Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Suchao Xie and Version 2 by Jessie Wu.

The sound of trains is considered a disturbance to most residents around the railroad and train passengers, and the sound generated by trains can interfere with sleep, life, and work. With increases in train speed, the main noise from high-speed trains has changed from rolling noise to aerodynamic noise, and the noise level and noise frequency range have also changed significantly. The current methods of noise reduction for trains are discussed.

- high-speed train

- noise control

- sound

1. Traditional Noise Control Methods for High-Speed Trains

1.1. Train Vibration Reduction

High-speed trains will inevitably impose a greater impulse on railroad infrastructure, causing an increase in the vibration intensity of the infrastructure and the environment along the railroad line [1][66]. Under the action of the cyclic force caused by high-speed trains, excessive vibration amplitudes can damage the infrastructure, while this vibration also generates much noise, affecting the safety, comfort, and stability of train operation [2][67].

At present, the main active isolation measures and passive isolation are adopted to reduce high-speed train vibration and thus control high-speed train noise. Active isolation measures include floating slabs [3][68], highly resilient rail pads [4][69], and high-performance wheels [5][70]. All these measures can directly reduce the vibration of the train to a large extent. Passive isolation measures include open trenches and soft-filled barriers [6][71]. Although the above measures show a good damping effect, damping to reduce the actual engineering problems related to noise still faces certain difficulties due to the huge mass and fast speed of high-speed trains.

1.2. Train Body Sound Insulation

The noise inside the high-speed train is mainly transmitted from outside. The sound source and vibration excitation outside the train can be transmitted to the inside of the train through two main paths: airborne sound and structural sound transmission, thus forming the noise inside the train [7][72]. Therefore, improving the sound insulation performance of the high-speed train carriage panel structure is conducive to improving the acoustic environment inside the car. The train carriage panels are mainly extruded aluminum profile structures (floor, roof, and sidewalls) and double-plate cavity structures (windows). At present, extruded aluminum profiles are the main sheet structure of high-speed train bodies, and their acoustic performance is one of the important factors influencing the acoustic environment inside the vehicle.

Due to the special structural form of extruded aluminum profiles, their sound insulation performance is poor. Improving the sound insulation performance of aluminum profiles is a key focus of much research in academe. Xin et al. [8][73] studied the sound insulation characteristics of orthogonally rib-stiffened sandwich structures and corrugated core sandwich structures and the mechanism of sound radiation during the vibration of these structures. Xie et al. [9][74] developed an acoustic model of the statistical energy method for the amount of sound insulation of extruded profiles, and the model was able to favorably predict vibration excitation. Kim et al. [10][75] improved the sound insulation performance of aluminum profiles by filling. Qin et al. [11][76] employed an optimized finite element energy statistics method (FE-SEA) and verified its efficacy. Li et al. [12][77] used a waveguide finite element (2.5-d FE) model combined with the energy statistics method to investigate the sound insulation model of extruded aluminum profiles. Zhang et al. estimated the coupling loss factors between the structure and cavity and established a statistical energy analysis model to make predictions of bogie noise and bottom plate sound transmission. Based on the model, they developed a program that can quickly design the internal panel structure of a train and proposed a model that can predict the sound absorption and insulation characteristics of the composite bottom panel of a train [13][14][78,79]. Thereafter, they proposed to improve the noise insulation of the train by adding high-damping rubber and water-based damping as a coating to the train floor [15][16][80,81].

For the double-plate cavity structure of the window part of the train, Xin et al. [17][82] systematically studied the sound insulation characteristics of the finite and infinite double-plate cavity structure using the wave propagation method. Zhang et al. [18][83] established and validated their sound transmission loss model of the window by measuring the vibration and the interior noise level of a window of a high-speed train.

1.3. Railroad Sound Barriers

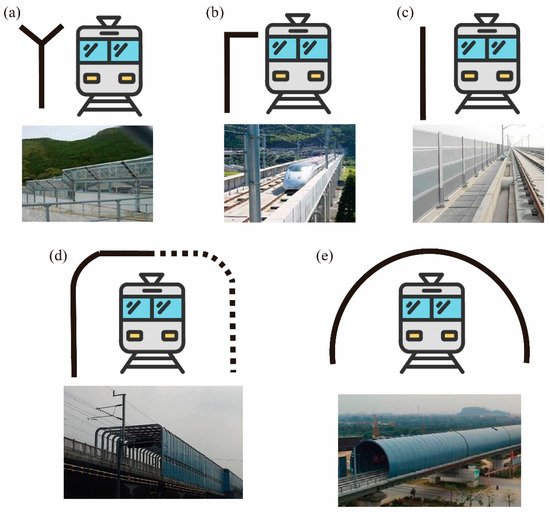

A sound barrier featuring easy installation and obvious noise reduction is an important method of traffic-noise management, which has been widely used and developed throughout the world [19][84]. Sound barriers mainly include wide top types, semi-enclosed types, fully enclosed types, etc. The diversity of sound barriers makes it possible to have different classification methods, which are based on appearance, line form, material, acoustic performance, structural form, etc. According to the differences in line form, the sound barriers can be classified into bridge sound barriers and road sound barriers; according to the differences in unit plate material, the sound barriers are classified into metal and non-metal sound barriers. As shown in Figure 1, the common structures of sound barriers are upright insert types, T types, inverted L types, Y types, multiple edge types, etc. [20][85]. In practical application, insert-type sound barriers are most widely used. May et al. [21][86] used proportional model experiments to compare the noise reduction effects of upright, T-shaped, and Y-shaped sound barriers and proposed, for the first time, that T-shaped sound barriers provide the best noise reduction effects. Defrance et al. [22][87] simulated the noise reduction effect of T-shaped sound barriers with sound-absorbing materials using the boundary element method and undertook experimental verification thereof. Baulac et al. [23][88] improved the acoustic performance by providing slots at the top of T-shaped sound barriers and optimizing the form and disposition of the slots using genetic algorithms. Oldham et al. [24][89] investigated the factors affecting the noise reduction effect of T-shaped sound barriers using numerical calculations and found that the additional noise reduction of the top structure is related to the locations of the source and receptor of the sound and the location and height of the sound barrier. Venckus et al. [25][90] studied the roof-inclination angle of upright-type sound barriers and found that the sound barrier was most effective in reducing high-frequency sound waves when the roof inclination angle was 120°. Zhang et al. [26][91] proposed a semi-enclosed sound barrier with slits and verified its sound insulation effect. At present, sound barriers provide good control of environmental noise along the railroad, but the noise frequency band they control is singular, and because most of them are reflective sound barriers, they will aggravate the noise inside the train instead.

Figure 1.

(

a

) Y-shaped sound barrier; (

b

) inverted L-shaped sound barrier; (

c

) upright type sound barriers; (

d

) semi-enclosed sound barrier; (

e

) fully enclosed sound barrier.

2. Acoustic Metamaterials Applied to High-Speed Train Noise Control

After the train speed is increased to 600 km/h, the aerodynamic noise and wheel-rail noise will be significantly increased, and the noise-reduction ability of the traditional extruded aluminum profiles used in the body of high-speed trains, the sound barriers along the railroad line, and the polyurethane foam materials laid inside the car body are all stretched to their operational limit. When traditional materials and structures fail to meet the needs of high-speed train development, acoustic metamaterials with exotic characteristics will become an important means by which to solve the noise problems associated with high-speed trains.

2.1. Definition and Development History of Acoustic Metamaterials

The term “metamaterial” is commonly used to describe artificial composites consisting of periodic or randomly arranged artificial subwavelength structures, a concept first introduced by Veselago in 1968 in the field of electromagnetism [27][92]. The emergence of electromagnetic metamaterials sharpens researchers’ understanding of metamaterial theory, and the concept of metamaterials was also introduced in the fields of optics, mechanics, and heat transfer. The concept of acoustic metamaterials can be traced back to Narayanamurti [28][93], who first discovered that periodic structures could be used to control high-frequency phonon propagation but did not refer to such periodic structured materials as acoustic metamaterials. In 2000, Liu et al. [29][94] designed a small ball made of high-density lead wrapped in rubber and then proposed the theory of locally resonant phonon crystals using this model, opening the door to the study of acoustic metamaterials. After this, acoustic metamaterials have been further developed by artificially designing microstructures to allow materials to present limitations beyond their original natural laws. This can realize a series of idiosyncratic material functions, including acoustic stealth [30][95], acoustic directional transmission [31][96], acoustic negative refraction [32][97], acoustic focusing [33][98], low-frequency sound absorption [34][99], and so on. At present, acoustic metamaterials have been applied to solve engineering problems such as aircraft cabin noise reduction, automotive NVH, and building facades and have achieved better vibration and noise suppression effects [35][100].

Metamaterials often have different properties from those of traditional materials. For natural materials, material parameters such as mass density, Young’s modulus, and Poisson’s ratio are positive in the natural case, while for artificial structures, effective material parameters may become negative within a specific frequency range. Some mechanical metamaterials have been applied in the field of energy-absorbing structures and body structures of high-speed trains [36][37][101,102], and the application of metamaterials to reduce railroad noise will be one of the important means of dealing with the noise problem associated with future high-speed trains.

2.2. Metamaterials Applied to Railroad Sound Barriers

At present, railroad sound barriers are mainly upright insert-type sound barriers. The wind pressure fluctuations, when passing through such sound barriers, can lead to the loosening and breaking of bolts and the destruction of sound barrier panels [38][103]. When designing high-speed railroad sound barriers, not only should the sound insulation and sound absorption characteristics of the barrier be considered, but also the dynamic response of the sound barrier structure. Conventional sound barriers produce sound reflections that lead to increased noise levels within high-speed trains. For future high-speed railroad sound barriers, they inevitably need to meet codified sound insulation criteria and, at the same time, have both ventilation and noise absorption capabilities.

There is always a balance between the thickness of a sound insulation device and its ventilation capacity. Zhang et al. [39][104] designed a binary structure consisting of a coiled unit and a hollow tube with a thickness of less than one-fifth of the wavelength, which can block low-frequency sound from different directions while allowing 63% of the airflow to pass through. Wu et al. [40][105] designed a vented metamaterial absorber operating at low frequencies (<500 Hz) with only two absorption units, achieving high-efficiency absorption under vented conditions by using weak coupling of two identical split-tube resonators. Huang et al. [41][106] combined spiral channels and embedded apertures; this metamaterial structure can absorb low-frequency noise while maintaining the requisite thickness. Ghaffarivardavagh et al. [42][107] proposed a deep sub-acoustic wavelength metamaterial cell that includes nearly 60% of the open area allowing passage of air and also serves as a high-performance selective sound muffler. Wang et al. [43][108] proposed an acoustic metamaterial composed of many cells, and this open metamaterial contains a large hole in each cell to ensure airflow. Kumar et al. [44][109] integrated eight labyrinth cells of different configurations to form an acoustic metamaterial and introduced a herringbone channel to achieve ventilation. Xie et al. [45][110] proposed a metamaterial with a conchoidal cavity structure and embedded this metamaterial into a conventional concrete or metal sound barrier, which can significantly improve the sound absorption capacity of the sound barrier and prevent sound pollution of the surrounding high-rise buildings by high-speed railroads.

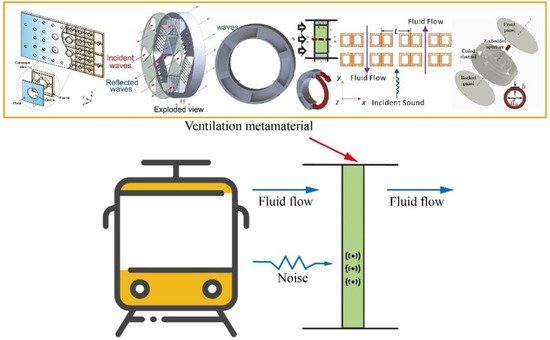

As shown in Figure 2, acoustic metamaterials can ensure better sound insulation and absorption effects under ventilation, but they have not been widely used in sound barriers due to their complicated production process and high cost of production. To increase the potential for wider engineering applications of acoustic metamaterials, researchers should further simplify their structure while considering the production cost in the design process and, furthermore, fit the specific use scenario for optimization.

Figure 2.

Acoustic metamaterials with ventilation properties applied in sound barrier.

2.3. Application of Metamaterials in Train Car Bodies

At present, the car body of high-speed trains is mainly fitted with a mixture of damping pulp and fibrous materials as sound insulation and vibration damping materials. At present, the train body shows poor sound insulation and absorption ability, especially for the long wavelengths of low-frequency noise, which passes more easily through the body structure and body gaps into the train interior. This impairs the quality of the acoustics within the train interior and adversely affects passenger comfort.

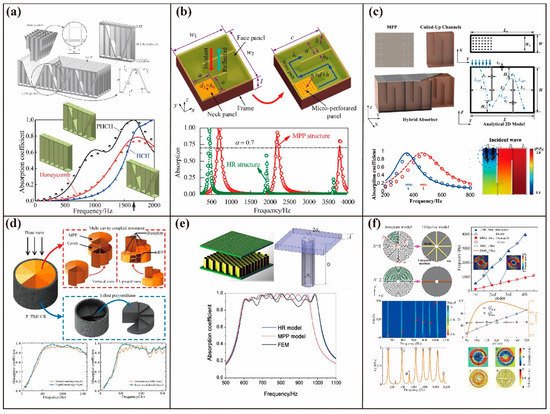

As shown in Figure 3, scholars have explored the application of acoustic metamaterials in engineering. Li et al. [46][111] combined microperforated plates and embedded partitions to design a controllable broadband acoustic unit with a thickness of only 70 mm. Liu et al. [47][112] added a separator plate with micro-perforations inside the cavity of a common Helmholtz resonator to demonstrate the absorber a multi-order absorption capability and expanded the absorption bandwidth of the absorber by combining eight absorbers. Long et al. [48][113] designed a multi-band quasi-perfect absorber constructed by a double-channel Mie resonator, which is more flexible, to achieve multi-band quasi-perfect absorption. The combination of labyrinth structure and micro-perforated plate structure often can produce better sound absorption. The labyrinth structure can partition the cavities, while the combination of different cavities and perforated plates can yield acoustic metamaterials with a wider frequency range. Zhang et al. [49][114] designed an acoustic metamaterial consisting of a single-hole plate and a labyrinth cavity combination, which achieved good sound absorption in the low-frequency range. Liu et al. [50][115] investigated an acoustic metamaterial that achieved nearly perfect sound absorption in the range of 380 to 3600 Hz by combining a variety of different micro-hole plates and labyrinth cavities. The honeycomb structure is the best topology covering two-dimensional planes with good mechanical properties and is often used as the core structure of high-speed train underlayment. Tang et al. [51][116] modified the traditional honeycomb sandwich panel by introducing micro-pores based on the honeycomb-corrugated hybrid core to acquire an acoustic metamaterial with good sound absorption in the low-frequency range. Peng et al. [52][117] designed a composite honeycomb structure by combining different microporous and honeycomb cavities to fabricate an acoustic metamaterial with 90% sound absorption in the range of 600 to 1000 Hz. Wang et al. [53][118] proposed a NOMEX honeycomb metamaterial with acoustic absorption capability based on NOMEX honeycomb, which can achieve quasi-perfect absorption against noise in high-speed train motion. Wu et al. [54][119] designed a hybrid metamaterial absorber based on a microperforated plate and a coiled Fabry channel, which can achieve more than 99% sound absorption at the resonant frequency (<500 Hz) of acoustic absorption. Xu et al. [55][120] designed a metamaterial consisting of three holes and three cavities connected in parallel and investigated the effects of different temperatures on its acoustic absorption. Xie et al. [56][121] added polyurethane material to the acoustic metamaterial composed of microporous plates and cavities to achieve continuous ultra-broadband acoustic performance.

Figure 3. (a) Schematic of perforated honeycomb-corrugation hybrid (PHCH) metamaterial [51][116]. (b) Schematic of the broadband metamaterial unit [50][115]. (c) Schematic diagram of a hybrid absorber with microperforated plates and coiled channels [54][119]. (d) Schematic representation of a tunable multi-cavity coupled-resonator with polyurethane-filled slits [56][121]. (e) Schematics of the composite honeycomb sandwich panels [52][117]. (f) Multiband quasi-perfect low-frequency sound absorber based on double-channel Mie resonator [48][113].

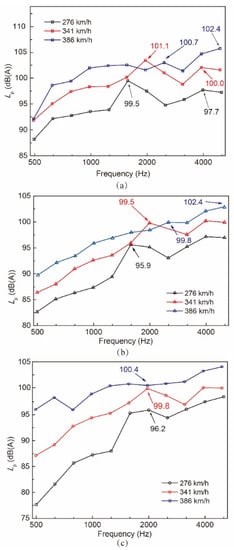

Figure 4 analyzes the main noise sources of high-speed trains, and it can be found that the wheel-rail area noise, pantograph noise, and inter-coach gaps noise all rise to a great extent as the speed of high-speed trains increases. Among the three main noise sources, the pantograph noise increases most significantly with speed, and when the speed reaches 386 km/h, its main noise level exceeds that of the wheel-rail area and inter-coach gaps. The frequency variation of the main noise sources also deserves attention; compared with the noise in the range of 2000 Hz–4000 Hz, the improvement is more obvious in the range of 500 Hz–2000 Hz. The pantograph noise changes more significantly with speed, and the noise level in the 500 Hz–1500 Hz range reaches nearly 100 dB(A) after the speed reaches 386 km/h. The significant increase in noise levels in the mid-frequency and low-frequency can seriously affect passenger comfort.

Figure 4.

The main noise frequencies characteristics of high-speed trains: (

a

) wheel-rail area; (

b

) inter-coach spacing; (

Traditional acoustic materials mainly use porous structures, such as acoustic sponges, felt, glass fiber, polyurethane foam, etc. When sound waves pass through the pores of various materials, their kinetic energy is converted into thermal energy, leading to the dissipation of sound wave energy to attenuate noise; however, porous materials have poor absorption capacity for low-frequency noise, and the material thickness is strictly limited due to the size of the train, which makes it difficult for the current acoustic insulation car body design to deal with low-frequency noise. In contrast, metamaterials, with their unique material properties, can absorb low-frequency noise while maintaining a small thickness.

According to the latest research on acoustic metamaterials shown in Figure 3, it can be found that acoustic metamaterials can cope with low-frequency and mid-frequency noise better and ensure a high noise absorption level in a thinner case. Figure 3d,e of the absorption coefficient curve can be found that in acoustic metamaterials in a wide range of frequencies, the sound absorption ability can reach more than 80%, and this acoustic characteristic can just meet the noise problems faced by high-speed trains. At present, acoustic metamaterials have been widely used in the fields of aerospace, ships, automobiles, and buildings. It is believed that acoustic metamaterials, with their excellent acoustic properties, will also become an important measure to solve the noise problem of high-speed trains.