2. Active Packaging Systems with Essential Oils Addition

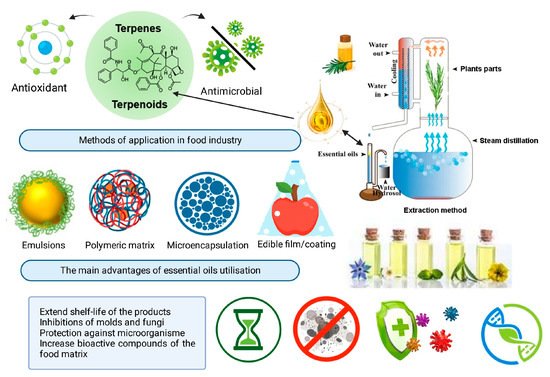

Food packaging protects food from environmental factors such as UV light, oxygen, water vapor, pressure, and heat and improves shelf-life and food safety. Active packaging interacts with the product and, although it may have some synthetic compounds, the addition of EOs and biodegradable materials has made industrial producers determined to use it as an environmental-friendly packing method, with increased consumer acceptability

[27][32]. Delivery systems may be particulate (lipid-based—emulsions, emulgels, nanostructured lipid carriers, and solid-lipid nanoparticles; self-assembled—liposomes, phytosomes, ethosomes, and niosomes; polymer-based—micro/nanoparticles, micro/nano-capsules, and nanofibers), macroscopic carriers (film and sponge), or molecular inclusion complexes (cyclodextrins and nontoxic cyclic oligosaccharides)

[28][33]. The EOs have a series of structural disadvantages that limit their industrial use: volatility (influenced by heat, air, illumination, or radiation); oxidizability, which may lead to compounds of degradation that produce consumer harm; an intense aroma that can cover or modify the original food smell; reduced solubility (they are hydrophobic and incorporation in water-based matrices is challenging); possible interaction with nutritional constituents from food

[29][34].

Nanotechnologies use liposome, nanoemulsion, or solid-lipid nanoparticle-based strategies to enhance water solubility and bioavailability, protect the EO, mask the unpleasant odor or taste, and assure a controlled release of active ingredients. Nano-encapsulation of EOs has a lot of benefits, but toxicological aspects of most of the nanocarriers are not fully explored and, before commercial application, consumer safety should be checked

[30][35]. Incorporation in colloidal delivery systems (emulsion-based, surfactant-based, or biopolymer-based) improved the antimicrobial activity of EO in the food industry by increasing the aqueous solubility and mass transfer of EO

[31][36].

Citrus spp. essential oils incorporated in edible films and coatings, microencapsulated biodegradable polymers, and nano-emulsion coatings were assessed for their potential in active packing with good effects as antimicrobials and antifungals and good environmental impact (by-products can be used, reducing food waste)

[32][37], but with limited use because of their interaction with food matrices, concerns about the optimum dose, its impact upon consumer’s sensorial perception, and its potential as an allergen

[33][34][38,39].

In active packaging design, it is very important to choose the appropriate coating or carrier material as a delivery system for EOs considering that the polymer needs to protect the EO, assure its controlled release, and be soluble in water, biocompatible, biodegradable, and low-cost

[35][40]. In essential oils–antibacterial packaging (EOs–AP) systems, active ingredients diffuse through micropores of the film and are released at the food surface, assuring antimicrobial protection. Several factors affect the antimicrobial efficiency: solubility of the antibacterial agent into food, the migration rate between the EOs–AP system and food, and microbial growth kinetics that must be considered when designing the AP, so the sustained release assures a minimum inhibitory concentration (MIC) and the interaction between EO constituents and AP formulation, so the physical properties of the packaging material are not affected

[36][41]. Polysaccharides are widely used because of their advantages: low cost, safety, accessibility, biodegradability, and biocompatibility.

3. Applicability of Essential Oils in Food Products

Considering that the EOs are perceived as an alternative eco-friendly food preservative, the interest in EOs application in the food industry and packaging has grown in recent years. The major sources relevant for industrial use are from

Alliaceae,

Apiaceae,

Asteraceae (

Compositae),

Lamiaceae (Labiatae),

Myrtaceae,

Poaceae,

Cupressaceae,

Lauraceae,

Pinaceae,

Zingiberaceae, and

Rutaceae plant families and the extraction can be made from different part of plants: flowers, leaves, fruits, seeds, grasses, roots, rhizomes, wood, bark, gum, tree blossoms, bulbs, and dried flower buds

[37][51]. EOs play significant roles in the food sector with a wide range of applications, mainly to prolong shelf-life and prevent oxidation. For this purpose, they are valorized by the addition to food products, either by direct mixing or in edible coatings and active packaging

[27][32]. Several EOs have GRAS status (Generally Recognized as Safe), including basil, cinnamon, clove, coriander, ginger, lavender, menthol, nutmeg, oregano, rose, sage, and thyme EOs. The reported EO constituent comprises carvacrol, carvone, citral, cinnamaldehyde, eugenol, limonene, linalool, thymol, and vanillin, with no antagonistic human health effects

[9][11]. In the study conducted by Macchia et al., 2022, the efficacy of pure EOs of eucalyptus, basil, cloves, thyme, pine tree, and tea tree was assessed in situ and compared to a conventional biocide based on quaternary ammonium salts. The tests revealed positive results concerning the synergy of the essential oils, showing a stronger biocide efficacy

[38][52].

Some properties of EOs, such as the low-level water solubility, the high volatility, and their powerful odor, can curb their use as food preservatives in the food industry

[39][40][87,88]. The antioxidant activity of biofilms depends on the antioxidant action of the EOs and the film’s oxygen permeability. Adding EOs into edible films can boost their antimicrobial capability, and the edible film’s efficacy against microbial growth will vary based on the oil’s chemical characteristics and microorganism type

[41][89]. Incorporating EOs and plant extracts into edible natural biopolymers represents one of the newest research trends of the food packaging industry

[42][43][90,91]. Their incorporation into packaging materials and coated films and straight into the food matrix as emulsions, nanoemulsions, and coatings are part of newer applications

[44][92].

Elevated contents of EOs can result in the transmission of off-flavors to the end product. Moreover, as EOs are lipophilic, it is difficult to disperse them in water-based washing solutions. Given this, an alternative was developed, namely their incorporation in nanoemulsions

[45][93]. Plant EOs are the organic and natural option to other preservatives with significant antimicrobial, antifungal, and antiviral properties when used to obtain innovative and healthy packaging. Consumers want to be assured that the packaging has the proper attributes for ensuring food quality and freshness and preventing microbial contamination.

3.1. Fruits and Vegetables

Fruits and vegetables are acknowledged increasingly for their health benefits, mainly due to their nutrients and fiber content, while being characterized by a short shelf-life due to weight loss and decay, caused mainly by fungal activity.

Botrytis cinerea appears very frequently in fruits during the postharvest period. Strategies enhancing the shelf life of fruits and vegetables cover the combined application of EOs into biofilms or MAP (modified atmosphere packaging)

[46][100]. To benefit from fresh fruits and vegetables in a time-convenient manner, the food industry has launched the concept of “fresh-cut food”, which implies that fruits or vegetables were physically altered but remained fresh. In addition to the health benefits, fresh-cut food is appealing (fresh-like appearance, taste, and flavor) and ready-to-eat

[47][101]. Among the advantages of this segment of products, there is the fact that they require less time to be prepared and consumed. These products are very time-convenient for customers as they are already cleaned and trimmed, reducing the preparation time. While fresh-cut fruits and vegetables (FCFV) hold some benefits (convenient, portable, and easy to eat) over the whole product, the industry and the processes followed to preserve their freshness and quality (free of pathogenic microorganisms) face considerable challenges

[48][102]. While the health benefits of fresh-cut products have persuaded consumers to increase their intake, studies have revealed that the number of illnesses caused by

Salmonella enterica,

Escherichia coli,

Shigella spp.,

Campylobacter spp.,

Listeria monocytogenes,

Staphylococcus aureus,

Yersinia spp., and

Bacillus cereus has also increased

[49][103].

There is an increasing trend in the fresh fruits and vegetable packaging area to substitute the traditional petrochemical-based packaging films with environmentally friendly and biodegradable materials, such as edible coatings. Most used compounds for obtaining edible coatings comprise chitosan, starch, cellulose, alginate, polyvinyl alcohol (PVA), carrageenan, zein, gluten, whey, carnauba, beeswax, and fatty acids

[50][104]. Another essential benefit of using edible coatings is reducing synthetic waste, given that edible coatings are made up of biodegradable material. For example, biodegradable green packaging can be obtained from tropical plants (neem, nutmeg, turmeric, cinnamon, and lemongrass) and some of their by-products (seeds, husks, kernels, and peels) with beneficial bioactive properties

[51][105]. In fresh or fresh-cut products such as fruits and vegetables, several parameters are evaluated to assess the EO coating efficiency: chemical properties (total soluble solids, vitamin C content, and titratable acidity), weight loss and firmness, respiration properties, microbiological properties, antioxidant properties (total phenolic content and DPPH radical scavenging activity), and impact upon sensorial characteristics (flavor, taste, visual appearance, and color)

[52][106].

3.2. Cereal-Based Products

In agriculture, crops are affected by fungal infections, and the antifungal effects of some EOs are already valorized in industrial settings: rosemary, clove, thyme, sesame, and garlic are just some of the natural sources of EOs included in commercial products for crop protection

[4][6]. Lee et al., 2017, used garlic, onion, ginger, fennel, and black pepper EOs on multilayered rice films made from rice flour and LDPE (low-density polyethylene) as a potential insecticide against

Plodia interpunctella larvae infestation on stored cereals. Garlic and onion EO had the best anti-insect effect, and allyl disulfide, extracted from garlic, was further used for brown rice packaging with good sensory evaluation

[53][130]. EOs loaded on lipid nanocarriers (nanoemulsions, solid-lipid nanoparticles, and liposomes) inhibit food pathogens by changes in the cellular morphology and functionality (ribosomes and cytoplasm), interruption of the electron transport chain, and inhibition of bacterial toxin release, and they can be used for preserving grains and flours

[54][131].

Oregano majorana EO encapsulated in a chitosan-based nanoemulsion inhibited lipid peroxidation and AFB1 (aflatoxin B1) production in maize without affecting the sensorial properties, being a promising antifungal agent for crops

[55][129]. Cinnamon and clove oils were added to a pectin-based film and applied to bread to reduce spoilage and increase shelf life. Cinnamaldehyde from cinnamon EO and eugenol from clove EO offered good antifungal protection against

Penicillium and

Aspergillus, increasing bread shelf life by 4 days

[56][132]. Das et al., 2019, concluded that

Coriandrum sativum essential oil (CSEO) and encapsulated CSEO nanoemulsion have a strong potency in the suppression of in situ Aflatoxin B1 production in stored rice seeds than a fungal infestation

[57][71].

3.3. Dairy Products

In cheese, the main concern is microbial spoilage due to fungi and bacteria. EO incorporation in cheese active packaging has benefits such as increasing the shelf-life of cheese products, but a series of limitations occur: cheese proteins interact with phenolic compounds from EO; fats surround hydrophobic constituents of EO, which may interfere with their antimicrobial activity; the physical structure of cheese may limit EO availability to microbial cells; the intense aroma of EO may interact with the cheese taste

[58][135]. Oregano or garlic EO was added to a whey protein (WPI) edible film and applied to Kasar sliced cheese to provide microbial reduction during cheese storage. Garlic EO-WPI was less effective than oregano EO-WPI on microbial protection, assuring 15 days of shelf life and contributing to reducing food waste

[59][136].

3.4. Eggs

Pires et al., 2020, covered eggs with a series of rice protein coatings enriched with 1% tea tree (

Melaleuca alternifolia), copaiba (

Copaifera langsdorffii), or thyme (

Thymus vulgaris) EO to increase the shelf life of eggs. After six weeks of storage, covered eggs had better internal properties than uncovered eggs, in terms of weight loss, albumen pH, and yolk index, probably due to the hydrophobicity of the rice coating and the lipophilic characteristics of EO that provide a barrier to mass and oxygen loss

[60][140]. Basil EO (BEO) and beeswax were incorporated in a chitosan-based emulsion and used for egg coating. The proportion of beeswax and BEO that assured the best coating properties by increasing the consistency coefficient of the emulsion, decreasing the droplet size, improving the stability by forming a multi-layer adsorption at the oil–water interface, and having bacteriostatic properties was, respectively, 0.5% and 1%. Shelf life was extended until day 35, with no height loss (eggs remaining in the AA category) and a better yolk index than the control group

[61][141].

3.5. Meat and Meat Products

Rosemary EO was incorporated in a bio-nanocomposite based on chitosan and montmorillonite (MMT) to develop an active packaging for fresh poultry meat. It increased the storage time up to 15 days by inhibiting lipid peroxidation and discoloration and assuring microbiological safety, but MMT interacted with the plastic wrap used for primary packing. In an industrial setting, either the fresh poultry meat producer chooses another way of primary packing, or the active packaging should be consisted of chitosan films enriched with rosemary EO, without MMT

[62][142].

3.6. Seafood

One of the biggest challenges for the seafood industry is the short shelf life of fresh marine food products due to microbial contamination and biochemical spoilage caused by lipid/protein oxidation, a problem of great economic concern. Seafood products are highly perishable due to a large amount of polyunsaturated fatty acids and the strong activity of endogenous enzymes

[63][64][147,148]. Fresh marine food products may be subjected to microbial contamination or biochemical spoilage during handling, processing, and storage. Therefore, the need for improving the quality and increasing the shelf life of fresh seafood products is currently increasing

[65][149]. Therefore, the need for improvement in the quality and increased shelf life of fresh seafood products is currently increasing. The need of increasing the shelf life of fresh fish and other seafood products without compromising on the quality and safety has led to an increased number of studies focusing on the application of natural antioxidants to retard lipid and protein oxidation

[66][150]. Modern consumers prefer the use of antioxidants from natural sources due to the lower risk of cardiovascular diseases and cancer

[23][25]. Most of the natural antioxidants used for seafood preservation belong to the group of phenolic compounds naturally found in plants such as phenolic acids, anthocyanins, and flavonoids. As these compounds originally protect plants from oxidative stress, they can successfully be used as a source of natural antioxidants for the preservation of marine food products. The use of natural antioxidants in the food industry including seafood processing is often performed by the application of EOs

[67][151].