The use of essential oils (EO) loaded with nanoparticles is the most promising alternative to increase food quality and safety. Their association with different nanosystems allows novel developments in the micronutrition, health promotion, and pathogen control fields, preventing the aggravation of bacterial microevolution and combating antibiotic resistance. Benefits to the environment are also provided, as they are biodegradable and biocompatible.

- food science

- nanotechnology

- essential oils

1. Introduction

The EOs are plant-derived compounds with complex aromatic structures and high volatility. The volatilomes [11][1] are presented as the total fraction of strong-smelling molecules produced in specialized plant cells (oil cells, ducts, or glands) [12][2]. They are secondary plant metabolites, which play essential roles in the dynamics of plants with their habitat through protection against pathogens and attraction of polarizers [13][3]. They can be extracted from all parts of plants (from leaves to roots) by using different methodologies. The presence, yield, and chemotype of EOs are influenced by many climatic and plant nutritional factors, as well as stress conditions. For commercial EO production (where increases in the yield are desirable), breeding and selection programs are implemented as a measure to foster specific compositions [14][4]. The structural profiles of commercial EOs have been previously provided by gas chromatography and mass spectrometry analysis [8,15,16][5][6][7]. In general, their molecular structure reveals two or three major compounds, corresponding to more than 20% of the full molecule, usually responsible for their biological properties [17,18,19][8][9][10].

2. Production Chain in the Food Industry (FI)

3. Nanostructured Delivery Systems (NDSs)

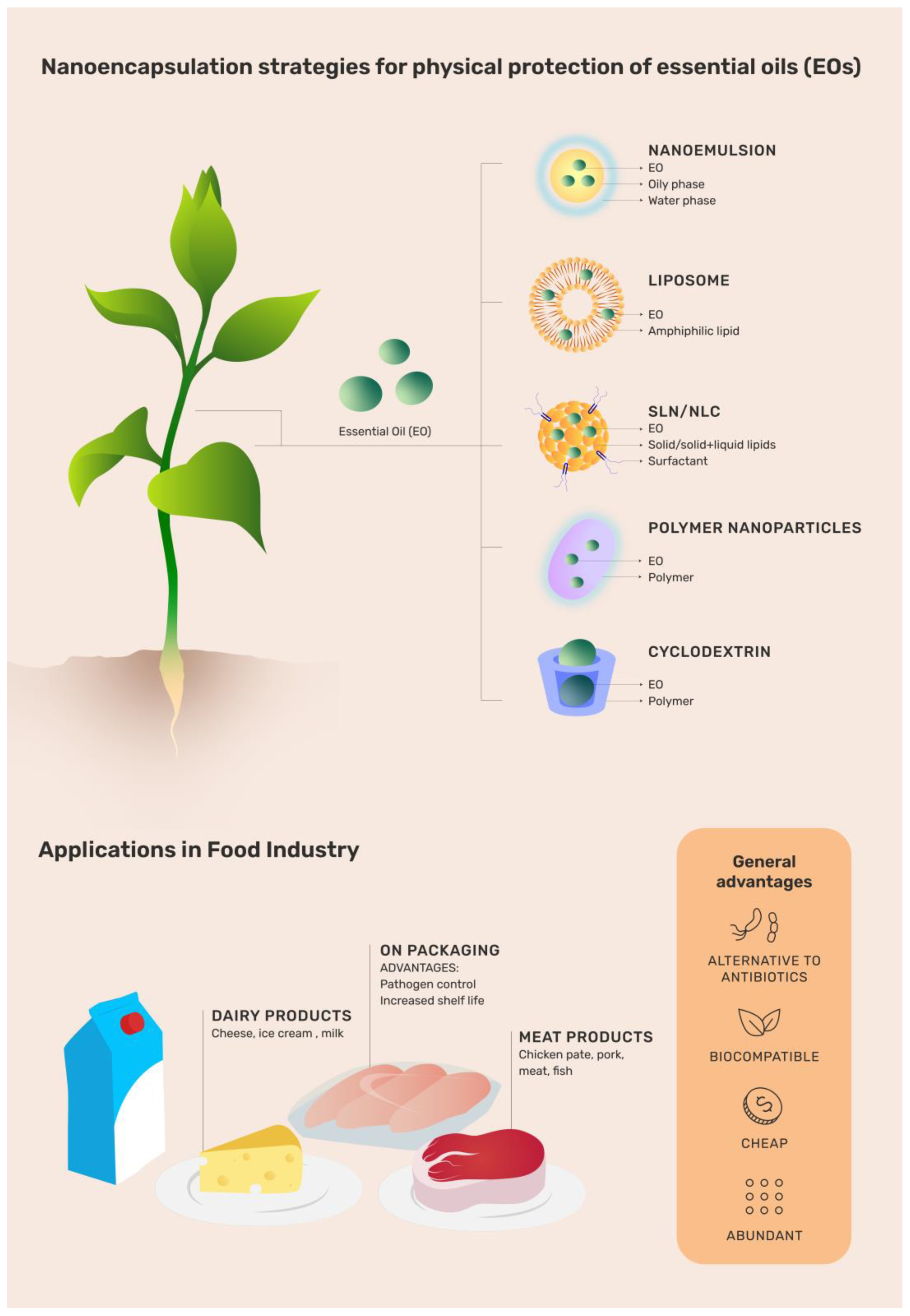

The nanostructured delivery systems (NDSs) are molecularly composed of different biomaterials and are processed as several forms in order to interact specifically with the targets. There are a lot of benefits of the EOs nanoencapsulation approach, such as bioactive protection to the external environment (e.g., products rich in unsaturated lipids can be peroxided over time); sustained release; desirable shelf time; to mask eventual bioactive unpleasant odor and/or flavor; and act as smart packaging with moisture maintenance, protection against pathogens, and monitoring of conditions during distribution [72,81,106][35][36][37]. Different NPs loading EOs have been proposed for pathogen control or incorporated as adjuvants in food-based products [41][26]. Furthermore, nanoencapsulation presents itself as a method to protect against formation of degraded compounds with toxic derivatives, such as the conversion of safrole (4-allyl-1,2-methylene dioxybenzene), derived from plants of the Lauraceae family (including nutmeg and black pepper) with hepatocarcinogenic effects [81,107][36][38].3.1. Liposomes

Liposomes are spherical vesicles composed of phospholipids spontaneously oriented as lipid bilayers (unilamellar or multilamellar) in aqueous solutions, given by the hydrophobic interactions of nonpolar acyl chains [108][39]. The amphiphilic nature of lipids is currently exploited to encapsulate food ingredients of different polarities, creating an efficient physical barrier system and protecting bioactives from environmental conditions [109][40]. The lipid bilayers allow interaction with the hydrophobic encapsulated compounds, being intrinsically related to NDS stability (fluidity, permeability, and polarity, among others), as well as encapsulation efficiency and sustained release profile [110][41]. In general, the analyzed reports showed that the EO-loaded liposomes provided optimized antimicrobial activity. Sebaaly et al. (2021) developed multilamellar liposomes composed of dipalmitoyl phosphatidylcholine (DPPC) encapsulating EO from Z. tingoassuiba, with a mean diameter of 9.37 ± 4.69 µm [111][42]. The in vitro antimicrobial activity was evaluated by the disc diffusion test. Antimicrobial activity against Staphylococcus aureus, Micrococcus luteus, and Streptococcus mutans, important pathogens related to the food infections, was observed [110][41].3.2. Nanoemulsions (NEs)

Nanoemulsions (NEs) are stable systems composed of two immiscible phases [112][43], being processed as water-in-oil or oil-in-water, stabilized by amphiphilic surfactant and co-surfactant. They exhibit excellent structural properties, with particle size between 50–250 nm and a monodisperse distribution [113][44]. Food-grade NEs containing bioactive components can be used to develop biodegradable packaging films. Promising results were provided of NEs that prevented foodborne diseases. In this sense, carvacrol-based NE was tested in minimal processes as an alternative to calcium hypochlorite use against Escherichia coli O157:H7 and Salmonella Typhimurium in contaminated broccoli and radish seeds. A system containing 0.4% carvacrol was able to inactivate contamination in low levels (about 2–3 log CFU/g) in radish seeds. The treatment was not effective for broccoli seeds [52][45].3.3. Solid Lipid Nanoparticles (SLNs)

SLNs emerged in 1991, firstly described by Professors Müller and Gasco, as an alternative to traditional colloidal systems such as liposomes [115,116][46][47]. This system is based on a lipid matrix composed of solid lipid stabilized by a surfactant [30,116][15][47]. SLNs have high affinity to load hydrophobic active into the solid matrix [117][48]. SLNs allow to improve the stability of loaded EOs under various adverse conditions, including food processing, heating, high pressure, drying, UV radiation, and bile salt [118][49]. Therefore, such a system was designed for applications in food distribution because it has interesting advantages to be used in this sector, such as the effective uptake of fat-soluble assets, sustained release profile, and long-term stability [119,120][50][51].3.4. Nanostructured Lipid Carriers (NLCs)

NLCs are the second generation of lipid nanoparticles, composed of a lipid matrix formed by a blend between solid and liquid lipids in room temperature, stabilized by a surfactant [115][46]. They are also considered to be safe and promising nanocarriers for the delivery of hydrophobic compounds, despite their hydrophilicity (colloid liquid systems), which is paramount for the establishment of water-based foods. Therefore, NLCs have industrial relevance as these nanocarriers also combine specific advantages for food uses, such as the ability to be successfully incorporated into transparent and opaque foods and beverages [115][46]. The encapsulation of EOs by NLCs has been proposed to exhibit higher stability, minimized toxicity, and preserve the therapeutic properties of pristine EOs [124][52]. EO-loaded NLC formulations have been widely described to increase the antimicrobial activity of EOs and protect them against environmental damage conditions (light, hydrolysis, and evaporation, among others) [31,125][16][53].3.5. Polymer Nanocapsules (NCs)

NCs are NDSs formed by a shell (polymer wall) and core (oil core) counterparts that have interesting physicochemical properties for application in food matrices, such as those derived from aliphatic polyester (ε-caprolactone), which are stable in storage and allow a sustained release of loaded actives. Such core–shell structure brings benefits that include the difficulty of contact with external substances and is better suited to lipophilic foods [128][54]. The encapsulation of EOs by polymer nanocapsules (NC) aims to improve hydrophilicity of insoluble compounds, protection against degradation, prevention of loss of volatile compounds caused by evaporation, and a sustained release. Their antimicrobial activity of NC loading Thymus capitatus EO with high amount of bioactives (43% thymol) was reported [8][5]. The association of polymers and thymol EO has immediate applicability against important pathogens in the FI (S. aureus, L. monocytogenes, B. cereus, S. typhi, S. dysenteriae, and E. coli).3.6. Cyclodextrins (CDs)

Cyclodextrins (CDs) are cyclic oligosaccharides that have glucose units linked by α-(1,4)-glycosidic bonds, derived from the enzymatic degradation of starch [110][41], mainly by B. macerans [34][19]. They present a cone-shaped morphology with a hydrophobic cavity and 7.9 Å diameter, and are able to form inclusion complexes with low-aqueous-solubility molecules [50][55]. The inclusion complexes formed by CDs and EOs improve the EO solubility and physicochemical stability, providing a sustained release of these compounds [131][56], also acting as physical barrier to protect the EO in procedures such as freezing, thawing, and/or microwaving during food processing [34][19]. In the FI, they are used to improve flavor and sorption of bitter compounds. Recently, CDs have been noticed as constituents of active packaging of edible products [132][57].3.7. Chitosan-Based Delivery Systems (CHT)

Chitosan (CHT) is a linear cationic polysaccharide formed by (1,4)-amino-deoxy-b-d-glucan chains derived from a deacetylated chitin of crabs and crustaceans, and is biocompatible, biodegradable, and cheap [64][58]. The use of CHT as a drug carrier has additional advantages as an NDS, such as the protection of the selected active, changes in temperature, and sustained release at the site of interest [136][59], given by the electrostatic interactions with anionic biological membranes. As a biopolymer, it can be processed as several forms and is abundant, cheap, and biodegradable [137][60]. CHT application in association with EOs has demonstrated higher antimicrobial activity against foodborne pathogens than biopolymer films and coatings [64][58]. Specifically, it has demonstrated its advantageous use as an NDS in food preservatives, as it allows a sustained release of active ingredients in the production of food films and coatings [64][58]. Its inherent antimicrobial activity has been attributed to the electrostatic forces between the cationic amino groups (NH3) of CHT and the negatively charged residues of the fatty acids located on the bacterial [138][61].4. Nanopackaging and Smart Control of Food Pathogens

EOs are widely explored for use in food packaging due to their potential antimicrobial activity [98][62]. Antimicrobial packaging is also able to maintain both the nutritional and sensory quality of food, extending its shelf life. Such approach seems to be an effective alternative to the addition of synthetic preservatives in the packages, as it will be in contact with the food products. Therefore, EOs are currently incorporated into the packages, aiming to decrease the maximum population growth rate and/or prolong the lag phase of the target microorganism by contact inactivation. When used in adequate concentrations, in addition to inhibiting foodborne pathogenic bacteria (Listeria, Salmonella, Aeromonas, Clostridium botulinum, Enterobacter, and Staphylococci) and their toxins, EOs can also improve the sensory properties of the food products [144][63]. However, the EOs incorporation in active and smart packaging needs to meet crucial safety requirements. For instance, the slow denaturation of EOs from the packaging material to the food surface allows maintaining a high concentration of EOs over a long period of time when compared to the direct addition of EOs in food, the result of which differs by the rapid diffusion of the bioactive with a consequent reduction in antimicrobial activity [145][64]. The application of nanotechnology in packaging development presents interesting opportunities to exploit the antimicrobial properties of EOs [146][65]. This strategy has been widely explored, mainly because they act as a physical barrier leading to decreased spoilage and improved inhibition of pathogenic microorganism growth [147][66]. Nanofilms composed of a thin layer of polymers, created using layer-by-layer deposition techniques, have potential applications in the field of active food packaging. They have been applied directly on the product, whereas non-edible coatings have a protective function specifically on the packaging. Their applicability also extends to surfaces that are in contact with food during processing or to prevent the formation of biofilms [28][13].References

- Filipiak, W.; Mochalski, P.; Filipiak, A.; Ager, C.; Cumeras, R.; Davis, C.E.; Agapiou, A.; Unterkofler, K.; Troppmair, J. A Compendium of Volatile Organic Compounds (VOCs) Released by Human Cell Lines. Curr. Med. Chem. 2016, 23, 2112–2131.

- Capelezzo, A.P.; Mohr, L.C.; Dalcanton, F.; de Mello, J.M.M.; Fiori, M.A. β-Cyclodextrins as Encapsulating Agents of Essential Oils. In Cyclodextrin. A Versatile Ingredient; Poonam, A., Neelima, D., Eds.; IntechOpen: London, UK, 2018.

- Dudareva, N.; Klempien, A.; Muhlemann, J.K.; Kaplan, I. Biosynthesis, function and metabolic engineering of plant volatile organic compounds. New Phytol. 2013, 198, 16–32.

- Thormar, H. Lipids and Essential Oils as Antimicrobial Agents; Thormar, H., Ed.; John and Wiley and Sons: Hoboken, NJ, USA, 2011; ISBN 9780470741788.

- Granata, G.; Stracquadanio, S.; Leonardi, M.; Napoli, E.; Consoli, G.M.L.; Cafiso, V.; Stefani, S.; Geraci, C. Essential oils encapsulated in polymer-based nanocapsules as potential candidates for application in food preservation. Food Chem. 2018, 269, 286–292.

- Leitão, S.G.; De Oliveira, D.R.; Sülsen, V.; Martino, V.; Barbosa, Y.G.; Bizzo, H.R.; Lopes, D.; Viccini, L.F.; Salimena, F.R.G.; Peixoto, P.H.P.; et al. Analysis of the chemical composition of the essential oils extracted from Lippia lacunosa Mart. & Schauer and Lippia rotundifolia Cham. (Verbenaceae) by gas chromatography and gas chromatography-mass spectrometry. J. Braz. Chem. Soc. 2008, 19, 1388–1393.

- Yan, D.; Wong, Y.F.; Tedone, L.; Shellie, R.; Marriott, P.J.; Whittock, S.; Koutoulis, A. Chemotyping of new hop (Humulus lupulus L.) genotypes using comprehensive two-dimensional gas chromatography with quadrupole accurate mass time-of-flight mass spectrometry. J. Chromatogr. A 2018, 1536, 110–121.

- Bilia, A.R.; Guccione, C.; Isacchi, B.; Righeschi, C.; Firenzuoli, F.; Bergonzi, M.C. Essential Oils Loaded in Nanosystems: A Developing Strategy for a Successful Therapeutic Approach. Evid. Based Complement. Altern. Med. 2014, 2014, 651593.

- Garcia, A.; Barbas, C. Gas Chromatography-Mass Spectrometry (GC-MS)-Based Metabolomics. In Metabolic Profiling; Humana Press: Totowa, NJ, USA, 2010; pp. 191–204.

- Satyal, P.; Jones, T.H.; Lopez, E.M.; McFeeters, R.L.; Ali, N.A.A.; Mansi, I.; Al-Kaf, A.G.; Setzer, W.N. Chemotypic Characterization and Biological Activity of Rosmarinus officinalis. Foods 2017, 6, 20.

- Zhang, X.; Ismail, B.B.; Cheng, H.; Jin, T.Z.; Qian, M.; Arabi, S.A.; Liu, D.; Guo, M. Emerging chitosan-essential oil films and coatings for food preservation—A review of advances and applications. Carbohydr. Polym. 2021, 273, 118616.

- Chivandi, E.; Dangarembizi, R.; Nyakudya, T.T.; Erlwanger, K.H. Use of Essential Oils as a Preservative of Meat. In Essential Oils in Food Preservation, Flavor and Safety; Academic Press: Cambridge, MA, USA, 2016; pp. 85–91.

- Joye, I.J.; Davidov-Pardo, G.; McClements, D.J. Nanotechnology in Food Processing. In Encyclopedia of Food and Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 49–55.

- Kumar, A.; Singh, P.; Gupta, V.; Prakash, B. Application of nanotechnology to boost the functional and preservative properties of essential oils. In Functional and Preservative Properties of Phytochemicals; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 241–267. ISBN 9780128185933.

- Prakash, B.; Kujur, A.; Yadav, A.; Kumar, A.; Singh, P.P.; Dubey, N.K. Nanoencapsulation: An efficient technology to boost the antimicrobial potential of plant essential oils in food system. Food Control 2018, 89, 1–11.

- Ribeiro, L.N.D.M.; de Paula, E.; Rossi, D.A.; Martins, F.A.; de Melo, R.T.; Monteiro, G.P.; Breitkreitz, M.C.; Goulart, L.R.; Fonseca, B.B. Nanocarriers from Natural Lipids With In Vitro Activity Against Campylobacter jejuni. Front. Cell. Infect. Microbiol. 2021, 10, 571040.

- FDA. Guidance for Industry Use of Nanomaterials in Food for Animals; FDA: Silver Spring, MD, USA, 2015; p. 10.

- Melo, R.T.; Galvão, N.N.; Guidotti-Takeuchi, M.; Peres, P.A.B.M.; Fonseca, B.B.; Profeta, R.; Azevedo, V.A.C.; Monteiro, G.P.; Brenig, B.; Rossi, D.A. Molecular Characterization and Survive Abilities of Salmonella Heidelberg Strains of Poultry Origin in Brazil. Front. Microbiol. 2021, 12, 674147.

- Pereira, A.G.; Carpena, M.; Oliveira, P.G.; Mejuto, J.; Prieto, M.; Gandara, J.S. Main Applications of Cyclodextrins in the Food Industry as the Compounds of Choice to Form Host-Guest Complexes. Int. J. Mol. Sci. 2021, 22, 1339.

- Wu, Z. Antimicrobial use in food animal production: Situation analysis and contributing factors. Front. Agric. Sci. Eng. 2018, 5, 301.

- Quinto, E.J.; Caro, I.; Villalobos-Delgado, L.H.; Mateo, J.; De-Mateo-Silleras, B.; Redondo-Del-Río, M.P. Food Safety through Natural Antimicrobials. Antibiotics 2019, 8, 208.

- Iriti, M.; Vitalini, S.; Varoni, E.M. Humans, Animals, Food and Environment: One Health Approach against Global Antimicrobial Resistance. Antibiotics 2020, 9, 346.

- Kon, K.V.; Rai, M.K. Plant essential oils and their constituents in coping with multidrug-resistant bacteria. Expert Rev. Anti-Infect. Ther. 2012, 10, 775–790.

- Ruddaraju, L.K.; Pammi, S.V.N.; Guntuku, G.S.; Padavala, V.S.; Kolapalli, V.R.M. A review on anti-bacterials to combat resistance: From ancient era of plants and metals to present and future perspectives of green nano technological combinations. Asian J. Pharm. Sci. 2019, 15, 42–59.

- Pérez-Rodríguez, F.; Taban, B.M. A State-of-Art Review on Multi-Drug Resistant Pathogens in Foods of Animal Origin: Risk Factors and Mitigation Strategies. Front. Microbiol. 2019, 10, 2091.

- Chouhan, S.; Sharma, K.; Guleria, S. Antimicrobial Activity of Some Essential Oils—Present Status and Future Perspectives. Medicines 2017, 4, 58.

- Ghorbanzade, T.; Jafari, S.M.; Akhavan, S.; Hadavi, R. Nano-encapsulation of fish oil in nano-liposomes and its application in fortification of yogurt. Food Chem. 2017, 216, 146–152.

- Ilyasoglu, H.; El, S.N. Nanoencapsulation of EPA/DHA with sodium caseinate–gum arabic complex and its usage in the enrichment of fruit juice. LWT 2013, 56, 461–468.

- McClements, D.J.; Öztürk, B. Utilization of Nanotechnology to Improve the Handling, Storage and Biocompatibility of Bioactive Lipids in Food Applications. Foods 2021, 10, 365.

- Dasgupta, N.; Ranjan, S. An Introduction to Food Grade Nanoemulsions; Springer: Singapore, 2018; Volume 1, ISBN 978-981-10-6985-7.

- Ranjan, S.; Dasgupta, N.; Chakraborty, A.R.; Samuel, S.M.; Ramalingam, C.; Shanker, R.; Kumar, A. Nanoscience and nanotechnologies in food industries: Opportunities and research trends. J. Nanoparticle Res. 2014, 16, 2464.

- Silva, H.D.; Cerqueira, M.; Vicente, A.A. Nanoemulsions for Food Applications: Development and Characterization. Food Bioprocess Technol. 2012, 5, 854–867.

- Kirby, C.J. Nanotechnology in the Food Sector. In Food Processing Handbook, 2nd ed.; Brennan, G.J., Grandison, A.S., Eds.; John and Wiley and Sons: Hoboken, NJ, USA, 2009; Volume 1, pp. 693–726.

- Gupta, S.V.S. Nanotechnology and Food Science: Tomorrow Design the Food. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 3553–3561.

- Beyki, M.; Zhaveh, S.; Khalili, S.T.; Rahmani-Cherati, T.; Abollahi, A.; Bayat, M.; Tabatabaei, M.; Mohsenifar, A. Encapsulation of Mentha piperita essential oils in chitosan-cinnamic acid nanogel with enhanced antimicrobial activity against Aspergillus flavus. Ind. Crop. Prod. 2014, 54, 310–319.

- Ferreira, C.D.; Nunes, I.L. Oil nanoencapsulation: Development, application, and incorporation into the food market. Nanoscale Res. Lett. 2019, 14, 9.

- Ribeiro, L.N.M.; Alcântara, A.C.S.; Da Silva, G.H.R.; Franz-Montan, M.; Nista, S.V.G.; Castro, S.R.; Couto, V.M.; Guilherme, V.A.; De Paula, E. Advances in Hybrid Polymer-Based Materials for Sustained Drug Release. Int. J. Polym. Sci. 2017, 2017, 1231464.

- Forensic Science. In Handbook of Analytical Separations; Elsevier: Amsterdam, The Netherlands, 2008.

- de Paula, E.; Oliveira, J.D.; de Lima, F.F.; de Morais Ribeiro, L.N. Liposome-Based Delivery of Therapeutic Agents. In Controlled Drug Delivery Systems; CRC Press: Boca Raton, FL, USA, 2020; pp. 299–324.

- Taylor, T.M.; Weiss, J.; Davidson, P.M.; Bruce, B.D. Liposomal Nanocapsules in Food Science and Agriculture. Crit. Rev. Food Sci. Nutr. 2005, 45, 587–605.

- Hammoud, Z.; Gharib, R.; Fourmentin, S.; Elaissari, A.; Greige-Gerges, H. New findings on the incorporation of essential oil components into liposomes composed of lipoid S100 and cholesterol. Int. J. Pharm. 2019, 561, 161–170.

- Sebaaly, C.; Trifan, A.; Sieniawska, E.; Greige-Gerges, H. Chitosan-Coating Effect on the Characteristics of Liposomes: A Focus on Bioactive Compounds and Essential Oils: A Review. Processes 2021, 9, 445.

- Ingle, A.P.; Shende, S.; Gupta, I.; Rai, M. Recent trends in the development of nano-bioactive compounds and delivery systems. In Biotechnological Production of Bioactive Compounds; Elsevier: Amsterdam, The Netherlands, 2019; pp. 409–431.

- Singh, Y.; Meher, J.G.; Raval, K.; Khan, F.A.; Chaurasia, M.; Jain, N.K.; Chourasia, M.K. Nanoemulsion: Concepts, development and applications in drug delivery. J. Control. Release 2017, 252, 28–49.

- Landry, K.S.; Micheli, S.; McClements, D.J.; McLandsborough, L. Effectiveness of a spontaneous carvacrol nanoemulsion against Salmonella enterica Enteritidis and Escherichia coli O157:H7 on contaminated broccoli and radish seeds. Food Microbiol. 2015, 51, 10–17.

- Müller, R.H.; Alexiev, U.; Sinambela, P.; Keck, C.M. Nanostructured Lipid Carriers (NLC): The Second Generation of Solid Lipid Nanoparticles. In Percutaneous Penetration Enhancers Chemical Methods in Penetration Enhancement; Dragicevic, N., Maibach, H.I., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 161–185. ISBN 978-3-662-45012-3.

- Trevaskis, N.L.; Charman, W.N.; Porter, C.J.H. Lipid-based delivery systems and intestinal lymphatic drug transport: A mechanistic update. Adv. Drug Deliv. Rev. 2008, 60, 702–716.

- Pink, D.L.; Loruthai, O.; Ziolek, R.M.; Wasutrasawat, P.; Terry, A.E.; Lawrence, M.J.; Lorenz, C.D. On the Structure of Solid Lipid Nanoparticles. Small 2019, 15, e1903156.

- Azar, F.A.N.; Pezeshki, A.; Ghanbarzadeh, B.; Hamishehkar, H.; Mohammadi, M. Nanostructured lipid carriers: Promising delivery systems for encapsulation of food ingredients. J. Agric. Food Res. 2020, 2, 100084.

- Katouzian, I.; Esfanjani, A.F.; Jafari, S.M.; Akhavan, S. Formulation and application of a new generation of lipid nano-carriers for the food bioactive ingredients. Trends Food Sci. Technol. 2017, 68, 14–25.

- Shegokar, R.; Athawale, R.; Kurup, N.; Yang, R.; Chougule, M.B. Lipid-Based Nanoparticles for Targeted Drug Delivery of Anticancer Drug. In Nanotechnology-Based Approaches for Targeting and Delivery of Drugs and Genes; Academic Press: Cambridge, MA, USA, 2017; pp. 287–321.

- Ribeiro, L.N.; Alcantara, A.C.; Franz-Montan, M.; Couto, V.M.; Nista, S.V.; de Paula, E. Nanostructured organic-organic bio-hybrid delivery systems. In Biomedical Application of Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 341–374.

- Khezri, K.; Farahpour, M.R.; Rad, S.M. Efficacy of Mentha pulegium essential oil encapsulated into nanostructured lipid carriers as an in vitro antibacterial and infected wound healing agent. Colloids Surf. A Physicochem. Eng. Asp. 2020, 589, 124414.

- Esmaeili, A.; Gholami, M. Optimization and preparation of nanocapsules for food applications using two methodologies. Food Chem. 2015, 179, 26–34.

- Detoni, C.B.; Cabral-Albuquerque, E.C.M.; Hohlemweger, S.V.A.; Sampaio, C.; Barros, T.F.; Velozo, E.S. Essential oil from Zanthoxylum tingoassuiba loaded into multilamellar liposomes useful as antimicrobial agents. J. Microencapsul. 2009, 26, 1–8.

- Chiriac, A.; Rusu, A.; Nita, L.; Chiriac, V.; Neamtu, I.; Sandu, A. Polymeric Carriers Designed for Encapsulation of Essential Oils with Biological Activity. Pharmaceutics 2021, 13, 631.

- Petitjean, M.; García-Zubiri, I.X.; Isasi, J.R. History of cyclodextrin-based polymers in food and pharmacy: A review. Environ. Chem. Lett. 2021, 19, 3465–3476.

- Yuan, G.; Chen, X.; Li, D. Chitosan films and coatings containing essential oils: The antioxidant and antimicrobial activity, and application in food systems. Food Res. Int. 2016, 89, 117–128.

- Mujtaba, M.; Khawar, K.M.; Camara, M.C.; Carvalho, L.B.; Fraceto, L.F.; Morsi, R.E.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Ullah, H.; et al. Chitosan-based delivery systems for plants: A brief overview of recent advances and future directions. Int. J. Biol. Macromol. 2020, 154, 683–697.

- Bonetti, F.M.R.; de Paula, E.; Fonseca, B.B.; da Silva, G.R.; da Silva, L.S.S.; de Moura, L.D.; Breitkreitz, M.C.; da Silva, G.H.R.; Ribeiro, L.N.D.M. Hybrid Nanobeads for Oral Indomethacin Delivery. Pharmaceutics 2022, 14, 583.

- Möller, H.; Grelier, S.; Pardon, A.P.; Coma, V. Antimicrobial and Physicochemical Properties of Chitosan−HPMC-Based Films. J. Agric. Food Chem. 2004, 52, 6585–6591.

- Zarzycki, P.K.; ena Fenert, B.; Głód, B.K. 17—Cyclodextrins-based nanocomplexes for encapsulation of bioactive compounds in food, cosmetics, and pharmaceutical products: Principles of supramolecular complexes formation, their influence on the antioxidative properties of target chemicals, and rec. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 717–767. ISBN 978-0-12-804307-3.

- Vergis, J.; Gokulakrishnan, P.; Agarwal, R.K.; Kumar, A. Essential Oils as Natural Food Antimicrobial Agents: A Review. Crit. Rev. Food Sci. Nutr. 2013, 55, 1320–1323.

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380.

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of Nanotechnology in Food Science: Perception and Overview. Front. Microbiol. 2017, 8, 1501.

- Anvar, A.A.; Ahari, H.; Ataee, M. Antimicrobial Properties of Food Nanopackaging: A New Focus on Foodborne Pathogens. Front. Microbiol. 2021, 12, 690706.