Since the mid-2010s, the circular economy has emerged as a key conceptual lever in corporate efforts to achieve greater environmental sustainability. Corporations have increasingly drawn upon the circular economy perspective in efforts to rethink sustainable supply chain management practices. This new corporate approach to sustainable supply chain management is evident in an emerging literature that has yet to be fully documented. In this systematic review of research, bibliometric methods were applied to a database of 709 Scopus-indexed documents.

- circular economy

- sustainable supply chain

- supply chain

- corporate sustainability

- bibliometric review

1. Introduction

[3]

[4]

[9]

[10]

[11]

[11]

2. Theoretical Background

Over the last three decades, supply chain management has become a key management discipline within the broader literature on managing for sustainability [1][2][18]. Sustainable supply chain management (S-SCM) addresses external pressures and incentives set by different stakeholder groups (e.g., government regulators, environmental and social movements, community members, and consumers) with respect to the production and consumption activities of companies and societies [18]. Researchers adopted Seuring and Müller’s (2008) definition of sustainable supply chain management as, “the management of material, information, and capital flows as well as cooperation among companies along the supply chain while taking goals from all three dimensions of sustainable development, i.e., economic, environmental and social, into account” (p. 1700).

Nimsai et al.’s (2020) review of research found exponential growth in publications on S-SCM since 2010 [19]. However, the Nimsai et al. (2020) review was concluded prior to the onset of the COVID-19 pandemic which challenged pandemic can be viewed as a new demarcation in the evolution of corporate sustainability strategies. This suggests the relevance of examining changes in sustainable supply strategies during this period of global economic disruption and highlights the need for identifying innovative approaches to existing management practices.

A review of research conducted by Türkeli and colleagues [20] found that the circular economy concept has been associated with related concepts such as industrial ecology [21], green and bio-economies [22], and sustainability [23]. The reverse supply chain, which emphasizes recovery of after-use products is at the interconnection of the circular economy and supply chain management concepts [24][25][26]. Value recovery at the end-of-product life can be performed by either original producers or other parties for the purposes of reuse, refurbishment, and recycling.

3. Results

3. Results

3.1. Growth Trend, Subject Areas, and Geographical Distribution of the Literature

The first documents that explicitly linked sustainable supply chain management (S-SCM) and circular economy were published in 2006 [28][29]. However, 2018 marked the beginning of exponential growth in articles that address the conjoint topics. One of the drivers explaining this pivot point is the adoption of sustainable development goals as part of the 2030 Agenda for Sustainable Development by United Nations member states in 2015 [30]. This agenda prioritized the circular economy and supply chain management as crucial means of achieving the 17 sustainable development goals (UN SDGs). Scholars from the United Kingdom, Italy, United States, India, and China have made the largest contributions to this literature.

3.2. High Impact Documents on Sustainable Supply Chain Management in a Circular Economy

The most highly cited documents in this knowledge base have focused on the conceptual integration of the core concepts (e.g., [31][32]), as well as on identifying relevant drivers, barriers, business models, practices, and strategies (e.g., [33][34]). The top-cited articles evidence a balance towards empirical studies (11 articles), when compared with conceptual (4) and review (4) articles. This suggests room for more conceptual development and reviews of research. For example, Winkler (2011) [35] introduced the sustainable supply chain network (SSCN) concept by moving from isolated applications of waste management in the production process to a closed-loop production system in which interacting companies work together to create a network for collecting and conditioning waste to be reused as resources. Winkler (2011) [35] emphasized that companies within an SSCN should involve those outside the same industry who can benefit from waste and use it as materials, as well as those providing know-how, technologies, and services in collecting, conditioning, or exchanging waste material.

The review conducted by Lüdeke-Freund et al. (2019) [34] identified 26 business models that derive from the integrated concepts (see also [36][32]). Govindan and Hasanagic (2018) [33] identified 34 practices carried out by enterprises after adopting a circular economy perspective on supply chain management. The review conducted by Kalmykova and colleagues (2018) [37] identified 45 circular economy strategies that can be applied by different actors in the value chain. These business models, practices, and strategies share similarities in terms of their enablers. However, these business models require clear performance measurement metrics in order to achieve desired systemic effects on the triple bottom line of corporate outputs. Notably, the literature suggests a current imbalance with social sustainability impact receiving less attention.

The empirical studies contained in the list of top-cited articles address production and consumption in a wide range of industries including aluminum, chemical, leather, building, construction, food, furniture, fashion, and electronics. Notably, however, only a single study focused on consumers [38]. Wang and Hazen (2016) examined the effect of remanufactured product knowledge on consumers’ perceptions and their purchase intent in China. They found that quality knowledge had the strongest effect on perception and purchase intention when compared with cost and green attributions. On the production side, empirical evidence captured by case studies and interviews underpins the integration of supply chain and circular economy concepts. For instance, Genovese et al. (2017) [24] provided evidence on emissions reduction through supply chain carbon mapping. Through four case studies, Geissdoerfer et al. (2018) [32] identified opportunities to reduce negative environmental and social impact through proactive multiple stakeholder management.

In addition, advanced technologies were studied as key enablers for sustainable production and supply chain management. For example, Pan et al. (2015) [39] reviewed waste-to-energy technologies and proposed strategies to implement waste-to-energy supply chains in a circular economy context. These included policy formation, economic schemes, performance evaluation measures, programs for social acceptance, and investment mobilization. Lopes de Sousa Jabbour et al. (2018) [40], Nascimento et al. (2019) [36], and Despeisse et al. (2017) [41] examined the applications of Industry 4.0 technologies such as additive manufacturing to manufacture products with 3D printers and treatment of waste for use as raw material.

3.3 Intellectual Structure of the Literature

The researcher co-citation map visualizes four schools of thought, which researchers have labeled Sustainable Supply Chain Management, Circular Economy, Sustainable Production and Environmental Management, and Reverse Supply Chain Management. The coherence of the clusters highlights the clarity of the literature’s conceptual structure. Though the smallest of the four schools of thought with five authors including Sarkis, Seuring, Carter, Zhu, and Lai, the central location and numerous links to other schools suggest that Sustainable Supply Chain Management is the conceptual anchor of this literature. The Circular Economy school, comprising 42 authors, is the largest of the four clusters. Key scholars in this cluster (e.g., Bocken, Geng, Ulgiati, Geissdoerfer, Ghisellini, Genovese) represent diverse fields including engineering, environmental science, science and technology, business and management, and sustainable development. The Sustainable Production and Environmental Management school comprises 18 authors, with key scholars including Mangla, Luthra, Jabbour, Gunasekaran and Kannan. Their research has focused on sustainable production, green manufacturing, production planning, optimization, and sustainable operations as well as environmental management. Recent publications have applied the circular economy concept explicitly to the production process [42][43][44][45]. The last cluster, Reverse Supply Chain Management, consists of 32 authors, led by Govindan, Van Wassenhove, Wang, Liu, and Guide. These authors span engineering, social sciences, business, and management. Their research has concentrated on reverse supply chain management, circular supply chains, waste management, and integrated reverse loop practices including reuse, remanufacturing, recycling, and product-service systems [46][47][48]. Notably, researchers school have also focused on the consumption side of supply chain management.

4. Discussion

The main contribution is to provide insights into how the conceptualization of sustainable supply chain management (S-SCM) is enriched through integration with the circular economy. It is confirmed that S-SCM in a circular economy is an emergent field of study. Moreover, researchers believe that stakeholder pressure for achieving the UN SDGs will continue to generate interest in this interdisciplinary field of research, policy, and practice [30][49][50][51].

Analysis of the top-cited documents highlighted the means through which the concept of the circular economy has transformed S-SCM strategies. This transformation is enabled by six reverse cycles of the circular economy: (1) repair and maintenance, (2) reuse and redistribution, (3) refurbishment and remanufacturing, (4) recycling, (5) cascading and repurposing, and (6) resource extraction [25][34]. Furthermore, these documents suggest that reframing supply chain management from a circular economy perspective has the potential to yield benefits at several levels.

At the macro level, countries can expect to achieve more rapid progress towards sustainable development goals related to resource security, emissions reduction, and landfill usage when supply chain management adopts circular economy principles [25]. At the meso level, industry collaboration can reduce resource scarcity and price volatility [40][52][53], lower harmful emissions [24][1], and increase support from communities through green operations and supply chain collaboration [26][35][54]. Collaboration creates the possibility for achieving the critical mass in operations that makes sustainable supply chain management economically viable for individual firms. At the micro level, adopting circular economy principles enables companies to position themselves with the right to operate in global markets, build brand reputation, create new revenue streams, and reduce business risks resulting from inventory and supply shortages [55][26][35][56]. Relevant metrics are reflected in environmental, social, and governance (ESG) goals that organizations develop and report. However, more attention needs to be given to the aggregation of corporate metrics from micro- to meso- level in the form of industry indexes and benchmarks, and in articulating linkage to the UN SDGs at the macro-level.

The top-cited studies also point towards the potential that Industry 4.0 technologies hold for leveraging circular economy principles in supply chain management. Technologies such as additive manufacturing, big data, artificial intelligence, blockchain, and cloud computing can be used to enhance resource recovery, reduce virgin material exploitation, and lower carbon emissions [42][41][37]. These technologies enable firms to gain greater precision in supply-demand forecasting, secure sustainable resources through circularity, and create new revenue streams from innovative products and services derived from circular economy strategies. Therefore, sustainable supply chain management enabled by advanced technologies has the potential to accelerate the transformation from linear to circular economy, and progress toward sustainable consumption and production [57][58].

The researcher co-citation map reframes sustainable supply chain management by connecting corporate practices to both production and consumption [27][59][60][61]. Nascimento et al. (2019) [37] asserted that supply networks must be circular in order to achieve sustainable production. Winkler (2011) [36] emphasized the need for all actors along the supply chain to co-operatively implement circular economy practices from production to consumption. The vital interdependency among circular economy, sustainable operations, and sustainable consumption is visualized on the map where sustainable supply chain management is located in the center linking the three concepts.

On the production side, studies revolve around the integration of circular economy and sustainable production and operations. The goal is to create self-sustaining production systems minimizing virgin material exploitation through waste recovery, reuse, and transformation [53][62][63]. In a circular economy, supply chain management practices recover waste which can be transformed into raw material for use in newly designed materials, products, and supply chains [64][65]. Such systems are enabled by cascading, repurposing, and extraction processes that are, in turn, driven by renewable energy [25][24][26].

Studies have also uncovered circular-economy-related supply chain practices that support sustainable consumption. These include infrastructure enabling maintenance and repair, redistribution and reuse, remanufacturing and refurbishment, and recycling services, education to change consumer attitudes and behaviors, and incentives in the form of competitive pricing achieved [39][49][59][60][66]. Both self-sustaining production systems and infrastructure that increases consumer awareness, involvement, and responsibility also offer possibilities for moving toward more sustainable consumption.

5. Implications

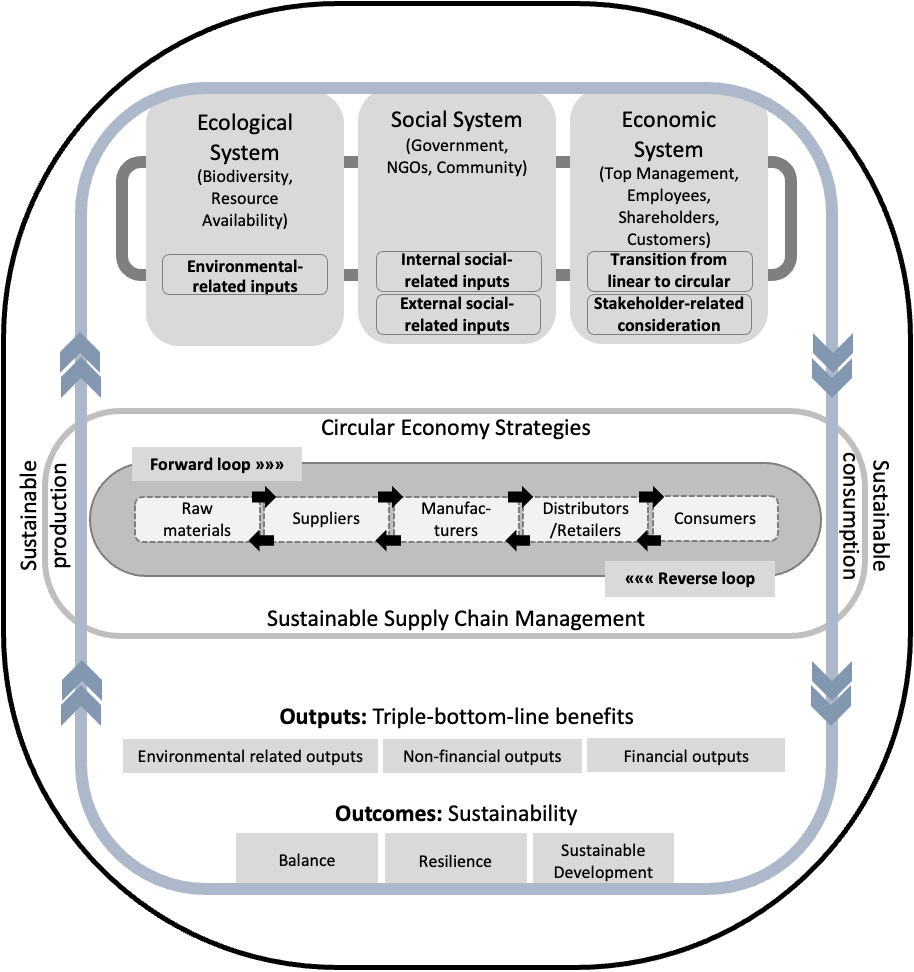

Drawing upon the findings, researchers have adapted Rebs, Brandenburg and Seuring’s (2019) [67] model of sustainable supply chain management in a circular economy model The original model included three key elements: circular supply chain, stakeholder engagement, and triple bottom line benefits. The proposed model expands the original Rebs et al. (2019) [67] model (Figure 1) to adopt a strategic perspective drawn from Suriyankietkaew and Petison’s (2020) [68] review of the literature on strategic management for sustainability. The integrated model incorporates macro-level environmental constituencies and pressures (e.g., global SDG movement, changing market demands, institutional policies) that can be viewed as drivers of change in sustainability policies and practices (i.e., balance, resilience, sustainable development) toward sustainable futures. The proposed framework may become a sustainable business model that provides pragmatic guidance toward corporate sustainability.

Figure 1. Proposed framework for sustainable supply chain in circular economy in the COVID-19 era.

Based on the enduring barriers identified in transitioning to a circular economy from supply chain management perspective [34][40][69], researchers identify several implications for policymakers. The most urgent tasks are the issuance of circularity policies, empowerment of enforcement bodies, and development of stronger, relevant performance management metrics. The launch of top-down initiatives in the forms of subsidies and tax benefits can reduce the burden of capital investment on eco-innovation for product/service redesign, production, and supply chain reconfiguration with reverse loops, and the deployment of advanced technologies. Along with these initiatives, a platform is needed that supports collaboration among different actors within and outside supply chains, enhances information sharing, and enables clearer benchmarking of progress and results. The launch of consumer education programs is needed to overcome attitudinal and behavioral barriers to the use of eco-products.

For practitioners, the proposed framework provides guidelines for evaluation of environmental impact, assessment of demand, and development of innovative strategies. Practitioners should seek to increase alignment between headquarters’ ESG goals and local ESG initiatives, particularly in multinational companies. There is evidence that can support managers in building a business case to secure budget for leveraging reverse loop practices in the supply chain.

Findings also suggest several directions for future research. First, future research can test and further refine the proposed framework. With the impact of COVID-19 pandemic, different countries and industries have their own challenges and priorities. It is imperative to validate the environment and consider different theories such as stakeholder theory and complexity theory. Second, it is found a geographical imbalance in the global literature, with limited research from developing countries. Thus, future studies should place greater emphasis on how developing nations are incorporating circular economy principles to refine supply chain management practices. Third, collaboration among actors within and outside supply chain has been highlighted as a crucial factor driving systems change [70][53][71][35]. Future research should look more in-depth into the duties and obligations of various supply chain participants. Finally, future studies are needed that examine the use of performance measurement metrics employed at micro, meso, and macro levels of S-SCM in a circular economy context. For example, research could investigate how ESG goals align with actions and how they are measured in relation to UN SDGs.

References

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457.

- Hallinger, P. Analyzing the intellectual structure of the knowledge base on managing for sustainability, 1982–2019: A meta-analysis. Sustain. Dev. 2020, 28, 1493–1506.

- Hallinger, P. A Meta-Synthesis of Bibliometric Reviews of Research on Managing for Sustainability, 1982–2019. Sustainability 2021, 13, 3469.

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710.

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114.

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341.

- Ansari, Z.N.; Kant, R. A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J. Clean. Prod. 2017, 142, 2524–2543.

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311.

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421.

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357.

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140.

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The circular economy: A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768.

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Change 2017, 115, 75–84.

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286.

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627.

- Bekrar, A.; El Cadi, A.A.; Todosijevic, R.; Sarkis, J. Digitalizing the Closing-of-the-Loop for Supply Chains: A Transportation and Blockchain Perspective. Sustainability 2021, 13, 2895.

- Cantini, A.; Peron, M.; De Carlo, F.; Sgarbossa, F. A decision support system for configuring spare parts supply chains considering different manufacturing technologies. Int. J. Prod. Res. 2022, 1–21.

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int J Inf Manage 2019, 49, 98–113.

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710.

- Nimsai, S.; Yoopetch, C.; Lai, P. Mapping the knowledge base of sustainable sup-ply chain management: A bibliometric literature review. Sustainability 2020, 12, 7348.

- Türkeli, S.; Kemp, R.; Huang, B.; Bleischwitz, R.; McDowall, W. Circular economy scientific knowledge in the European Union and China: A bibliometric, network and survey analysis (2006–2016). J. Clean. Prod. 2018, 197, 1244–1261.

- Saavedra, Y.M.B.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2017, 170, 1514–1522.

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734.

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The circular economy: A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768.

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357.

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32.

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384.

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2015, 18, 429–472.

- Winkler, H.; Kaluza, B. Sustainable supply chain networks—A new approach for effective waste management. WIT Trans. Ecol. Environ. 2006, 92, 10.

- Zhu, H. Strategic green supply chain based on circular economy—A new view for sustainable manufacturing in China. J. Wuhan Univ. Technol. China 2006, 28, 289–292.

- UN. Sustainable Development Goals: The 17 Goals; Department of Economic and Social Affairs of the United Nations (UN): New York, NY, USA, 2021; Available online: https://sdgs.un.org/goals (accessed on 25 November 2021).

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543.

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721.

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311.

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61.

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246.

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627.

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201.

- Wang, Y.; Hazen, B.T. Consumer product knowledge and intention to purchase remanufactured products. Int. J. Prod. Econ. 2016, 181, 460–469.

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421.

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286.

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Change 2017, 115, 75–84.

- Cesur, E.; Cesur, M.R.; Kayikci, Y.; Mangla, S.K. Optimal number of remanufacturing in a circular economy platform. Int. J. Logist. Res. Appl. 2020, 25, 454–470.

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Helo, P. Supplier relationship management for circular economy: Influence of external pressures and top management commitment. Manag. Decis. 2019, 57, 767–790.

- Lopes de Sousa Jabbour, A.B.; Rojas Luiz, J.V.; Rojas Luiz, O.; Jabbour, C.J.C.; Ndubisi, N.O.; Caldeira de Oliveira, J.H.; Junior, F.H. Circular economy business models and operations management. J. Clean. Prod. 2019, 235, 1525–1539.

- Yadav, G.; Mangla, S.K.; Bhattacharya, A.; Luthra, S. Exploring indicators of circular economy adoption framework through a hybrid decision support approach. J. Clean. Prod. 2020, 277, 124186.

- Govindan, K.; Agarwal, V.; Darbari, J.D.; Jha, P.C. An integrated decision making model for the selection of sustainable forward and reverse logistic providers. Ann. Oper. Res. 2019, 273, 607–650.

- van Loon, P.; Van Wassenhove, L.N. Assessing the economic and environmental impact of remanufacturing: A decision support tool for suppliers. Int. J. Prod. Res. 2018, 56, 1662–1674.

- Wang, Y.; Yuan, Z.; Tang, Y. Enhancing food security and environmental sustainability: A critical review of food loss and waste management. Resour. Environ. Sustain. 2021, 4, 100023.

- Asif, M.; Searcy, C.; Zutshi, A.; Fisscher, O.A. An integrated management systems approach to corporate social responsibility. J. Clean. Prod. 2013, 56, 7–17.

- Bocken, N.M.P.; Short, S.W. Unsustainable business models—Recognising and resolving institutionalised social and environmental harm. J. Clean. Prod. 2021, 312, 127828.

- Seuring, S.; Gold, S. Sustainability management beyond corporate boundaries: From stakeholders to performance. J. Clean. Prod. 2013, 56, 1–6.

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989.

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. J. Clean. Prod. 2017, 155, 54–65.

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602.

- Zhu, Q.; Geng, Y.; Lai, K.-H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331.

- Ibn-Mohammed, T.; Mustapha, K.B.; Godsell, J.; Adamu, Z.; Babatunde, K.A.; Akintade, D.D.; Acquaye, A.; Fujii, H.; Ndiaye, M.M.; Yamoah, F.A.; et al. A critical analysis of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies. Resour. Conserv. Recycl. 2021, 164, 105169.

- Suriyankietkaew, S.; Nimsai, S. COVID-19 Impacts and Sustainability Strategies for Regional Recovery in Southeast Asia: Challenges and Opportunities. Sustainability 2021, 13, 8907.

- Gülserliler, E.G.; Blackburn, J.D.; Van Wassenhove, L.N. Consumer acceptance of circular business models and potential effects on economic performance: The case of washing machines. J. Ind. Ecol. 2022, 26, 509–521.

- Wang, Y.; Hazen, B.T.; Mollenkopf, D.A. Consumer value considerations and adoption of remanufactured products in closed-loop supply chains. Ind. Manag. Data Syst. 2018, 118, 480–498.

- Jia, J.; Xu, S.H.; Guide, V.D.R., Jr. Addressing Supply-Demand Imbalance: Designing Efficient Remanufacturing Strategies. Prod. Oper. Manag. 2016, 25, 1958–1967.

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698.

- Belhadi, A.; Kamble, S.; Gunasekaran, A.; Mani, V. Analyzing the mediating role of organizational ambidexterity and digital business transformation on industry 4.0 capabilities and sustainable supply chain performance. Supply Chain Manag. Int. J. 2021.

- Kamble, S.S.; Belhadi, A.; Gunasekaran, A.; Ganapathy, L.; Verma, S. A large multi-group decision-making technique for prioritizing the big data-driven circular economy practices in the automobile component manufacturing industry. Technol. Forecast. Soc. Change 2021, 165, 120567.

- Jabbour, C.J.C.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177.

- Wang, Y.; Yin, X.; Du, Q.; Jia, S.; Xie, Y.; He, S. Consumers’ green preferences for remanufactured products. In Recent Advances in Intelligent Manufacturing. ICSEE IMIOT 2018. Communications in Computer and Information Science; Springer: Singapore, 2018; Volume 923, pp. 332–342.

- Rebs, T.; Brandenburg, M.; Seuring, S. System dynamics modeling for sustainable supply chain management: A literature review and systems thinking approach. J. Clean. Prod. 2019, 208, 1265–1280.

- Suriyankietkaew, S.; Petison, P. A Retrospective and Foresight: Bibliometric Review of International Research on Strategic Management for Sustainability, 1991–2019. Sustainability 2020, 12, 91.

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2020, 243, 118360.

- Ansari, Z.N.; Kant, R. A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J. Clean. Prod. 2017, 142, 2524–2543.

- Galvão, G.D.A.; Homrich, A.S.; Geissdoerfer, M.; Evans, S.; Ferrer, P.S.S.; Carvalho, M.M. Towards a value stream perspective of circular business models. Resour. Conserv. Recycl. 2020, 162, 105060.

- Galvão, G.D.A.; Homrich, A.S.; Geissdoerfer, M.; Evans, S.; Ferrer, P.S.S.; Carvalho, M.M. Towards a value stream perspective of circular business models. Resour. Conserv. Recycl. 2020, 162, 105060.