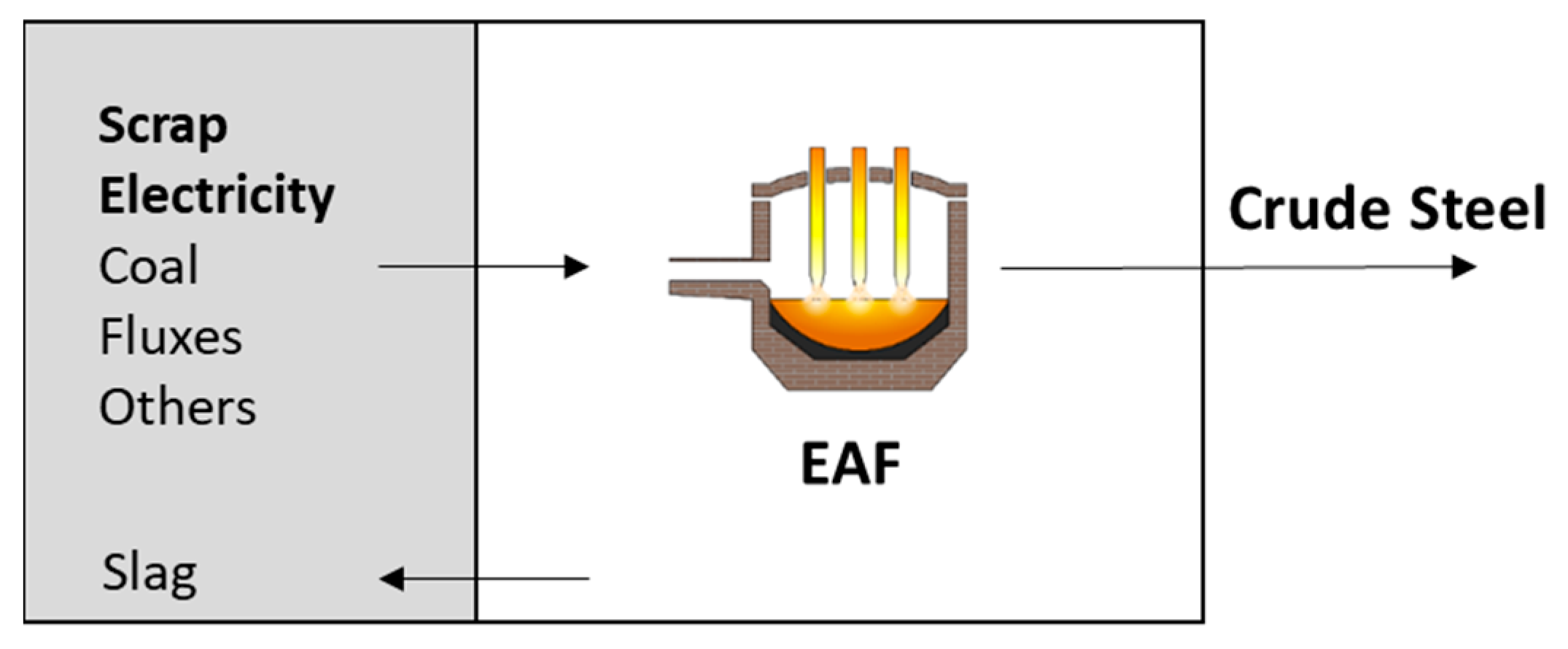

Besides primary steel production from iron ores, steel can be produced via scrap recycling. Globally, about 26% of steel is produced via the scrap-based electric arc furnace (EAF) route in year 2020 [1]. In an EAF, scrap is melted by electrodes via an electric arc, see Figure 2. Carbon and oxygen are added to form a foaming slag. The foamed slag infolds the electrodes, and thus it reduces radiation losses and protects the refractories. In addition, lime is added to improve the foaming properties of slag and to bind undesirable components in the slag [15].

Figure 2. System boundary of an EAF-based recycling steel production.

In the following, a literature overview on LCA studies of a scrap-based steel production via an EAF is presented.

Neugebauer and Finkbeiner (2012) presented, as part of a multirecycling approach, an LCA for a scrap-based EAF production for the product hot-rolled coil [3]. Thereby a cradle-to-gate approach was followed. Within the results presented in Table 2, the scrap is not evaluated. The electricity input for the EAF has a major impact on the impact categories GWP, AP, ADPf as well as on the CED. A German grid mix is assumed in the study. Credits for co-products are not given [3].

Burchart-Korol (2013) analysed the Polish steel production via an EAF following the LCA methodology [4]. Within a cradle-to-gate approach, several impact categories were evaluated for the product crude steel, some of which are listed in Table 2. An environmental burden of scrap is not mentioned and is most likely not considered in regard to the results presented for the EAF route. The cumulative energy demand (1.3 MJ/kg) is quite low considering the fact 1.5 MJ/kg of electricity is required for the EAF [4]. About 6.8 MJ/kg steel credit is given for the EAF slag. Without this credit, the CED would be 8.1 MJ/kg steel. Furthermore, the GWP would be 0.91 kg CO2 eq/kg steel without considering a credit for the EAF slag.

Norgate et al. (2007) presented an LCA for stainless steel from an EAF [2]. The GWP is 6.8 kg CO2 eq/kg steel following a cradle-to-gate approach. Due to the high share of alloying elements, stainless steel is not considered in this comparison.

Table 2. Overview of life cycle assessment (LCA) studies for an EAF produced steel and hot-rolled coil production.

| Study | Year | Product | Methodology | Impact Categories | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | Scrap | Co-Products | Impact Method | GWP kg CO | 2 | eq | AP kg SO | 2 | eq | ADPf MJ |

CED MJ |

||

| [3] | 2012 | HRC | RC | n. a. | CML 16 | 0.74 | 0.0020 | 7.5 | 11 | ||||

| [4] | 2013 | Steel | n. s. | Credit for EAF Slag | Recipe Midpoint | 0.77 | 0.0025 | n. a. | 1.3 | ||||

Abbreviations: HRC (Hot-rolled coil); RC (Recycled Content); GWP (Global Warming Potential); AP (Acidification Potential); ADPf (Abiotic Depletion Potential for fossil resources); CED (Cumulative Energy Demand); n. a. (not available); n. s. (not specified).

The environmental impact of steel production benefits from its recycling potential, which is clearly pointed out within the multirecycling approach by Neugebauer and Finkbeiner (2012) [3]. End-of-life scrap can be reused by melting it nearly infinite times. Comparing Table 1 and Table 2, it becomes apparent that the process of scrap recycling is significantly less energy and emission intensive than the primary steel production. With regard to the transformation of the global steel industry towards climate neutrality, it is important that secondary steel production will be continued but there is no global benefit if a single steel producer shifts from primary to secondary steel production. For decarbonizing the steel industry, breakthrough technologies are required, especially in the primary production route.

References

- World Steel Association: World Steel in Figures. 2021 . World Steel in Figures. 2021. Retrieved 2022-11-3

- T.E. Norgate; S. Jahanshahi; W.J. Rankin; Assessing the environmental impact of metal production processes. Journal of Cleaner Production 2007, 15, 838-848, 10.1016/j.jclepro.2006.06.018.

- Neugebauer, S.; Finkbeiner, M. Ökobilanz nach ISO 14040/44 für das Multirecycling von Stahl; Wirtschaftsvereinigung Stahl: Düsseldorf, Germany, 2012.

- Dorota Burchart-Korol; Life cycle assessment of steel production in Poland: a case study. Journal of Cleaner Production 2013, 54, 235-243, 10.1016/j.jclepro.2013.04.031.

- Pietro A. Renzulli; Bruno Notarnicola; Giuseppe Tassielli; Gabriella Arcese; Rosa Di Capua; Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability 2016, 8, 719, 10.3390/su8080719.

- DIN EN 19694-2; Stationary Source Emissions—Greenhouse Gas (GHG) Emissions in Energy-Intensive Industries—Part 2: Iron and Steel Industry. Deutsches Institut für Normung: Berlin, Germany, 2016.

- Dora-Andreea Chisalita; Letitia Petrescu; Paul Cobden; H.A.J (Eric) van Dijk; Ana-Maria Cormos; Calin-Cristian Cormos; Assessing the environmental impact of an integrated steel mill with post-combustion CO2 capture and storage using the LCA methodology. Journal of Cleaner Production 2018, 211, 1015-1025, 10.1016/j.jclepro.2018.11.256.

- IEA (International Energy Agency). Iron and Steel CCS Study. (Techno-Economis Integrated Steel Mill). 2013 . International Energy Agency. Retrieved 2022-11-3

- Jana Backes; Julian Suer; Nils Pauliks; Sabrina Neugebauer; Marzia Traverso; Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability 2021, 13, 3443, 10.3390/su13063443.

- WSA. World Steel Association: Life Cycle Assessment Methodology Report; World Steel Association: Brussels, Belgium, 2011.

- Vanessa Bach; Matthias Finkbeiner; Approach to qualify decision support maturity of new versus established impact assessment methods—demonstrated for the categories acidification and eutrophication. The International Journal of Life Cycle Assessment 2016, 22, 387-397, 10.1007/s11367-016-1164-z.

- Yusra Khalid; May Wu; Armin Silaen; Francisco Martinez; Tyamo Okosun; Bethany Worl; John Low; Chenn Zhou; Kurt Johnson; David White; et al. Oxygen enrichment combustion to reduce fossil energy consumption and emissions in hot rolling steel production. Journal of Cleaner Production 2021, 320, 128714, 10.1016/j.jclepro.2021.128714.

- N. Schmitz; L. Sankowski; F. Kaiser; C. Schwotzer; T. Echterhof; H. Pfeifer; Towards CO2-neutral process heat generation for continuous reheating furnaces in steel hot rolling mills – A case study. Energy 2021, 224, 120155, 10.1016/j.energy.2021.120155.

- Dutta, S.K.; Chokshi, Y.B.. Basic Concepts of Iron and Steel Making; Springer: Berlin/Heidelberg, Germany, 2020; pp. 7-10.

- Richard D. M. MacRosty; Christopher L. E. Swartz; Dynamic optimization of electric arc furnace operation. AIChE Journal 2007, 53, 640-653, 10.1002/aic.11104.

More