Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by ANA LAURA REYES REYES and Version 2 by Catherine Yang.

Lipases are efficient enzymes with promising applications in the nutraceutical and food industry, as they can offer high yields, pure products under achievable reaction conditions, and are an environmentally friendly option.

- lipases

- food

- nutraceutical industry

1. Lipases as Biocatalysts in the Food and Nutraceutical Industry

Lipases are widely used in the food industry [1][2][9,10]. Lipases (triacylglycerol hydrolases EC 3.1. 1.3) play a crucial role in numerous industrial food processes [3][4][11,12] because they participate in reactions that improve product quality and provide greater stability, solubility, durability, and better organoleptic characteristics [2][5][6][10,13,14].

1.1. Lipase Characteristics

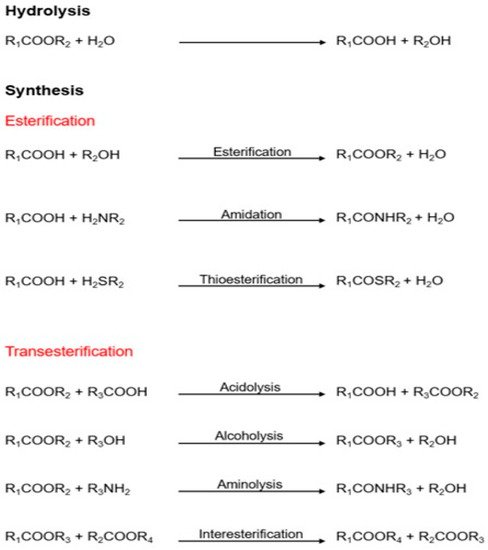

These enzymes can hydrolyze triglycerides to obtain free fatty acids, monoacylglycerols (MAGs), diacylglycerols (DAGs), and glycerol; on the other hand, they can synthesize new products in organic media by esterification, transesterification, and aminolysis mechanisms (Figure 1) [7][8][15,16]. Lipases have a highly conserved catalytic triad comprising serine as a nucleophile, an aspartate/glutamate as an acidic residue, and histidine. In their active conformation, lipases present in their active center a group of hydrophobic residues arranged around the catalytic serine that constitute an electrophilic region known as an oxyanion cavity. Lipases are also characterized by the presence of disulfide bridges that give them stability and are critical for their catalytic activity [8][16]. Some lipases also have a structural feature covering the active site, called the “lid,” that opens at hydrophobic/hydrophilic interphases. Ancient classifications denoted esterases as lipolytic enzymes lacking a lid. However, because some lipases, such as Candida antarctica lipase B (CALB), lack the lid, an alternative classification has been proposed [9][17].

Lipases are characterized by maintaining their activity and high production in nonaqueous media [10][18], high production, and stability at pH ranges and do not require cofactors. According to their substrate specificity, lipases can be chemoselective, regioselective, or stereoselective. The first lipase type can selectively catalyze a reaction. The second type catalyzes a reaction specifically with one of the triglyceride positions (sn-1,3 regioselective, sn-2 regioselective, or nonregioselective). Additionally, the third type catalyzes reactions selecting only one of the stereoisomers from a mixture of enantiomers [2][8][10,16].

1.2. Sources and Tools to Improve Lipase-Catalyzed Reactions

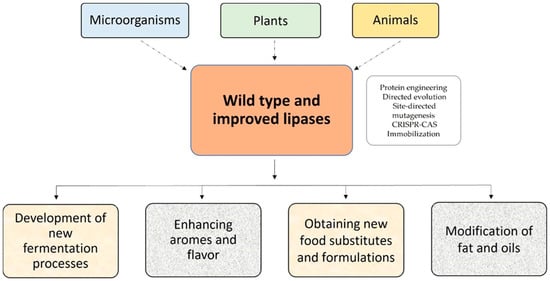

Lipases are ubiquitous enzymes produced by various organisms, including microorganisms, plants, and animals [4][11][12][13][14][15][16][12,19,20,21,22,23,24]. Because of the increased commercial interest in these proteins in the food and nutraceutical industry, the use of recombinant production technology is critical.

The productivity of lipase production bioprocesses has been increasing, reducing the cost of enzymes by using cell factories for the heterologous production of lipases. Between them, Komogataella phaffi (P. pastoris) is one of the most common cell factories used [17][25].

Lipases have been improved using natural evolution techniques, protein engineering, bioinformatics design, directed evolution, saturation mutagenesis, site-directed mutagenesis, and DNA shuffling [18][26]. However, in the food industry, the native form is often preferred (Figure 2).

Figure 2.

Sources and use of lipases in the food industry.

Table 1 shows some microbial lipases that are commercially available and immobilized on different supports to enhance their efficiency and reuse [19][20][21][22][27,28,29,30]. Most commercially important lipase-producing yeasts belong to the class of ascomycetes, such as Candida sp. and Rhizopus sp. Novozymes® (Bagsværd, Denmark), DuPont® (Wilmington, DE, USA), Roche® (Basel, Switzerland), and Amano (Yokohama, Japan) are the main companies that produce and commercialize lipases [23][31].

Table 1. Sources of lipases with applications in food and nutraceutical industry.

| Source/Commercial Name | Type | Application/Products | Reference |

|---|---|---|---|

| Candida antarctica lipase B (CALB)/Novozym 435/Lipozyme 435 | Recombinant | Flavor esters | [24][32] |

| Candida rugosa | Wild type | Glycerides, production flavor compounds | [25][26][33,34] |

| Termomyces lanuginosus/Lipozyme TL IM | Engineered | Food formulation, Interesterification of fats and oils | [27][28][35,36] |

| Aspergillus sp. | Wild type | Flavor and fragance | [29][37] |

| Aspergillus oryzae | Wild type | Interesterification of fats and oils | [28][36] |

| Geotrichum candidum | Wild type | Oil with increased unsaturation | [28][36] |

| Rhizomucor miehei/Lipozyme RM IM | Recombinant | Enhancing fruit fragrance | [30][38] |

| Modification of the amount and composition of volatile components in bovine milk | [31][39] | ||

| Ras Cheese Flavor Concentrate (RCFC) | [32][40] | ||

| Rhizopus oryzae | Wild type | Human Milk Fat Substitutes | [33][41] |

| Lactococcus chungangensis | Wild type | Flavoring in milk, cream cheese, yogurt and butter. | [34][42] |

| Lactobacillus plantarum | Wild type | Fermented food and cheese | [35][43[36],44] |

| Staphylococcus epidermidis | Wild type | Flavor-compound production | [37][45] |

| Ophiostoma piceae | Wild type | Flavor-compound production | [38][46] |

| Meyerozyma guilliermondii | Wild type | Feed industry | [39][47] |

Other important bottlenecks of the free enzymes in general and lipases are the low operational stability in synthesis reactions using solvents and substrates such as alcohols and organic acids, the high cost of the enzymes, and the need to reuse the biocatalyst minimizing product separation.

Different approaches are being applied (Figure 2) to solve these drawbacks. The use of enzyme immobilization methods normally increases biocatalyst stability, specificity and selectivity, allows the reutilization of the enzyme, and minimizes downstream processes, and has been reflected in the number of articles and patents published in this field [40][48].

Advances in the study of lipases seek to develop more efficient processes and, for this purpose, their stability under certain temperatures, solvents, and pH conditions, among others. The development of a specific reaction medium to increase the activity, stability, and productivity of biocatalysts has been a recurring topic of research over the last three decades. The remarkable properties and useful applications of enzymes, particularly lipases, have inspired various strategies to improve their performance in near-anhydrous media. Therefore, medium engineering can be used to modulate the activity and selectivity of lipase-catalyzed reactions [41][49].

Ionic liquids (ILs) are molten salts that originate from the association of organic cations and organic/inorganic anions. The use of ILs as solvents in biocatalysis processes has recently received increased attention, and substantial progress has been made, particularly in lipase-catalyzed reactions. ILs have the advantages of low volatility, low inflammability, and a low melting point [42][50]. Deep eutectic solvents [43][51] are eutectic mixtures of salts and hydrogen bond donors with sufficiently low melting points to act as solvents. DESs were demonstrated to be a viable alternative to traditional organic solvents and ILs in many biocatalytic processes, particularly for lipases. DESs have additional advantages over ILs in simple preparation and lower costs because of their renewable and readily available raw materials [44][52].