Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Franc Mihalic and Version 2 by Conner Chen.

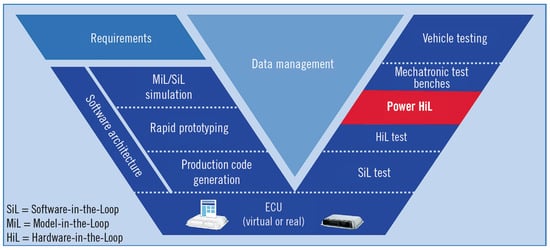

The design of modern industrial products is further improved through the hardware-in-the-loop (HIL) simulation. An HIL model can bypass serious damage to the real object, reduce debugging cost, and, finally, reduce the comprehensive effort during the testing.

- hardware-in-the-loop (HIL)

- controller-in-the-loop (CIL)

- power hardware-in-the-loop (PHIL)

1. Introduction

During the system development process, using parts or complete hardware in the simulation loops is very important for the so-called hardware-in-the-loop (HIL) simulations. The real hardware (when available) is used in the simulation loop instead of strenuous and long-term testing of the control algorithms [1][2][1,2]. At the same time, HIL simulation also includes controller-in-the-loop (CIL) simulations, forming the backbone of the automotive, defense, marine, and space industries. This simulation is infallible in testing a component, such as an electronic control unit (ECU), and is connected to the simulation instead of the real equipment under control. The fact is that the actuators are hard to model, and, when they are available, can be incorporated into the simulation loop to improve the simulation.

Usually, the testing of the system and then its evaluation are run in real time. The control input is provided within the desired sampled period in such an embedded system. It is important to point out that the control signal is crucial for the stability of the system. HIL simulation as a tool for testing the control system has been present for the longest time in the aerospace industry: here, the software for flight control systems could be a safety critical issue, and the combination of all these aspects has encouraged its use in the following:

- Intense pressure to reduce development cycles;

- Safety requirements which require exhaustive testing of a control system before using on the real plant;

- The need to prevent costly failures, either in-service or late in the design cycle;

- Reduced cost and greater availability of off-the-shelf products for HIL simulation.

-

Intense pressure to reduce development cycles;

-

Safety requirements which require exhaustive testing of a control system before using on the real plant;

-

The need to prevent costly failures, either in-service or late in the design cycle;

-

Reduced cost and greater availability of off-the-shelf products for HIL simulation.

In the last half-century, HIL simulation has played an essential role in the field of flight simulation [3]. At the same time, broad use of this method can also be found in the testing of missile guidance systems [4]. Even before this, highly maneuverable aircraft technology (HiMAT) was developed by NASA [5]. Within this program, the use of advanced concepts was investigated (such as fly-by-wire and reduced static stability). Additional to NASA’s development of an area of high-fidelity HIL simulations, the USAF Phillips Lab has developed a laboratory to integrate component technologies and demonstrate spacecraft subsystem/payload level capabilities [6].

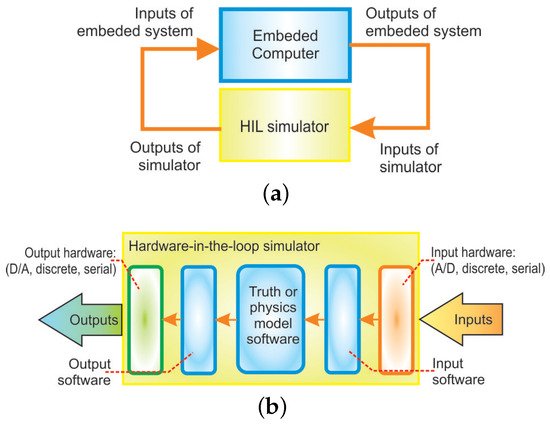

HIL simulation is developing fast from a system model design, synthesis, and simulation criterion. An HIL simulator is often a powerful tool in many applications, such as airplanes, missiles, and uncrewed aerial- or ground-traffic vehicles, where the autopilots play a crucial and vital role [7]. Through the HIL simulator, the embedded system is forced to operate in real time, such as in the real world with real inputs and outputs. For example, the autopilot fools the aircraft system into thinking that it is flying. Figure 1a shows a general block scheme of an embedded system where an HIL simulator is used for testing, while Figure 1b shows the necessary components of a simple HIL simulator.

Figure 1. HIL simulator: (a) Block diagram of embedded system connected to a HIL simulator; (b) components of a simple HIL simulator [7].

Like Gomez in [7] already reported more than 20 years ago, giving monetary judgments about the HIL simulators is tough and ungrateful. Unfortunately, there is almost no off-the-shelf HIL simulator for sale, although a couple of products and providers can come close. For example (according to [7]), if the first self-designed simulator in the mid-1990s cost slightly over EUR 100,000 (with 100 inputs and outputs), then the second identical unit cost about EUR 25,000 to build. This was considered a bargain compared to the multi-million dollar unmanned aerial vehicles (UAVs) they were developing—if the HILS prevented the crash of just one UAV, the company would get its money’s worth. There was another, even more, valuable benefit: a HILS allows the software to be developed and tested without waiting for the actual hardware to be built (or, in this case, built and flown).

In recent years, pweople have faced very complex power electronic systems, electric drives, and their control. Their use is growing significantly in distributed power generation, such as home and industrial electronics, traction, automotive, hybrid vehicles, aerospace systems, and the marine industry. Based on the significant progress in the field of power semiconductors, and various platforms, such as microcontrollers, microcomputers, and microprocessors, field programmable gate array (FPGA), and digital signal processor (DSP), peoplewe are witnessing high-performance electric drives [8]. Advanced software tools, such as MATLAB/Simulink [9] and real-time simulators [10], are used broadly in many engineering fields, i.e., education, research groups, and industry. The involvement of real-time simulations in modern engineering ensures an excellent aid for academia and researchers. It is, however, also very beneficial to have the HIL simulation become a part of the control development toolset [11].