The incorporation of probiotics in non-dairy matrices is challenging, and probiotics tend to have a low survival rate in these matrices and subsequently perform poorly in the gastrointestinal system. Encapsulation of probiotics with a physical barrier could preserve the survivability of probiotics and subsequently improve delivery efficiency to the host.

- encapsulation

- non-dairy

- probiotics

- stability

- storage

1. Introduction

2. Encapsulation

To date, encapsulation is one of the most promising techniques in protecting active compounds against adverse environments. Encapsulation technology has been widely used in the pharmaceutical, medicine, nutritional, food science, biological, agriculture, toiletries, and cosmetics industries for over 50 years. The goal of encapsulation is to protect the encapsulated active compound (core material) against unfavorable or adverse environments (such as light, moisture, temperature, and oxygen). In food industries, a broad range of products (including probiotics, antioxidants, antimicrobials, flavors, enzymes, and nucleic acids) are encapsulated to (a) prevent the core material from degradation, (b) slow down the evaporation rate of volatile core material, (c) separate the components that would otherwise react with each other, (d) modify the nature of the core material for easier handling, (e) increase the stability, (f) to mask undesired tastes, colors, and odors, (g) enable sustained and controlled release (release slowly over time at a constant rate), (h) control oxidative reactions, (i) use with bacteriophages to control foodborne pathogens, and (j) extend the shelf life. Indeed, encapsulation is one of the new and effective methods to protect probiotics from the harsh conditions they encounter throughout food processing, shelf storage, and gastrointestinal transit [1][39][40][41][1,40,41,42].3. Probiotic Encapsulation Techniques

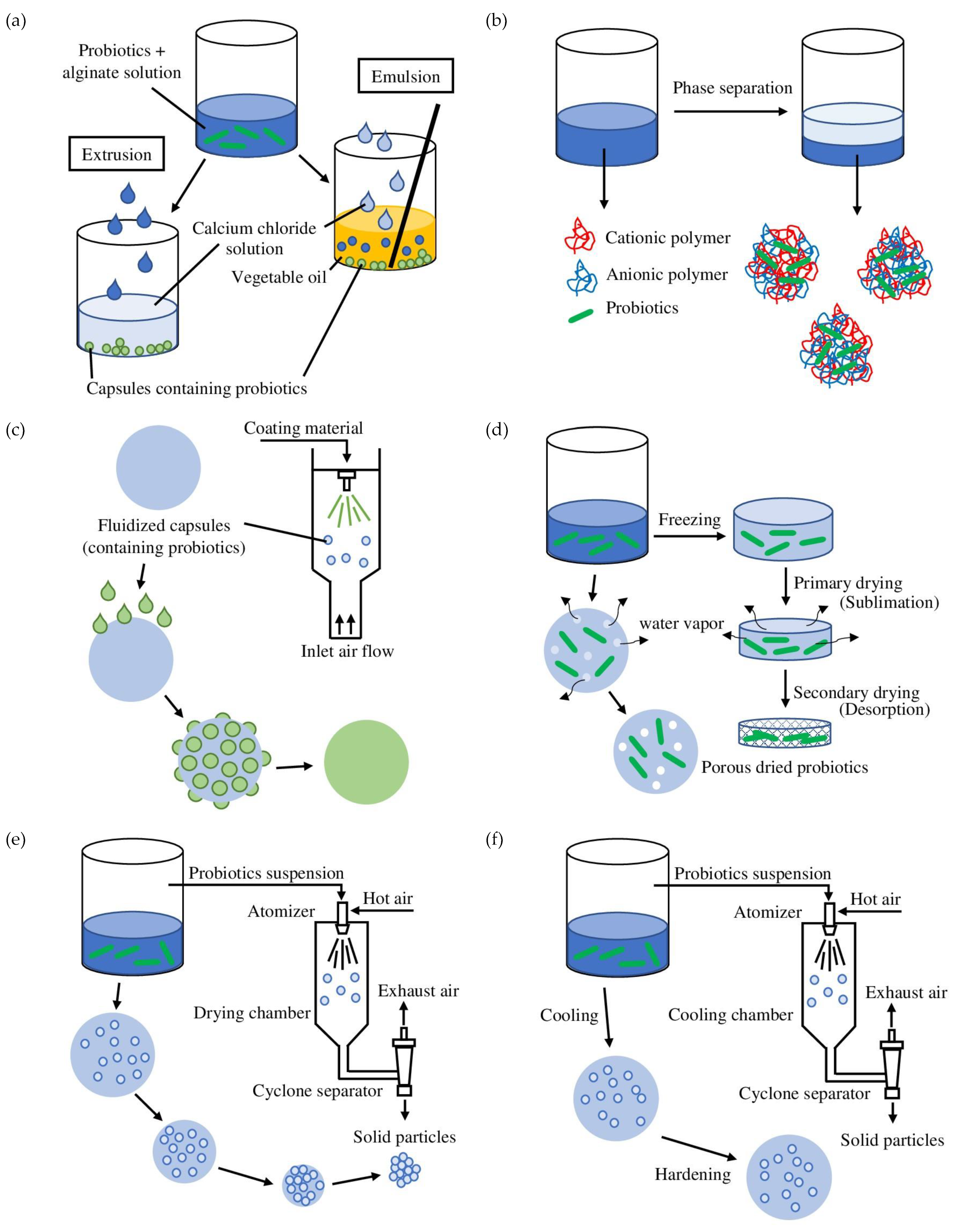

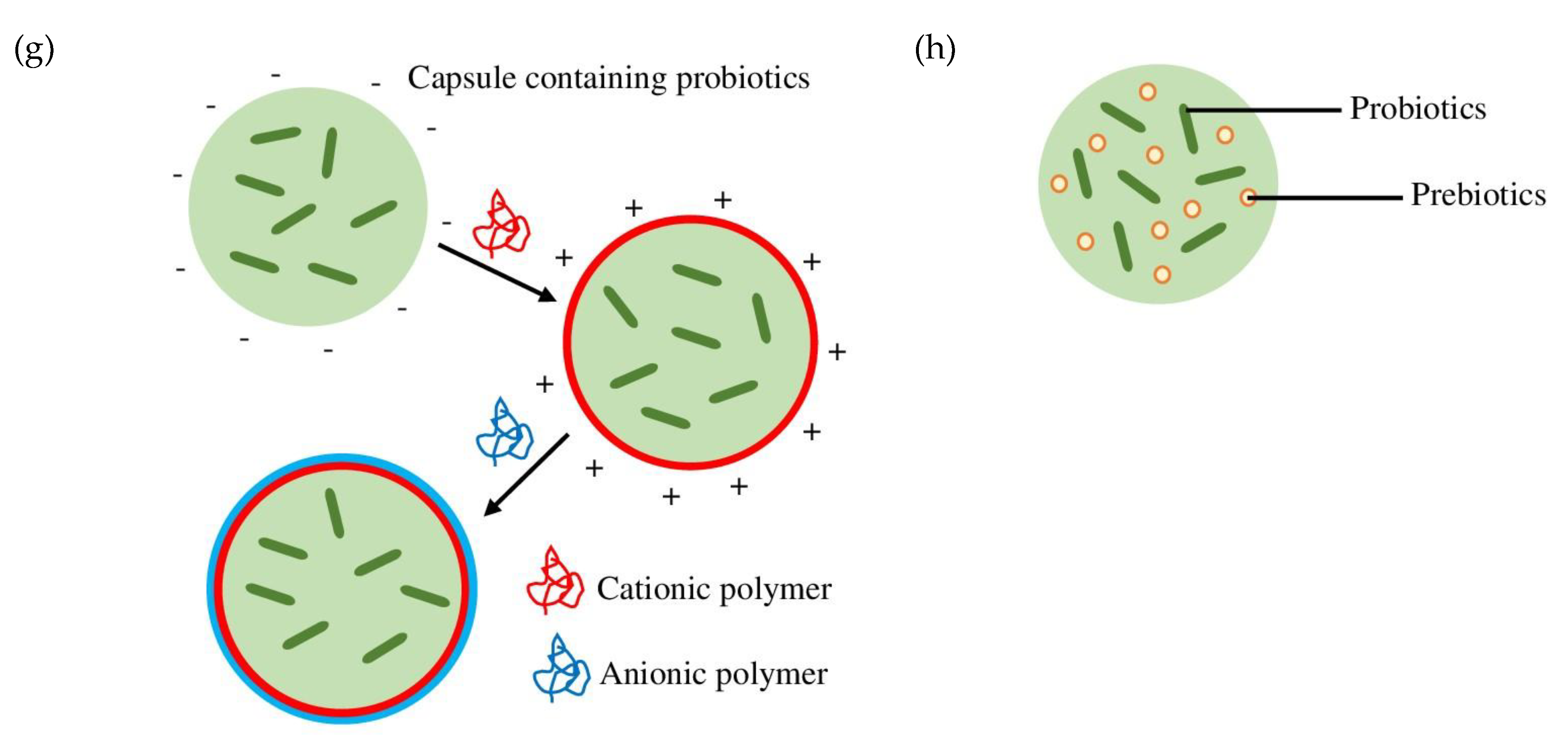

Numerous encapsulation technologies have been developed and adopted to protect probiotics. All the techniques aim to protect the viability and stability of probiotics. However, their concepts, operation methods, and properties of produced capsules are different. Each technique also has its own strengths and drawbacks. Figure 1 illustrates different types of probiotics encapsulation techniques and the morphologies of corresponding microcapsules obtained. Various aspects must be taken into consideration before the selection of encapsulation techniques. Selecting a suitable encapsulation technique depends on several parameters, such as the nature of the probiotics, the operational conditions of the encapsulation technique, the properties of the biomaterials used, the particle size needed to deliver the adequate probiotics load without affecting the sensory properties, the release mechanism and release rate, the composition of the target food application, the storage conditions of the food products before consumption, and lastly, the cost limitation of production [42][43][43,44].

|

Methods |

Properties of Encapsulation |

Advantages |

|---|

|

Category |

Biomaterial |

Characteristics and Advantages Disadvantages |

References |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Category | Limitations |

Technology Remarks |

References |

||||||||||

Probiotic/LAB Strain |

Encapsulating Agent |

Food Product |

Results |

Reference |

|||||||||

|

Extrusion (external ionic gelation) |

Produces capsules with sizes of 100 μm to 3 mm. Can encapsulate hydrophilic and hydrophobic/lipophilic compounds. |

||||||||||||

|

Fruit and vegetable-based | Monodispersity. Simple and mild process.Can be conducted under both aerobic and anaerobic conditions. | ||||||||||||

|

Carbohydrate |

Alginates |

Emulsion Low operation cost. High survival rate of probiotics. |

Anionic character, non-toxic, biocompatibility, biocompostability, cell affinity, strong bioadhesion, absorption characteristics, antioxidative, anti-inflammatory, and low in cost. Stable (shrink) in the low acidic stomach gastric solution and gradually dissolve (swell and release encapsulated probiotics) under alkaline conditions in the small intestine. Produces relatively large beads.Slow solidification process. Not suitable for mass production. Additional drying process is required. |

Bifidobacterium bifidum Sensitive to heat treatment, highly porous, poor stability and barrier properties. |

|||||||||

Technique: extrusion, emulsion.Could form a strong gel network by interacting with cationic material (e.g., chitosan). | Combination: pectin, starch, chitosan. |

60 mL sodium alginate, κ-carrageenan, 5 g Tween 80 [52] |

The viability of B. bifidum was enhanced from 6.58 log CFU/mL (free) to 8.51 log CFU/mL (sodium alginate-encapsulated) and 7.09 log CFU/mL (κ-carrageenan-encapsulated) after 35 days of storage. |

[7] |

Emulsion (internal ionic gelation) |

Produces capsules with sizes of 200 nm to 1 mm. | |||||||

|

Can encapsulate hydrophilic and hydrophobic compounds. |

Chitosan | ||||||||||||

|

Extrusion Simple process. Produces relatively small beads. Suitable for mass production. High survival rate of bacteria. |

Polydispersity. |

Cationic character, non-toxic, biodegradability, bioadhesiveness, antimicrobial, antifungal, low in cost, high film-forming properties, great probiotics biocompatibility, resistance to the damaging effects of calcium chelating and anti-gelling agent, generate strong beads. |

Enterococcus faecium High operation cost. Conventional emulsions are thermodynamically unstable. Not suitable for low-fat food matrices. Additional drying process is required. |

Degrade easily in low pH conditions, water-insoluble at pH > 5.4. Pose inhibitory effect against lactic acid bacteria. |

2% (w/w) sodium alginate |

||||||||

Technique: extrusion, layer-by-layer (LbL), emulsion.Normally used as a coating rather than as a capsule. | Combination: alginate, pectin. |

Cherry juice |

Encapsulated probiotics had higher viability during storage (4 and 25 °C) and stronger tolerance against heat, acid, and digestion treatments than free probiotics. |

[13] |

Coacervation (complex coacervation) |

Produces capsules with sizes of 1 μm to 1 mm. | |||||||

Encapsulates hydrophobic compounds. |

Simple and mild process. Suitable for the food industry. High encapsulation efficiency. Controlled release potential. |

Starch and starch derivatives High operational cost. |

GRAS is abundant, low in cost, non-allergenic, and biodegradable. Could produce gels with strong but flexible structure, transparent, colorless, flavorless, and odorless gel that is semi-permeable to water, carbon dioxide, and oxygen. Resistant to pancreatic enzymes. Pose prebiotic properties. Not suitable for mass production.Animal-based protein is commonly used. Only stable at a narrow pH, ionic strength, and temperature range. |

||||||||||

Exhibit high viscosity in solution. | Technique: extrusion, emulsion. Combination: alginate. |

||||||||||||

|

Emulsion |

Lactobacillus salivarius spp. salivarius CECT 4063 |

100 mL of sodium alginate (3%), 1 mL Tween 80 |

Apple matrix |

Encapsulated L. salivarius spp. Salivarius had higher survivability (3%) than those non-encapsulated (19%) after 30 days of storage. |

[10] |

Spray-drying |

Produces capsules with sizes of 5–150 μm. Encapsulateshydrophilic and hydrophobic compounds. |

Monodispersity. Fast, continuous process.L ow operation cost. Suitable for mass production. Produces dry beads with low bulk density, water activity, and high stability. |

Low cell viability. Produces beads with low uniformity.Biomaterials used have to be water-soluble. |

||||

Cellulose and cellulose derivatives |

Complex coacervation |

Bifidobacterium animalis subsp. lactis |

6% whey protein concentrate, 1% gum Arabic, 5% (] |

Abundant, low in cost, biodegradability, biocompatibility, tunable surface properties. Insoluble at pH ≤ 5 but soluble at pH ≥ 6, effective in delivering probiotics to the colon. [ |

Cannot form gel beads by extrusion technique. w/w) proanthocyanidin-rich cinnamon extract (bioactive compound) |

||||||||

Technique: emulsion, spray-drying. | Combination: alginate, protein. |

Sugar cane juice |

Co-encapsulation of compounds was effective in protecting the viability of B. animalis and the stability of proanthocyanidins during storage and allowing simultaneous delivery. |

[14] |

Freeze-drying |

Produces capsules with sizes of 1–1.5 mm. Encapsulates hydrophilic and hydrophobic/lipophilic compounds. |

Suitable for temperature-sensitive probiotics. | ||||||

|

Emulsion |

Dried end product is suitable for most food applications. |

Lactobacillus acidophilus PTCC1643, Bifidobacterium bifidum PTCC 1644 High operation cost. Not suitable for mass production. Cryoprotectants are needed. |

[ |

||||||||||

[ | ] | [ |

Spray chilling |

||||||||||

w | ) sodium alginate, 5 g/L Span 80 emulsifier | Produces capsules with sizes of 20–200 µm. Encapsulates hydrophobic compounds. |

Carrageenan (κ-carrageenan) Monodispersity. Fast, continuous, mild process. Low operation cost. Suitable for mass production.Promising in controlled release of probiotics. |

Low encapsulation efficiency. Rapid release of the encapsulated probiotics. Special storage conditions can be required. |

|||||||||

] | |||||||||||||

|

Maltodextrin |

Non-toxic, bland in taste, abundant, low in cost, good solubility, low viscosity even at high solid content. Excellent thermal stability. Pose (moderate) prebiotic properties. |

Low emulsifying capacity. |

Technique: spray-drying. Combination: gum Arabic, sodium caseinate. |

Grape juice |

The survivability of L. acidophilus and B. Bifidum in the encapsulated samples (8.67 and 8.27 log CFU/mL) was higher than free probiotics (7.57 and 7.53 log CFU/mL) after 60 days of storage at 4 °C. |

[15] |

|||||||

Pose thermosensitive and thermoreversible characteristics, the probiotic release can be controlled with temperature. |

Emulsion followed by coating |

Lactobacillus plantarum, Lactobacillus fermentum, Lactobacillus casei, Lysinibacillus sphaericus, Saccharomyces boulardii The gel beads produced are irregular in shape, brittle and weak, and their probiotic release rate is much slower than alginate beads. |

Emulsion: 20 mL of sodium alginate (2%), 0.1% Tween 80 Technique: extrusion, emulsion. Dissolves at 80–90 °C. Addition of probiotics at 40–50 °C. Gelation at room temperature. Combination: milk protein, alginate, locust bean gum (LBG), carboxymethyl cellulose. |

Coating: 0.4% chitosan in acidified distilled water |

Tomato and carrot juices |

Encapsulated probiotics had higher viability than free probiotics during storage of 5–6 weeks at 4 °C. Lys. sphaericus was observed to have higher viability and stability than other probiotics. |

[ |

Fluidized bed coating |

Produces capsules with sizes of 5–5000 μm. Encapsulateshydrophilic and hydrophobic compounds. |

Mild process.Low operation cost. Suitable for mass production. Can provide multi-coating layers. Suitable for temperature-sensitive probiotics. |

Slow process. Probiotics have to be pre-encapsulated and dried. |

||

|

Pectin |

Anionic character, abundant, non-toxic, water-soluble, biocompatibility, biodegradability, bioadhesiveness, antimicrobial, antiviral, good gelling, emulsifying, thickening and water binding properties, prebiotic effect. | [ |

Low in thermal stability, poor mechanical properties. High water solubility. High concentration of sucrose contents. |

4. Biomaterials Utilized for Probiotics Encapsulation

] | ||||||||||||||

Technique: spray-drying. | ||||||||||||||

Combination: a variety of carbohydrate-based biomaterials. | [ | |||||||||||||

|

Co-encapsulation (extrusion) |

Lactococcus lactis ABRIINW-N19 |

1.5, 2% alginate-0.5% Persian gum (hydrogels), 1, 1.5, 2% fructooligosaccharides (FOS; prebiotic), and 1, 1.5, 2% inulin (prebiotic) |

Orange juice | |||||||||||

All formulations used were able to retain the viability of | L. lactis | during 6 weeks of storage at 4 °C. Encapsulated | L. lactis | were only released after 2 h and remained stable for up to 12 h in colonic conditions. |

[17] |

Gums |

||||||||

Xanthan gum |

Vibrating nozzle method (evolved extrusion) Anionic character, non-toxic, biodegradable, biocompatible, excellent gelling properties, highly soluble in both cold and hot water. Excellent heat and acid stability. Resistant to gastrointestinal digestion and enzymatic decomposition. Could also act as a source prebiotic. |

High susceptibility to microbial contamination, unstable viscosity, and uncontrollable hydration rate. Gels produced solely using xanthan gum are relatively weak. |

Technique: spray and freeze-drying. Combination: alginate, chitosan, gellan, and β-cyclodextrin. |

[40] |

||||||||||

2% sodium alginate |

Pineapple, raspberry, and orange juices |

After 28 days of storage at 4 °C, some microcapsules were observed as broken in pineapple juice, but the viability was 100% (2.3 × 107 CFU/g spheres). 91% viability (5.5 × 106 CFU/g spheres) was observed in orange juice. Raspberry juice was not a suitable medium for L. casei. |

[18] |

Gellan gum |

Anionic character, non-toxic, biocompatible, biodegradable, water-soluble, and low in cost. High resistance against heat, acidic environments, and enzymatic degradation. Swell at high pH. |

High gel-setting temperatures (80–90 °C) cause heat injuries to probiotics. |

||||||||

|

Co-encapsulation (spray-drying) | Technique: spray-drying. | Combination: gelatin, sodium caseinate, and alginate. |

Lactobacillus reuteri |

|||||||||||

60 g maltodextrin, 0−2% gelatin | Passion fruit juice powder |

The use of gelatin in combination with maltodextrin was more efficient in maintaining the cellular viability and retention of phenolic compounds than maltodextrin alone. |

[19] |

Gum Arabic | ||||||||||

|

Spray-drying Anionic character, acid stability, highly water soluble, low in viscosity. Exhibit surface activity, foaming, and emulsifying abilities. Could prevent complete dehydration of probiotics during the drying process and storage. |

Lactobacillus plantarum Restricted availability and high cost. Show only partial protection against oxygen. |

0.5% (w/w) magnesium carbonate, 12% (w/w) maltodextrin Technique: spray-drying. Combination: maltodextrin, gelatin, whey protein isolates. |

Sohiong (Prunus nepalensis L.) juice powder |

|||||||||||

The quality of probiotic Sohiong juice powder and viability of | L. plantarum | (6.12 log CFU/g) could be maintained for 36 days without refrigeration (25 °C and 50% relative humidity). | [20] |

Animal-based proteins |

Gelatin |

Amphoteric character, could form complexes with anionic polymers. Could produce beads with strong structure and impermeable to oxygen. |

||||||||

|

Fluidized bed drying | High solubility. |

Bacillus coagulans Technique: extrusion, complex coacervation, spray chilling, spray-drying, lyophilization. Combination: alginate, pectin. |

Mixture of 0.0125 g/mL hydroxyethyl cellulose and 1.17 µL/mL polyethylene glycol |

|||||||||||

Dried apple snack | Encapsulated | Bacillus coag-ulans in dried apple snacks had high viability (>8 log CFU/portion) after 90 days of storage at 25 °C. |

[11] |

Whey protein |

Amphoteric character, highly nutritious, high resistance and stability against pepsin digestion, great gelation properties, thermal stability, hydration, and emulsification properties. |

The gel beads or matrices produced are weak. |

Technique: extrusion. Combination: gum Arabic, pectin, maltodextrin. |

|||||||

|

Extrusion |

Lactobacillus plantarum |

Mixtures (1:2, 1:4, 1:8, 1:12) of 4% (w/v) sodium alginate and 20% (w/v) soy protein isolate |

Mango juice |

Homogenous aqueous solutions of alginate and soy protein isolate (1:8) increased the thermal resistance of L. plantarum against pasteurization process. The viability of L. plantarum remained high after the pasteurization process (8.11 log CFU/mL; reduced 0.99 log CFU/mL). |

[21] |

Milk protein (casein) |

Amphiphilic character, abundant, low in cost, possess excellent gelling and emulsifying properties, self-assembling properties, biocompatibility, biodegradability, produce gel beads with varying sizes (range from 1 to 1000 µm), higher density and better protection, high resistance to thermal denaturation (sodium caseinate). |

Lactobacillus plantarum 299v Immunogenicity and allergenicity. |

First layer: 1% (w/v) carboxymethyl cellulose (CMC) and 50% w/w (based on CMC weight) glycerol; Second layer: 5% (w/v) zein proteinTechnique: extrusion, emulsification, spray-drying, enzyme-induced gelation. Combination: a variety of carbohydrate-based biomaterials. |

Apple slices |

||||

|

Layer-by-layer (Coating) |

The viability of CMC-zein protein-coated | L. plantarum | 299v was higher than CMC-coated L. plantarum 299v in apple slices under simulated gastrointestinal conditions (120 min digestion; CMC-zein protein-coated: 1.00 log CFU/g reduction, CMC-coated: 2.18 log CFU/g reduction). |

[12] |

Plant-based proteins |

|||||||||

Zein protein |

Complex coacervation (associated with enzymatic crosslinking) Amphiphilic character, biocompatible, biodegradable, water-insoluble, high resistance against gastric juice. |

Highly unstable, aggregate in aqueous solutions. |

Lactobacillus acidophilus LA-02 Technique: electro-spinning, electro-spraying, spray-drying. Combination: sodium caseinate, alginate, pectin. |

Complex co-acervation: 2.5% gelatin, 2.5% gum Arabic; Crosslinking: 2.5, 5.0 U/g transglutaminase |

Apple and orange juices |

|||||||||

Encapsulated | L. acidophilus | LA-02 incorporated in fruit juices was able to survive throughout the storage period of 63 days (4 °C). | [22] |

Soy protein |

High nutritional value, less allergenic, surface active, good emulsifying, absorbing, film forming properties, high resistance against gastric juice. |

|||||||||

|

Freeze-drying, spray-drying |

Enterococcus faecalis (K13) |

Heat-induced gel formation. |

Gum Arabic and maltodextrin Technique: extrusion, spray-drying, coacervation. Combination: carrageenan, pectin. |

Carrot juice powder |

Heat injuries to the probiotics are lower in the freeze-drying technique compared to spray-drying. After being stored for 1 month, the viability of freeze-dried E. faecalis89,90] |

|||||||||

remained high (6–7 log CFU/g). | [ | ] |

Lipids |

|||||||||||

Natural waxes, vegetable oils, diglycerides, monoglycerides, fatty acids, resins |

Spray-drying Low in polarity, excellent water barrier properties, thermally stable, and could encapsulate hydrophilic substances. |

Lactobacillus casei Shirota, Lactobacillus casei Immunitas, and Lactobacillus acidophilus Johnsonii Weak mechanical properties, chemically unstable, might negatively affect the sensory characteristics of food products due to lipid oxidation. |

Technique: spray chilling, spray coating.Have melting points ranging from 50–85 °C. Combination: polysaccharides or proteins. |

5. Application of Probiotics Encapsulation in Non-Dairy-Based Food and Beverage Products

Maltodextrin and pectin at weight ratio of 10:1 | ||||||

Orange juice powder | ||||||

The combination of pectin and maltodextrins effectively protected the probiotics during the spray-drying process and storage (4 °C) | ||||||

[ | ||||||

] | ||||||

|

Freeze-drying |

Lactobacillus acidophilus, Lactobacillus casei |

Whey protein isolate, fructooligosaccharides, and combination of whey protein isolate, fructooligosaccharides (1:1) |

Banana powder |

L. acidophilus and L. casei encapsulated with the combination of whey protein isolate and fructooligosaccharides had higher survivability after being stored for 30 days at 4 °C and more resistant to the simulated gastric fluid intestinal fluid than free probiotics. |

[25] |

|

|

Fluidized bed drying |

Lactobacillus plantarum TISTR 2075 |

3% (w/w) gelatin and 5% (w/w) of monosodium glutamate, maltodextrin, inulin, and fructooligosaccharide |

Carrot tablet |

Encapsulated L. plantarum TISTR 2075 in carrot tablet (survivability: 77.68–87.30%) had higher tolerance against heat digestion treatments than free cells (39.52%). |

[26] |

|

|

Other beverages |

Spray-drying |

Lactobacillus rhamnosus GG (LGG) |

Mixtures (1:1.6 (w/w)) of 7.5% (w/v) whey protein isolate and 20% (w/v) modified huauzontle’s starch (acid hydrolysis-extrusion), supplemented with ascorbic acid |

Green tea beverage |

The viability of LGG remained above the recommended 7 log CFU/mL after 5 weeks of storage at 4 °C. |

[28] |

|

Co-encapsulation (extrusion) |

Lactobacillus acidophilus TISTR 2365 |

Alginate, egg (0, 0.8, 1, and 3%, w/v), and fruiting body of bamboo mushroom (prebiotic) |

Sweet fermented rice (Khoa-Mak) sap beverage |

All formulations used were able to provide high encapsulation yields (95.72−98.86%) and high viability of L. acidophilus (>8 log CFU/g) in Khoa-Mak sap beverages for 35 days of storage at 4 °C. Encapsulation with involvement of 3% egg of bamboo mushroom increased the survival of L. acidophilus the most. |

[27] |

|

|

Co-encapsulation (extrusion) |

Lactobacillus acidophilus NCFM (L-NCFM) |

Co-extrusion: 0–2% (w/v) LBG, 0–5% (w/v) mannitol (prebiotic) Coating: sodium alginate |

Mulberry tea |

L-NCFM encapsulated with LBG and mannitol (0.5% (w/v) and 3% (w/v), respectively) showed microencapsulation efficiency and viability of 96.81% and 8.92 log CFU/mL, respectively. Among other samples, L-NCFM microencapsulated with mannitol showed the highest survivability (78.89%) and viable count (6.80 log CFU/mL) after 4 weeks of storage at 4 and 25 °C. |

[29] |

|

|

Bakery products |

Double-layered microencapsulation, combination of spray chilling and spray-drying |

Saccharomyces boulardii, Lactobacillus acidophilus, Bifidobacterium bifidum |

Spray chilling: 5% (v/w) blend of gum Arabic and β-cyclodextrin solution (9:1 (w/w), 20 g in total), 1% lecithin Spray-drying: 5% (v/w) blend of gum Arabic and β-cyclodextrin solution, 20 g hydrogenated palm oil, 2% Tween 80 emulsifier |

Cake |

The survivability of probiotics during the cake baking process was improved by double-layered microencapsulation. |

[31] |

|

Fluidized bed drying |

Lactobacillus sporogenes |

First layer: 10 g microcrystalline cellulose powder and alginate or xanthan gum Second layer: gellan or chitosan |

Bread |

Encapsulated L. sporogenes in alginate (1%) capsule tolerated the simulated gastric acid condition the best. The incorporation of chitosan (0.5%) as an outer layer improved the heat tolerance of L. sporogenes. Encapsulated L. sporogenes with an outer layer coated with 1.5% gellan showed the highest survivability 24 h after baking. |

[32] |

|

|

Emulsion |

Lactobacillus acidophilus ATCC 4356 |

1. Alginate 2%; 2. Alginate 2% + maltodextrin 1%; 3. Alginate 2% + xanthan gum 0.1%; 4. Alginate 2% + maltodextrin 1% + 0.1% xanthan gum |

Bread |

Among the encapsulation agents, probiotics encapsulated using the combination of maltodextrin, xanthan gum, and alginate (4) had the highest survivability under storage (7.7 log CFU/bread) and simulated gastrointestinal conditions. |

[33] |

|

|

Sauce |

Co-encapsulation (extrusion) |

Lactobacillus casei Lc-01, Lactobacillus acidophilus La5 |

4% (w/v) sodium alginate and 2% alginate mixture in distilled watercontaining 2% high amylose maize starch (prebiotic), 0.2% Tween 80 |

Mayonnaise |

The viability of L. casei and L. acidophilus encapsulated with high amylose maize starch (7.204 and 8.45 log CFU/mL, respectively) was higher than free probiotics (6.23 and 6.039 log CFU/mL, respectively) and those without high amylose maize starch (7.1 and 7.94 log CFU/mL, respectively) after 91 days of storage at 4°C. |

[35] |

|

Others |

Extrusion followed by freeze-drying |

Lactobacillus casei (L. casei 431) |

3% (w/v) quince seed gum, sodium alginate, quince seed gum-sodium alginate |

Powdered functional drink |

Quince seed gum-alginate microcapsules provided encapsulation efficiency of 95.20% and increased the survival rate of L. casei to 87.56%. The powdered functional drink was shelf stable for 2 months. |

[37] |

|

Spray chilling |

Lactobacillus acidophilus and Bifidobacterium animalis subsp. lactis |

Vegetable fat (Tri-HS-48) |

Savory cereal bars |

The viabilities of spray-chilled probiotics were higher than freeze-dried and free probiotics in the savory cereal bars after being stored for 90 days at 4 °C. |

[34] |

|

|

Co-encapsulation (extrusion) |

Lactobacillus reuteri |

2% (w/v) sodium alginate, 5 mL of inulin and lecithin solution (0, 0.5, and 1%) |

Chewing gum |

After storing for 21 days with encapsulation, L. reuteri remained viable. The viability of the probiotic increased with the concentration of inulin and lecithin. |

[36] |