This entry concentrates on some examples of success stories from the synthesis of approved medicines and drug candidates using epoxide chemistry in the development of robust and efficient syntheses at large scale. The focus is on those parts of each synthesis related to the substrate-controlled/diastereoselective and catalytic asymmetric synthesis of epoxide intermediates and their subsequent ring-opening reactions with various nucleophiles. These are described in the form of case studies of high profile pharmaceuticals spanning a diverse range of indications and molecular scaffolds such as heterocycles, terpenes, steroids, peptidomimetics, alkaloids and main stream small molecules. Representative examples include, but are not limited to the antihypertensive diltiazem, the antidepressant reboxetine, the HIV protease inhibitors atazanavir and indinavir, efinaconazole and related triazole antifungals, tasimelteon for sleep disorders, the anticancer agent carfilzomib, the anticoagulant rivaroxaban the antibiotic linezolid and the antiviral oseltamivir. Emphasis is given on aspects of catalytic asymmetric epoxidation employing metals with chiral ligands particularly with the Sharpless and Jacobsen–Katsuki methods as well as organocatalysts such as the chiral ketones of Shi and Yang, Pages's chiral iminium salts and typical chiral phase transfer agents.

- epoxides

- drug development

- catalytic asymmetric epoxidation

- organocatalysis

- process development and manufacturing routes

- Sharpless and Jacobsen–Katsuki asymmetric epoxidat

- chiral ketones/dioxiranes

- iminium/oxaziridinium salts

- epoxide ring opening.

- Introduction

1. Introduction

Epoxides are versatile electrophiles that support the stereospecific formation of ring-opened products with a wide array of nucleophiles. The implications of this reactivity in the context of drug design and desired biologic action as well as manifestation of adverse effects has been reviewed previously [1–4] [1][2][3][4] although these are best exemplified by the plethora of natural products and the 14 approved drugs containing the epoxide functionality [5,6][5][6]. In the context of organic synthesis, the ring strain-induced electrophilicity of epoxides renders them excellent reactive intermediates for constructing in stereoselective/specific manner key bonds in larger and more complex molecules. From an academic perspective, general aspects of epoxide synthesis and ring-opening reactions spanning various levels of organic chemistry research have been reviewed extensively [7–9][7][8][9]. What is lesser known is how pivotal has been the successful management of epoxide chemistry on scale leading to robust, cost-effective and safe manufacturing processes. Emphasis is also given in the way certain intermediates are handled due to safety, reactivity, inappropriate state (oils, low melting point solids) or physical properties (hygroscopicity, poor filtration characteristics) or even time constraints. For example, in several cases a "telescoped" process is implemented which is a process term to describe a reaction that despite work up, washes, filtration of unwanted materials (inorganics, charcoal), etc., avoids any isolation and a solution of the intermediate is carried forward in the next step, not necessarily in the same reactor. The more common term "one-pot" implies no processing/work up and the reagents for the next step are added sequentially in the same vessel. The focus of this review is the implementation of epoxide chemistry from a process development perspective and is presented through dedicated discussions to high profile approved drugs and clinical candidates.

- LY459477—Development of a Selective Route via a Desymmetrization Process of a Meso-Epoxide

2. LY459477—Development of a Selective Route via a Desymmetrization Process of a Meso-Epoxide

LY459477 (1) is a potent (EC50 1 nm) orthosteric agonist for rodent and human mGlu2 and mGlu3 receptors. Development of an appropriate large-scale synthesis of LY459477 was required to support clinical trials for schizophrenia, generalized anxiety disorder and bipolar disorders [10]. Moreover, the supply route for LY459477 served as an excellent platform for the development of subsequent structurally related mGlu2/3 agonists as drug candidates for neuropsychiatric disorders [11].

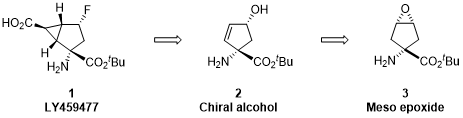

Scheme 1. Retrosynthesis of LY459477 into the key alcohol and epoxide intermediates.

The chemotype of LY459477 was based on a cyclopentene scaffold first introduced by Hodgson and scientists at GlaxoSmithKline (then Glaxo Wellcome) [12][12] where the key intermediate, chiral alcohol 2, was obtained from desymmetrization of the meso epoxide 3 (Scheme 1).

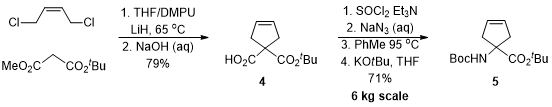

Scheme 2. Synthesis of meso-epoxide precursor 5.

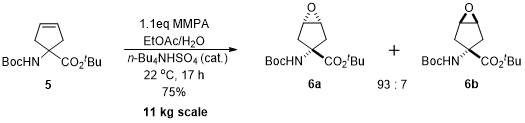

A team of process chemists from Eli Lilly developed the original synthesis further in order to deliver cyclopentene precursor 5 on a multikilogram scale (Scheme 2). The synthesis comprises of six discreet steps but proceeds through several telescoped stages with only two isolable intermediates; monoacid 4 and cyclopentene 5. Peracid-mediated epoxidation of 5 delivers the oxygen atom preferentially on the same face of the cyclopentene as the NHBoc substituent as result of a hydrogen bonding interaction between the oxidant and the latter functionality. A variety of conditions were examined for optimum diastereoselectivity in the epoxidation of 5 towards the desirable diastereomer 6a, concluding to magnesium monoperoxyphthalate in a biphasic water/ethyl acetate mixture with n-Bu4NHSO4 as a phase transfer catalyst (Scheme 3). This method was successfully scaled up to 11 kg and the final product was recrystallized from EtOAc/heptane giving 6a at 75% yield with 3% of the diastereomer 6b.

Scheme 3. Substrate-controlled diastereoselective epoxidation of 5.

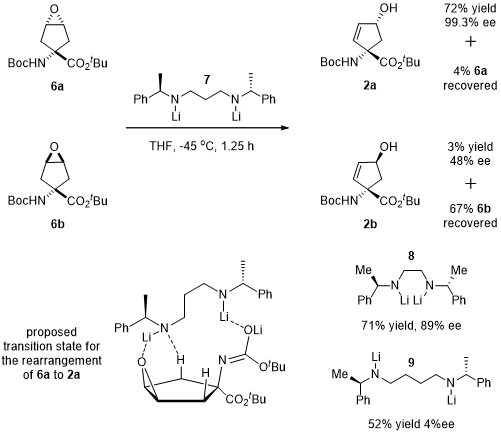

The desymmetrization of epoxide 6a into chiral allylic alcohol 2 demanded a wide screen of chiral lithiated mono- and diamines as well as amino alcohols, temperatures, additives, reaction times and stoichiometry in order to achieve maximum yield and enantioselectivity. Best results were obtained with diamine 7 (Scheme 4) affording the desired chiral allylic alcohol in 72% yield and >99% ee, followed closely by the corresponding diamine with an ethylene linker between the nitrogen atoms (71% yield and 89% ee) whereas the analog with the butylene spacer proved non selective. Interestingly, under the same conditions diastereomeric epoxide 6b essentially does not rearrange. The rearrangement of epoxides to allylic alcohols has been demonstrated to proceed via abstraction of either the syn-β H or the anti-β H, with cyclopentane skeletons favoring the former mode. This was also shown to be the case for 6a through deuterium labeling studies.

A transition state consistent with above findings was proposed and involves the complexation of the lithiated diamine with both the (deprotonated under the reaction conditions) Boc group and the epoxide. In the latter case the lithium cation serves as a Lewis acid activating the epoxide towards ring opening with concomitant abstraction of the adjacent enantiotopic epoxide-syn-β H. This epoxide activation would be absent in the analogous complex of the lithiated diamine and the Boc group of diastereoisomer 6b (being in opposite sides) thus consistent with the inertness of the latter. The proposed transition state also exemplifies the importance of the distance between the two lithiated amino groups as this must match the distance between the epoxide and Boc oxygen atoms so that a stable complex is formed. This in turn supports the alignment of one of the basic nitrogen atoms with one of the two enantiotopic syn-β H atoms, abstraction of which leads to high enantioselectivities.

Scheme 4. Desymmetrization of meso epoxide 6a with chiral bases.

The cost-effectiveness and of this competitive synthesis stems from the inexpensive starting materials including chiral diamine 7 which can be easily prepared from (R)-α-methyl benzylamine and is recovered up to 80% from the pilot-plant operations. Overall, an important chiral and pharmaceutically privileged scaffold is accessed in multikilogram quantities through the desymmetrization of a meso epoxide.

- Tasimelteon —Comparison of Large-Scale Catalytic Asymmetric Epoxidation Processes Towards a Chiral Dihydrobenzofuran Epoxide

3. Tasimelteon —Comparison of Large-Scale Catalytic Asymmetric Epoxidation Processes Towards a Chiral Dihydrobenzofuran Epoxide

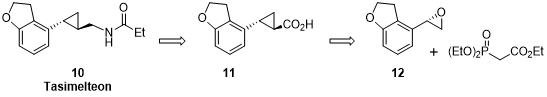

Agonism at the melatonin receptors 1 and 2 has produced drug molecules that have been approved for the treatment of insomnia and circadian rhythms sleep–wake disorders (ramelteon, tasimelteon) as well as for depression (agomelatine) [13]. During the development of tasimelteon, 10 (Scheme 5) by Bristol-Myers Squibb, provision of large quantities of 11, required the development of a supply route. One of the first syntheses examined by process chemists at BMS involved chiral epoxide 12 as the key intermediate as this could be transformed to acid 11 by reaction with triethyl phosphonoacetate followed by ester hydrolysis [14].

Scheme 5. Retrosynthetic analysis of tasimelteon into key epoxide intermediate 12.

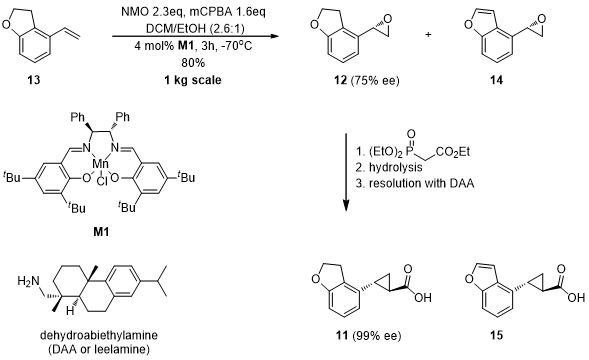

Initially the Jacobsen–Katsuki asymmetric epoxidation (AE) [15–17][15][16][17] was attempted and its optimization involved extensive screening of catalysts, solvents, oxidants, additives, reaction temperature and time. It quickly became evident that the reaction needed to be carried out at very low temperature in order to achieve significant enantioselectivity which never actually exceeded 76% ee. mCPBA (meta-chloroperoxybenzoic acid) provided higher enantioselectivities than MMPP (magnesium monoperoxyphthalate) or bleach and addition of NMO (N-methylmorpholine N-oxide) was also beneficial. DCM proved the best solvent both in terms of conversion and enantioselectivities, yet this also proved the Achilles heel of the process since it caused significant safety and operational issues. Specifically, the moderate solubility of mCPBA in DCM exacerbated by the low reaction temperature at −75 to −65 °C, caused precipitation of the reagent leading to inconsistent reaction mixtures. More frequently than not, large exotherms and abrupt gas evolution were observed upon addition of the mCPBA solution in the reaction mixture which caused serious safety concerns. Adjusting for concentration, time and order of reagent addition did not solve these issues. Solvents in which mCPBA dissolves better, like EtOAc or ethanol were attempted as DCM replacements, but the reaction did not proceed. Finally, by keeping DCM as the reaction and using the minimum amount of ethanol to dissolve and transfer the mCPBA into the reaction mixture solved these issues and provided a fast reaction reaching 95% conversion within the three hours employed for addition of the mCPBA at −70 °C. The optimized process involving catalyst M1 (Scheme 6) was successfully scaled up to 1 kg scale and delivered chiral epoxide 12 in 80% yield and 74% ee. This was deemed acceptable at this point since a resolution step, using dehydroabietylamine (leelamine), was to be implemented later in the synthesis at the amine intermediate which upgraded the optical purity to 99% ee.

Scheme 6. Catalytic asymmetric epoxidation of 13 and conversion to cyclopropane intermediate 11.

Despite the temporary success in supplying the initially required quantities of drug substance, the necessity for a resolution step, the varying levels of manganese salts in the isolated intermediates and the apparently unavoidable formation of benzofuran impurity 14 (>3%), undermined the potential of this route in developing into a manufacturing process. Overoxidized impurity 14 in particular, presumably formed by mCPBA or catalyst-induced hydroxylation at the benzylic position followed by dehydration [18[18][19],19], posed significant quality issues as it transformed through the synthesis to species that were difficult to purge, such as the acid 15, due to the high similarity with the desired intermediates and ultimately with the final product.

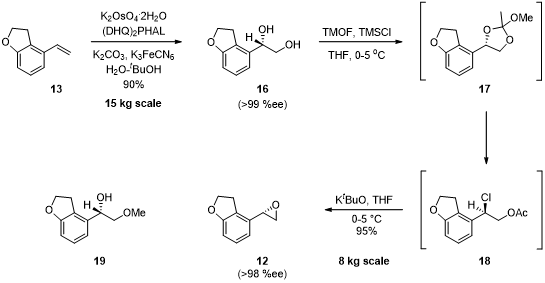

This prompted the investigation of an alternative route to epoxide 12. Towards this end, Sharpless Asymmetric Dihydroxylation on alkene 13 followed by transformation of the chiral diol 16 (Scheme 7) to the epoxide was considered next [20]. Encouraging results were obtained from preliminary experiments as diol 16 was isolated with high ee as a crystalline and easy to handle solid. Significant work was dedicated before selecting potassium ferricyanide as the osmium reoxidant over the less expensive NMO. Potassium ferricyanide requires larger solvent quantities to be suspended adequately, produces a significant solid waste that must be removed during isolation and constitutes an additional burden in terms of toxic materials in the process. Nevertheless, it provided consistently high enantioselectivities (98–99% ee) thus eliminating the necessity for a resolution step and robust reactions whereas the process with NMO proved sensitive to the rate of addition of alkene 13. The next issue that had to be dealt with was the poor solubility of 13 in tert-butanol/water mixtures which was eventually solved by replacing tert-butanol with isopropanol. Interestingly the reaction failed to proceed with commercially available AD-Mix-α, and potassium persulfate was used and required the in situ preparation of the catalyst. The final problem intrinsically linked to the Asymmetric Dihydroxylation reaction was the reduction of the toxic osmium species to pharmaceutically acceptable levels which for the isolated diol intermediate was set at <10 ppm. Following a screening of resins, filter aids and reagents as well as the development of an appropriate analytical method, the use of a sodium sulfite wash in the work up reduced the osmium levels to less than 6 ppm as determined by inductively coupled plasma atomic emission spectroscopy (ICP-ES).

The optimized process (Scheme 7) was gradually scaled up to 1, 8 and 15 kg scale furnishing diol 16 in 90% yield, HPLC purity of 98% and >99% ee and as a crystalline solid, provided the water content of the organic solution after work up was <1% w/w.

Scheme 7. Synthesis of chiral epoxide 12 via Sharpless asymmetric dihydroxylation of 13.

Finally, diol 16 was transformed to the desired epoxide 12 through the Kolb -Sharpless method [21], by treatment with trimethyl orthoacetate and trimethylsilyl chloride followed by base. In this process, the initially formed orthester 17 is converted in situ to chloroacetate intermediate 18 with inversion of configuration and after hydrolysis of the ester and ring closure, also with inversion of configuration, provides the desired chiral epoxide 12. When the traditional conditions of K2CO3/MeOH were used for the latter part of the process, significant amounts of impurity 19 were observed (up to 10%) presumably via opening of the epoxide by methoxide anion. The epoxide stability issue surfaced required investigation of appropriate solvents, bases, reaction temperature and times temperatures as well as work up procedures in order to inhibit the formation of impurity 19. The optimum conditions found involved confirming by HPLC the completion of chloroacetate formation, followed by charging a solution of KOtBu in THF at 0–5 °C and maintaining at the same temperature until conversion to the epoxide was complete (~1 h) (Scheme 7). No deterioration of the epoxide quality is observed under these conditions even after prolonged reaction times. The optimized process was successfully scaled up to 8 kg batches delivering the epoxide 90–95% yield and >98% ee.

Overall, the efforts to develop a large-scale route to tasimelteon culminated in interrogating the performance and viability of two of the most popular asymmetric transformations, namely the Jacobsen–Katsuki Asymmetric Epoxidation and the Sharpless Asymmetric Dihydroxylation. Both processes required careful navigation through safety and product quality issues arising from reagents, catalysts and associated process impurities as well as technical difficulties in several unit operations. Despite the shorter route offered by the Asymmetric epoxidation process, the lower enantioselectivity achieved renders imperative the implementation of a resolution step and in addition, suffers from a persistent impurity. The Asymmetric Dihydroxylation route although more process intensive, provides excellent enantioselectivity, superior purity profile and higher overall yield of the final drug substance (43% vs 22%).

References

- 1 Gehringer, M.; Laufer, S.A. Emerging and re-emerging warheads for targeted covalent inhibitors: Applications in medicinal chemistry and chemical biology. J. Med. Chem. 2019, 62, 5673–5724, doi:10.1021/acs.jmedchem.8b01153.

- 2 Zhang, T.; Hatcher, J.M.; Teng, M.; Gray, N.S.; Kostic, M. Recent advances in selective and irreversible covalent ligand development and validation. Cell Chem. Biol. 2019, 26, 1486–1500, doi:10.1016/j.chembiol.2019.09.012.

- 3 Kalgutkar, A.S. Designing around Structural Alerts in Drug Discovery. J. Med. Chem. 2020, 63, 6276–6302, doi:10.1021/acs.jmedchem.9b00917.

- 4 Coulup, S.K.; Huang, D.S.; Wong, H.L.; Georg, G.I. Identification of the metabolic profile of the alpha-tubulin-binding natural product (-)-pironetin. J. Med. Chem. 2019, 62, 1684–1689, doi:10.1021/acs.jmedchem.8b01774.

- 5 Marco-Contelles, J.; Molina, M.T.; Anjum, S. Naturally occurring cyclohexane epoxides: Sources, biological activities, and synthesis. Chem. Rev. 2004, 104, 2857–2899, doi:10.1021/cr980013j.

- 6 Delost, M.D.; Smith, D.T.; Anderson, B.J.; Njardarson, J.T. From oxiranes to oligomers: Architectures of U.S. FDA approved pharmaceuticals containing oxygen heterocycles. J. Med. Chem. 2018, 61, 10996–11020, doi:10.1021/acs.jmedchem.8b00876.

- 7 Yudin, K.A. Aziridines and Epoxides in Organic Synthesis; Wiley: Hoboken, NJ, USA, 2006.

- 8 Meninno, S.; Lattanzi, A. Organocatalytic asymmetric reactions of epoxides: Recent progress. Chemistry 2016, 22, 3632–3642, doi:10.1002/chem.201504226.

- 9 Delost, M.D.; Njardarson, J.T. Oxiranes and Oxirenes: Monocyclic; Elsevier: Amsterdam, The Netherlands, 2019.

- 10 Varie, D.L.; Beck, C.; Borders, S.K.; Brady, M.D.; Cronin, J.S.; Ditsworth, T.K.; Hay, D.A.; Hoard, D.H.; Hoying, R.C.; Linder, R.J.; et al. Design, development, and scale-up of a selective meso-epoxide desymmetrization process. Org. Process Res. Dev. 2007, 11, 546–559, doi:10.1021/op060225.

- 11 Célanire, S.; Duvey, G.; Poli, S.; Rocher, J.P. Chapter six-mGluR2 activators and mGluR5 blockers advancing in the clinic for major CNS disorders. Annu. Rep. Med. Chem. 2012, 47, 71–88, doi:10.1016/B978-0-12-396492-2.00006-0.

- 12 Hodgson, D.M.; Thompson, A.J.; Wadman, S.; Clare, J.; Keats, C.J. On the possibility of carbamate-directed hydroboration. An approach to the asymmetric synthesis of 1-aminocy clopentane-1,3-dicarboxylic acid. Tetrahedron Lett. 1999, 55, 10815–10834, doi:10.1016/S0040–402000596–7.

- 13 Laudon, M.; Frydman-Marom, A. Therapeutic effects of melatonin receptor agonists on sleep and comorbid disorders. Int. J. Mol. Sci. 2014, 15, 15924–15950, doi:10.3390/ijms150915924.

- 14 Prasad, S.J.; Vu, T.; Totleben, M.J.; Crispino, G.A.; Kacsur, D.J.; Swaminathan, S.; Thornton, J.E.; Fritz, A.; Singh, A.K. Development of jacobsen asymmetric epoxidation and sharpless asymmetric dihydroxylation methods for the large-scale preparation of a chiral dihydrobenzofuran epoxide. Org. Process Res. Dev. 2003, 7, 821–827, doi:10.1021/op025622e.

- 15 Brandes, B.D.; Jacobsen, E.N. Highly enantioselective, catalytic epoxidation of trisubstituted olefins. J. Org. Chem. 1994, 59, 4378–4380, doi:10.1021/jo00095a009.

- 16 Zhang, W.; Loebach, J.L.; Wilson, S.R.; Jacobsen, E.N. Enantioselective epoxidation of unfunctionalized olefins catalyzed by (salen) manganese complexes. J. Am. Chem. Soc. 1990, 112, 2801–2803 doi:10.1021/ja00163a052.

- 17 Jacobsen, E.N.; Zhang, W.; Muci, A.R.; Ecker, J.R.; Deng, L. Highly enantioselective epoxidation catalysts derived from 1,2-diaminocyclohexane. J. Am. Chem. Soc. 1991, 113, 7063–7064, doi:10.1021/ja00018a068.

- 18 Ma, D.; Xia, C.; Tian, H. Oxidation of benzylic methylene compounds to ketones with m-chloroperoxybenzoic acid and oxygen. Tetrahedron Lett. 1999, 40, 8915–8917, doi:10.1016/S0040–403901886–9.

- 19 Konoike, T.; Araki, Y.; Kanda, Y. A novel allylic hydroxylation of sterically hindered olefins by Fe-porphyrin-catalyzed mCPBA oxidation. Tetrahedron Lett. 1999, 40, 6971–6974, doi:10.1016/S0040–403901437–9.

- 20 Sharpless, K.B.; Amberg, W.; Bennani, Y.L.; Crispino, G.A.; Hartung, J.; Jeong, K.S.; Kwong, H.L.; Morikawa, K.; Wang, Z.M. The osmium-catalyzed asymmetric dihydroxylation: A new ligand class and a process improvement. J. Org. Chem. 1992, 57, 2768–2771, doi:10.1021/jo00036a003.