Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Qufu Wei and Version 2 by Rita Xu.

Triboelectric nanogenerator (TENG), as a green energy harvesting technology, has aroused tremendous interest across many fields, such as wearable electronics, implanted electronic devices, and human-machine interfaces. Fabric and fiber-structured materials are excellent candidates for TENG materials due to their inherent flexibility, low cost, and high wearing comfort. Consequently, it is crucial to combine TENG with fabric/fiber materials to simultaneously leverage their mechanical energy harvesting and wearability advantages.

- triboelectric nanogenerator

- fabric/fiber structure

- wearable self-powered sensors

1. Introduction

In recent years, mobile wearable devices and wireless communication networks, as symbols of the new era, have gradually changed people’s ways of life [1][2][3][1,2,3]. Particularly, flexible energy supply devices have attracted extensive attention with the development of wearable electronic markets. Although the external power supplies of wearable electronic products, such as small solid batteries, supercapacitors, lithium-ion batteries, etc., are becoming more and more miniaturized and portable, their rigid nature contradicts the flexibility of fabric, resulting in inferior comfort of wear [4][5][4,5]. In addition, these battery devices cannot provide a long-term energy supply during repeated charging/discharging. Moreover, a large amount of wasted electronics needs high disposal and recycling costs during the disposal and recycling process, which also lead to soil and water pollution [6][7][8][6,7,8]. What is more dangerous is that in complex working environments, they might easily cause leakage of electrolyte and oxidized materials within the battery, resulting in severe harm to users. Therefore, from the perspective of economic and sustainable development, rigid battery devices are a poor choice for the future development of wearable sensors [9][10][9,10]. Hence, it is of the utmost importance to select a sustainable green and environmentally friendly flexible power supply that is not only integrated and miniaturized, but also environmentally credible and will not accidentally harm the human body [11][12][13][14][11,12,13,14].

Collecting energy from the surrounding environment is one potential solution to this issue. As a revolutionary energy harvesting technology, triboelectric nanogenerators (TENGs) utilize simple construction and mechanisms to effectively harvest mechanical energy and play a crucial role in the construction of portable power sources or self-powered systems [15][16][17][15,16,17]. Moreover, compared to traditional power supply systems, TENGs have the advantages of light weight, simple structure, and strong material adaptability [18][19][18,19]. As one of the most abundant energies in the human living environment, mechanical energy possesses the qualities of continuity, independence, easy access, and widespread existence. It has significant application potential in the fields of smart wearables and biomedical engineering. As the human body is not only a rich source of green mechanical energy but also an application terminal for smart wearables, the acquisition and utilization of required energy can be accomplished through human movement by integrating nanogenerator and human movement [20][21][20,21]. Although some polymer films (e.g., polytetrafluoroethylene, polydimethylsiloxane) can also adhere to the human body (e.g., knees, arms) to harvest mechanical energy or monitor movements, the poor wearing comfort and durability remains a great challenge. By comparison, fabrics and fiber materials have natural wearability, inherent durability, and can withstand complex mechanical deformations such as stretch, twist, bend and tear, owning to its uniqueness. Thus, the integration of cutting-edge energy collection technology and fabric/fiber materials are advantageous for the development of wearable self-powered sensor [22][23][22,23].

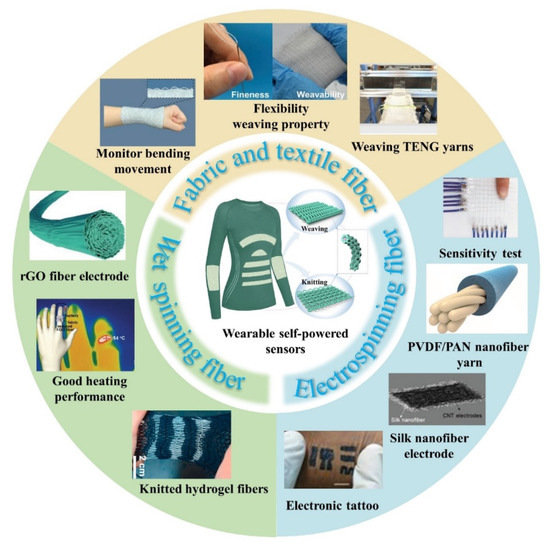

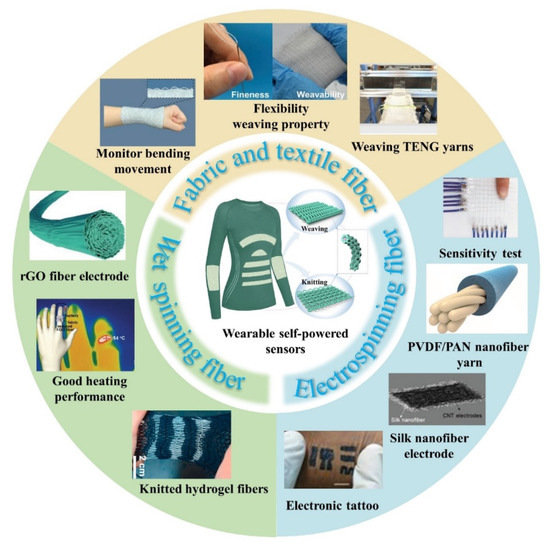

The application advantages of fabric/fiber material in the fields of TENG and the feasibility of self-powered wearable sensors. Firstly, the structure design and operating mechanisms of TENG is introduced. Followed by the uniqueness of fabric/fiber materials based on TENG. Fabric/fiber materials are divided into three categories based on their preparation methods: fabric and textile fiber (spinning and weaving method), wet spinning fiber materials (wet spinning method), and electrospinning nanofibers (electrospun method). Figure 1 depicts recent research progress of fabric/fiber-based TENGs made mainly through these methods [24][25][26][27][28][24,25,26,27,28]. In addition to energy harvesting, human motion detection and functional applications can also be incorporated. These applications fully confirm the vast potential of fabric/fiber-based TENG in the field of self-powered wearable sensors, bringing revolutionary changes to the future development of wearable technology and greatly promoting the robust growth of the wearable electronics market.

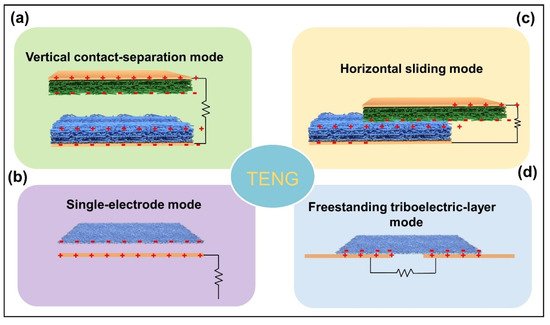

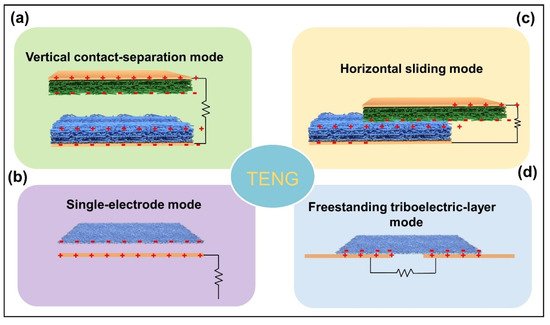

In particular, according to the polarization direction and electrode structure, as shown in Figure 3, the TENG can be mainly divided into four basic working modes: vertical contact-separation mode, single-electrode mode, horizontal sliding mode and freestanding triboelectric-layer mode [36][37][36,37]. Based on the different working modes of TENG, various forms of mechanical energy collection and self-powered sensors in various application scenarios can be realized. The basic working modes are as follows:

In particular, according to the polarization direction and electrode structure, as shown in Figure 3, the TENG can be mainly divided into four basic working modes: vertical contact-separation mode, single-electrode mode, horizontal sliding mode and freestanding triboelectric-layer mode [36][37][36,37]. Based on the different working modes of TENG, various forms of mechanical energy collection and self-powered sensors in various application scenarios can be realized. The basic working modes are as follows:

Figure 1. Schematic of recently reported fabric/fiber-based TENG.

2. The Mechanism and Structure Design of TENG

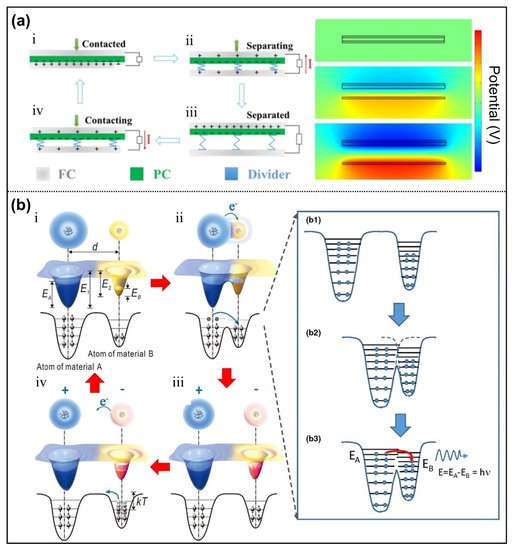

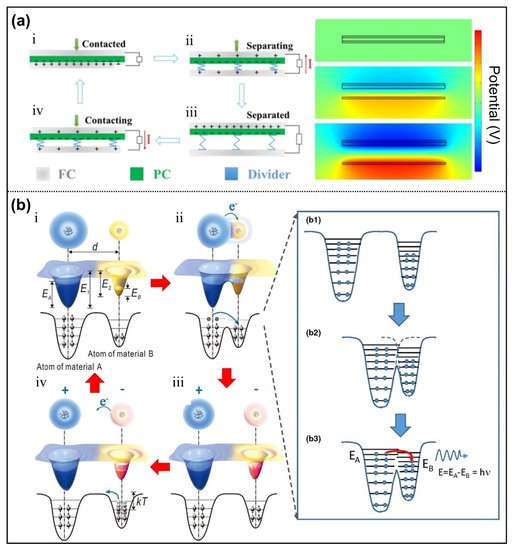

TENG is a new energy collection technology device proposed by Professor Wang in 2012 [29][30][29,30]. It can convert surrounding mechanical energy into electric energy by utilizing the dual effects of contact electrification (CE) and electrostatic induction (EI). Specifically, when two kinds of materials are in contact with each other under external force (Figure 2a(i),(iv)), the surface of the materials will produce positive or negative charges due to different polarities of triboelectric materials. When the two materials are separated (Figure 2a(ii),(iii)), the positive and negative static charges generated by contact electric charge are also detached, thus the induced potential difference is correspondingly produced on electrodes. If the two electrodes are in loaded or in a short-circuit state, the electrons driven by potential difference would flow in the external circuits, thus transform mechanic energy into electric energy. The difference in surface potential significantly affects the triboelectric property. In short, this CE phenomenon is closely related to electron transfer, which can be easily explained by the electron cloud/potential well mechanism (Figure 2b) [31]. Compared to piezoelectric nanogenerators (PENG) and pyroelectric nanogenerators, TENG have the advantages of high output power, a wide selection of materials, simple fabrication, low cost, and light weight [32][33][34][32,33,34]. In the past decade, TENG has attracted significant attention, and a number of research advancements have been accomplished in terms of device working mode design, physical mechanism disclosure, and study of practical applications.

Figure 2. Working mechanism of TENG. (a) Working models, which include: (i) original state, (ii) separating state, (iii) fully separated, (iv) contacting each other. Reprinted with permission from Ref. [35]. Copyright 2020 American Chemical Society. (b) The electron cloud/potential well mechanism for the contact-electrification phenomenon. Reprinted with permission from Ref. [31]. Copyright 2022 Elsevier.

Figure 3. The basic structure mode of TENGs. (a) Vertical contact-separation model. (b) Single-electrode mode. (c) Horizontal sliding mode. (d) Freestanding triboelectric-layer mode.