Basic Oxygen Furnace (BOF) steelmaking is, worldwide, the most frequently applied process. According to the world steel organization statistical report, 2021, it saw a total production share of 73.2%, or 1371.2 million tons per year of the world steel production in 2020. The rest is produced in Electric Arc Furnace (EAF)-based steel mills (26.3%), and only a very few open-hearth and induction furnace-based steel mills. The BOF technology remains the leading technology applied based on its undoubted advantages in productivity and liquid steel composition control. The BOF technology started as the LD process 70 years ago, with the first heat applied in November 1952 in a steel mill in Linz, Austria. The name LD was formed from the first letters of the two sites with the first industrial scale plants, Linz and Donawitz, both in Austria. The history and development of the process have been honored in multiple anniversary publications over the last few decades. Nevertheless, the focus of the steel industry worldwide is significantly changing following a social and political trend and the requirement for fossil-free energy generation and industrial production to be in accordance with the world climate targets committed to in relation to the decades leading up to 2050.

1. How It Started

At the end of WWII, Austria was occupied by the allied forces: the USA, UK, France, and the Soviet Union. All industrial assets had been heavily damaged by air raids during the war. In 1946, the assets were returned to the newly formed Republic of Austria, and reconstruction under the framework of the Marschall Plan started at VÖEST-Linz and ÖAMG-Donawitz. In June 1947, the first blast furnace in Linz was blown-in, and steel production restarted with a repaired open-hearth furnace. In 1948 the new government launched the “Iron and Steel Plan”, which allocated the production of flat steel to Linz and the production of long products to Donawitz. The plan included starting the production of finished products in a heavy-plate mill, restored after air raids and demolition, and building a new slabbing and hot-strip mill in Linz.

In the meantime, all important players in the LD-history: T. Suess, H. Trenkler, H. Hauttmann, and H. Weitzer had arrived back in Austria from their former employments in the German steel industry

[1]. From the very beginning, it was obvious that basing the future flat production in Linz on open-hearth technology was too expensive to succeed, but time was running out because the new facilities were already under construction. Based on this conclusion and knowledge about trials carried out during the war to produce steel from hot metal by oxygen refining, the team searched for other activities in this field in Europe

[2].

When they heard about successful trials with oxygen purification at the von Roll steel mill in Gerlafingen, Switzerland, directed from Prof. R. Durrer, the Austrian engineers visited the plant for a technical exchange. After this visit, the decision was taken to develop the process

[3].

In May 1949, a conference on oxygen metallurgy was held at the Montanuniversität, Leoben, with participants from Austria, Germany, and Switzerland. A division of tasks in developing oxygen for steel production was agreed upon between von Roll’s Gerlafingen, Mannesmann AG, VÖEST, and ÖAMG. In Gerlafingen, oxygen refining would take place in the EAF, in Huckingen, bottom injection would be carried out in the Thomas converter, in Donwitz, oxygen was used for ore reduction in a shaft furnace and for obtaining a manganese-rich slag for alloying purposes, and in Linz, the refining of hot metal with pure oxygen was to be developed

[4].

Trials began in Linz on 2 June 1949. In a two-ton converter with vertical blowing of oxygen onto a hot metal melt, the breakthrough was achieved on 25 June after initial failures. Hot metal could be refined in a reproducible manner into steel with lower oxygen pressure and a greater distance of the blowing lance from the melt. The steel could be rolled without any problems, and the testing laboratory managed by H. Hauttmann judged the quality of the new steel to be excellent.

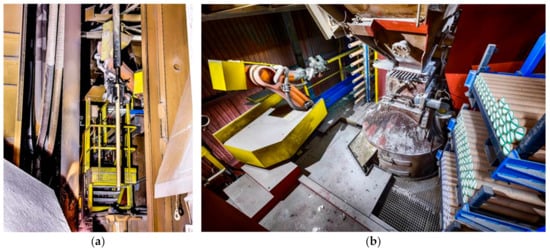

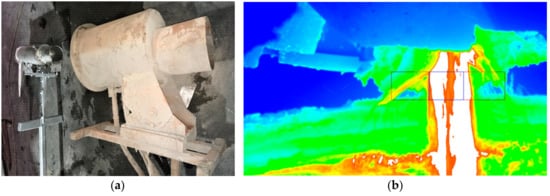

In Linz, the trials were systematically continued. In parallel, a refining station for blowing oxygen in a 15-ton vessel was built on the outer wall of the steel plant, which was commissioned with the first batch on 2 October 1949; see

Figure 1 [5]. These trials subsequently clarified questions of the large-scale feasibility of the process, its economy, and the new steel’s service properties. It was possible to roll plates of excellent quality from 11-ton slab blocks

[6].