Thise paper aims to assess the relationship between Industry 4.0 (I4.0) and the circular economy that could contribute to supply chain vertical disintegration of companies has increased the complexity of management performance. To achieve this, a combination of the interpretative structural modelling (ISM) and (cross-impact matrix multiplication applied to classification) MICMAC approach was used to establish the interrelationships between these topics. The developed analysis reveals that there are 19 constructs capable of elucidating this relationship and that there is a hierarchy between these constructs, which are presented in a structural model. Further, the different levels of dependency and driving power arein terms of time and quality and increased uncertainty in the markets, making it impossible today for companies to compete effectively if they are isolated from their suppliers and other stakeholders. In this context, adopting the concept of supply chains (SCs) is increasingly essential for a compared in a cluster diagram. As the main result, it was found that there is a strong mutual relationship between the basic technologies. The use of Internet of Things and cloud computing technologies influencesny’s performance. Moreover, two themes are being increasingly discussed in the context of SCs, the collection of large amounts of data, leading to big data, which in turn influence the use of data analytics tools to obtain competitive advantages. These outcomes may contribute to managers’ more assertive decision-making regarding the selection, implementation, and evaluation of projects adopting Industry 4.0 technologies and circular economy approaches in supply chains. Moreover, our study could bircular economy (CE) and Industry 4.0 (I4.0). The CE paradigm consists of a possible way to achieve environmental objectives and economic sustainability by developing systemic changes that go beyond the individual company and involve the basis for future empirical research to investigate how companies incorporate Industry 4.0 technologies into their processes and how this influences the quest for sustainablother actors in the SC, contributing to adding value to a product and/or service supply chains.

- circular economy

- industry 4.0

- supply chain management

- interpretive structural modelling

- MICMAC approach

1. Introduction

2. The Importance of the CE and I4.0 for SC Performance

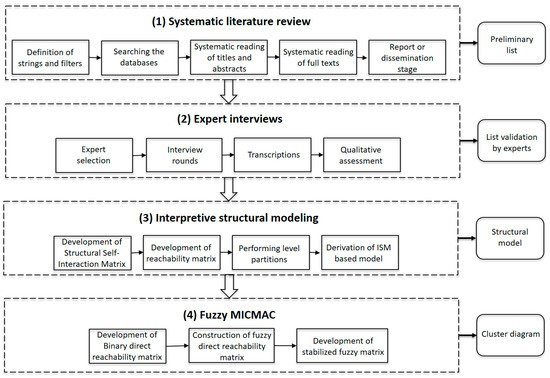

Population growthe potential effect of these constructs on SC performance? As a starting point, a syste linked to economic and technological development has led to changes in the types of production and consumption, making SCs increasingly dependent and unsustainable [4]. Growing marketic literature review (SLR) was developed, resulting in 19 constructs. Subsequently, the interaction competitiveness, environmental changes, public pressure, and environmental legislation have generated the need for organizations to change their production systems’ operations to ensure the coexistence of industrial development and environmental protection [16]. For these between these conchanges to occur, it is necessary to redefine the basic structs aure of SCs to include environmental issues [17]. As recommended by the strengCE literature [5], the of the driving and dependence power of this relfirst step of this change is to migrate from a linear SC to a closed-loop one. When SCs extend environmental concerns to their operationship were p, they are characterized as a circular supply chain (CSC) [6]. According to Srivastava [18] (posed. 54), using a combined interpretive structural modelling (ISM) and fuzzy MICMAC (Matrice d’Impacts Croisés Multiplication Appliqués à un Classement (ccircular supply chain management (CSCM) can be defined as “the integration of environmental thinking with supply chain management, including product design, material selection and supply, manufacturing process-impact matrix multiplication applied to classifices, delivery of the final product to consumers and the management of the entire product life cycle, even after the end of its useful life”. The adoption) an of the CSCM requires a paradigm shift [13][18]. Specificallysis.2. Theoretical Background

3. Research Method

T0 withis research aims to identifythe goals of the circular economy”. Therefore, there is an opportunity to investigate the relationships between these three themes.3. The Literature Regarding the Relationship between the CE and I4.0 and Its Effect on SC Performance

The need to optimise SCs due to the competitive pressures of the market promotes and encourages the adoption of I4.0 technologies, in parallel with CE approaches [15]. According to Rajput [24], andthe SC performance. For this, the ISM approach was chosen to identify and classifyCE integration with I4.0 is a way to achieve sustainability, as it reduces barriers such as lack of information regarding the life cycle of products and uncertainty about the return on investments [25]. Forela example, as Tiwari [8] (p. 2) stated, “the advent and adoptionships between variables [10] of digital technologies based on the principles of Industry 4.0 may This methodology involves four steps [10,31,32]:help to overcome the barriers to the adoption of CE”. In other words, if organisations want (1)to identification of elements thamaintain and strengthen their competitive potential, they need to embrace technological and environmental changes together [12]. In this context, relatJabbour et al. [15] proposed the three research topirelationship between the CE business actions and I4.0 technologies (Table 1).| ReSOLVE Strategies | I4.0 Technologies |

|---|---|

| Regenerate | Internet of Things (IoT) |

| Share | Cloud computing and IoT |

| Optimise | Cyber–Physical Systems (CPS) and IoT |

| Loop | CPS, IoT and Cloud computing |

| Virtualise | Cloud computing, IoT and Additive Manufacturing |

| Exchange | Additive Manufacturing |

4. Conclusions

The main contribution of this research is to present the relationships between the different constructs of the studied themes. The ISM model, the reachability matrix, and the strength matrix of relationships are, together, valuable tools for understanding the direction, order, and power of the complex relationships between I4.0, the CE, and SC performance. Using these tools, managers can make more proactive and consistent decisions regarding implementing I4.0 technologies and CE approaches. They can also select the main performance measures associated with this implementation, allowing the evaluation of the performance of projects with greater accuracy.

References

- Kaur, H.; Prakash Singh, S. Multi-stage hybrid model for supplier selection and order allocation considering disruption risks and disruptive technologies. Int. J. Prod. Econ. 2021, 231, 107830.

- Mastos, T.D.; Nizamis, A.; Vafeiadis, T.; Alexopoulos, N.; Ntinas, C.; Gkortzis, D.; Papadopoulos, A.; Ioannidis, D.; Tzovaras, D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. J. Clean. Prod. 2020, 269, 122377.

- Abdul-Hamid, A.-Q.; Ali, M.H.; Osman, L.H.; Tseng, M.-L. The drivers of industry 4.0 in a circular economy: The palm oil industry in Malaysia. J. Clean. Prod. 2021, 324, 129216.

- Kakadellis, S.; Woods, J.; Harris, Z.M. Friend or foe: Stakeholder attitudes towards biodegradable plastic packaging in food waste anaerobic digestion. Resour. Conserv. Recycl. 2021, 169, 105529.

- Elia, V.; Gnoni, M.G.; Tornese, F. Evaluating the adoption of circular economy practices in industrial supply chains: An empirical analysis. J. Clean. Prod. 2020, 273, 122966.

- Ozkan-Ozen, Y.D.; Kazancoglu, Y.; Kumar Mangla, S. Synchronized Barriers for Circular Supply Chains in Industry 3.5/Industry 4.0 Transition for Sustainable Resource Management. Resour. Conserv. Recycl. 2020, 161, 104986.

- Vacchi, M.; Siligardi, C.; Cedillo-González, E.I.; Ferrari, A.M.; Settembre-Blundo, D. Industry 4.0 and smart data as enablers of the circular economy in manufacturing: Product re-engineering with circular eco-design. Sustainability 2021, 13, 10366.

- Tiwari, D.; Miscandlon, J.; Tiwari, A.; Jewell, G.W. A review of circular economy research for electric motors and the role of industry 4.0 technologies. Sustainability 2021, 13, 9668.

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721.

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34.

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687.

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the influence of industry 4.0 technologies on the circular economy. J. Clean. Prod. 2021, 321, 128944.

- Ambec, S.; Lanoie, P. Negotiating Identities: Proceedings of the 13th Annual Conference of the South African Association of Art Historians. Acad. Manag. Rev. 2008, 45–63.

- Bashtannyk, V.; Buryk, Z.; Kokhan, M.; Vlasenko, T.; Skryl, V. Financial, economic and sustainable development of states within the conditions of industry 4.0. Int. J. Manag. 2020, 11, 406–413.

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286.

- Díaz-Chao, Á.; Ficapal-Cusí, P.; Torrent-Sellens, J. Environmental assets, industry 4.0 technologies and firm performance in Spain: A dynamic capabilities path to reward sustainability. J. Clean. Prod. 2021, 281, 125264.

- Hummels, H.; Argyrou, A. Planetary demands: Redefining sustainable development and sustainable entrepreneurship. J. Clean. Prod. 2021, 278, 123804.

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80.

- Díaz-Ramírez, M.C.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Environmental assessment of electrochemical energy storage device manufacturing to identify drivers for attaining goals of sustainable materials 4.0. Sustainability 2020, 12, 342.

- Isernia, R.; Passaro, R.; Quinto, I.; Thomas, A. The reverse supply chain of the e-waste management processes in a circular economy framework: Evidence from Italy. Sustainability 2019, 11, 2430.

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177.

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71.

- Bhargava, B.; Ranchal, R.; Ben Othmane, L. Secure information sharing in digital supply chains. Proceedinigs of the 2013 3rd IEEE International Advance Computing Conference (IACC), Ghaziabad, India, 22–23 February 2013; 2013; pp. 1636–1640.

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113.

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Sarkis, J.; Filho, M.G. Unlocking the circular economy through new business models based on large-scale data: An integrative framework and research agenda. Technol. Forecast. Soc. Chang. 2019, 144, 546–552.

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583.

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers. Comput. Ind. 2020, 122, 103280.

- Manavalan, E.; Jayakrishna, K. An analysis on sustainable supply chain for circular economy. Procedia Manuf. 2019, 33, 477–484.

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627.