1. Pathway of Sensor Development in Transmission and Distribution Systems: From Yesterday to Today and Tomorrow

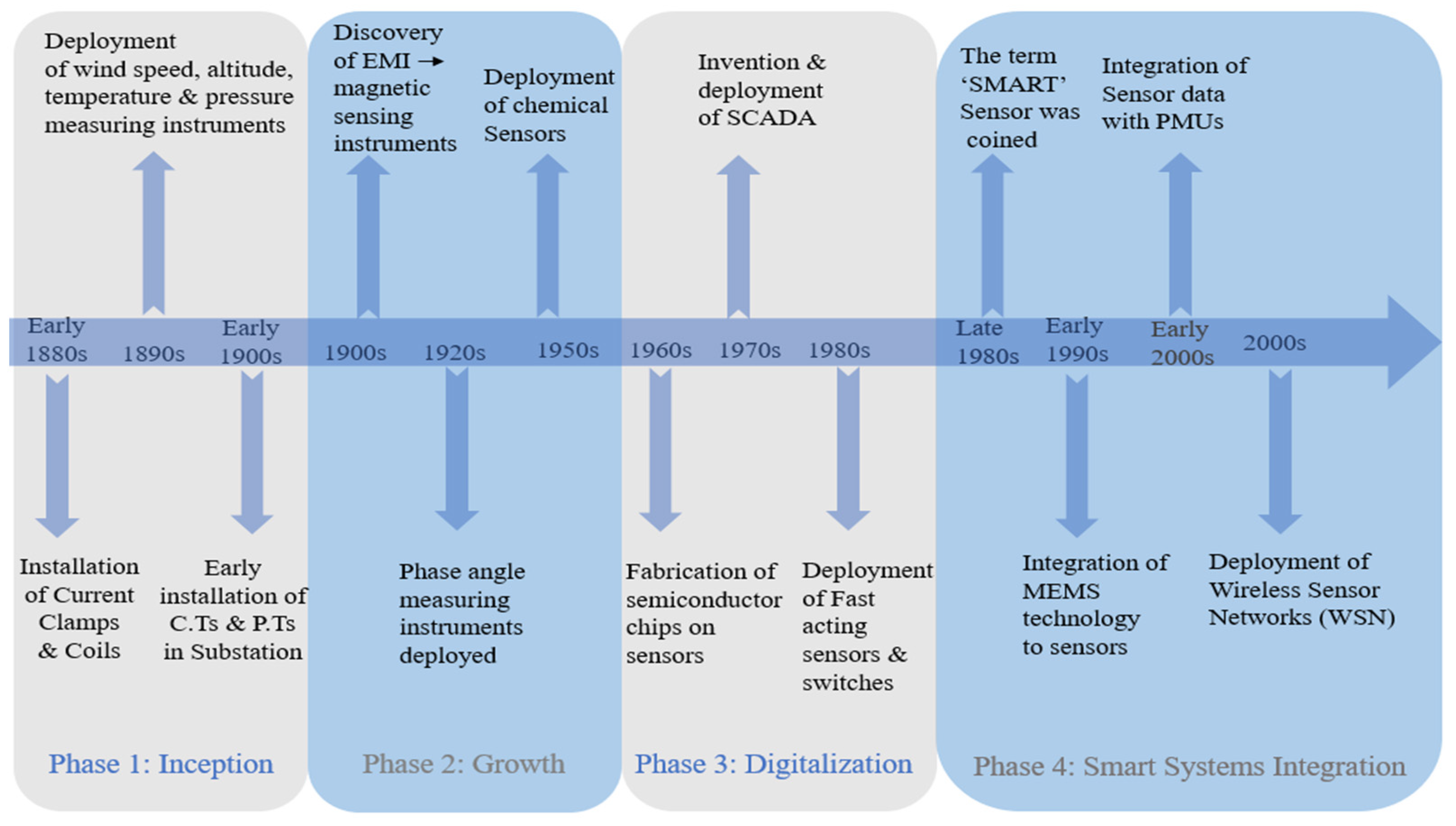

The timeline for the development of sensor technology in the power grid is depicted in

Figure 31. The study of this timeline is essential not only to understand and appreciate the process of evolution of sensors to what it is today but also to take inspiration from it while building the smart sensors of tomorrow. This timeline as depicted in

Figure 3 is elucidated in a detailed manner as follows. The entire timeline can be divided into four major phases. The first phase or the inception phase represents the early deployment of instruments to measure basic grid and atmospheric parameters. It starts with the mounting of basic and crude instruments to measure the current in the grid. This is because the current was recognized as a local parameter and its measurement was deemed necessary, especially during fault conditions to isolate and protect expensive grid equipment. In the early 1800s, current measurement was conducted with current clamps and coils. In the 1890s, instruments were deployed to record the atmospheric parameters that affected the operations of grid components. There are reports of the first remote sensing device, "radiosonde"

[135][1], being deployed in power grids for the measurement of atmospheric parameters such as temperature, pressure, wind speed, altitude, and humidity. In the early 1900s, crude current measuring instruments developed into more sophisticated electromechanical systems such as current transformers and potential transformers. These instruments were bulky and were installed mostly on power transformers to measure the two key parameters of the power grid – the voltage and the current.

Figure 31.

Timeline for development of modern sensor technology.

Phase 2, or the growth phase, resembles the period where the importance of measuring devices in the power grid was recognized, especially for monitoring and protective purposes. Researchers aimed at developing special devices, later defined as sensors, that could provide a response to indicate the presence of various parameters in the grid. Furthermore, various other grid parameters, apart from currents and voltages, were measured or detected by these devices. One of those parameters to be considered first was the phase angle. Phase angle measurements were conducted to get a clearer estimation of real and reactive power flows in the system. The discovery of electromagnetic induction in the early 1900s paved the way for the development of magnetic sensing instruments which were unique because of their non-invasive nature

[98][2]. In addition, in the late 1950s, multiple technologies and principles of science were incorporated into the design of new sensors. This made the sensors versatile and enabled them to measure several other fault indicators such as temperature, acoustics, pressure, chemicals, and gas.

Phase 3 is referred to as digitalization, which resembles the period where system size, system speed and system integration were given greater importance by the researchers. Since the sensors not only measured the values under observation but were also capable of detecting small changes in them, it was realized that they could be used for fault detection purposes. Hence, it was the need of the hour to have sensors that could function faster and measure multiple components of the grid for fault detection. Developments in the semiconductor industry in the 1960s with the fabrication of system-on-chip devices were a breakthrough that paved way for high performance but low-powered and lightweight sensors that replaced the bulky and lossy measuring instruments on the power grid

[63][3]. These features made it possible for the sensors to be installed remotely and increased the visibility of the grid components, especially those that were installed outside the substations. In the 1970s, the Supervisory Control and Data Acquisition system was invented and deployed in the power grid. This facilitated the deployment of monitoring instruments and sensors that had faster response times and that could initiate local protective actions such as the action of circuit breakers, reclosers, and isolators. However, these sensors had lower sampling rates that were insufficient in the detection of details of transient phenomena that occurred in mere milliseconds. To capture this underlying data for optimum asset utilization, fast acting sensors and switches were deployed in the late 1980s.

Phase 4 is the smart systems integration. It represents the current period where researchers are more focused on developing smart sensors that can enable pervasive sensing with system integration and realize system miniaturization. In the early 1990s, MEMS technology was integrated with sensors that improved their accuracy and sensitivity to detect multiple grid parameters. Next, the early 2000s saw the integration of sensors with phase measuring units and measuring units which enabled real-time monitoring with very high sampling rates. Furthermore, the sensor technology matured from the deployment of single sensing devices to its incorporation with SCADAs, PMUs, and MUs, constituting the wide area monitoring systems for complete, synchronized, and digital monitoring of various components of the power grid. Currently, power system operators demand SCADA- and PMU-based real time data to monitor the dynamic power flow of the grid. With the help of these real time grid parameters, responses to emergency, fault and failure events are swift, thereby improving power security. Therefore, SCADAs and PMUs form an integral part of the online dynamic security assessment (DSA) systems

[136][4]. Real time and online system measurements obtained from them are used for system estimation and system modeling to perform power system security analysis. A range of various off-line applications such as validating system models, operations planning, diagnostics, and post-event analyses, etc. are also conducted with these measurements

[137][5]. When this is combined with newer software developments, advanced machine learning based algorithms with improved computational capabilities, and matured fiber optic based wired or wireless communication technologies using Wi-Fi, LoRa, ZigBee, and NB-IOT,

[65][6] advanced applications such as “faster than real-time” state estimation

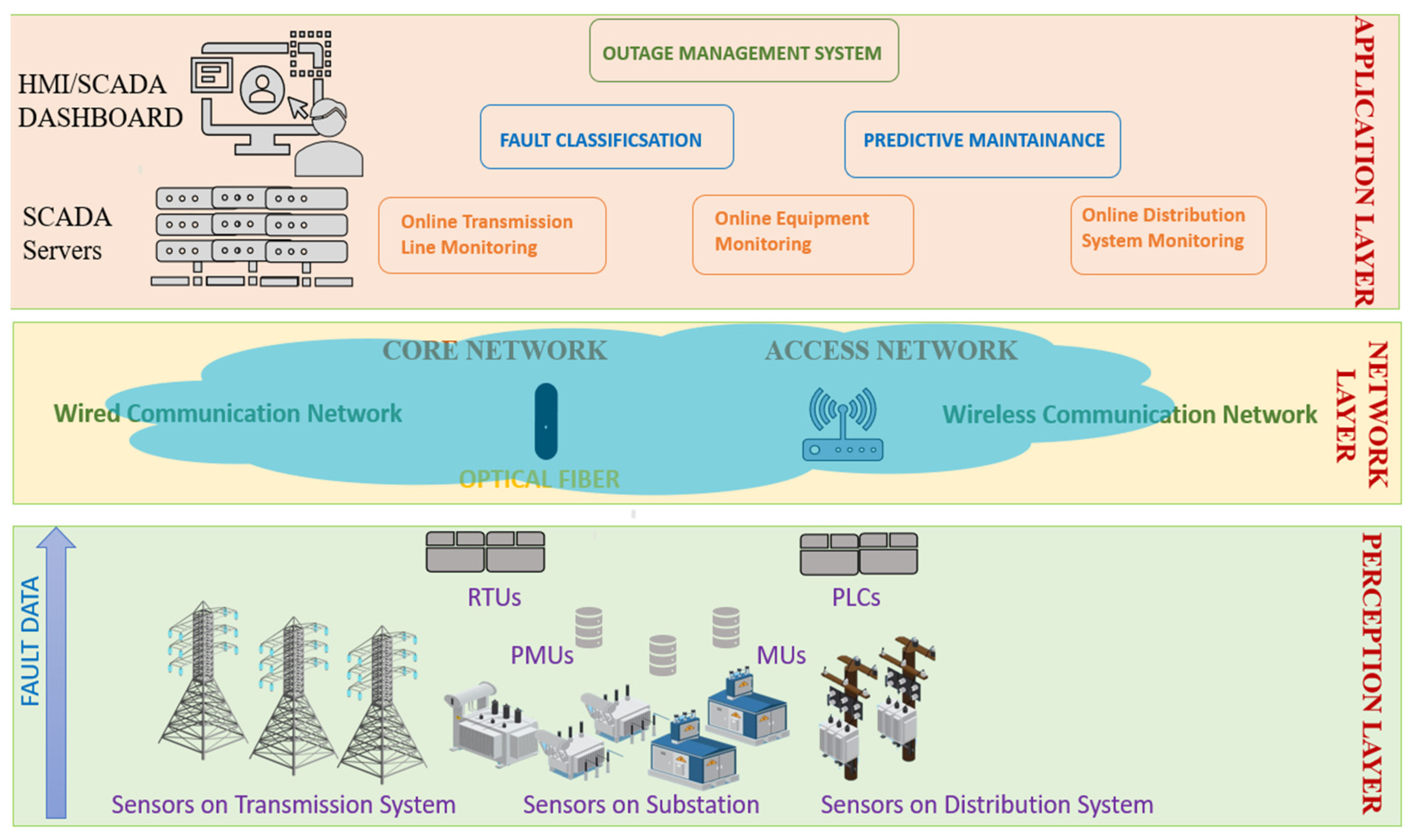

[18][7], predictive controls, and rapid contingency analyses are realized. This creates a pervasive sensing network architecture for the power grid as modeled in

Figure 42. Furthermore, the sensor data from equipment monitoring is also integrated into control systems, and new control strategies are devised to deal with the risks of equipment failures, etc. For example, currently, advanced automation schemes such as fault location, isolation, and service restoration systems (FLISR)

[138][8] are being deployed in distribution systems that are controlled in real time by SCADA. They provide support for the enabling of DERs and improve distribution automation with efficient fault localization.

Figure 42.

Pervasive sensing network framework in a power system.

The current trend in the modern-day sensor technology is the integration of multiple sensors and other connected devices to form wireless sensing networks (WSN). The deployment of WSNs in the transmission and distribution systems is unique since it is an advanced technology facilitating not only efficient data acquisition but also data transmission and data processing to provide complete real-time monitoring of the grid. WSNs enable pervasive sensing among the transmission and distribution system components for fault measurements as well as the continuous monitoring of power system components for state estimations and forecasting

[3][9]. This pervasive sensing network framework in power systems is depicted in

Figure 42. The figure clearly demarcates the three major layers that constitute WSNs

[2][10] that are deployed in transmission and distribution systems. The first layer is the perception layer or the input layer. It consists of the deployment of multiple sensors on various components of the transmission and distribution system. These sensors are often referred to as input sensors or source sensor nodes. The sensor nodes can also contain a sensor module along with a processor module for data processing, a wireless communication module for data transmission, and an energy management module to supply power to the other modules

[139][11]. These sensor nodes can be deployed remotely to acquire raw grid parameter values essential for monitoring individual grid components. These sensor nodes can form part of a bigger assembly of sensors constituting SCADAs, PMUs, and MUs, for time synchronized data acquisition. The raw grid parameter values acquired can be interfaced with hardware for processing or control purposes through remote terminal units and programmable logic controller devices. The second layer facilitates the transmission of the raw grid parameter data into the application layer for further processing. The network layer broadly consists of two networks for data transmission called the core networks and the access networks

[140][12]. The core networks are responsible for the wired transmission of data, especially with the help of optical fiber as a network channel. Access networks enable data transmission through wireless communication systems. Various modern wireless communication technologies

[141][13] such as Wi-Fi, LoRa, NB-IoT, ZigBee, and satellites can be employed here. The third layer is called the application layer. This layer constitutes several application infrastructures, middleware, and application systems like SCADA servers and SCADA dashboards, where the transmitted data is analyzed, generally by operator personnel. The grid parameter data can also be processed in the application layer for the detection of developing fault features for online transmission system monitoring and online distribution system monitoring or online individual equipment monitoring. Intelligent computing with machine learning techniques can be used to process the raw grid parameter data for fault classification and fault forecasting, leading to the predictive maintenance of the system. This in turn forms an outage management system

[142][14] for the transmission and distribution system components. Hence, through this process, pervasive sensing with WSN is realized in transmission and distribution systems.

The future development of sensors must consider certain unique features of the future power grids and the upcoming smart grids. To transition into smart grids

[143][15] in the future, the existing power grids must dynamically configure themselves in accordance with the demand side changes for which they require instantaneous and simultaneous data from multiple nodes on the power grid. This calls for advanced sensing structures that would provide the real-time information on the status of a multitude of parameters of the power grid. This real-time information is not only essential for controlling the direction of power flow and information about energy consumption and production but also helps in the prediction or at least faster remediation of sudden events such as device failures, demand drops, etc. and forms a big part of the distribution automation and outage management system. It is also required to help with the synchronization within the grid as well as outside the grid. This is conducted by employing smart sensors at multiple pivotal points on the grid constituting the wireless sensor network.

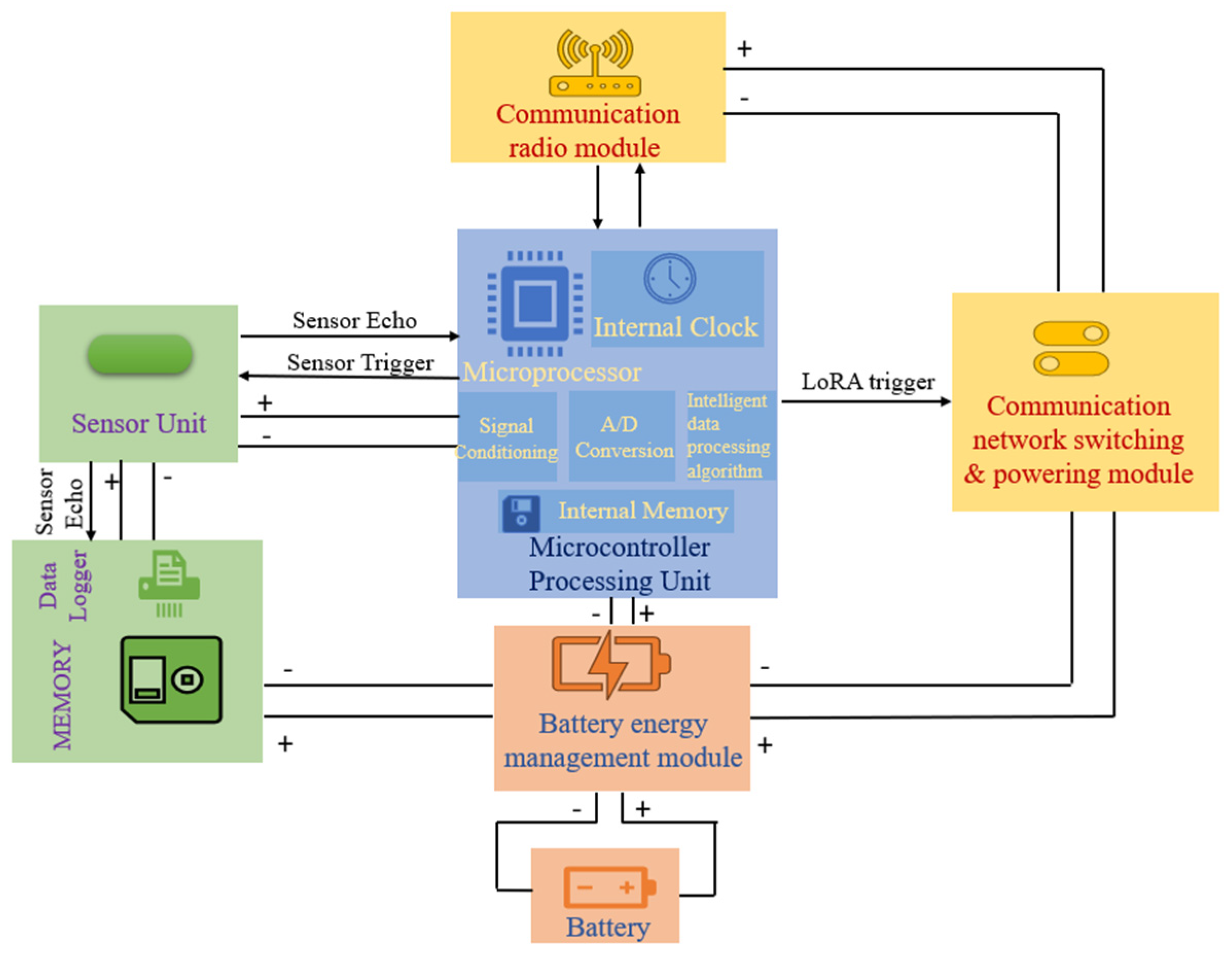

Currently, smart sensors are being developed by taking into consideration the above features so that they could be deployed in the upcoming power grids and smart grids. These smart sensors have features of high speed, high accuracy and high sensitivity for data sensing and data processing. They have multiple sensing capabilities and intelligent sensing capabilities such as self-identification, self-localization, self-awareness, self-diagnostics, self-calibration, and self-compensation

[6,70][16][17]. The general model of a smart sensor

[6][16] employed in smart grids essentially consists of four modules as depicted in

Figure 53. The sensing module includes a set of sensors for data acquisition along with memory for data storage. The processing module includes an internal clock and an external time reference for synchronized data processing by means of A/D conversions and data processing algorithm-based microprocessors along with internal memory. It can also contain independent modules for signal processing at the edge such as signal conditioning modules, signal conversion modules and intelligent data processing algorithm modules. The network and communication module with a radio module for transmission and a switching module is used for data networking and communication to the master centers via wired (serial or ethernet) or wireless cellular networks through standard communication protocols. Finally, the battery management module consists of an energy source and switching module that powers the sensing, processing, and communication module. These advances in smart sensors lead to the evolution of advanced metering infrastructures and smart IoT devices that in the future could have the capability of addressing the variable and unpredictable load profiles and enable system-wide coordination and protection. Along with this, the greater deployment of distributed generation, the use of aggregated demand response for the deployment of microgrids and smart grids, greater customer participation in power markets with dynamic pricing, and the integration of electric vehicles, smart buildings, smart industries, etc. on a larger, commercial scale can be realized

[144][18]. Thus, the smart sensors of the future hold tremendous potential not only in their development but also in the development and functionality of future smart grids.

Figure 53.

Block diagram of a smart sensor.

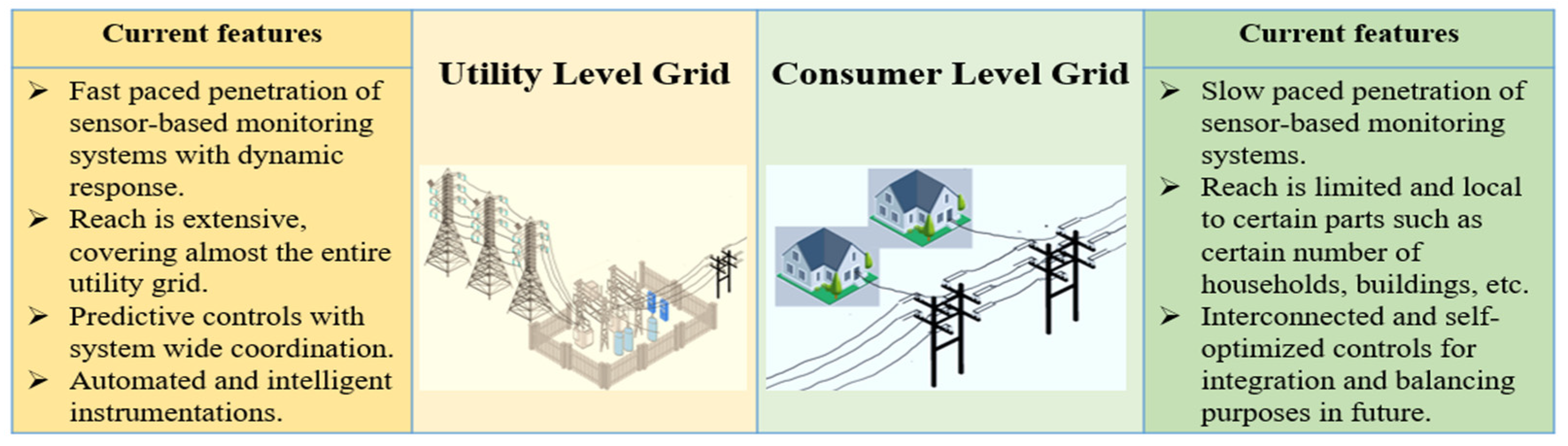

2. Advances in Utility Level and Consumer Level Grids with Modern Day Sensor Technology

Modern-day sensor technology has certain technical ramifications in the utility level and consumer level grid connections. From the re

vise

warch, it can be inferred that at the utility grid level, substantial advancements have been realized in the past decade to upgrade the sensors used on transmission and distribution systems. Firstly, the deployment of sensors has been fast paced with an extensive reach, covering almost the entire utility grid. Sensors have developed from just directly measuring the traditional grid parameters such as values of voltages and currents to sensing more complex grid features such as the electromagnetic signatures, material properties, acoustics, and frequency of operations to estimate more accurate values of the sensed parameters. Second, modern-day sensor technology has predictive controls enabling the integration of automated and intelligent models and instrumentation. Sensor technology has matured from the deployment of single sensing devices on the power grid components to its incorporation with SCADAs, PMUs, MUs, etc. constituting the wide area monitoring systems for complete, synchronized, and digital monitoring of multiple components of the power grid. The incorporation of advanced communication protocols such as wired fiber optics communications and wireless communications with Wi-Fi, LoRa, ZigBee, NB-IOT, etc., have helped to improve the efficiency and speed of data transmission... Finally, the incorporation of machine learning and IoT into the maturing sensor technology is another attractive feature that not only improves the sensing process but also efficiently integrates the sensed raw grid parameter data for synchronized data collection and transmission with artificial intelligence and cognitive data analysis at the edge, thereby reducing outage management time and boosting the holistic asset utilization of the power grid

[145,146][19][20].

However, at the consumer level, transformation of the traditional sensors and the electric meters with advanced sensor technology is still latent but will be coming in a few years. The pace of deployment of modern-day sensors has been slow and their reach is very limited to a particular area for a particular functioning. For smart meters and meter data management systems, MDMS installed at certain consumer-side loads can provide data on energy usage, power quality and economic metrics with remote communication facilities to the grid operator. There is still a requirement for pervasive and smart sensing techniques that will enable customized scheduling, reduced billing, demand response, and the support of new controlling strategies to accommodate the needs of smart homes and smart buildings

[23][21]. This is also required for electrical market analysis to facilitate planning, load forecasting, and structuring of engineering designs and standards

[147][22]. Furthermore, there is a requirement for enhancing customer service and customer experience by competing energy service companies. Various customer centric applications such as reports on charging-discharging time and time-of-use rates

[147][22], especially for bigger loads like electric vehicles, can be provided through appropriate embedded sensors. Smart sensors and advanced metering instruments (AMI) can also help increase consumers’ participation in the energy market and energy management processes. The modern-day sensor technology from the point of view of the utility level grid and consumer level grid has been depicted in

Figure 64.

Figure 64.

Current features of the modern-day sensor technology in the utility level grid and consumer level grid.

3. Advances in Transmission and Distribution Systems with Modern Day Sensor Technology

Modern sensor technology can prove itself instrumental in remodeling the traditional transmission and distribution systems to cope with the impending developments in the near future. Some of the significant developments that can be realized in the existing transmission and distribution systems by their integration with modern-day sensor technology are discussed below and are tabulated in Table 31.

Table 31. A summary of the scope for future developments in transmission and distribution systems with its integration with modern-day sensor technology.

Modern-day sensor technology has the ability to bring significant developments in the existing structure and functionality of transmission systems. The current operations of the transmission systems are mostly based on operator-based controls. To realize autonomy, synchronicity, efficiency, and faster response of the transmission system in the future, there is a need to replace the operator dependent controls with automatic controls. The modern-day sensor technology can form an important part of this automation system by enabling the detection and measurement of physical or grid parameter variations which could provide essential information to the control system to take necessary actions without being dependent on the expertise of operator personnel

[148][23]. Automatic controls can also improve the existing islanding and anti-islanding issues in microgrids and configure switchable networks to relieve congestion issues and improve the transmission capacity of the system. Along with this, modern-day sensor technology can help monitor the bidirectional flow of power when the traditional transmission systems evolve into smart grids in the future. Furthermore, the incorporation of machine learning and IOT-based real time condition monitoring and predictive maintenance of the entire system along with strong cybersecurity protocols can vastly reduce the vulnerability to faults, destabilizing issues, and cybersecurity threats

[145,149][19][24]. The current transmission system is predominantly equipped with SCADA systems with integrated PMU-based wireless sensing networks for real time monitoring. This situation is expected to be improved with the incorporation of new and forthcoming developments in sensor technology that will allow for real time, time-synchronized monitoring, and adaptive transmission line measuring instrument sensors for multi-level coordination of the entire transmission system. ‘Faster-than-real-time’

[142][14] monitoring and predictive maintenance will help build sturdier transmission systems and will enable ‘on-need-basis’ dispatch and re-dispatch of generation. The inclusion of optimized energy storage systems in wireless sensor networks will reduce the dependency on the main grid, thereby not affecting the normal operation of the transmission system due to the failure of sensors or a wireless sensor network

[150,151][25][26].

The modern-day sensor technology has also brought significant developments to the existing structure and functionality of distribution systems. The current structure of the distribution system is mostly ‘floating on the transmission line’

[142][14] with limited monitoring and controls that are restricted to the substation. Furthermore, the topology of the distribution systems is mostly a radial structure that supports power flow in a single direction. The coming age of smart grids calls for the facilitation of bidirectional power and distribution system automation. Distribution system automation is essential for the real-time adjustment of the system in response to the dynamic changes in loads and other fault conditions without operator intervention. This automation with advanced distribution management systems for automatic controls and monitoring can be brought about with the help of modern-day sensor technologies. Autonomous controls can be realized by installing sensors and PMUs and MUs-based wireless sensing networks outside the substation along the entire length of the distribution system. The current monitoring of the distribution system is mostly restricted to the substation. However, with the implementation of modern sensor technology, on-site, remote, and real-time distribution system asset monitoring can be realized

[152][27]. This will strongly isolate the transmission system faults from dissipating into the distribution system, improving the reach of protection and the distribution system capacity. Furthermore, as discussed above for transmission lines, modern sensor technology could also improve the resiliency of the distribution systems by facilitating real time, time-synchronized condition monitoring and predictive maintenance

[153][28] to cope with vulnerabilities of distribution systems to such things as faults, destabilizing issues, and cybersecurity threats. Hence, the development of transmission and distribution systems and the development of modern-day sensor technology go hand in hand. Thus, the study of the latest developments in sensor technology is a precursor to realize the necessary developments in the power grid.