Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by James Read and Version 2 by Rita Xu.

Survivability assessment can be defined as the method by which the penetration performance of a protective material is measured. The key metric here is how effective the material is at dissipating energy throughout its molecular matrix, thereby protecting the material’s integrity and providing enhanced protection to the user from both ballistic and non-ballistic threats.

- tissue analogue

- ballistic gelatine

1. Survivability Assessment

Because of protective materials’ applications, they are subjected to a rigorous qualification process that describes how the materials should be tested and the pass criteria for both ballistic- and-stab resistant materials [1][3]. This assessment is traditionally conducted by applying tensile load to the material sample until failure occurs [2][4]. Thereby providing a comprehensive understanding of the material’s limitations and the applicability for its intended purpose.

This alone cannot be relied upon to portray a full perspective of what is happening on impact. To accurately assess a projectile’s influence on the human body, the specialist field of wound ballistics is used. Wound ballistics primarily concerns itself with three types of projectiles (handgun bullets, bullets from long-range weapons, and fragmentation), their differences in behaviour within the target, and wound channel formation [3][5].

Upon impact with the front face of the simulant, the projectile decelerates, which, as it continues inside the medium, exhibits radial energy, creating the ‘Temporary Cavity’ [4][6]. This reaction can also be seen to ‘pulse’ when the energy exerted inside the body and the entry and exit of air into the wound causes expansion and contraction of the tissue before collapsing because of the human anatomy’s internal elasticity [3][5]. Simulants such as gelatine have been reported to be most desirable for this research because their elasticity is similar to that of the human torso [3][5], but because of this elasticity, the cavity collapses immediately [5][7], which, without the use of high-speed video footage, would be rendered useless because of the inability for the human eye to witness a millisecond reaction.

The permanent cavity is more simplistic; this is the pathway the projectile has created, which can vary in size and routing depending on factors such as tissue density, muscle content, and bone location [3][5] as well as projectile size, yaw, tumbling, and the angle of entry [6][8]. The permanent cavity is traditionally clearly identified post impact [7][9], but the analysis of the temporary cavity can better identify the amount of force generated upon projectile impact and the dissipation of that energy throughout the surrounding tissues/organs.

2. Simulants

Traditionally, human cadavers and animals have been used to assess wounding and behind-armour effects [8][10], but they do not provide an accurate enough material when an assessment of penetration or perforation is required [9][11]. With more ethical considerations at the forefront of any research project in the modern day, simulants have become the go-to material for many researchers. The cost and availability benefits are notable, whilst the ability to replicate and validate existing experiments is the main benefit compared with animal anatomy, which differs with the individual animal [3][5]. Whilst these top-level advantages provide some justification for using simulants, there are also drawbacks that should be examined.2.1. Ballistic Gelatine

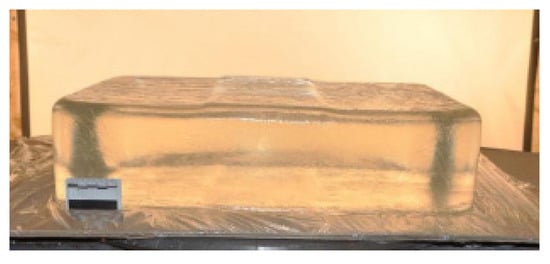

Ballistic gelatine is a widely accepted material for survivability assessment and wound ballistic research. Two types are readily available: Type A, which is derived from acid-treated collagen found in pig skin, and Type B, which is derived from alkali-treated beef skin [10][12]. As the human anatomy is more closely aligned to that of porcine anatomy [8][11][10,13], the most widely used gelatine is Type A. Type A material consists of an acid-treated collagen protein found in animal products [8][10] and is manufactured in 10 and 20% mass constructs before being conditioned at specific temperatures before use. Both 10 and 20% constructs’ ability to replicate the human body is measured by their strength and stiffness properties, which are referred to as the ‘bloom number’. Ballistic gelatine is available in 50–300 bloom constructs [8][10]; however, the Type A bloom number must reside between 250 and 300 to provide accurate results in wound ballistic research [12][14]. To provide the bloom number, a 112 g sample of 6.67 w/w gelatine is manufactured to standardised time and temperature systems before undergoing a compressive test resulting in the bloom figure [13][15]. It has been reported that the concentration and temperature during preparation can also influence the performance ability [9][11] but should be controlled using calibration. Currently calibrated using the US Fackler method [14][16], the 10% construct (Figure 1) is reported to be the most beneficial for uses in which penetrating impact analyses are required [15][17]. Manufactured with 90 parts water and 10 parts gelatine, the material can be affected by water quality, temperature, and post-manufacture conditioning [13][15], leading to inconsistencies in output data. However, with variables that can be controlled in lab environments, this material has historically shown its viability in wound ballistic research. By contrast, the 20% construct is uncalibrated [15][17] and is often referred to as ‘NATO’ gelatine [13][15], which is manufactured with 80 parts water and 20 parts gelatine powder [3][5]. It has been reported that 20% gelatine is superior to 10% gelatine when examining deflection and force data, with outputs showing reactions closer to those of human responses [16][18]; however, this evidence is singular, and the claim that performance is only viable for these measurements cannot be found elsewhere. Similar to the 10% construct, this material also exhibits issues with water quality, temperature, and post-manufacture conditioning, but because of the uncalibrated manufacturing technique [12][14], researchers can vary their manufacturing method, increasing the difficulty in experiment repeatability. Regardless of which construct of ballistic gelatine is used, the shelf life remains poor [12][13][14,15]. Polymer-based gels, such as the brain tissue simulants Sylgard and Styrene-Ethylene-Butylene-Styrene (SEBS), which is a thermoplastic elastomer [17][19], have been developed to provide a suitable alternative with similar performance properties to those of ballistic gelatine to measure behind-armour blunt trauma and back-face deformation. This may eliminate storage requirements and alleviate shelf-life issues; however, the existing issue of manufacturing variable control remains of concern for survivability.2.2. Perma-Gel®

Although 10 and 20% constructs are valid means by which to assess multiple technologies within both the defence and civilian research fields, Perma-Gel® (shown in Figure 2) provides re-meltable and re-castable properties that reduce both project costs and environmental impacts yet has been reported to exhibit similar performance properties to both types of gelatine [18][19][20,21]. Perma-Gel can be categorised as a transparent synthetic thermoplastic material that is manufactured using gellants, mineral oil, and butylated hydroxytoluene [19][21]. Previous research has also shown that this material’s response to impact is similar to that of other co-polymers of similar compositions [20][22]. Other advantages include increased shelf life in comparison to gelatine; no pre-conditioning being required, cutting project time; and its transparency and ability to analyse various wound ballistics perimeters, such as temporary and permanent cavities [3][4][5,6]. It has been reported that, once remelted and reformed, the material behaves differently and can affect Depth of Penetration values [12][14]. Although this has been reported, no work appears to have further explored why this phenomenon occurs. Furthermore, there have been reports that the material may only be suitable for reuse between 10–15 times, and the more the material is remelted and reused, a yellow tint appears to form within the blocks, which may interfere with output data [13][15]. A. Mabbot’s work provided insight into Perma-Gel® and confirmed that either information on these data is unverified or that gaps exist in the literature [13][15].2.3. Ballistic Soap

Ballistic soap (shown in Figure 3) has been reported to produce the same desirable characteristics as gelatine (density, isotropy, and homogeneity) [21][23]; however, it lacks the elasticity properties required for survivability assessment. This material is typically manufactured using the hydrolysis of fats with a strong base to form sodium or potassium salts of carboxylic acid. This, paired with the remaining glycerine by-product, generates long aliphatic hydrocarbon chains that govern the behaviour of ballistic soap [22][24]. Upon the impact of a bullet, ballistic soap exhibits plastic-like behaviour and is thus more suited to capturing information on the maximum sizes of the temporary cavity rather than exploring the permanent cavity pathway. This can be carried out using X-ray or by cutting into the block to reveal the wound profile [3][5]. It is thus only viable to use this material for partial experimental data capture, as all-encompassing use would result in invalid conclusions because of the inability to analyse the full extent of the damage caused by the bullet impact and inaccurate results. Unlike gelatine, ballistic soap has a much longer storage life (a number of years as opposed to days) [9][11]; this is predominantly due to the complex glycerine manufacturing process, which means the material is purchased by the researcher as opposed to being made on site. Prior to any data capture, the material should undergo baseline testing to ensure that viable performance is shown and that a comparison can be made with previous/future blocks. However, as these are not reusable materials, nor are they transparent, the opportunity to realise cost savings and use high-speed video footage to analyse results is limited.2.4. Roma Plastilina® Clay No. 1

Traditionally used to measure behind-armour blunt trauma (BABT), Roma Plastilina No. 1 modelling clay consists of minerals, oils, and waxes [24][25][26,27]. It is placed within a 420 × 350 × 100 mm steel tray with one large face exposed, ensuring that no air gaps exist [1][3]. The exposed face is made smooth by scraping the material to align with the edges of the steel tray, thereby creating a defect-free face. Because of the complexity in manufacture, ROMA Plastilina No. 1 is traditionally bought from a supplier before being moulded, as stated above, and conditioned within laboratory conditions [25][27]. Prior to exposure to experimental conditions, the moulded blocks must be calibrated to ensure that the material aligns with both the National Institute of Justice [26][28] and CAST standards [27][29] depending on the customer base and test location. This begins with the material being conditioned to 30 °C for at least 3 h prior to calibration. The material is then led flat, and a minimum of 3 drop tests from 1.5 m ± 0.5 (2 m for NIJ) are conducted using a 1.043 kg spherical steel ball 63.5 mm in diameter [26][27][28,29]. To pass, the material must not decompress more than 15 mm ± 1.5 mm for CAST and 20 mm ± 3 mm for NIJ, which is measured using a vernier calliper from the top of the tray [28][30]. Once calibrated, experimentation must be conducted at a controlled temperature [29][31], ensuring that the output data remain consistent and no premature ageing of the material occurs [30][32]. Additionally, the material is considered to be out of calibration within 45 min [31][33]. The protective material is located centrally to the front face of the Plastilina and secured to minimise movement; this is highlighted in Figure 4. Once testing has been completed, the protective material is removed from the front face of the Plastilina, and any depth of indentation is measured using a vernier calliper or another agreed-upon method [15][17]. It should be noted that, because of the construction of Roma Clay, the mixture equates to roughly twice the density of human tissue and is thus used as a worst-case testing material [29][31]. Survivability assessment can be achieved using a magnitude of materials [32][34]. Regardless of which gelatine or alternative synthetic material is used, excessive water is used and waste is generated during experimental regimes, which, in a world that is aiming to reduce its impact on climate change, is unacceptable, and a shift in approach is required. To further elaborate on the advantages and disadvantages of the previously discussed materials, see Table 1.| Simulant Name | Reported Advantages | Reported Disadvantages |

|---|---|---|

| Gelatine | Removes ethical concerns | Lacks biomechanical properties of organs and tissues |

| Accepted as human tissue simulant | Only represents human torso/porcine thigh | |

| History of extensive testing | Radial cracks occur during bullet penetration | |

| Demonstrates temporary and permanent cavity mechanics | Affected by bacterial contamination, decomposition, and short storage life (2–3 days prior to use) | |

| Elasticity similar to human tissue | Different blooms used | |

| Transparency | Varying concentrations | |

| Not re-useable | ||

| Temperature-dependant—must be kept refrigerated | ||

| No standard manufacturing procedure | ||

| Perma-Gel® | Reported to be re-useable (8–15 times) | Limited data to confirm claims on performance and re-useability |

| No pre-conditioning required | Only comes in one block size | |

| Clear and odourless material | Difficulties with disposal (synthetic polymer) | |

| Captures permanent cavity | ||

| Displays temporary cavity formation | ||

| Ballistic Soap | Long storage life | Not re-useable |

| No pre-conditioning required | Purchase only—not made in-house because of manufacturing complexity | |

| Captures max size of temporary cavity (viewed in place) | Opaque nature—limited opportunity to review high-speed video | |

| Non-elastic nature | ||

| Roma Plastilina® | History of extensive testing | Opaque nature—limited opportunity to review high-speed video |

| No pre-conditioning required | Non-elastic nature | |

| Moulding to shapes is easy | Purchase only—not made in-house because of manufacturing complexity |