Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Tapas Mandal and Version 2 by Conner Chen.

Mono-, few-, and multi-layer graphene can be synthesized using various methods, including micromechanical exfoliation, chemical vapour deposition, and chemical methods such as oxidizing graphene into graphene oxide and then reducing it chemically or thermally.

- 2D nanosheet

- nanomaterial

- layered material

1. Introduction

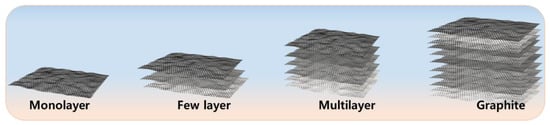

The sixth element is truly fascinating due to its allotropic forms [1][2][1,2]. Its allotropes are as soft as graphite [3][4][3,4] and as hard as diamond [5]. Graphite is three-dimensional structure that is made up of stacking multiple one-atom-thick layers, which are formed from strong sp2 hybridized carbon atoms arranged in a hexagonal lattice [6][7][6,7]. This two-dimensional monatomic thick crystal structure consists of single atomic sheet of graphite, and is called “graphene” [8]. Recently, graphene, an allotrope of carbon, has become a hot topic of research due to its good physico-chemical properties [9][10][9,10]. When stacked, graphene forms different types of graphene, such as monolayer graphene [11], few-layer graphene [12] and multilayer graphene [13]. The properties of graphene are dependent on the number of stacked layers; for example, monolayer graphene has better properties than few-layer graphene and multi-layer graphene [14][15][14,15].

Scientists described the theoretical existence of single layer graphene more than 80 years ago [16]. Then, the practical existence of two-dimensional graphene was considered physically impossible [17]. However, in 2004, Geim et al. isolated single-sheet graphene via the scotch tape method and demonstrated its properties experimentally [18]. This was the first time researchers came to know about the remarkable properties of graphene [19]. Since then, there has been an exponential rise in studies of graphene-based materials to determine the various applications of their properties, such as in biomedical applications [20][21][20,21].

Due to the expert attention paid to graphene-based materials, high-performance materials were successfully produced. However, achieving these high performance levels involves various challenges, especially in relation to monolayer graphene [22][23][22,23]. One of these challenges is the synthesis of monolayer or few-layer graphene in bulk with high purity, which is an is extremely difficult process [24]. Other challenges include the restacking of monolayer graphene in few-layer and multi-layer graphene [25][26][25,26]. This restacking results in the decreased performance of the graphene-based devices. Therefore, the control of lateral size and aggregation states, in addition to the process of the oxidation of graphene in graphene oxide, is essential for developing graphene-based high-performance devices [27][28][27,28].

After achieving the synthesis of monolayer graphene, which exhibits good characteristics for a roadmap of graphene-based devices, the characterization of the order of stacking in graphene became a subject of interest for researchers [29][30][29,30]. These characterization techniques include atomic force microscopy (AFM) [31], Raman spectra [32], Raman mapping [33], and Transmission electron microscopy (TEM) [34]. Among these techniques, Raman spectra and TEM are methods frequently used to determine whether the synthesized material is monolayer graphene, few-layer graphene, or multi-layer graphene [32][34][32,34]. After characterization, the graphene material can be used for different applications, such as biosensors [35], tissue engineering [36], drug carriers [37], and other biomedical applications.

2. Production of Mono-, Few-, and Multi-Layer Graphene

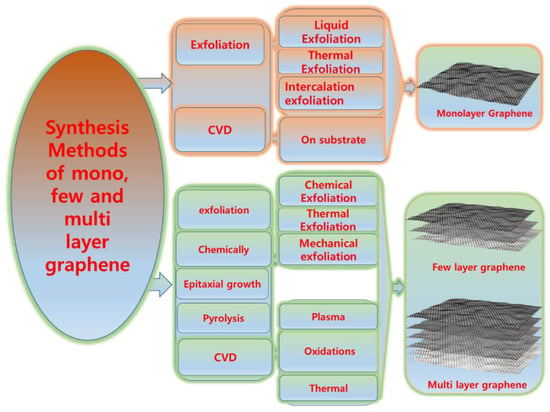

Graphene, especially monolayer graphene, has received a great deal of attention since 2004 due to its good mechanical, electrical, and thermal properties [18]. However, the synthesis of monolayer graphene is extremely difficult and expensive [38][39][38,39]. Therefore, synthesizing few-layer graphene or multi-layer graphene is also a subject of interest [40]. A general scheme represents monolayer, few-layer, and multi-layer graphene (Figure 1). Mono-, few-, and multi-layer graphene can be synthesized using various methods, including micromechanical exfoliation [41], chemical vapour deposition [42], and chemical methods such as oxidizing graphene into graphene oxide [43] and then reducing it chemically [44] or thermally [45]. A few methods provide high-quality, large-scale few-layer and multi-layer graphene but small amounts of monolayer graphene, such as the chemical method; however, the purity and defect density remain matters of concern [46][47][46,47]. Similarly, large-scale monolayer graphene can be synthesized by chemical vapour deposition, but purity still is a topic of concern [48]. The various methods for producing mono-, few-, and multi-layer graphene are as follows.

Figure 1.

Schematic overview of monolayer, few-layer and multi-layer graphene.

2.1. Synthesis of Few- to Multi-Layer Graphene

2.1.1. Exfoliation of Graphite

Graphite is an abundant material and well known for its lubricating properties [49][50][49,50]. However, it has poor mechanical, electrical, and thermal properties. Graphite can be exfoliated into different types of graphene, but we must first overcome the weak van der Waals forces which hold the different types of graphene into graphite [51]. A general scheme of the process for obtaining different layers of graphene is shown in Figure 2.

Figure 2.

Schematic overview of the process for obtaining different layers of graphene.

- (a)

-

There are several ways to overcome these weak interactions, and the most promising among them is the sonication of graphite in different solvents; however, the yields of multi-layer and monolayer graphene [52] are very poor in this process.

- (b)

-

Another promising strategy to obtain graphene from graphite involves oxidizing graphite by various methods, such as Hummer’s method, and reducing it chemically or thermally to obtain a large-scale yield [53]. However, the redox results of graphite into graphene mostly provide high yields of few-layer graphene or multi-layer graphene.

- (c)

-

Another method of producing few- and multi-layer graphene involves the exfoliation of graphite via graphite intercalation [54][55][54,55]. Different types of chemicals can be inserted to graphite interlayer space, thereby increasing the interlayer distance of adjacent graphene sheets in graphite. This phenomenon also changes the properties of graphene, since the increase in interlayer spacing affects electronic coupling between adjacent graphene sheets in graphite [56].

- (d)

-

Another way to exfoliate graphite into few- and multi-layer graphene is via ball milling [57]. This is a way of exfoliating graphite via mechanical exfoliation. Ball milling has been extensively used in the past to reduce the particle size of a material [58]. Scientists thus propose ball milling as a way to mechanically exfoliate graphite in small-size nano-graphite, increasing the mixing time to obtain few- or multi-layer graphene. Thus, ball milling is a promising technique for exfoliating graphite into graphene. The advantage of using ball milling to produce graphene is its low production cost, its easy handling, and its ability to produce graphene at large scale.

- (e)

-

The plasma synthesis method is another significant way to produce graphene with few-to-multiple layers. Microwave plasmas produced by surface waves at a stimulation frequency of 2.45 GHz and under atmospheric pressure conditions were successfully used to produce highly structured and stable self-standing graphene sheets [16]. There were also investigations into how the addition of hydrogen affects the density of the carbon precursor (C2, C) and the structural soundness of synthetic graphene sheets. Changes in the sp3/sp2 ratio and the C2 and C number densities were shown to be correlated [59]. Microwave-driven plasmas were used to control oxygen functions and the sp2/sp3 carbon ratio (~15) to a high degree [60].

2.1.2. Synthesis of Monolayer Graphene

- (a)

-

In 2004, for the first time, Geim and Novoselov developed a method of synthesizing graphene using micromechanical cleavage as “scotch tape” via mechanical exfoliation [18]. This was for the first time in history that any scientist experimentally synthesized monolayer graphene. After synthesizing the monolayer graphene, these scientists further demonstrated its outstanding properties [61]. However, due to the uneven thickness of the graphene flakes and its high production costs, the mechanical exfoliation method was not suitable for the mass production of graphene that might be used to study graphene-based devices.

- (b)

-

Another method of producing monolayer graphene is the chemical vapour deposition method [62]. Monolayer graphene can be grown epitaxially on a silicon carbide substrate, and can be used for various applications, such as transistors. The size of the monolayer graphene grown depends on the size of the silicon wafer. The surface of the silicon wafer also influences the properties of the synthesized monolayer graphene.