Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Beatrix Zheng and Version 3 by Beatrix Zheng.

In view of EU environmental policy, reducing energy consumption, developing energy-saving technologies and solutions, and reducing pollutant emissions are immensely relevant concerns. Waste heat recovery (WHR) systems enable these tasks to be achieved, and the favorable global situation implies that solutions for waste heat recovery from gas-fired radiant heaters for large-hall heating should attract the interest of many stakeholders.

- low-emission technologies

- luminous local space heater

- waste heat

1. WHR Potentiality

Wherever goods are produced, thermal processes are carried out, machines and equipment are operated, and waste heat is generated and released into the environment by radiation, convection, conduction, or in the form of cooling fluids, exhaust gases, steam, or air [1][2]. Sensible and latent heat that is generated during these processes but is not their target is defined as waste heat. For industrial processes, the waste heat that is generated is defined as industrial waste heat, while that from processes associated with the operation of residential and public buildings is called commercial waste heat [3]. The potential for waste heat utilization may be considered as: theoretical (physical) potential, technical potential and economic (feasible) potential [4][5][6][7].

The theoretical potential analyses the occurrence of waste heat in the physical sense as heat with a source above ambient temperature, and it does not consider the possibility of recovering and using this heat. The technical potential, on the other hand, defines the possibility of recovering and using waste heat, and then technological solutions are considered. The technical constraints are, for example: the minimum temperature for a recovery system operation or temperature reduction due to heat transfer. The technical potential for waste heat utilization is determined by boundary conditions and requires the description of technology and determination of the heating or cooling demand. In addition, the technical potential can also be divided into the theoretical technical potential and the applicable technical potential. The first is calculated by means of a theoretical process analysis and the second is calculated on the basis of data, taking into account all the parameters that are specific to the recovery process under analysis. When considering the economic potential, also called feasible potential, financial parameters such as energy prices, interest rates and payback periods are considered [5][6].

In line with current efforts to reduce CO2 emissions and increase energy efficiency in appliances and buildings, the use of waste heat recovery systems plays an important role and technical solutions in this area are one of the main areas of research. It is considered that, in certain solutions, waste heat recovery (WHR) systems can be more economical than renewable energy installations [1][7]. The potentiality for industrial WHR in countries in the European Union is displayed in Ref. [8].

Solutions for waste heat recovery systems can be based on the following devices: heat pipes; heat pumps: air/air, water/air, air/water, water/water; regenerators in furnaces; recuperators; rotary heat exchangers; plate heat exchangers; shell and tube heat exchangers; economizers; spiral-type heat exchangers; and water-tube boilers [8][9][10][11][12].

The design of an optimal heat recovery system depends on many factors, while the key factor is the temperature of the waste heat carrier, which can be divided into three ranges: low temperature for temperatures below 100 °C; medium temperature for temperatures between 100 °C and 400 °C; and high temperature for temperatures above 400 °C [11]. For each temperature range of the waste heat carrier, the incorporation of a heat recovery system is possible by using an appropriate recovery unit. In some cases, the waste heat is divided according to additional temperature criteria. Considering the waste heat from the flue gases, by temperature it can be classified into ranges: low—for temperatures below 230 °C; medium—for temperatures between 230 °C and 650 °C; and high—for temperatures above 650 °C [1][9].

2. Gas Radiant Heaters

Infrared gas heaters are primarily installed to heat the entire interior of a large building, a separate area, or to heat up a workstation [13][14][15]. Ceramic radiators can also be used outdoors to heat sports stands, train station platforms or to defrost ramps. In addition to the heating function, they can be used, among other things, to dry thin layers of loose materials and paint coatings (on the product surface) in the brick and ceramics industry.

Radiant gas heaters are most commonly used in warehouses, logistics centers and production halls. They are also known to be used in aircraft hangars and shelters, auditoriums and sports facilities in the United States, as well as in indoor swimming pools, wholesale and retail pavilions, livestock buildings and breeding farms, greenhouses, churches, and public transport vehicle depots [1][14][15]. The heating of living and office spaces with gas-fired radiant heaters is not permitted. They must not be implemented in rooms where flammable materials are stored and where substances forming explosive mixtures, flammable gases, dust and vapors are produced or stored.

The main division of gas infra-red heaters is determined by their construction; therefore, based on the method of combustion of the air–gas mixture and the flue gases removal, infra-red heaters can be divided into: high-intensity, so-called ceramic or luminous radiators; and low-intensity radiant tube heaters, so-called dark radiant tube heaters. The main difference in their design is where the combustion of the air–gas mixture occurs: in tube heaters it takes place inside the tube, while in ceramic heaters it takes place on the surface of the ceramic plate [13][15].

Ceramic radiant heaters are less popular than tubular radiant heaters, but sometimes they can be the better, or only, solution. They can be mounted on columns or vertical partitions so that they do not burden roofs, and they do not require the installation of chimneys due to the discharge of flue gases into the room. Ceramic radiant heaters are also easier to access for annual maintenance. Some types have a higher radiant efficiency, not achievable with tubular radiant heaters, which also require a supply of clean air for combustion. However, the dustiness of the air outside the hall can be so high that it is impossible to supply it to the tube heater. It then becomes necessary to use only ceramic radiant heaters, which draw air from inside the hall, supplied from outside through appropriate filters. The criterion for dividing gas infrared heaters can also be the type of infrared heater power control. Some models have automatic burner control and a manual heat-output setting with a potentiometric controller. Automatic modulation of the burner is possible in various power ranges, e.g., from 50 to 70% [15][16].

The radiation factor Rf is a parameter that determines the quality of the radiant heater and the energy consumption. It is defined as the ratio of heat that is emitted from the device by the reference radiation plane to the heat load, which is related to the calorific value of the gas that is used in the test. It is determined depending on the type of radiant heater, based on the guidelines that are contained in two standards: PN-EN 419-2 and PN-EN 416-2. The radiant factor Rf of ceramic radiant tube heaters that are available on the market ranges from 60.6% to 80.9%, while for tube heaters the range is from 55% to 83% [17].

Appliances placed on the market that comply with eco-design requirements are described by parameters according to Regulation 2015/1188:

-

Seasonal energy efficiency of space heating ηs, %—the ratio between the demand for space heating that is provided by the on-site space heater and the annual energy consumption that is required to meet that demand;

-

Nitrogen oxides emissions, mg/kWhinput–nitrogen oxide emissions at a rated heat output based on GCV (gross calorific value moisture free) for gaseous or liquid-fuel space heaters and commercial space heaters.

Table 1, in accordance with Annex II of Regulation, sets out the specific eco-design requirements for commercial space heaters.

Table 1. Eco-design requirements for gas heaters acc. to Ref. [18].

| Seasonal Energy Efficiency of Space Heating by Infrared Heater ηs, % |

Emissions of Nitrogen Oxides by the Ceramic and Tube Radiant Heater, mg/kWhinput | |

|---|---|---|

| Ceramic | Tube | |

| 85 | 74 | 200 |

The temperature of the exhaust gases at the exit of a tubular radiant heater depends on its type and efficiency. For highly efficient tube heaters (with radiation efficiency ηR = 72%), the temperature of the exhaust gases at the exit of the heater is slightly less than 200 °C, while for heaters with lower efficiency (ηR = 52–59%), the temperature of the exhaust gases is approximately 350 °C. On the other hand, the temperature on the surface of the ceramic panel of a luminous radiant heater can reach a value of up to 1200 °C. Moreover, the screen of a ceramic radiant heater with lower efficiency heats up to high temperatures, generating heat by convection and radiation [19]. Radiant heaters can be equipped with modulating burners, with power controlled depending on the external or internal temperature, which results in savings in gas consumption.

3. Flue-Gases Heat Recovery of Gas Radiant Heaters

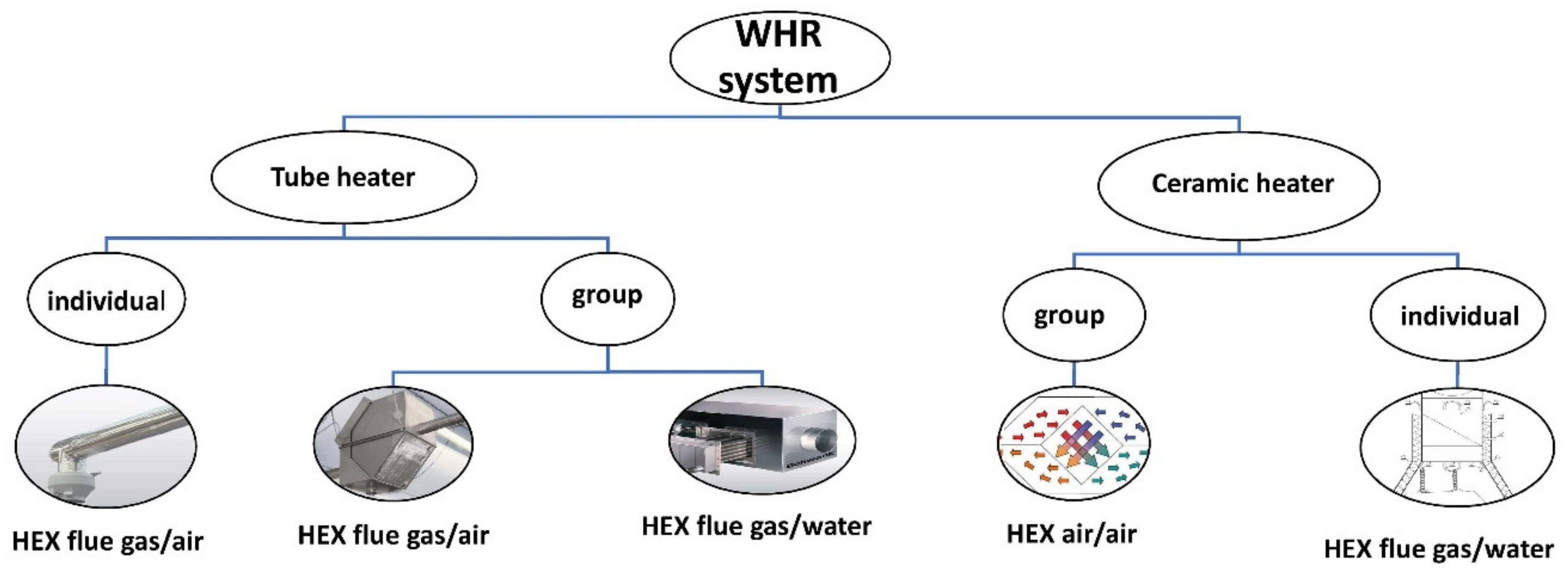

Waste heat recovery systems for gas infrared heaters using flue-gas/water, flue-gas/air and air/air heat exchangers have appeared on the market, providing additional economic benefits. They can be designed for a single unit (individual) or a group (collective) of units [16][20]. Figure 1 shows a new graph presenting the division of heat recovery systems from the flue-gas of gas radiant heaters with exemplary heat exchangers.

Figure 1. WHR systems from flue-gas of gas-fired radiant heaters.

The recovery systems shown in Figure 1 can be divided into:

-

With a flue-gas/air heat exchanger dedicated to individual radiant tube heaters;

-

With a flue-gas/air heat exchanger dedicated to a group of radiant tube heaters;

-

With a flue-gas/water heat exchanger dedicated to radiant tube heaters;

-

With an air/air heat exchanger dedicated to ceramic radiant heaters;

-

With a flue-gas/water heat exchanger dedicated to ceramic radiant heaters.

The characteristics of four of these systems have been widely described by the authors in publications [1][9][16][19].

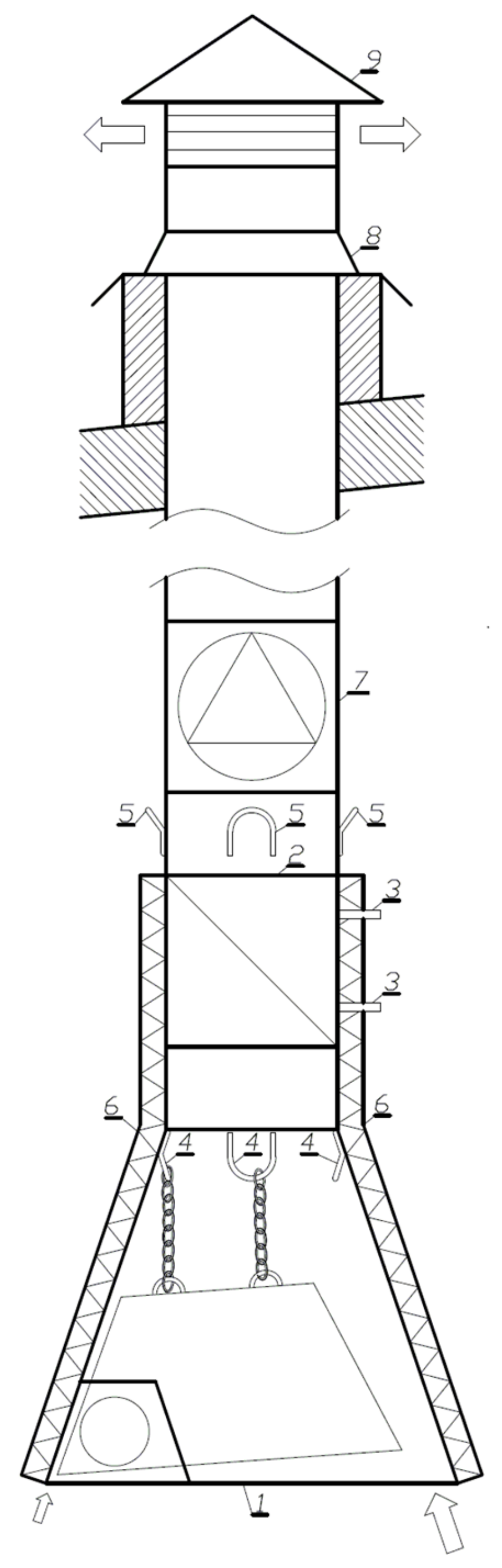

The fifth system with an exhaust gas/water heat exchanger dedicated to a single ceramic radiator, presented in detail in Figure 2, is the authors’ innovative solution described in the patent application [21]. Its working principle is described below.

Figure 2. System for heat recovery from ceramic gas heater: 1—hood; 2—heat exchanger; 3—connections for medium; 4—brackets to fix radiators; 5—brackets to fix hood; 6—insulation; 7—fan, 8—roof base, 9—roof ejector [21].

The Innovative WHR Solution

The system for waste heat recovery and the removal of pollutants from ceramic gas radiators, according to the invention [21], is characterized by the fact that it has the form of a hood located above the ceramic gas radiant heater, into which a heat exchanger is integrated, whereby the ceramic gas radiant heater under the hood is fixed at an angle to the floor level, and its lower edge is located above the edge of the hood. In the multi-row cross-flow finned heat exchanger that is installed in the hood, the heat from the air/flue-gas mixture stream is transferred to the liquid working medium. The channel exhaust fan is fixed in the flue-gas duct. The cooled flue gases are discharged through a duct to the roof-mounted ejector.

4. Environmental Outlook

The environmental impact of heating systems is indisputable, especially in buildings in the industrial sectors. The importance of the effect of a heating system can be detected by measuring and comparing the emissions of each source and their toxicity.

Environmental pollution varies significantly between seasons, and the critical impact of heating systems makes it very high in winter. When determining this impact, the emissions of CO, CO2, NOx, SO2, PMs, N2O, CH4, volatile organic compounds, polycyclic aromatic hydrocarbons and aldehydes are typically analyzed. These emissions depend mainly on the type of heat source that is used in the heating system. Generally, the heat sources can be coal, wood, natural gas, diesel oil, solar energy, bioenergy, geothermal energy and waste heat [22].

In the heating systems that are analyzed in this research, the main source of pollutant emissions is the combustion of natural gas. In such systems, additional emission are usually caused by electricity consumption for auxiliary devices (pumps, fans). However, this influence can be avoided when the demand for electricity is covered, for example, by using photovoltaic panels.

In the case of gas fuels, the KOBIZE report (National Centre for Balancing and Managing Emissions Institute of Environmental Protection National Research Institute) [23][24] provides emission values of PM2.5, PM10, CO2, CO, NOx/NO2, SOx/SO2 and benzo(a)pyrene. The Ministry of Environmental Protection, Natural Resources and Forestry in Poland [25] provides SO2, NO2, CO, CO2 and PM emissions for natural gas. Furthermore, while calculating CO2 emissions from natural gas combustion, the CO2 emission factor from the KOBIZE report [23] is used, when determining the energy performance of buildings.

On the topic of the environmental impact of natural gas, various possibilities are discussed in the literature [22]. It is indicated that the use of natural gas boilers instead of solid fuel boilers can reduce CO2, NOx and PM2.5 emissions [26][27]. Another possibility may be that, in the event of a system malfunction, a natural gas leakage can have a more significant impact on global warming than CO2 emissions from gas combustion [28].

In order to minimize both toxic and global-warming gas emissions, it is vital to increase the usage of renewable energy and WHR systems [22]. This is particularly important in the case of existing buildings, which use much more energy than newly constructed energy-efficient ones.

5. Conclusions

Waste heat recovery enables an excellent opportunity for energy savings and is beneficial from an environmental perspective. Waste heat from radiant heaters is classified as low-temperature waste heat; however, its value depends on devices that are characterized by radiant factor and seasonal efficiency.

The analysis of the results allowed the researchers to notify several important aspects:

- A limited amount of waste energy is in the system

- A limited amount of waste energy is in the system

The analysis of the results allowed the researchers to notify several important aspects:

- A limited amount of waste energy is in the system.

- A limited amount of waste energy is in the system.

- The heat recovery system supports the DHW preparation system.

- Ensuring adequate waste heat collection is necessary.

- The consequence of the temperature of the flue gases is undeniable.

- The analysis of a gas-fired radiant heating system with the WHR system must consider the sum of the final thermal-energy demands for the whole building.

- Period for waste heat recovery is limited.

- Emissions reduction potentiality is definitive.

The innovative solution can improve the system efficiency for all types of ceramic radiant heaters. The spectacular improvement of the environmental effect and the achievement of

the highest level of fuel savings can be obtained in existing industrial buildings that are heated with luminous heaters with the lowest radiant efficiency.

the highest level of fuel savings can be obtained in existing industrial buildings that are heated with luminous heaters with the lowest radiant efficiency.

References

- Dudkiewicz, E. Wielokryterialna Ocena Systemy Odzysku Ciepła Odpadowego z Promienników Gazowych; Polska Akademia Nauk, Komitet Inżynierii Środowiska: Wrocław, Polska, 2021.

- Alwetaishi, M.; Gadi, M.; Issa, U. Reliance of building energy in various climatic regions using multi criteria. Int. J. Sustain. Built Environ. 2017, 6, 555–564.

- Huang, F.; Zheng, J.; Baleynaud, J.; Lu, J. Heat recovery potentials and technologies in industrial zones. J. Energy Inst. 2016, 90, 951–961.

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167.

- Brückner, S.; Schäfers, H.; Peters, I.; Lävemann, E. Using industrial and commercial waste heat for residential heat supply: A case study from Hamburg, Germany. Sustain. Cities Soc. 2014, 13, 139–142.

- Panayiotou, G.P.; Bianchi, G.; Georgiou, G.; Aresti, L.; Argyrou, M.; Agathokleous, R.; Tsamos, K.M.; Tassou, S.; Florides, G.; Kalogirou, S.; et al. Preliminary assessment of waste heat potential in major European industries. Energy Procedia 2017, 123, 335–345.

- Brueckner, S.; Miró, L.; Cabeza, L.F.; Pehnt, M.; Laevemann, E. Methods to estimate the industrial waste heat potential of regions—A categorization and literature review. Renew. Sustain. Energy Rev. 2014, 38, 164–171.

- Bianchi, G.; Panayiotou, G.P.; Aresti, L.; Kalogirou, S.A.; Florides, G.A.; Tsamos, K.; Tassou, S.A.; Christodoulides, P. Estimating the waste heat recovery in the European Union Industry. Energy Ecol. Environ. 2019, 4, 211–221.

- Dudkiewicz, E.; Fidorów-Kaprawy, N. Hybrid Domestic Hot Water System Performance in Industrial Hall. Resources 2020, 9, 65.

- Jaber, H.; Khaled, M.; Lemenand, T.; Ramadan, M. Short Review on Heat Recovery from Exhaust Gas, in: Technol. Mater. Renew. Energy Environ. Sustain. 2016, 1758, 030045.

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289.

- Reddy, C.C.S.; Naidu, S.V.; Rangaiah, G.P. Waste heat recovery methods and technologies. Chem. Eng. 2013, 120, 28–38.

- Zhelykh, V.; Ulewicz, M.; Spodyniuk, N.; Shapoval, S.; Shepitchak, V. Analysis of the processes of heat exchange on infrared heater surface. Diagnostyka 2016, 17, 81–85.

- Spodyniuk, N.; Zhelykh, V.; Dzeryn, O. Combined heating systems of premises for breeding of young pigs and poultry. FME Trans. 2018, 46, 651–657.

- Marklowitz, C.A.M. Installing Gas-Fired Infrared Heaters. HPAC Eng. 2004, 8, 44–48.

- Dudkiewicz, E.; Szałański, P. Overview of exhaust gas heat recovery technologies for radiant heating systems in large halls. Therm. Sci. Eng. Prog. 2020, 18, 100522.

- Dudkiewicz, E. Selecting of heating by gas radiant heaters in relation to the new ecodesign requirements on the example of large–cubage halls. E3S Web Conf. 2018, 44, 00036.

- Rozporządzenie Komisji (UE). 2015/1188 z Dnia 28 Kwietnia 2015 r. w Sprawie Wykonania Dyrektywy Parlamentu Europejskiego i Rady 2009/125/WE w Odniesieniu do Wymogów Dotyczących Ekoprojektu Dla Miejscowych Ogrzewaczy Pomieszczeń; European Commission: Brussels, Belgium, 2014.

- Dudkiewicz, E.; Szałański, P. A review of heat recovery possibility in flue gases discharge system of gas radiant heaters. E3S Web Conf. 2019, 116, 00017.

- Schwank, Technologie Kondensacyjne i Odzyskiwanie Ciepła. 2020. Available online: https://schwank.pl (accessed on 1 March 2022).

- Dudkiewicz, E.; Szałański, P. System for Waste Heat Recovery and Contaminant Removal from Ceramic Gas Radiant Heaters. P.440644 , 2022.

- Mahmoud, M.; Ramadan, M.; Naher, S.; Pullen, K.; Olabi, A.-G. The impacts of different heating systems on the environment: A review. Sci. Total Environ. 2020, 766, 142625.

- Wartości Opałowe (WO) i Wskaźniki Emisji CO2 (WE) w Roku 2019 do Raportowania w Ramach Systemu Handlu Uprawnieniami do Emisji za Rok 2022; Krajowy Ośrodek Bilansowania i Zarządzania Emisjami: Warszawa, Polska, 2021; Available online: https://kobize.pl (accessed on 1 March 2022).

- Wskaźniki Emisji Zanieczyszczeń ze Spalania Paliw dla Źródeł O Nominalnej Mocy Cieplnej do 5 MW, Zastosowane do Automatycznego Wyliczenia Emisji w Raporcie do Krajowej Bazy za 2020 r; National Centre for Emissions Management: Warszawa, Polska, 2021; Available online: https://kobize.pl (accessed on 1 March 2022).

- Wskaźniki Emisji Substancji Zanieczyszczających Wprowadzanych do Powietrza z Procesów Energetycznego Spalania Paliw. Ministerstwo Ochrony Środowiska, Warszawa. 1996. Available online: https://odpady-help.pl/uploads/files/89/WSKAZNIKI-EMISJI-SUBSTANCJI-ZANIECZYSZCZAJACYCH-WPR0WADZANYCH-DO-POWIETRZA.pdf (accessed on 1 March 2022).

- Cui, Y.; Zhang, W.; Wang, C.; Streets, D.G.; Xu, Y.; Du, M.; Lin, J. Spatiotemporal dynamics of CO2 emissions from central heating supply in the North China Plain over 2012–2016 due to natural gas usage. Appl. Energy 2019, 241, 245–256.

- Aste, N.; Adhikari, R.; Compostella, J.; Del Pero, C. Energy and environmental impact of domestic heating in Italy: Evaluation of national NOx emissions. Energy Policy 2013, 53, 353–360.

- Mena, M.; Oliva, E.; Saide, P.; Spak, S.; de la Maza, C.; Osses, M.; Tolvett, S.; Campbell, J.E.; Tsao, T.E.C.-C.; Molina, L.T. Estimating the health benefits from natural gas use in transport and heating in Santiago, Chile. Sci. Total Environ. 2012, 429, 257–265.

More