In this entry, the 3D CAD reconstructions and 3D multi-material polymer replica printings of knight Götz von Berlichingen´s first "„Iron Hand",,“ which were developed in the last few years at Offenburg University, are presented. Even by today's standards, the first “Iron Hand”–as could be shown in the replicas–demonstrates sophisticated mechanics and well thought-out functionality and still offers inspiration and food for discussion when it comes to the question of an artificial prosthetic replacement for a hand.

- Iron Hand

- Götz von Berlichingen

- 3D computer-aided design

- finite element method

- 3D multi-material polymer printing

- replica

- hand prosthesis

- neuroprosthetics

1. Introduction

The famous Franconian knight Gottfried (also called “Götz”) von Berlichingen (1480–1562) was born into a time of upheaval during the transition from the late Middle Ages to modern times. During the Landshut War of Succession (1504/05), he lost his right hand due to a cannon ball splinter injury in 1504 at the age of 24 years. The cannon fire came from his own countrymen by accident[1].

Götz already thought about replacing his hand artificially during his time in the sick bay and early on commissioned a gunsmith to build the first “Iron Hand.” In this prosthesis, the artificial thumb and two finger blocks (index and middle finger, and ring finger and little finger, respectively) could be moved in their basic joints by a spring mechanism and released by a push button. Photographs of the first hand can be seen under the following permalinks of the Landesarchiv Baden-Württemberg, Abteilung Generallandesarchiv Karlsruhe:

- http://www.landesarchiv-bw.de/plink/?f=4-1081856-1 (hand closed);

- http://www.landesarchiv-bw.de/plink/?f=4-1081855-1 (hand open).

2. Second Hand

Some years later, presumably around 1530, a second “Iron Hand” was built. In this, the fingers could be moved passively in all joints. Photographs of the second hand can be seen under the following permalinks of the Landesarchiv Baden-Württemberg, Abteilung Generallandesarchiv Karlsruhe:

- http://www.landesarchiv-bw.de/plink/?f=4-1078548-1 (hand closed);

- http://www.landesarchiv-bw.de/plink/?f=4-1078549-1 (hand open).

Although the second prosthesis was more elaborate than the first prosthesis, it seems that the knight continued to use the first one much more often, as, opposed to the first, the second prosthesis has nearly no traces of usage. However, since only certain things could be held, the environment of Götz had to be adapted in such a way that dealing with the first “Iron Hand” was as simple as possible. In the museum at Jagsthausen, Germany, one can see some of these adapted instruments: his crossbow and his cutlery and travel set.

3. The First 3D CAD Reconstruction

The first 3D CAD reconstruction[2] of the first "Iron Hand" was based on data from Quasigroch, 1982[3]. For static reasons, however, a few dimensional data points had to be changed, and since not all components of the riveted mechanical part of the Götz hand were visible to Quasigroch and thus measurable without destroying the hand, some assumptions were made for the reconstruction that resulted from the creation of the 3D CAD data (Figure 1). This 3D CAD reconstruction was then printed with a multi-material printer (Stratasys J750, Eden Prairie, MN, USA), which allows for the production of different polymer materials (including transparent, non-transparent, stiff, or elastic components)[4] (Figure 2).

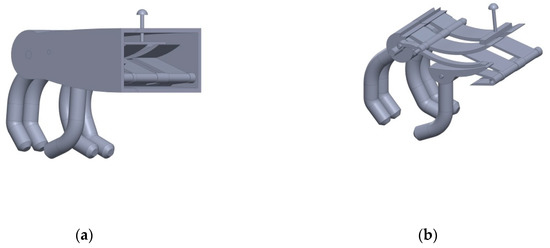

Figure 1. Initial 3D computer-aided design (CAD) reconstruction of the first “Iron Hand” of Götz von Berlichingen. (a) General view of the artificial prosthetic hand; (b) view after virtual removal of the chassis with insight into the mechanics.

Figure 2. Initial 3D-printed polymer replica of the first “Iron Hand” of Götz von Berlichingen.

In our investigations with the 3D-printed polymer replica, we found that simple actions for daily use, such as holding a wine glass, a mobile phone, a bicycle handlebar grip, a horse’s reins, or some grapes, are possible without effort[5].

4. The Second 3D CAD Reconstruction with An Improved Thumb Lever Mechanism

During the use of the initial 3D reconstruction of the hand, it was observed that the thumb lever broke under greater stress. The increased forces mainly in the thumb lever could be confirmed by finite element method (FEM) analysis (see Figure 1 in[6] or under the link: https://doi.org/10.3390/prosthesis2030020). Therefore, the mechanism of the thumb lever was revised: The newly developed mechanism of the thumb joint, which causes the finger and thumb roller to rotate in opposite directions, was realized with two power levers. This improved the tension and the distribution of forces in the parts[7]. The 3D-printed polymer replica can be seen in Figure 3.

Figure 3. Second 3D-printed polymer replica of the first “Iron Hand” of Götz von Berlichingen with an improved thumb lever mechanism. (a) General view of the artificial prosthetic hand; (b) view after removal of the lateral chassis cover with insight into the new mechanics.

5. The Third 3D CAD Reconstruction with An Opening Mechanism by a Torsion Spring

In previous reconstructions, the resetting mechanism was not considered. In the original Götz hand, however, when the button is pressed, one can observe a clear rebound of the fingers to their original position. Quasigroch could not exactly fathom this mechanism, and so a spring mechanism was considered that could be well fitted into the existing mechanics. For this purpose, a torsion spring was selected for each finger block. Its strength was first calculated according to the principles of today’s engineering art; then the springs were inserted into a slight 3D-CAD modification of the second variant of the replica described above. This (third) reconstruction was then printed out on a 3D printer; the inserted torsion springs can be seen in Figure 4[8].

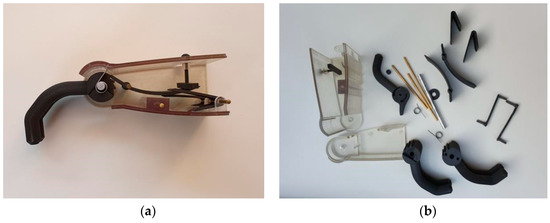

Figure 4. Third 3D-printed polymer replica of the first “Iron Hand” of Götz von Berlichingen with an opening mechanism by a torsion spring. (a) In this photograph, the first finger block, the new thumb lever mechanism, and the lateral chassis cover are removed to see the torsion spring; (b) view of all components after disassembling the hand.

References

- Quasigroch, G.; Die Handprothesen des fränkischen Reichsritters Götz von Berlichingen—Der Landshuter Unfall [The hand prostheses of the Franconian imperial knight Götz von Berlichingen–The Landshut accident]. Z. der Ges. für Hist. Waffen-und Kostümkunde 1980, 22, 108–112.

- Weinert, O.; Otte, A.; 3-D CAD-Rekonstruktion der ersten „Eisernen Hand “des Reichsritters Gottfried von Berlichingen (1480–1562). Arch. Kriminol. 2017, 240, 50–58.

- Quasigroch, G.; Die Handprothesen des fränkischen Reichsritters Götz von Berlichingen. 1. Fortsetzung: Die Ersthand [The hand prostheses of the Franconian imperial knight Götz von Berlichingen. 1st continuation: The first hand]. Z. der Ges. für Hist. Waffen-und Kostümkunde 1982, 24, 17–33.

- 4. Otte, A.; Weinert, O.; Junk, S. 3D-multimaterial printing–Knight Götz von Berlichingen’s trendsetting “iron hand”. Science 2017. Available online: http://science.sciencemag.org/content/353/6307/aaf2093/tab-e-letters (accessed on 2 December 2017).

- Otte, A.; Weinert, O.; Junk, S.; 3-D CAD-Rekonstruktion der ersten “Eisernen Hand“ des Reichsritters Gottfried von Berlichingen (1480–1562): 1. Fortsetzung: Funktionsprüfung mittels 3-D Druck. [3D CAD reconstruction of the first “Iron Hand” of German knight Gottfried von Berlichingen (1480–1562)—First continuation: Function test by means of 3D print]. Arch. Kriminol. 2017, 240, 185–192.

- Andreas Otte; Invasive Versus Non-Invasive Neuroprosthetics of the Upper Limb: Which Way to Go?. Prosthesis 2020, 2, 237-239, 10.3390/prosthesis2030020.

- 7. Brezo, K. 3-D-CAD-Konstruktion Eines Neuen Doppelgelenks für den Daumenhebel bei der rekonstruierten ersten “Eisernen Hand“ des Götz von Berlichingen [3-D CAD Design of a New Double Joint for the Thumb Lever in the Reconstructed First “Iron Hand” of Götz von Berlichingen]. Bachelor’s Thesis, Offenburg University, Offenburg, Germany, 30 August 2019.

- 8. Sadrija, A. 3D-unterstützte Optimierung der Mechanik der Fingerblöcke bei der ersten “Eisernen Hand“ des Götz von Berlichingen [3D-Supported Optimization of the Mechanics of the Finger Blocks in the First “Iron Hand” of Götz von Berlichingen]. Bachelor’s Thesis, Offenburg University, Offenburg, Germany, 17 April 2020.