Recent advances Thin computing allows researchers to propose the automation of hydroponic systems to boost efficiency and reduce manpower demands, hence increasing agricultural produce and profit. A completely automated hydroponic system should be equipped with tools capable of detecting plant diseases in real-time. Deep-learning-based plant disease detection models leverage computer vision capability and come up with a model that can diagnoses entry described the power deep lesrning in detecting plant diseases by scanning plant leaves. The system is capable of diagnosing a given sample by simply taking the leaf image as input and returning the class of the disease that is affecting the plant on screen to ascertain whether the plant is healthy or not, alongside the name of the diseases that are affecting the plantin smart Hydroponics systems.

1. Introduction

Hydroponics is a technique of crop cultivation without using soil

[1][2][1,2]. Although the term hydroponic might sound new, the concept was long practiced by Ancient Egyptians: They used similar concepts to grow crop in roof tops and walls

[3]. These new portable systems of farming have many benefits such as (1) a small amount land is needed; (2) faster plant growth; (3) it is less prone to diseases; (4) it is portable, as soil is not needed; (5) seasonal changes do not affect plant growth; and (6) little or no pesticides and herbicides are needed

[4][5][4,5].

Some works on Computer-Aided Diagnosis (CAD) of plants have been conducted using techniques such as expert systems and rule-based models

[6][7][6,7], which are confined to the knowledge of the expert and hence have the potential for mistakes in result interpretations. Artificial Neural Networks (ANNs) were investigated in this domain to improve the diagnostic process, such as the system found in a IoT-based deep learning system for plant disease detectio

n [8].Deep-learning-based plant disease detection models leverage computer vision capability and come up with a model that can

[8]diagnose plant diseases by scanning plant leaves. The system is capable of diagnosing a given sample by simply taking the leaf image as input and returning the class of the disease that is affecting the plant on screen to ascertain whether the plant is healthy or not, alongside the name of the diseases that are affecting the plant.

2. AI

An Artificial Neural Network (ANN) is an Artificial Intelligent (AI) paradigm where problem-solving behaviors of biological nerve cells known as neurons are simulated

[9][10][9,10]. A Convolutional Neural Network (CNN) is an ANN that has more than one layer and trains its models by adjusting its weights using optimization methods such as gradient descent algorithms

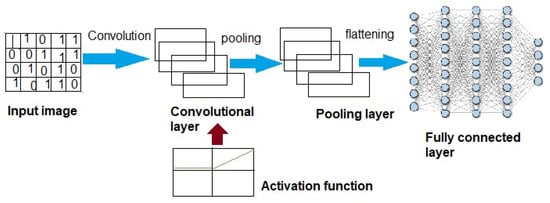

[11]. The first layer in the CNN is the “convolution layer”, which uses the operation of convolution to search for patterns. Neurons in this network are used to perform the convolution operations, i.e., filtering images to look for patterns. The neurons in each given filter share the same weight and bias thus giving them the ability to search for the same pattern in different parts of the image. The second layer is the “rectified linear unit layer”, which focuses on building up the patterns discovered by the convolution layer. The third layer in the CNN is the “pooling layer”. This layer reduces the number of patterns allowing the neural network to focus only on important patterns. The final layer is called the fully “Connected layer”, which makes the CNN able to classify data into appropriate labels.

Figure 1, highlight the arrangement of layers in CNN. The accuracy of the CNN classifier is largely dependent on the size of the dataset it trains on, as it usually requires a very large set of training data

[12][13][12,13].

Figure 1.

Convolutional neural network adopted from superdatascience.

2.1. Internet of Things (IoT)

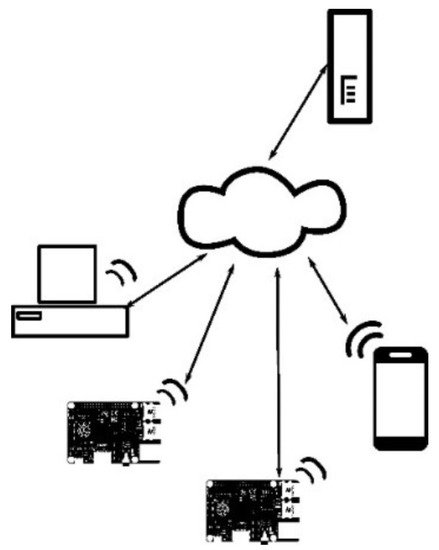

Internet of things (IoT) is a branch of distributed systems that tends to allow devices to communicate automatically with minimal or no human intervention, as shown in

Figure 2, and the IoT is a system of interrelated computing devices, sensors, and CPUs that are provided with unique identifiers (UIDs) and the ability to transfer data over a network without requiring human-to-human or human-to-computer interactions

[8]. An IoT-based hydroponics system is designed to monitor and/or control a hydroponic system with the help of a server. The system communicates with the server through Ethernet, Wi-Fi, GPRS, or satellite radio communication.

Figure 2.

Typical IoT system.

2.2. Energy Harvesting

Energy harvesting techniques are different sets of processes of converting the ambient energy present in the environment into electrical energy to be used in powering wireless sensors or embedded devices

[14]. These technologies often supplement batteries in situations where their integration is feasible. Energy harvesting become popular in wireless sensor technology and autonomous devices due to the nature of the environment these devices operate in. For example, devices that are deployed in drones, underwater, and so on, cannot have access to any physical power source; as such, harvesting energy from the environment becomes necessary. This technique provides energy ranging from microwatts to megawatts. When selecting energy-harvesting techniques, factors such as the nature of the environment, the source of available energy nearby, and the energy consumption of the devices have to be put into consideration before a particular method is selected.

Table 1 summarizes the energy-harvesting techniques as well as the strengths and weaknesses of the discussed methods.

Table 1.

Energy Harvesting Techniques.

| S/N |

Ambient Source |

Technology |

Strength |

Weakness |

| 1 |

Solar |

photovoltaic |

Easier and cheap |

Not suitable in all environments |

| 2 |

Thermal |

Thermoelectric converters |

Can be used both in indoor and outdoor situations |

Lower power density than the rest of the methods |

| 3 |

Vibration |

Electromagnetic and others |

Has high power density |

Difficult to

fabricate, and the performance largely depends on the vibration

property |

| 4 |

Wind |

Electromechanical converter |

Has high power density and is easy to fabricate |

The reliability of the power heavily depends on the wind speed |

| 5 |

Radiofrequency |

Electromagnetic converter |

The sources are largely available nowadays |

Low power density and expensive to fabricate |

| 6 |

Acoustic noise |

Piezoelectric converter |

Can be installed both indoors and outdoors |

Expensive and difficult to fabricate |

Looking at the nature of the proposed model, and the environment within which the model is to be deployed, that is, smart hydroponics available at farms located in remote areas, many of these farms are not connected to the national power grids because of their location. Therefore, an alternative energy source is needed.

2.3. Knowledge Distillation

Knowledge Distillation (KD), as proposed by Hinton et.al.

[15][20], is a type of knowledge transfer that was developed around convolutional neural networks, the idea behind KD is to train a large, complex model using high computational resources and use the learned parameters from the model to teach a small model with fewer computational resources. The process usually utilized two network structures, which are named teacher and student. The teacher is a model with a strong capability, while the student is a simple shallow neural network model which mimics the behavior of the teacher model by transferring significant knowledge from the teacher model

[16][21].

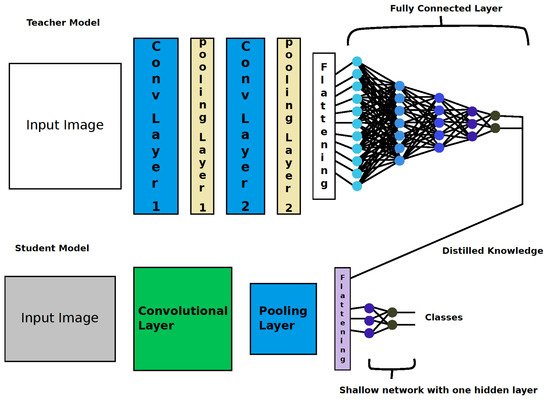

The process of knowledge distillation is well-represented in

Figure 3, where two models are defined with different architectures. On the top is teacher model with multiple convolutional layers and hidden layers, whereas the picture of student model with only a convolutional layer and one hidden layer is on the bottom. This indicates that the two models differ physically, and therefore, they have different computational requirements. The student models mimic the behavior of the teacher model by training on the soft level generated by the teacher model, otherwise called the distilled knowledge from the teacher. Unlike transfer learning, this technique does not require the Internet, and it does not require that the student model architecture be the same as the teacher.

Figure 3.

Structure of knowledge distillation.

3. Deep Learning for Plant Disease Detection for Smart-Hydroponics

The IoT originates from embedded systems, which is a branch of distributed systems. These systems are made up of small devices such as smartphones and personal computers, characterized by low resources and low computing power, that communicate through the Internet. Data generated from IoT systems are saved and monitored through a server or a broker depending on the design. Research has been carried out on the use of the IoT in hydroponic systems

[17][18][19][22,23,24].

In

[20][25], an IoT-based hydroponics system was designed using Arduino and Raspberry. The system is connected via USB and saves experimental data on a Pi card memory. External users and programmers were able to connect to the Pi via the internet and interact with the system. The greenhouse-based hydroponic system′s temperature and humidity were controlled by the system. The system increases the efficiency of crop growth. When compared to traditional methods, the technology has been shown to be substantially faster. The system′s configuration, however, was difficult due to the additional plug-ins and the third-party software needed. In addition, using image processing, the system allows for plant growth tracking. Unfortunately, because it only provides cooling systems to reduce high temperatures, the system was built to favor crop production during the summer months only. Furthermore, neither the pH nor the nutrient solution concentration (EC) levels were tested, so the nutrient combination and pH information acquired from the system will be unreliable.

Rau et al.

[21][30] used MATLAB-based image processing to design a less expensive method of automatic irrigation for recognizing rice illnesses and nutritional deficits. The system was built using a Raspberry Pi, a DHT11 temperature and humidity sensor, and solenoid valves. The farmer can keep an eye on the weather. The user or the Pi camera sends images of the leaves to the Pi for analysis with MATLAB. The scientists constructed a database that calculated attributes including contrast, correlation, mean, standard deviation, and entropy, as well as assigning a name to each ailment. The properties of the selected picture were derived from the clusters after the images were segmented into clusters and a Region of Interest (ROI) was chosen

[22][31]. The illnesses are recognized based on the values of parameters that match the values in the database. The farmer will be fully informed on strategies to save the plant from the disease′s effects via the feedback process. This IoT-based intelligent system with nutrient and disease analysis is smarter and optimized for irrigation, lowering overheads and allowing for more effective water usage, which aids in water conservation. Furthermore, the automatic diagnosis of nutrient insufficiency and disease analysis will allow farmers to boost their yield with less effort.

The performance of CNN in object recognition and image classification has been on the rise, large cumbersome models such as Resnet50, Alexnet are achieving state-of-the-art accuracies at the cost of computation. The accuracy of these models increases as their parameters are increasing exponentially. This performance along with the simplicity of CNN’s paved the way for ML to be applied in many domains where image classification can solve the problem, such as a disease diagnosis from medical imaging

[23][32].

Interestingly, the effort to minimize power consumption of edge devices can be from both hardware and software perspectives. Knowledge distillation reduces the number of parameters in the model, which reduced the number of computations, which in turn reduced the number of memory accesses, thus reducing power consumption. From the hardware point of view, different techniques are available which can be used to reduce the power consumption of the processing unit of an edge device or a sensor node. An example of such techniques is Dynamic Voltage and Frequency Scaling (DVFS).

According to Senadeera et al.

[24][39], DVFS is designed to minimize the power consumption during the execution of tasks by adjusting the operating voltage and frequency dynamically depending on the system performance requirement at a fixed time. It is also possible to investigate the power consumption of the wireless node during different activities. Depending on the design, IoT devices can be designed to have various operating modes, such as standby, battery saver, fully operational, and so on. In each state, the amount of energy consumes differs

[25][40]. For example, in standby, the system reserves the energy without performing any heavy task. Under a power saver, the power has dropped below a certain threshold, and there, some of the system functionalities are turned off automatically to minimize the power consumption. This second aspect can also be regarded as energy management.

Energy management is a way of using the available energy in edge devices carefully to maximize operation time and minimize power consumption, it is a critical part of a system that is powered by energy harvesting technology. An efficient energy management solution enables long-lasting devices and IoT systems. It minimizes the failure rate by preventing frequent system downtime as well as reducing maintenance costs

[26][41].

From the software aspect as well, due to the rise in these edge devices and the popularity of IoT systems, researchers are investigating ways of building and efficient CNN models with good accuracy, as well as low power consumption. The reason behind this shift was that CNN achieves significant breakthroughs in term of image classification at the cost of computation. These models contain millions of parameters and perform hundreds of thousands of operations during training, which is why the models can only be trained on a high-performance computer with GPUs. This limits the possibilities of these models to be deployed on embedded devices. The devices are usually resources constrained, in terms of power, computing resource, and network connectivity.