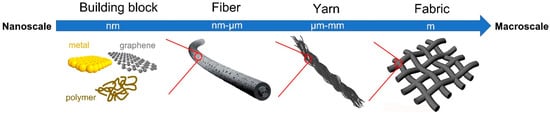

Smart textiles have recently aroused tremendous interests over the world because of their broad applications in wearable electronics, such as human healthcare, human motion detection, and intelligent robotics. Sensors are the primary components of wearable and flexible electronics, which convert various signals and external stimuli into electrical signals. While traditional electronic sensors based on rigid silicon wafers can hardly conformably attach on the human body, textile materials including fabrics, yarns, and fibers afford promising alternatives due to their characteristics including light weight, flexibility, and breathability. Of fundamental importance are the needs for fabrics simultaneously having high electrical and mechanical performance.

- textile

- sensor

- hierarchical design

- wearable electronics

1. Introduction

2. Selection of Constituent Materials

2. Selection of Constituent Materials

The first step for the design of wearable electronics is the selection of building blocks, which are able to afford outstanding mechanical properties without sacrificing electrical performance.2.1. Metallic Nanostructure

Thanks to the high free-electron density, metals are deemed as the most conductive materials on Earth, among which silver is the most widely studied given its highest conductivity [25,26][8][9]. However, as metal wires are relatively rigid and cannot be effectively woven into fabric, they are usually coated on polymer fibers or embedded in composite fibers. More intriguingly, when the size of metals decreases down to nanoscale, their physical properties become distinct from the bulk counterparts. This enables the metal nanostructures to be competent candidates for conductive-filled materials in textile-based sensors. Extensive studies have demonstrated the successful application of gold, silver, and copper nanowires in electronic textile devices [27][10].2.2. Conductive Polymer

Conducting polymers with π-conjugated bond structures possesses superior electrical properties comparable to metals. Besides that, they have additional advantages including light weight, transparency, intrinsic flexibility, processability, cost-effectiveness, biocompatibility, and so forth. Commonly used conductive polymers include polypyrrole (PPy), polyaniline (PANI), polythiophenes (PTs), and poly(3,4-ethylenedioxythiophene) (PEDOT) [9][11], which satisfy different practical requirements. In particular, polypyrrole has been widely utilized in biomedical applications, attributed to its thermal stability, biocompatibility, and biodegradability [30,31,32][12][13][14]. Nevertheless, it is sensitive to moisture and prone to deterioration over time when exposed to a humid environment [33][15]. In contrast, PANI displays high environmental stability and is the optimal choice for corrosion protection, while its non-biodegradability, low processability, and low flexibility limit its application in biological fields [34,35,36][16][17][18].2.3. Carbon Nanomaterial

Carbon nanomaterials (e.g., carbon nanotubes (CNTs), graphene and its derivatives) hold enormous potential in the application of flexible sensors. This is due to their low-dimensionality, huge specific surface area, and a collection of fascinating physical properties, including excellent flexibility, ultrahigh strength, and electrical conductivity.2.4. Two-Dimensional (2D) Materials

The intensive study of graphene has drawn worldwide attention to other 2D materials as well. Some emerging 2D materials such as transition metal dichalcogenides (TMDs) [49[19][20][21],50,51], transition metal carbides and nitrides (MXene) [52][22], black phosphorus [53][23], and metal-organic frameworks (MOFs) [54][24] have been synthesized and used for the preparation of flexible sensors.3. Microstructural Control of Fiber

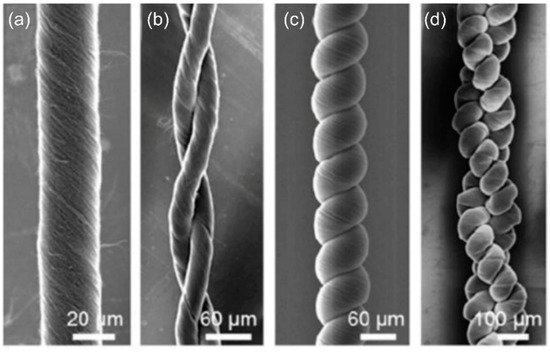

Fibers act as the building blocks of textiles to create various styles of clothes through knitting or weaving technologies. They are usually prepared by a spinning method (e.g., wet-spinning and electrospinning) and present a straight configuration with limited stretchability [58,59,60][25][26][27]. To this end, substantial efforts have been dedicated to improving the deformability of fiber sensors while maintaining high electrical conductivity.3.1. Helical or Twisted Structure

The creation of the helical structure of fibers affords an effective way to increase the stretchability, which can be achieved by mechanically twisting or coiling straight fibers. When the helix fiber is under tension, it is subject to a straightening process first, so that the tensile strain directly imposed on the fiber is minimized. It has been documented that the spiral-arranged textures along twisted graphene fibers improve their tear resistance and fracture toughness [61][28]. From a mass production perspective, twisting and coiling is also a relatively common process in industry and is simple to scale up.3.2. Core–Sheath Structure

The design of coaxial fibers provides an alternative pathway to gain higher stretchability. Coaxial fibers commonly include a conductive core wrapped by an elastic shell. Distinct from the twisting structure, the core–sheath structure offers a shorter ion transport path and a higher stability upon external loading due to the strong interface bonding within the layer-by-layer configuration [65][29].3.3. Buckling Structure

Introducing buckling structure via the pre-stretch-and-release method has been manifested as a facile way to realize the high stretchability and flexibility in electronic devices [70,71][30][31]. Similar to helical configuration, the buckling structure is flattened first under tensile loading, thus giving rise to a stable conductance during deformation. According to the literature [3[3][6],6], a buckling structure can be created in either conductive core fibers in TPE or conductive coating materials wrapped on pre-stretched elastomeric fibers.4. Configurational Engineering of Yarn

Yarn is defined as an assembly of a bunch of fibers held together through the insertion of twist to form continuous strands. From the structure point of view, typically, there are three main technologies involved in the production of yarn [77][32]: (1) Yarns are produced by placing the fibers in parallel that are bonded together via mutual frictional forces. Given the weak friction resistance dominated by van der Waals forces, the tensile loads imposed to the yarn easily induces mutual slippage when the yarn suffers from severe bending or twisting deformation. This is an irreversible process that can cause easier failure at low strains and faster degradation of conductivity. (2) Densely aligned CNT bundles can be prepared by twist spinning, typically showing a high conductivity of 300 S/cm) and high strength of more than 100 MPa, whereas the interfibrillar slip phenomena are still inevitable. As a result, the sensitivity of the helical fiber strain sensors is relatively low and strain range is also lower less than the maximum sustained strain. (3) In light of the limited stretchability of straight or twisted yarns, substantial efforts have been directed towards configurational engineering by introducing multiply or coiled structures via overtwisting the yarns under tension (Figure 6) [78][33].

4.1. Coiled Configuration

4.1. Coiled Configuration

Leveraging high flexibility of CNTs, Cao’s group [79][34] demonstrated the controlled fabrication of a yarn-derived spring-like CNT rope, where the loops were uniformly arranged. Inside each loop, the CNT bundles were observed to twist with slight alignment. These CNT ropes exhibited outstanding axial stretchability up to strain of 285% by loop unfolding and straightening during the stretching. Accordingly, the fracture toughness was also as high as 28.7 J/g. More importantly, the electrical conductivity of such CNT yarns was nearly 440 S/cm at the initial state and no degradation was noted after repeated loading cycles. Later on, Cao et al. [80][35] modified the spinning strategy and accurately controlled the loop position and number, and successfully fabricated a partial-helical structure. In contrast to the fully helical configuration, the partial one exhibited a better elasticity up to the strain of 25% as well as a linear resistance–strain relationship that is important for strain sensor applications.4.2. Two-Ply Coiled and Supercoiled Configuration

In order to further improve the strain range and failure limit, Cao’s group [82][36] proposed a two-level hierarchical composite structure composed of double-helix CNT yarn segments. During the stretching process, a two-stage fracture behavior could be observed, which gave rise to higher tensile strain and effectively delayed the failure process. When the first yarn fractured at around 75% strain, the resistance of double-helix CNT yarns exhibited a sudden change; after that, it kept increasing steadily until the eventual failure at around 170% strain. Apparently, such a hierarchical design would prolong the service lifetime of the double-helix CNT yarn-based sensors. Moreover, the toughness could be significantly enhanced to guarantee the device stability.4.3. Entangled Configuration

In addition to the coiled or double-helix yarns with relatively regular configurations, extreme overtwisting can produce entangled CNT yarns with a higher complexity [85][37]. With increasing overtwisting, the straight yarn gradually self-assembled into single-helix and then double-helix structures and finally developed random at multiple sites along the yarn axis while intertwining to generate amorphous configurations. An aggregation containing multiple self-interlocked twists were eventually generated. Such an entangled yarn structure was highly stable and could be stretched to 500% strain, with no change of resistance when disentangled. According to the stress–strain curves, multiple stress peaks were visible, corresponding to the resolving events of the double-helix segments within the entanglement. In addition to the large sensing range, the entangled coiled CNT yarn presented a cyclic stretching–releasing stability at 500% strain for 600 cycles.5. Pattern Design of Fabric

A fabric structure is made by the interlacement of yarns or intermeshing of the loops to act as 2D flexible materials [86][38]. The engineering design of patterns applied to smart textiles are based on mature textile manufacturing and garment assembly routines, such as knitting, weaving, braiding, embroidery, and sewing. From a mechanical and structural perspective, different fabric structures are entirely dissimilar to each other. For instance, the yarns in woven pattern are nearly immobile and form a dense and stable structure, so that the fabric is almost inextensible with limited deformations in the yarn structure. By comparison, the interlocked loops in a knit pattern usually deform and slide readily, giving rise to a high stretchability with significant changes in small-scale structure [87,88][39][40]. From the application perspective, each fabric manufacturing technique has its own pros and cons in light of specific substrate properties, of which the selection depends on the end-use of the electronic textile.5.1. Weaving

The most commonly used are the woven fabrics, consisting of yarn interlacements mutually in orthogonal directions [90][41]. The length, frequency, and distribution of interlacements in a woven fabric structure collectively decides its mechanical and functional characteristics. The above parameters are critical to the electrical performance as well since the consecutive points in interlacements influence the electrical contact [91][42]. According to the weave patterns, woven fabrics can be classified into plain weave, satin weave, twill weave, and so on, which can satisfy the needs of different applications.5.2. Knitting

Different from weaving, knitted fabric is created by interlocking loops of neighboring threads [97][43]. In contrast to woven fabrics that require elastic yarn with accessible extension < 10%, knitted fabrics offer high elasticity and can develop large extensions as high as 100% even based on non-elastic yarns. As mentioned above, although the stretching deformation of knits that involves a flattening of yarn loop curvature usually quickly recovers, the further deformation beyond such elastic stage would lead to yarn sliding against each other, which cannot be recovered immediately. The relevant energy dissipation accounts for higher fracture toughness and impact resistance of knitted fabric compared to the woven fabric.5.3. Non-Woven

A non-woven textile is produced by the physical or chemical bonding of fibers without any restriction. Both staple and filament fibers from different generic groups can be used to produce the non-woven fabrics (NWF). Apparently, the properties of NWF depend on the selection of fiber materials, the arrangement of fibers, and the bonding types and intensity. So far, some studies have demonstrated the application of NWF in wearable sensors, leveraging its specific functions including softness, resilience, flame retardancy, washability, and so forth.6. Coating Technology

The simplest way to manufacture textile-based sensors is spinning conductive fibers and yarns, followed by weaving and knitting. Alternatively, coating of conductive materials on fiber, yarn, or fabric affords another facile and efficient approach for the large-scale production of electronic textiles. Commonly used coating methods include in situ polymerization, vapor-phase polymerization, dip coating, spray coating, vacuum filtration, and rod coating. Chemical polymerization is suitable for making fabrics coated with conductive polymers such as PPy and PEDOT:PSS. A common practice is soaking the fabric in a solution containing the monomer, the oxidant, and the dopant to initiate the polymerization process. For example, Lycra fabric-based stretchable and conductive sensor was prepared by coating a PPy layer using a chemical polymerization method [104][44]. In contrast, vapor-phase polymerization provides a higher homogeneity of coating than chemical polymerization. Therein, the textile substrate is immersed in a solution of oxidant and dopant and then exposed to the vapor of the monomer to form the polymer layer. As a result, the sensitivity is higher but the sensing range is lower compared to the fabric coated with the in situ polymerization method [105][45]. Dip coating represents a simple way to prepare the conductive textiles. Soaking a Spandex fabric in aqueous PEDOT:PSS dispersion was demonstrated to endow the fabric with an electric conductivity of 0.06 S/cm [106][46]. Multiple dip coating can further increase the conductivity up to 1.7 S/cm; however, over-coating would lead to the interfacial delamination failure which has a negative effect on the electric performance. Spray coating has an advantage of better thickness controllability compared to dip coating.References

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001.

- Heo, J.S.; Eom, J.; Kim, Y.-H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14, 1703034.

- Seyedin, S.; Zhang, P.; Naebe, M.; Qin, S.; Chen, J.; Wang, X.; Razal, J.M. Textile strain sensors: A review of the fabrication technologies, performance evaluation and applications. Mater. Horiz. 2019, 6, 219–249.

- Li, S.; Xiao, X.; Hu, J.; Dong, M.; Zhang, Y.; Xu, R.; Wang, X.; Islam, J. Recent Advances of Carbon-Based Flexible Strain Sensors in Physiological Signal Monitoring. ACS Appl. Electron. Mater. 2020, 2, 2282–2300.

- Niu, B.; Hua, T.; Hu, H.; Xu, B.; Tian, X.; Chan, K.; Chen, S. A highly durable textile-based sensor as a human-worn material interface for long-term multiple mechanical deformation sensing. J. Mater. Chem. C 2019, 7, 14651–14663.

- Wang, J.; Lu, C.; Zhang, K. Textile-Based Strain Sensor for Human Motion Detection. Energy Environ. Mater. 2020, 3, 80–100.

- Chatterjee, K.; Ghosh, T.K. 3D Printing of Textiles: Potential Roadmap to Printing with Fibers. Adv. Mater. 2020, 32, e1902086.

- Duan, F.; Li, W.; Wang, G.; Weng, C.; Jin, H.; Zhang, H.; Zhang, Z. Can insulating graphene oxide contribute the enhanced conductivity and durability of silver nanowire coating? Nano Res. 2019, 12, 1571–1577.

- Weng, C.; Dai, Z.; Wang, G.; Liu, L.; Zhang, Z. Elastomer-Free, Stretchable, and Conformable Silver Nanowire Conductors Enabled by Three-Dimensional Buckled Microstructures. ACS Appl. Mater. Interfaces 2019, 11, 6541–6549.

- Hatamie, A.; Angizi, S.; Kumar, S.; Pandey, C.M.; Simchi, A.; Willander, M.; Malhotra, B.D. Review—Textile Based Chemical and Physical Sensors for Healthcare Monitoring. J. Electrochem. Soc. 2020, 167, 037546.

- Ghahremani Honarvar, M.; Latifi, M. Overview of wearable electronics and smart textiles. J. Text. Inst. 2016, 108, 631–652.

- Ferraz, N.; Strømme, M.; Fellström, B.; Pradhan, S.; Nyholm, L.; Mihranyan, A. In vitro and in vivo toxicity of rinsed and aged nanocellulose–polypyrrole composites. J. Biomed. Mater. Res. 2012, 100, 2128–2138.

- Mehdinia, A.; Bashour, F.; Roohi, F.; Jabbari, A. A strategy to enhance the thermal stability of a nanostructured polypyrrole-based coating for solid phase microextraction. Microchim. Acta 2012, 177, 301–308.

- Liu, Y.; Hu, J.; Zhuang, X.; Zhang, P.; Wei, Y.; Wang, X.; Chen, X. Synthesis and characterization of novel biodegradable and electroactive hydrogel based on aniline oligomer and gelatin. Macromol. Biosci. 2012, 12, 241–250.

- Saxena, R.; Sharma, K.; Saxena, N.; Sharma, T. Effect of annealing on structural and optical properties of polypyrrole doped with different acids. Polym. Compos. 2009, 30, 820–826.

- Ansari, R.; Keivani, M. Polyaniline conducting electroactive polymers thermal and environmental stability studies. E-J. Chem. 2006, 3, 202–217.

- Kalendová, A.; Veselý, D.; Sapurina, I.; Stejskal, J. Anticorrosion efficiency of organic coatings depending on the pigment volume concentration of polyaniline phosphate. Prog. Org. Coat. 2008, 63, 228–237.

- Park, C.S.; Lee, C.; Kwon, O.S. Conducting polymer based nanobiosensors. Polymers 2016, 8, 249.

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712.

- Rao, C.N.; Gopalakrishnan, K.; Maitra, U. Comparative Study of Potential Applications of Graphene, MoS2, and Other Two-Dimensional Materials in Energy Devices, Sensors, and Related Areas. ACS Appl. Mater. Interfaces 2015, 7, 7809–7832.

- Wang, G.; Zhang, Z.; Wang, Y.; Gao, E.; Jia, Z.; Dai, Z.; Weng, C.; Liu, L.; Zhang, Y.; Zhang, Z. Out-of-Plane Deformations Determined Mechanics of Vanadium Disulfide (VS2) Sheets. ACS Appl. Mater. Interfaces 2021, 13, 3040–3050.

- An, J.; Ma, Y.; He, M.; Yan, J.; Zhang, C.; Li, X.; Shen, P.; Luo, S.; Gao, Y. A Wearable and Highly Sensitive Textile-based Pressure Sensor with Ti3C2Tx Nanosheets. Sens. Actuators A Phys. 2020, 311, 112081.

- Eswaraiah, V.; Zeng, Q.; Long, Y.; Liu, Z. Black Phosphorus Nanosheets: Synthesis, Characterization and Applications. Small 2016, 12, 3480–3502.

- Stassen, I.; Burtch, N.; Talin, A.; Falcaro, P.; Allendorf, M.; Ameloot, R. An updated roadmap for the integration of metal-organic frameworks with electronic devices and chemical sensors. Chem. Soc. Rev. 2017, 46, 3185–3241.

- Xu, T.; Zhang, Z.; Qu, L. Graphene-Based Fibers: Recent Advances in Preparation and Application. Adv. Mater. 2020, 32, e1901979.

- Wu, S. Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors. Crystals 2021, 11, 1484.

- Wu, S.; Qureshi, T.; Wang, G. Application of Graphene in Fiber-Reinforced Cementitious Composites: A Review. Energies 2021, 14, 4614.

- Fang, B.; Chang, D.; Xu, Z.; Gao, C. A Review on Graphene Fibers: Expectations, Advances, and Prospects. Adv. Mater. 2020, 32, e1902664.

- Wang, L.; Fu, X.; He, J.; Shi, X.; Chen, T.; Chen, P.; Wang, B.; Peng, H. Application Challenges in Fiber and Textile Electronics. Adv. Mater. 2020, 32, e1901971.

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607.

- Zhao, L.; Zhang, L.; Zhao, J.; Shi, J.; Dai, Z.; Wang, G.; Zhang, C.; Li, B.; Feng, X.; Zhang, H.; et al. Engineering Surface Patterns with Shape Memory Polymers: Multiple Design Dimensions for Diverse and Hierarchical Structures. ACS Appl. Mater. Interfaces 2019, 11, 1563–1570.

- Huang, C.-T.; Shen, C.-L.; Tang, C.-F.; Chang, S.-H. A wearable yarn-based piezo-resistive sensor. Sens. Actuators A Phys. 2008, 141, 396–403.

- Jang, Y.; Kim, S.M.; Spinks, G.M.; Kim, S.J. Carbon nanotube yarn for fiber-shaped electrical sensors, actuators, and energy storage for smart systems. Adv. Mater. 2020, 32, 1902670.

- Shang, Y.; He, X.; Li, Y.; Zhang, L.; Li, Z.; Ji, C.; Shi, E.; Li, P.; Zhu, K.; Peng, Q.; et al. Super-stretchable spring-like carbon nanotube ropes. Adv. Mater. 2012, 24, 2896–2900.

- Shang, Y.; Li, Y.; He, X.; Zhang, L.; Li, Z.; Li, P.; Shi, E.; Wu, S.; Cao, A. Elastic carbon nanotube straight yarns embedded with helical loops. Nanoscale 2013, 5, 2403–2410.

- Shang, Y.; Li, Y.; He, X.; Du, S.; Zhang, L.; Shi, E.; Wu, S.; Li, Z.; Li, P.; Wei, J.; et al. Highly twisted double-helix carbon nanotube yarns. ACS Nano 2013, 7, 1446–1453.

- Li, Y.; Shang, Y.; He, X.; Peng, Q.; Du, S.; Shi, E.; Wu, S.; Li, Z.; Li, P.; Cao, A. Overtwisted, resolvable carbon nanotube yarn entanglement as strain sensors and rotational actuators. ACS Nano 2013, 7, 8128–8135.

- Banerjee, P.K. Principles of Fabric Formation; CRC Press: Boca Raton, FL, USA, 2014.

- Gong, H.; Ozgen, B. Fabric structures: Woven, knitted, or nonwoven. In Engineering of High-Performance Textiles; Elsevier: Amsterdam, The Netherlands, 2018; pp. 107–131.

- Maziz, A.; Concas, A.; Khaldi, A.; Stalhand, J.; Persson, N.K.; Jager, E.W. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327.

- Behera, B.K.; Hari, P. Woven Textile Structure: Theory and Applications; Elsevier: Amsterdam, The Netherlands, 2010.

- Agcayazi, T.; Chatterjee, K.; Bozkurt, A.; Ghosh, T.K. Flexible Interconnects for Electronic Textiles. Adv. Mater. Technol. 2018, 3, 1700277.

- Spencer, D.J. Knitting Technology: A Comprehensive Handbook and Practical Guide; CRC Press: Boca Raton, FL, USA, 2001; Volume 16.

- Wu, J.; Zhou, D.; Too, C.O.; Wallace, G.G. Conducting polymer coated lycra. Synth. Met. 2005, 155, 698–701.

- Li, Y.; Cheng, X.; Leung, M.; Tsang, J.; Tao, X.; Yuen, M. A flexible strain sensor from polypyrrole-coated fabrics. Synth. Met. 2005, 155, 89–94.

- Ding, Y.; Invernale, M.A.; Sotzing, G.A. Conductivity trends of PEDOT-PSS impregnated fabric and the effect of conductivity on electrochromic textile. ACS Appli. Materi. Interfaces 2010, 2, 1588–1593.