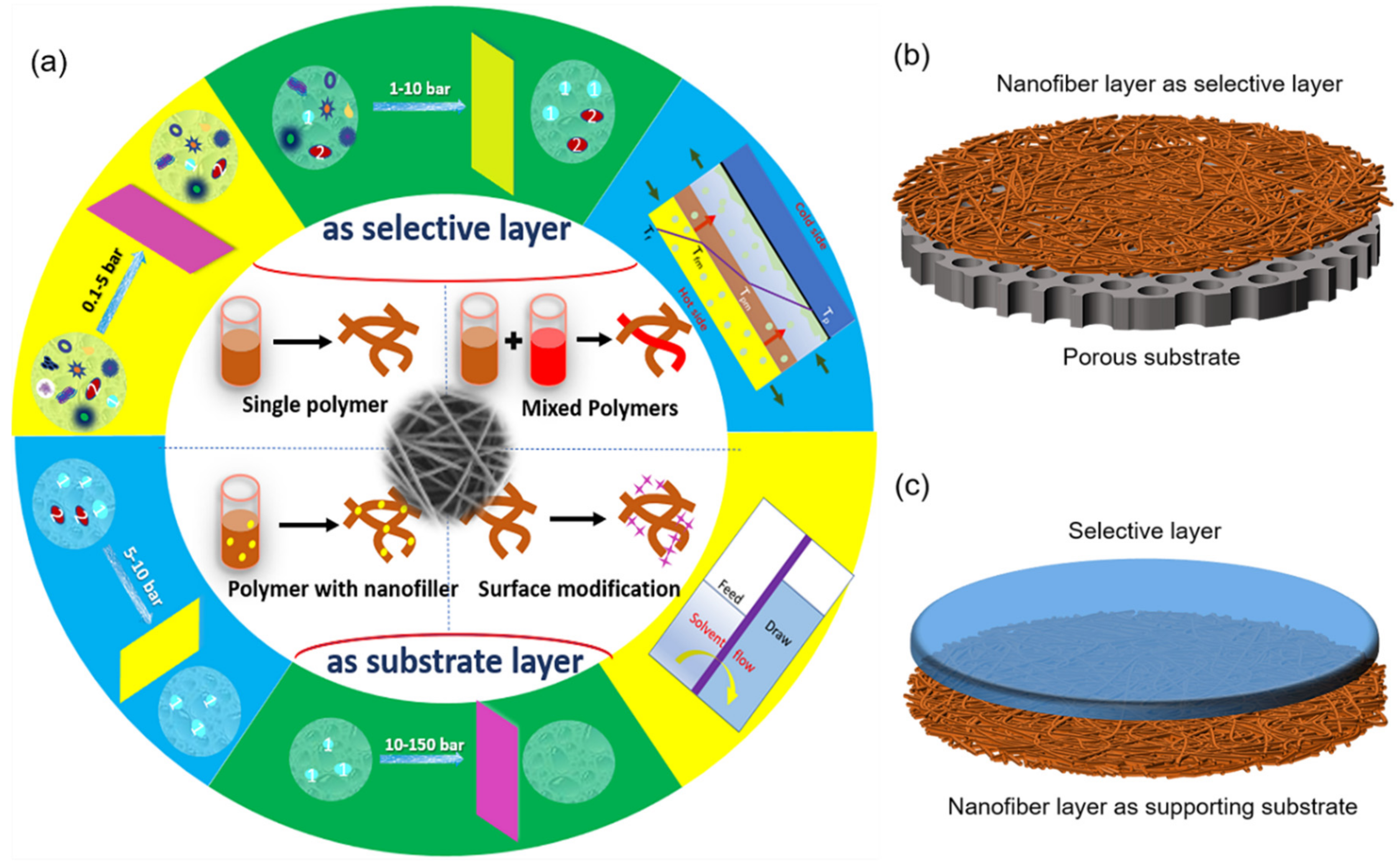

Electrospun nanofiber-based membranes (ENMs), benefitting from characteristics such as a higher specific surface area, higher porosity, lower thickness, and possession of attracted broad attention, has allowed it to evolve into a promising candidate rapidly. According to the roles of electrospun nanofiber layers, NMs can be divided into two categories: (i) nanofiber layer serving as a selective layer, (ii) nanofiber layer serving as supporting substrate.

- electrospinning

- electrospun nanofiber-based membranes (ENMs)

- nanofiber layer

- membrane fabrication

- water treatment

1. Introduction

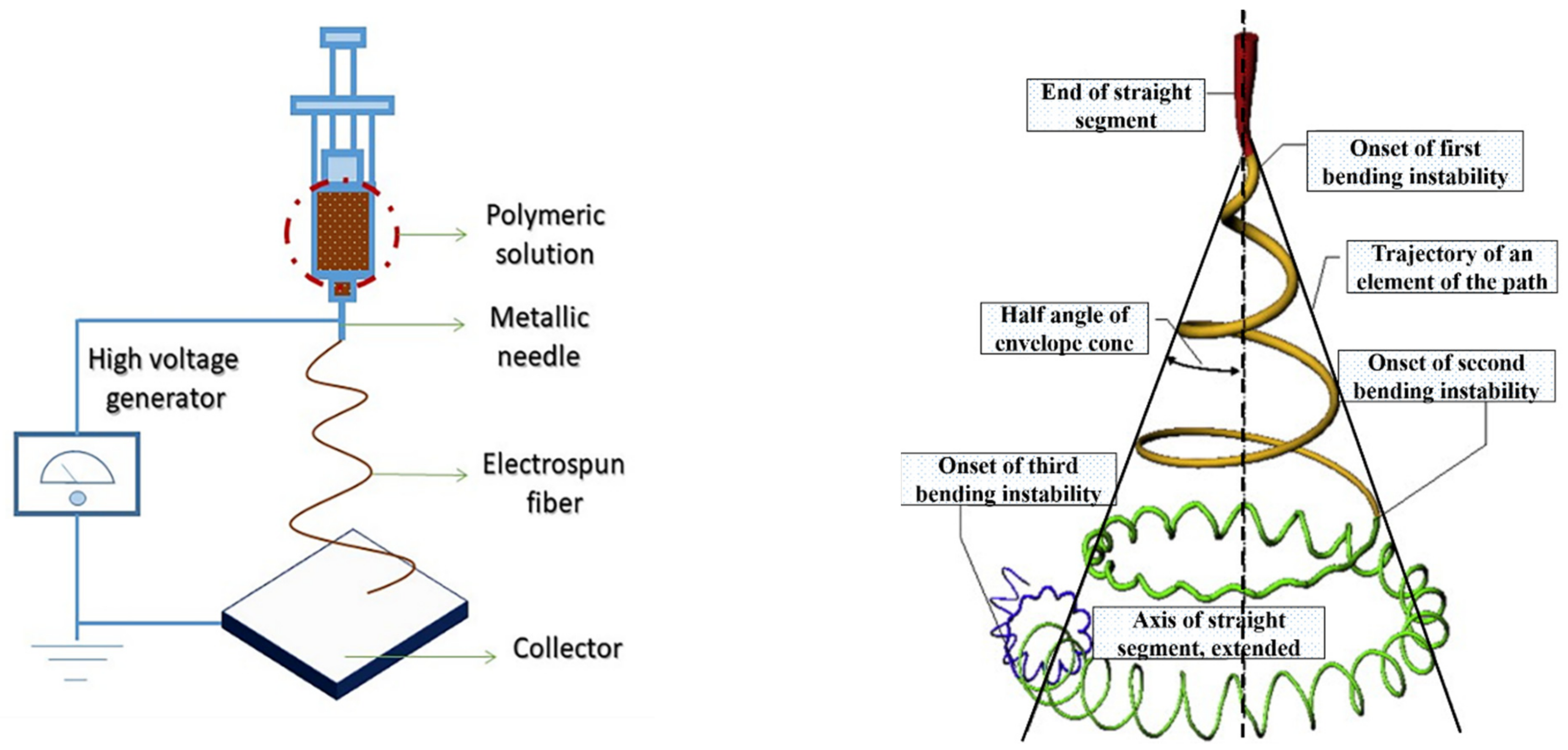

The rapid expansion of nanotechnology, such as nanomaterials with extraordinary physical and chemical properties, could assist in satisfying the demand for high-quality purification applications. The nanomaterials include zero-dimensional nanoparticles (all three dimensions are in the range of 1–100 nm, for example, quantum dots), one-dimensional materials (one of the dimensions is on a nanometer scale, examples include nanofibers, nanorods, nanotubes, nanowires), and two-dimensional nanosheets (all three dimensions are >100 nm) [4][1]. Among these, nanofibers, especially synthesized by electrospinning for a predominant electroactive phase, contribute extraordinary features to nanotechnology’s development [5][2]. Nanofibers are unique among the numerous types of nanomaterials due to their remarkably high specific surface area and porosity. In general, there are many techniques to produce nanofibers, such as bicomponent extrusion, electrospinning, melt blowing, phase separation, centrifugal spinning, drawing, self-assembly, and template synthesis (Table 1). The electrospinning (ES) technique is a cost-effective, simple and economic strategy for nanofiber production with the most control over parameters of nanofibers varying in size, shape, and doping [6][3]. Relatively symmetrical and homogeneous-structured nanofiber scaffolds can be developed alongside the production of membranes with excellent performance in water purification operations [7][4]. Membranes mainly fabricated via a sole or integrated ES technique, typically known as electrospun nanofiber-based membranes (ENMs), consist of nanofiber layers with overlapped nanofibers of diameters ranging from several nanometers to a few microns. ENMs have been regarded as one of the most promising orientations for energy storage, health care, electricity generation, biotechnology, and environmental applications, benefiting from these features, especially water purification and desalination [8][5].

| Techniques | Technical Process | Materials | Benefits | Drawbacks | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrospinning |

| Polyester, polyamide, polyvinyl alcohol, polyacrylonitrile, polyurethane, polyp-benzoyl, p-phenylenediamine etc. |

|

| [11,12] | [6][7] | ||||||

| Dry spinning |

| Cellulose acetate, polyolefin, polyvinyl chloride, vinylidene chloride spandex etc. |

|

| [13,14] | [8][9] | ||||||

| Wet spinning |

| Polyacrylonitrile, polyvinyl alcohol, polyvinyl chloride, viscose, polypyrrole, conductive polyaniline, inorganic nanofibers like carbon nanotubes etc. |

|

| [15,16] | [10][11] | ||||||

| Emulsion spinning |

| Polytetrafluoroethylene, ceramic, silicon carbide, monox, chloroethylene etc. |

|

| [17,18] | [12][13] | ||||||

| Melt spinning |

| Polyolefin, polyamide, polyester, polyvinyl chloride etc. |

|

| [19,20] | [14][15] | ||||||

| Phase separation spinning |

| Polyacrylonitrile, poly (2, 6-dimethyl p-phenyl ether), polypropylene, polyvinyl alcohol |

|

| [21,22] | [16][17] |

The efficiency of a membrane-based desalination system, particularly its permeability (water flux) and separation efficiency (solute rejection), depend considerably on the membrane properties and performance [9][18]. For increasingly enhanced separation requirements to be met, the ENMs require constant improvements and optimization for increased efficiency in both pressure-driven and thermal-driven processes with less consumption. According to our bFest knowledge, few w studies have focused on the production and application of ENMs, with an eye to functionalized nanofibers for specific applications. As shown in Figure 1a, ENMs can be divided into the following two categories according to the roles of electrospun nanofiber layers: (i) nanofiber layer serving as a selective layer, (ii) nanofiber layer serving as supporting substrate. The synthesis method of ENMs can be classified as single polymers, mixed polymers, polymers with nanofiber, and surface modifications. ENMs mainly have the following application fields: microfiltration, ultrafiltration, nanofiltration, reverse osmosis, forward osmosis, pervaporation, membrane distillation, etc. Regarding applications in water purification and desalination, the position of the nanofiber layer in ENMs have suggested that there are two types of ENMs, with the nanofiber layer serving as a selective layer and a support substrate, respectively (Figure 1b,c).

2. Electrospinning Technique and Process

2.1. Electrospinning Technique

2.2. Effects of Electrospinning Parameters

Nanofibers with variable dimensions or morphologies can be manufactured under different ES conditions [28,29][24][25]. The polymer fiber diameter and morphology are affected by both the polymeric solution properties as well as the process parameters. The main factors influencing the polymer solution properties include polymer weight and architecture, solution concentration, polymer viscosity, solution conductivity, and surface tension and solvent. Operating parameters include electric potential, polymer solution flow rate, the distance between the capillary and collector, needle gauge, collector, ambient temperature, humidity, and air velocity in the chamber.

3. ENMs with a Nanofiber Layer as the Selective Layer

3.1. Conventional ENMs

3.2. Mixed Matrix ENMs

3.2.1. Inorganic Metal Incorporation

Inorganic metal modification consists of metal nanoparticles (Ag, Fe) and metal oxide materials (Al2O3, TiO2, MOFs) [78][37]. Morphologies and structures of the composite mixed matrix ENMs are altered, hence varying from that of the original. This generates excellent water purification efficiency in heavy metal ions adsorption, organic dyes removal, antibacterial applications, oil–water separation, and some membrane distillation processes. Ag nanoparticles of dimensions ranging from several nanometers to tens of nanometers, with their excellent properties of killing and inhibiting bacteria and microorganisms [79][38], have sparked great interest in mixed matrix electrospun selective layer formation in membrane production for water desalination [80][39]. However, when directly added to the polymer solution, Ag nanoparticles will agglomerate, and hardly disperse on the electrospun nanofibers. Therefore, the reduction reaction between Ag+ and Ag nanoparticles is selected to solve this problem.3.2.2. Inorganic Nonmetal Incorporation

Inorganic nonmetallic nanomaterials such as SiO2 [86][40], carbon nanotubes (CNTs), zeolite [87[41][42],88], graphene, and graphene oxide (GO) were incorporated into the polymeric solution for functional improvements. Silica nanoparticles added to the polymer solution have the ability to improve the mechanical strength of nanofibers, increase the glass transition temperature of ENMs, and prevent the appearance of beads throughout the ES process [89,90][43][44]. Hou et al. [91][45] dissolved the polyvinylidene fluoride-co-hexafluropropylene (PVDF-HFP) in a cosolvent of DMF/acetone, and added SiO2 emulsion into the reagent to obtain PVDF-HFP/SiO2 ENMs. With the mass ratio of SiO2 increasing, though the membrane porosity decreased gradually, the pores shrunk while the thickness of membranes was enhanced, resulting in the improvement of salt rejection efficiency. The WCA was over 150°, owing to the rougher hydrophobic surface. The highest permeate flux was up to 48.6 kg/m2h and the rejection of NaCl was maintained at nearly 100% after 240 h of continuous operation of the membrane distillation process.3.2.3. Organic Incorporation

In contrast to various inorganic additives, there are fewer applications of organic additives due to various rigorous conditionalities, which, in general, are covalent organic frameworks (COFs), metal organic frameworks (MOFs), poly-cyclodextrin [103[46][47],104], β-cyclodextrin, and their modifiers [105][48]. MOFs are a class of nanoporous materials composed of central metal clusters or ions and organic ligands, which possess a large specific surface area, a high porosity, a low thermal conductivity, and ordered nanopores [106][49]. In recent years, MOFs have attracted significant interest for their role as nanofillers in pressure-driven liquid separations to drastically improve separation performances by providing additional water channels [107][50]. COFs are a class of robust two- or three-dimensional extended network materials known for their artistic structures and for their potential for a wide range of applications [113,114][51][52].3.3. Surface Modification

The internal structure of the membrane, created by the random accumulation of nanofibers as well as surface modification, can affect both pore size and liquid entry pressure. A surge of composite ENMs with a modified nanofiber layer via organic grafting of additional functional groups has attracted great interest to achieve a higher separation performance. Wang et al. [117][53] grafted hyperbranched polyethylenimine (HPEI) and glycidol onto PAA ENMs to form PAA/HPEI-glycidol ENMs via the reaction between the carboxylic group on PAA with the amine groups in HPEI, followed by the ring-opening of amine terminal groups with glycidol. The formation of the complexation compound formed boron and hydroxyl groups in glycidol, which vastly improved boron adsorption. The maximum boron adsorption capacity of the optimized ENMs achieved up to 5.7 mmol/g and remained approximately 94% after 10 operation cycles.4. ENMs with Nanofiber Layer as Supporting Substrates

4.1. With the Selective Layer via Secondary-Electrospinning

Dual-layer hydrophobic composite ENMs with two kinds of nanofiber layers were superior candidates in the water desalination process, especially membrane distillation, owing to its unique advantages of well-connected inner pores and low mass transfer resistance. It was reported that dual-layer ENMs, generally composed of hydrophobic/hydrophilic or superhydrophobic/less hydrophobic layers, exhibit better performance in membrane distillation than single-layer hydrophobic ENMs of the same thickness [124,125][54][55]. Besides, using a hydrophobic/hydrophilic dual-layer hollow fiber membrane for long-term DCMD operation demonstrated fewer pore wetting issues [126,127][56][57].4.2. With the Selective Layer via Inorganic Deposition

ENMs obtained with the selective layer via inorganic deposition from the nanofiber layer can usually enhance membranes’ thermodynamic and chemical stability. Properties of such hierarchical membranes are strongly affected by the selectivity of nanomaterials, which are commonly applied to heavy metals, some toxic ions adsorption and oil–water separation [131][58].4.3. With the Selective Layer via Polymer Coating

Various materials, such as chitosan [137][59], PES [138][60], DETA, PVA [139][61], and PDMS [140][62], with or without nanoparticles such as TiO2 incorporated, were coated as selective layers on the surface of nanofiber layers, forming new types of ENMs to be applied in ultrafiltration and oil–water separation processes specifically [141][63].4.4. With the Selective Layer via Interfacial Polymerization

Besides deposition and coating, selective layers prepared via interfacial polymerization (IP) can also be formed on the surface of nanofiber layers to fabricate ENMs, which are mainly used for osmosis and nanofiltration processes. The typical material of this selective layer is polyamide (PA), which is prepared through the reaction of polyamines and acyl chloride [145][64].5. Conclusions

ENMs, with the nanofiber layers serving as selective layers, are mainly produced in three ways: conventional ENMs, mixed matrix ENMs, and surface modification via grafting. For the production of mixed matrix electrospinning solutions, inorganic nanomaterials and organic materials are both furnished by some examples which play different roles in bacterial inhibition, dye removal, separation of oil/water systems, and so on. Such hierarchical membranes’ efficiency is apparently improved by various modifiers, nanoparticles, cross-linked organic reagents, and active biopolymers. However, nanofibers’ direct work as a selective layer has a relatively limited scope of utilization in low-pressure driven process like ultrafiltration, and microfiltration, as well as in thermal-driven process like membrane distillation, due to its poor mechanical strength. Therefore, typical nanofiber layers like PAN, PVDF, and PSF nanofibers and so on are widely installed as a supporting substrate, fixed with an additional skin layer by inorganic deposition, polymer coating, and interfacial polymerization to meet the demand of water treatment in different conditions. All of these contribute to the separation performances of organic pollutants, heavy metals, and antifouling performance in water treatment. It is considered that the ENM market has enormous potential for further development and is anticipated to boom in the immediate future for water purification.

References

- Saleem, H.; Trabzon, L.; Ali, K.; Zaidia, S.J. Recent advances in nanofibrous membranes Production and applications in water treatment and desalination. Desalination 2020, 478, 114178.

- Orudzhev, F.; Ramazanov, S.; Sobola, D. Ultrasound and water flow driven piezophototronic effect in self-polarized flexible α-Fe2O3 containing PVDF nanofibers film for enhanced catalytic oxidation. Nano Energy 2021, 90, 106586–106599.

- Kaspar, P.; Sobola, D.; Částková, K. Case study of polyvinylidene fluoride doping by carbon nanotubes. Materials 2021, 14, 1428.

- Manaf, O.; Anjana, K.; Prasanth, R.; Reshmi, C.R.; Juraij, K.; Rajesh, P.; Chingakham, C.; Sajith, V.; Sujith, A. ZnO decorated anti-bacterial electrospun ABS nanocomposite membrane for oil-water separation. Mater. Lett. 2019, 256, 126626.

- Shibuya, M.; Park, M.J.; Lim, S.; Phuntsho, S.; Matsuyama, H.; Shon, H.K. Novel CA/PVDF nanofiber supports strategically designed via coaxial electrospinning for high performance thin-film composite forward osmosis membranes for desalination. Desalination 2018, 445, 63–74.

- Niknejad, A.S.; Bazgir, S.; Kargari, A. Desalination by direct contact membrane distillation using a superhydrophobic nanofibrous poly (methyl methacrylate) membrane. Desalination 2021, 511, 115108.

- Liu, Y.; Gao, X.; Zhang, L.; Shen, X.; Du, X.; Dou, X.; Yuan, X. Mn2O3 nanoflower decorated electrospun carbon nanofibers for efficient hybrid capacitive deionization. Desalination 2020, 494, 114665.

- Yao, M.; Woo, Y.C.; Tijing, L.D.; Shim, W.-G.; Choi, J.-S.; Kim, S.-H.; Shon, H.K. Effect of heat-press conditions on electrospun membranes for desalination by direct contact membrane distillation. Desalination 2016, 378, 80–91.

- Liu, Y.; Du, X.; Wang, Z.; Zhang, L.; Chen, Q.; Wang, L.; Liu, Z.; Dou, X.; Zhu, H.; Yuan, X. MoS2 nanoflakes-coated electrospun carbon nanofibers for “rocking-chair” capacitive deionization. Desalination 2021, 520, 115376.

- Essalhi, M.; Khayet, M.; Ismail, N.; Sundman, O.; Tavajohi, N. Improvement of nanostructured electrospun membranes for desalination by membrane distillation technology. Desalination 2021, 510, 115086.

- Zhong, D.; Zhou, J.; Wang, Y. Hollow-fiber membranes of block copolymers by melt spinning and selective swelling. J. Memb. Sci. 2021, 632, 119374.

- Cai, J.; Liu, X.; Zhao, Y.; Guo, F. Membrane desalination using surface fluorination treated electrospun polyacrylonitrile membranes with nonwoven structure and quasi-parallel fibrous structure. Desalination 2018, 429, 70–75.

- Liu, Y.; Gao, J.; Ge, Y.; Yu, S.; Liu, M.; Gao, C. A combined interfacial polymerization and in-situ sol-gel strategy to construct composite nanofiltration membrane with improved pore size distribution and anti-protein-fouling property. J. Memb. Sci. 2021, 623, 119097.

- Wu, W.; Yu, L.; Li, L.; Li, Z.; Kang, J.; Pu, S.; Chen, D.; Ma, R.; An, K.; Liu, G.; et al. Electrospun nanofiber based forward osmosis membrane using graphene oxide as substrate modifier for enhanced water flux and rejection performance. Desalination 2021, 518, 115283.

- An, X.; Liu, Z.; Hu, Y. Amphiphobic surface modification of electrospun nanofibrous membranes for anti-wetting performance in membrane distillation. Desalination 2018, 432, 23–31.

- Sequeira, R.S.; Miguel, S.P.; Cabral, C.S.D.; Moreira, A.F.; Ferreira, P.; Correia, I.J. Development of a poly(vinyl alcohol)/lysine electrospun membrane-based drug delivery system for improved skin regeneration. Int. J. Pharm. 2019, 570, 118640.

- Sutisna, B.; Musteata, V.; Pulido, B.; Puspasari, T.; Smilgies, D.-M.; Hadjichristidis, N.; Nunes, S.P. High flux membranes, based on self-assembled and H-bond linked triblock copolymer nanospheres. J. Memb. Sci. 2019, 585, 10–18.

- Huang, D.; Wu, J.; Wang, L.; Liu, X.; Meng, J.; Tang, X.; Tang, C.; Xu, J. Novel insight into adsorption and co-adsorption of heavy metal ions and an organic pollutant by magnetic graphene nanomaterials in water. Chem. Eng. J. 2019, 358, 1399–1409.

- Gao, N.; Yang, J.; Wu, Y.; Yue, J.; Cao, G.; Zhang, A.; Ye, L.; Feng, Z. β-Cyclodextrin functionalized coaxially electrospun poly(vinylidene fluoride) @ polystyrene membranes with higher mechanical performance for efficient removal of phenolphthalein. React. Funct. Polym. 2019, 141, 100–111.

- Attia, H.; Osman, M.S.; Johnson, D.J.; Wright, C.; Hilal, N. Modelling of air gap membrane distillation and its application in heavy metals removal. Desalination 2017, 424, 27–36.

- Pant, B.; Park, M.; Park, S. Drug delivery applications of core-sheath nanofibers prepared by coaxial electrospin-ning: A Review. Pharmaceutics 2019, 11, 305.

- Wang, J.; Sun, Y.; Bi, W.; Jiang, Z.; Zhang, M.; Pang, J. High-strength corrosion resistant membranes for the separation of oil/water mixtures and immiscible oil mixtures based on PEEK. J. Memb. Sci. 2020, 616, 118418.

- Reneker, D.; Yarin, A. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425.

- Al-Attabi, R.; Rodriguez-Andres, J.; Schütz, J.A.; Bechelany, M.; Des Ligneris, E.; Chen, X.; Kong, L.; Morsi, Y.S.; Dumée, L.F. Catalytic electrospun nano-composite membranes for virus capture and remediation. Sep. Purif. Technol. 2019, 229, 115806.

- Zahari, A.M.; Shuo, C.W.; Sathishkumar, P.; Yusoff, A.R.M.; Gu, F.L.; Buang, N.A.; Lau, W.J.; Gohari, R.J.; Yusop, Z. A reusable electrospun PVDF-PVP-MnO2 nanocomposite membrane for bisphenol A removal from drinking water. J. Environ. Chem. Eng. 2018, 6, 5801–5811.

- Wang, Z.; Sahadevan, R.; Crandall, C.; Menkhaus, T.J.; Fong, H. Hot-pressed PAN/PVDF hybrid electrospun nanofiber membranes for ultrafiltration. J. Memb. Sci. 2020, 611, 118327.

- Li, Z.; Liu, Y.; Yan, J.; Wang, K.; Xie, B.; Hu, Y.; Kang, W.; Cheng, B. Electrospun polyvinylidene fluoride/fluorinated acrylate copolymer tree-like nanofiber membrane with high flux and salt rejection ratio for direct contact membrane distillation. Desalination 2019, 466, 68–76.

- Ghorai, S.K.; Roy, T.; Maji, S.; Guha Ray, P.; Sarkar, K.; Dutta, A.; De, A.; Bandyopadhyay, S.; Dhara, S.; Chattopadhyay, S. A judicious approach of exploiting polyurethane-urea based electrospun nanofibrous scaffold for stimulated bone tissue regeneration through functionally nobbled nanohydroxyapatite. Chem. Eng. J. 2022, 429, 132179.

- Chailek, N.; Daranarong, D.; Punyodom, W.; Molloy, R.; Worajittiphon, P. Crosslinking assisted fabrication of ultrafine poly(vinyl alcohol)/functionalized graphene electrospun nanofibers for crystal violet adsorption. J. Appl. Polym. Sci. 2018, 135, 46318.

- Kallem, P.; Banat, F.; Yejin, L.; Choi, H. High performance nanofiber-supported thin film composite forward osmosis membranes based on continuous thermal-rolling pretreated electrospun PES/PAN blend substrates. Chemosphere 2020, 261, 127687.

- Apul, O.G.; Von Reitzenstein, N.H.; Schoepf, J.; Ladner, D.; Hristovski, K.D.; Westerhoff, P. Superfine powdered activated carbon incorporated into electrospun polystyrene fibers preserve adsorption capacity. Sci. Total Environ. 2017, 592, 458–464.

- Zhang, H.; Li, B.; Sun, D.; Miao, X.; Gu, Y. SiO2-PDMS-PVDF hollow fiber membrane with high flux for vacuum membrane distillation. Desalination 2018, 429, 33–43.

- Moradi, G.; Rajabi, L.; Dabirian, F.; Zinadini, S. Biofouling alleviation and flux enhancement of electrospun PAN microfiltration membranes by embedding of para-aminobenzoate alumoxane nanoparticles. J. Appl. Polym. Sci. 2018, 135, 45738.

- Herrero, M.; Gómez, A. Vallés-Lluch, Role of Electrospinning Parameters on Poly(Lactic-co-Glycolic Acid) and Poly(Caprolactone-co-Glycolic acid). Membranes 2021, 13, 695.

- Xue, J.; Wu, T.; Dai, Y. Electrospinning and electrospun nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415.

- Karatepe, U.; Ozdemir, T. Improving mechanical and antibacterial properties of PMMA via polyblend electrospinning with silk fibroin and polyethyleneimine towards dental applications. Bioact. Mater. 2020, 5, 510–515.

- Yin, X.; Zhang, Z.; Ma, H.; Venkateswaran, S.; Hsiao, B.S. Ultra-fine electrospun nanofibrous membranes for multicomponent wastewater treatment: Filtration and adsorption. Sep. Purif. Technol. 2020, 242, 116794.

- Zhan, F.; Yan, X.; Sheng, F.; Li, B. Facile in situ synthesis of silver nanoparticles on tannic acid/zein electrospun membranes and their antibacterial, catalytic and antioxidant activities. Food Chem. 2020, 330, 127172.

- Zhang, L.; Li, L.; Wang, L.; Nie, J.; Ma, G. Multilayer electrospun nanofibrous membranes with antibacterial property for air filtration. Appl. Surf. Sci. 2020, 515, 145962.

- Hosseini, S.A.; Vossoughi, M.; Mahmoodi, N.M.; Sadrzadeh, M. Efficient dye removal from aqueous solution by high-performance electrospun nanofibrous membranes through incorporation of SiO2 nanoparticles. J. Clean. Prod. 2018, 183, 1197–1206.

- Habiba, U.; Afifi, A.M.; Salleh, A.; Ang, B.C. Chitosan/(polyvinyl alcohol)/zeolite electrospun composite nanofibrous membrane for adsorption of Cr6+, Fe3+ and Ni2+. J. Hazard. Mater. 2017, 322, 182–194.

- Anis, S.F.; Lalia, B.S.; Lesimple, A.; Hashaikeh, R.; Hilal, N. Electrically conductive membranes for contemporaneous dye rejection and degradation. Chem. Eng. J. 2022, 428, 131184.

- Rasekh, A.; Raisi, A. Electrospun nanofibrous polyether-block-amide membrane containing silica nanoparticles for water desalination by vacuum membrane distillation. Sep. Purif. Technol. 2021, 275, 119149.

- Zhao, R.; Li, Y.; Sun, B.; Chao, S.; Li, X.; Wang, C.; Zhu, G. Highly flexible magnesium silicate nanofibrous membranes for effective removal of methylene blue from aqueous solution. Chem. Eng. J. 2019, 359, 1603–1616.

- Hou, D.; Lin, D.; Ding, C.; Wang, D.; Wang, J. Fabrication and characterization of electrospun superhydrophobic PVDF-HFP/SiNPs hybrid membrane for membrane distillation. Sep. Purif. Technol. 2017, 189, 82–89.

- Celebioglu, A.; Yildiz, Z.I.; Uyar, T. Electrospun crosslinked poly-cyclodextrin nanofibers: Highly efficient molecular filtration thru host-guest inclusion complexation. Sci. Rep. 2017, 7, 7369.

- Yao, Z.; Guo, H.; Yang, Z.; Qing, W.; Tang, C.Y. Preparation of nanocavity-contained thin film composite nanofiltration membranes with enhanced permeability and divalent to monovalent ion selectivity. Desalination 2018, 445, 115–122.

- Zhang, J.; Fang, W.; Zhang, F.; Gao, S.; Guo, Y.; Li, J.; Zhu, Y.; Zhang, Y.; Jin, J. Ultrathin microporous membrane with high oil intrusion pressure for effective oil/water separation. J. Memb. Sci. 2020, 608, 118201.

- Huang, Z.; Yang, G.; Zhang, J.; Gray, S.; Xie, Z. Dual-layer membranes with a thin film hydrophilic MOF/PVA nanocomposite for enhanced antiwetting property in membrane distillation. Desalination 2021, 518, 115268.

- Wu, X.-Q.; Mirza, N.R.; Huang, Z.; Zhang, J.; Zheng, Y.-M.; Xiang, J.; Xie, Z. Enhanced desalination performance of aluminium fumarate MOF-incorporated electrospun nanofiber membrane with bead-on-string structure for membrane distillation. Desalination 2021, 520, 115338.

- Gonzales, R.R.; Park, M.J.; Bae, T.H.; Yang, Y.; Abdel-Wahab, A.; Phuntsho, S.; Shon, H.K. Melamine-based covalent organic framework-incorporated thin film nanocomposite membrane for enhanced osmotic power generation. Desalination 2019, 459, 10–19.

- Lim, S.; Akther, N.; Tran, V.H.; Bae, T.-H.; Phuntsho, S.; Merenda, A.; Dumée, L.F.; Shon, H.K. Covalent organic framework incorporated outer-selective hollow fiber thin-film nanocomposite membranes for osmotically driven desalination. Desalination 2020, 485, 114461.

- Wang, Z.; Wu, Z.; Zhang, Y.; Meng, J. Hyperbranched-polyol-tethered poly (amic acid) electrospun nanofiber membrane with ultrahigh adsorption capacity for boron removal. Appl. Surf. Sci. 2017, 402, 21–30.

- Ursino, C.; Di Nicolò, E.; Gabriele, B.; Criscuoli, A.; Figoli, A. Development of a novel perfluoropolyether (PFPE) hydrophobic/hydrophilic coated membranes for water treatment. J. Memb. Sci. 2019, 581, 58–71.

- Yang, H.C.; Xie, Y.; Hou, J.; Cheetham, A.K.; Chen, V.; Darling, S.B. Janus Membranes: Creating Asymmetry for Energy Efficiency. Adv. Mater. 2018, 30, 1801495.

- Woo, Y.C.; Tijing, L.D.; Park, M.J.; Yao, M.; Choi, J.-S.; Lee, S.; Kim, S.-H.; An, K.-J.; Shon, H.K. Electrospun dual-layer nonwoven membrane for desalination by air gap membrane distillation. Desalination 2017, 403, 187–198.

- Essalhi, M.; Khayet, M.; Tesfalidet, S.; Alsultan, M.; Tavajohi, N. Desalination by direct contact membrane distillation using mixed matrix electrospun nanofibrous membranes with carbon-based nanofillers: A Strategic Improvement. Chem. Eng. J. 2021, 426, 131316.

- Pornea, A.M.; Puguan, J.M.C.; Deonikar, V.G.; Kim, H. Robust Janus nanocomposite membrane with opposing surface wettability for selective oil-water separation. Sep. Purif. Technol. 2020, 236, 116297.

- Guo, J.-W.; Wang, C.-F.; Chen, S.-H.; Lai, J.Y.; Lu, C.-H.; Chen, J.-K. Highly efficient self-cleaning of heavy polyelectrolyte coated electrospun polyacrylonitrile nanofibrous membrane for separation of oil/water emulsions with intermittent pressure. Sep. Purif. Technol. 2020, 234, 116106.

- Chowdhury, M.R.; Huang, L.; McCutcheon, J.R. Thin Film Composite Membranes for Forward Osmosis Supported by Commercial Nanofiber Nonwovens. Ind. Eng. Chem. Res. 2017, 56, 1057–1063.

- Shen, L.; Wang, F.; Tian, L.; Zhang, X.; Ding, C.; Wang, Y. High-performance thin-film composite membranes with surface functionalization by organic phosphonic acids. J. Memb. Sci. 2018, 563, 284–297.

- Jiao, L.; Yan, K.; Wang, J.; Lin, S.; Li, G.; Bi, F.; Zhang, L. Low surface energy nanofibrous membrane for enhanced wetting resistance in membrane distillation process. Desalination 2020, 476, 114210.

- Löffler, F.B.; Altermann, F.J.; Bucharsky, E.C.; Schell, K.G.; Litter, M.I. Morphological characterization and photocatalytic efficiency measurements of pure silica transparent openell sponges coated with TiO2. Int. J. Appl. Ceram. Tec. 2020, 17, 1930–1939.

- Al-Attabi, R.; Morsi, Y.; Schutz, J.A.; Dumee, L.F. One-pot synthesis of catalytic molybdenum based nanocomposite nano-fiber membranes for aerosol air remediation. Sci. Total Environ. 2019, 647, 725–733.