Carbon Capture and Utilization (CCU) is a viable solution to valorise the CO2 captured from industrial plants’ flue gas, thus avoiding emitting it and synthesizing products with high added value. The first step in a CCU process is the capturing ofOn the other hand, using CO2 through well-known technologie as, such as oxyfuel combustion, pre-combustion or post-combustion, or as a direct-air capture process. Post-combustion carbon capture can be achieved by physical or chemical separation methods, such as membranes, adsorption, absorption and cryogenic processes. After having captured and concentrated the CO2, a reactant in chemical processes is a challenging task, and a rigorous analysis of the performance its can be fneeded to a chemical reactor for its conversion into products, such as syngas, urea, methane, ethanol, formic acid, etcevaluate the real impact of CCU technologies in terms of efficiency and environmental footprint.

1. Introduction

Climate change mitigation is a worldwide effort that involves all countries around the world. Among all problems, greenhouse gas (GHG) emissions have a significant impact on the environment. Regarding this matter, the Intergovernmental Panel on Climate Change (IPCC) and the United Nations Climate Change Conference have established the needs of reducing CO2 emissions (recognized as the gas mainly responsible for climate change) and mitigating the global average temperature increase. Targets were set up, proposals to reach them were provided, and some technologies were identified as a solution in counteracting this issue.

The extensive concentration of carbon dioxide in the atmosphere is a threat to environmental safety, contributing to the greenhouse effect, but CO

2 is a source of carbon for plants and can also be used as a reactant in chemical reactions

[1][2][3][1,2,3]. This concept has led to the development of Carbon Capture and Utilization (CCU) technologies, which are perceived as a more justified and socially acceptable technology for CO

2 management than Carbon Capture and Storage (CCS). However, even if they can be considered a feasible solution, their cost is still an issue. Hasan et al. proposed a national Carbon Capture Utilization and Storage (CCUS) supply chain network for a U.S. case study in their multiscale framework analysis

[4]. With the proposed solution focused on profit rather than maximizing CO

2 utilization, average profits between $0.3 and $17.6 per ton of CO

2 were achieved (depending on the weighted average total costs of capturing and utilizing a ton of CO

2).

There are plenty of ways to apply CCU technology wherever there is a CO2-emitting source, e.g., energy-intensive industry branches, such as energy, petrochemical and cement or iron and steel production. Additionally, CCU reactions can be supported with green technologies, such as renewable energy sources (RES).

The first step in a CCU process is the capturing of CO

2 through well-known technologies, such as oxyfuel combustion, pre-combustion or post-combustion, or as a direct-air capture process

[5][6][5,6]. Post-combustion carbon capture can be achieved by physical or chemical separation methods, such as membranes, adsorption, absorption and cryogenic processes. Many of these technologies are already applied in industry

[7]. Pre-combustion processes capture CO

2 prior to the combustion reaction and it can be achieved with the coal gasification process or with oil or gas fuel-reforming processes

[8][8].After having captured and concentrated the CO2, it can be fed to a chemical reactor for its conversion into products, such as syngas, urea, methane, ethanol, formic acid, etc. This paper is focused on the analysis of configurations to synthesize methanol and dimethyl ether (DME) from CO2.

Dimethyl ether (DME) or methoxymethane is the simplest aliphatic ether with the molecular formula CH

3OCH

3. It is a colourless, near-odourless gas under ambient conditions. It is neither a toxic nor carcinogenic compound, with properties similar to liquid petroleum gas (LPG); thus, it can be easily blended with it and used as a fuel

[9][10][11][9,10,11]. In the chemical industry, it is mainly used to produce diethyl sulphate, methyl acetate, light olefins and gasoline

[12]. Nowadays, it is considered an alternative fuel with low emissions of NOx, hydrocarbons and carbon monoxide

[2][13][2,13]. DME can be obtained in two ways: direct synthesis and through the methanol dehydration process. The first method’s reactions are:

The process of direct DME synthesis is exothermic (c.a. 246.2 kJ/mol DME); therefore, the heat produced during the reactions has to be removed. The inlet reactant mixture is composed of CO and H2.

Methanol dehydration to produce DME is also an exothermic process. CO

2 can be used to produce methanol and then dehydrate it to DME. This has been proven to be a very economical way of utilizing carbon dioxide

[2][14][15][2,14,15]. The chemical reactions occurring during the process are presented below:

Reverse water–gas shift (rWGS)

In Ref.

[16], the authors explored the profitability of DME production from biogas; in Ref.

[17], a techno-economic assessment of bio-DME and bio-methanol production from oil palm residue was proposed. Methanol is a colourless, flammable liquid under ambient conditions with a characteristic odour. As one of the most important raw materials, it is a substrate in many syntheses of chemical compounds, including formaldehyde, acetic acid and chloromethane. It is also a very good solvent and it is easily miscible with water, alcohols and organic solvents. Due to its wide application in many industries (fuel, chemical and other industries), the demand for methanol is constantly growing, i.e., from 47 Mt/a in 2011

[18] to 100 Mt/a in 2021

[19]. According to the report made by the International Renewable Energy Agency

[19], in 2021, only 0.2% of global production of methanol came from renewable sources—more than 60% was converted by natural gas reformation and the rest was produced by natural coal gasification.

Methanol can be synthesized from a gas containing either carbon monoxide or carbon dioxide when it reacts with hydrogen:

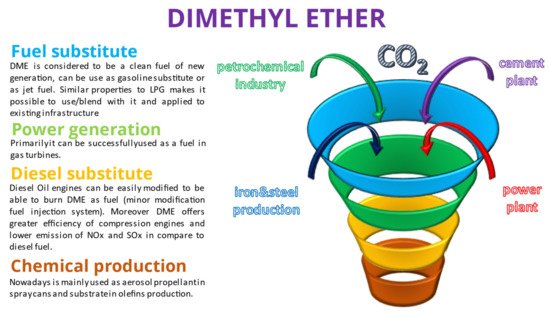

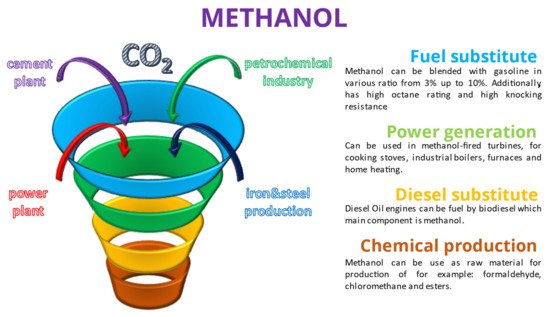

The main properties of DME and methanol in comparison with LNG and diesel oil are shown in Table 1. Moreover, several potential major applications of DME and methanol are shown below in Figure 1 and Figure 2.

Figure 1. Applications of DME [20][21]. Applications of DME [20,24].

Figure 2. Applications of methanol [18][19][22]. Applications of methanol [18,19,25].