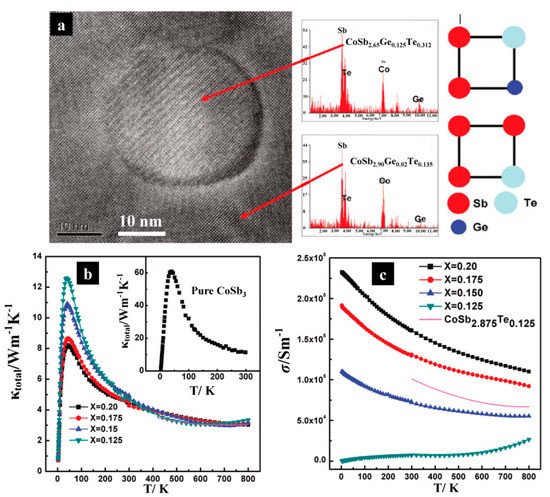

material prepared under different preparation conditions. The inset shows the temperature dependence of lattice thermal conductivity

.

The high-temperature and high-pressure (HTHP) method is one of the effective methods to prepare high-performance skutterudites

[52][53][54][55][56][57][53,54,55,56,57,58]. Generally, the experimental raw materials are weighed in a fixed proportion, fully ground under Ar atmosphere (to prevent the material from being oxidized), and later placed in a vessel for sintering at a certain temperature and pressure. This method is convenient for controlling the external temperature and pressure conditions, while it can greatly reduce the experimental time and has important practical significance in large-scale production. Han et al.

[54][55] prepared Te-doped filled skutterudites under different pressure conditions using a high temperature and high-pressure method and investigated the synergistic relationship between Te doping and pressure regulation. It was found that Te doping could effectively optimize the electrical transport properties of the samples, while some defects appeared in the crystals at high pressure. This further reduced the lattice thermal conductivity of the materials, and the lattice thermal conductivity of the In

0.05Ba

0.15Co

4Sb

11.5Te

0.5 samples prepared at 2.0 GPa was only 1.02 W·m

−1·K

−1 with a maximum

ZT value of 1.23.

3.3. Pulsed Laser Deposition

Pulsed laser deposition (PLD), also known as pulsed laser ablation (PLA), is the use of laser light to bombard a target material so that the bombarded plasma is deposited on a specific substrate to form a thin film. At present, with the continuous development of laser technology, pulsed laser technology is gradually being applied in many material preparation fields

[58][59]. In recent years, pulsed laser deposition has also been applied to the preparation of skutterudite TE films

[59][60][61][60,61,62]. This technique has the advantages of a relatively short preparation time, homogeneous film material composition, and no special requirements for the target type. Sarath et al.

[59][60] prepared In and Yb doped CoSb

3 thin films using pulsed laser deposition. During the preparation, the process window for the growth of single-phase skutterudite thin films was very narrow. It was found that the information and the increase in surface roughness of CoSb

3 after heating in an argon environment may lead to irreversible changes in film resistivity and Seebeck coefficient at 207 °C. The highest power factor of 0.68 W·m

−1·K

−1 could be obtained for this film at 427 °C, which is five times lower compared to most of the blocks, probably due to the high resistivity of the film material.

3.4. Magnetron Sputtering

Magnetron sputtering is one of the types of physical vapor deposition (PVD). With the advantages of magnetron sputtering coming to the fore, it has gradually gained wide application

[62][63]. The specific principle is that when the accelerated electrons hit the argon atoms, the resulting argon ions then collide with the target material, causing the bombarded target atoms to be deposited on the substrate to form a thin film. This technique has the characteristics of fast low temperature, large deposition rate, and can be made into a large area of thin film. In recent years, this technique has also been applied to the preparation of skutterudite TE films

[63][64][65][64,65,66]. Fan et al.

[63][64] used magnetron sputtering to grow Ag-doped CoSb

3 films directly on heated substrates. It was found that the doped films had a single-phase CoSb

3 crystal structure and good crystallinity, and the CoSb

3 films with high electrical transport properties could be obtained with the appropriate amount of doping. The films had a maximum power factor of 2.97 × 10

−4 W·m

−1·K

−2 at 0.3% Ag doping.

3.5. Molecular Beam Epitaxy (MBE)

MBE is a novel method for the epitaxial preparation of thin film materials and has also been used in recent years for the preparation of skutterudite TE thin film materials

[66][67][68][69][70][67,68,69,70,71]. MBE is a novel process for coating on substrates under ultra-high vacuum. The advantages of this preparation method are: (1) the thickness of the film can be precisely controlled at a slower growth rate; (2) the preparation method is a physical process without considering intermediate chemical processes, which can interrupt the progress of the experiment at any time; and (3) the substrate temperature of this method does not need to be too high, which reduces various adverse effects caused by thermal expansion, etc. Daniel et al.

[68][69] deposited CoSb

3 thin films with a thickness of 30 nm at different substrate temperatures using the MBE method. It was found that the deposition method and the temperature of the substrate used for the deposition process had a significant effect on the grain size of the CoSb

3 films, and the higher the temperature, the smaller the grain size. After deposition at room temperature, annealing is required to crystallize them, and they can crystallize into phases quickly when deposited at high temperatures. The annealed film has a very smooth surface, less roughness, and possesses a larger single-phase component. In addition, the smaller grain size of the films prepared at higher substrate temperatures allows for lower thermal conductivity.

3.6. Self-Spreading High-Temperature Synthetic (SHS)

The self-spreading high-temperature synthetic process is also called combustion synthesis technology (SHS)

[71][72][73][72,73,74]. This technology uses external energy to initiate chemical reactions. Then, the exothermic reaction is used to initiate new chemical reactions. Thus, the chemical reaction will spread to the whole reactor. Finally, the target product can be obtained. Su et al.

[74][75] proposed for the first time the use of SHS for the rapid preparation of TE materials.

This Aarticle also reported a high-performance Cu

2Se TE material

is also reported. Because this technology has the characteristics of high purity of products, low energy consumption, simple equipment and short reaction time, TE researchers have rapidly prepared high-performance TE materials of different systems through SHS

[27][75][76][77][27,76,77,78]. Liang et al.

[27] applied SHS to the synthesis of CoSb

3 TE materials for the first time. In this experiment, the single-phase CoSb

3 material was quickly synthesized by igniting the powder of Co and Sb using the characteristics of heat released by chemical reaction. Then, CoSb

3−xTe

x bulk materials were prepared by plasma-activated sintering (PAS). The bulk materials prepared by SHS-PAS have rich nanostructures. Combined with Te-doping to control the carrier concentration of the material, the electrical conductivity of the material is improved. As a result, the maximum

ZT value of this sample at 547 °C is 0.98, which is the CoSb

2.85Te

0.15 sample prepared by SHS-PAS.

3.7. Microwave Sintering

At present, 300~3 × 10

5 MHz is generally defined as the microwave frequency band. Its wavelength is 1~1 × 10

3 mm. In practice, the microwave frequency band used in microwave sintering is 2.45 × 10

3 MHz. Because microwaves can be absorbed by materials, it changes from electromagnetic energy to thermal energy in the material, which makes the material temperature rise rapidly and realizes the purpose of sintering. Compared with traditional sintering, microwave sintering has the characteristics of short sintering time, selective sintering and energy saving. Thus, the sintering process has also been used in the preparation of TE materials in recent years

[78][79][80][81][82][83][79,80,81,82,83,84]. Biswas et al.

[78][79] used a microwave synthesis device to synthesize In

0.2Co

4Sb

12 skutterudite powder in a short time (2 min), which is much shorter than the traditional preparation method (3 days). After sintering, the

ZT value of the powder sample synthesized by microwave is equivalent to that of the bulk sample obtained by the traditional preparation method.

3.8. High Pressure Torsion (HPT)

Severe plastic deformation (SPD) of materials can be formed via high-pressure torsion (HPT). The ultra-fine grains in the sub-micrometer or nanometer range can be obtained by SPD via HPT

[84][85]. At the same time, a large number of dislocations will be produced in the material. Due to the huge changes in the grain size and dislocation density of the materials, these changes will significantly improve the performance of the TE materials

[85][86]. It enables the production of samples in large quantities (50 g) by this advanced preparation technology, and is therefore usable for industrial production

[86][87][88][87,88,89]. A high

ZT value of p- and n-type skutterudites can be obtained through this advanced preparation technology

[86][87][87,88].

4. Conclusions

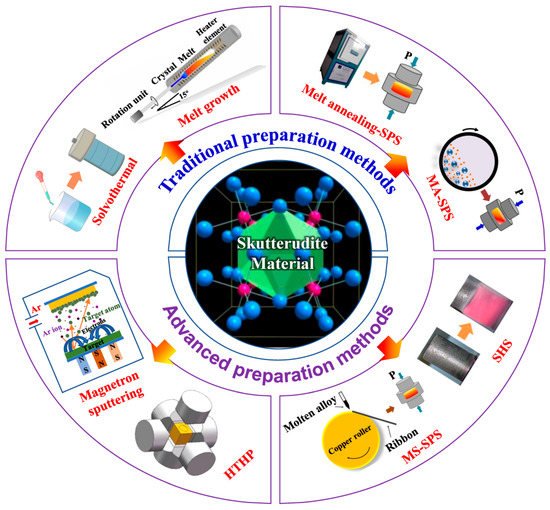

Skutterudite is a kind of TE material with excellent performance in the middle temperature region, which is expected to have a good application and development prospects in the field of power generation. Due to the special icosahedral cage structure, there are many ways to improve the

ZT value of skutterudite material. In order to obtain skutterudite with excellent properties, it is very important to select appropriate preparation methods

. This review systematically summarized some traditional and advanced preparation methods of skutterudites in recent years, and the principles of these preparation methods were briefly introduced. The traditional preparation methods of TE materials (such as the solid-state reaction method) are time-consuming and use large amounts of energy, but the prepared materials have high density, are of uniform composition, and have good mechanical properties and stable TE properties. The new preparation method has a shorter preparation time, lower energy consumption and higher properties. The rapidly prepared TE materials usually have different types of defect structures (such as dislocation, pores, superlattice and nano-grain boundaries). These defects help to scatter multi-scale phonons and significantly reduce the thermal conductivity of the material. Therefore, TE materials can have high TE properties. The approach is relatively poor in terms of densification and mechanical properties compared with traditional preparation methods. Therefore, there are still some problems in the preparation process of TE materials, which need to be further studied.