It is impossible to describe the recent progress of our society without considering the role of polymers; however, for a broad audience, “polymer” is usually related to environmental pollution. The poor disposal and management of polymeric waste has led to an important environmental crisis, and, within polymers, plastics have attracted bad press despite being easily reprocessable. Nonetheless, there is a group of polymeric materials that is particularly more complex to reprocess, rubbers. These macromolecules are formed by irreversible crosslinked networks that give them their characteristic elastic behavior, but at the same time avoid their reprocessing. Conferring them a self-healing capacity stands out as a decisive approach for overcoming this limitation. By this mean, rubbers would be able to repair or restore their damage automatically, autonomously, or by applying an external stimulus, increasing their lifetime, and making them compatible with the circular economy model.

- self-healing materials

- self-healing rubbers

- natural rubber

- synthetic rubber

- dynamic networks

- supramolecular chemistry

1. Introduction

2. To Boldly Go Where No Material Has Gone before: Self-Healing Concepts

Self-healing is the ability to repair or restore damages [45,46,47,48]. To scientifically understand healing as a physical process, four key concepts must be considered in rubbers: (1) Mechanism, (2) Mobility, (3) Localization and (4) Temporality [49]. In elastomers, the success of the self-healing process goes hand in hand with the adequate selection of a mechanism that guarantees the necessary molecular mobility of the polymeric chains, as well as enough time for the restoration of the damage according to its location (on a macroscopic or microscopic scale) [50]. The first concept is the mechanism. Self-healing can occur extrinsically or intrinsically [51,52]. Extrinsic mechanisms are based on an external healing agent that is incorporated into the matrix in an encapsulated form, in vascular networks or freely dispersed. When damage occurs, these agents are released and/or flow through the damage area, sealing it. Despite being the first mechanisms used, according to the historical development, their use in rubbers is very limited due to the difficulties of preserving the stability of the agent during the conventional mixing process of rubber recipes (enormous shear forces) [49]. The intrinsic mechanisms are based on the creation of crosslinking points using dynamic covalent bonds or supramolecular interactions. On one hand, dynamic covalent bonds activate this character under different external stimuli and can occur through an associative or dissociative pathway. The associative pathway is characterized by a constant crosslink density during the exchange. Meanwhile, the dissociative one is characterized by a change in the crosslink density over time, due to an independent reformation and formation of the bonds [15,53]. On the other hand, supramolecular interactions are non-covalent in nature and have also been shown to be successful strategies to achieve repairability [15,54,55]. From a general point of view, intrinsic mechanisms can be classified as [51]:- Non-covalent intrinsic mechanisms, such as hydrogen bonds, ionic interactions, metal–ligand coordination, among others; and,

- Covalent intrinsic mechanisms, such as disulfide bond exchange (associative), Diels–Alder chemistry (dissociative), transesterification reactions (associative), bonds based on boron and imines chemistry (dissociative), among others.

3. Current Developments in Self-Healing Elastomers

3.1. Self-Healing Natural Rubber

Natural rubber (NR) consists of cis-1,4-polyisoprene chains [56]. It is the only natural macromolecule completely constituted by carbon (C) and hydrogen (H) atoms, obtained from multiple varieties of plants and fungi, where the most commercially representative is the Hevea Brasiliensis tree [57]. NR is characterized by having high elasticity, even in the unvulcanized state, due to a naturally occurring network of the non-rubber components, which is responsible for its green strength and facilitates the strain-induced crystallization behavior characteristic of this material [58,59,60,61,62,63]. NR has its origin in South America, but currently, the largest production is concentrated in Southeast Asia, with Thailand and Indonesia concentrating more than 50% of the world’s production. Among its most common applications is the manufacture of large tires, especially for aircraft, vehicles, and heavy machinery, as well as bridge mounts, anti-vibration devices, conveyor belts, and other high-performance elastomeric parts [56]. Due to the demands of its processing, NR is not among the most studied rubbers for self-healing; however, Spanish scientists were pioneers in the study of this material, taking advantage of the existence of sulfur crosslinked points that can serve as healing moieties. Table 1 shows the studies available in the literature.|

Matrix |

Mechanism |

Healing Moieties |

Filler |

Reference |

|---|

|

Matrix |

Mechanism |

Healing Moieties |

Filler |

Reference |

||||

|---|---|---|---|---|---|---|---|---|

|

NR |

SBR Covalent intrinsic |

Diels–Alder chemistry |

Covalent intrinsic |

Disulfide exchange Unfilled |

Unfilled [64] |

|||

[ | , | 78] |

ENR |

Non-covalent intrinsic |

Hydrogen bonds |

Unfilled |

||

|

XNBR |

Non-covalent intrinsic |

Ionic interactions |

Unfilled [65] |

|||||

[ | ] |

NR |

Covalent intrinsic |

|||||

|

PUU |

Covalent intrinsic |

Disulfide exchange |

Graphene oxide |

Disulfide exchange [66] |

||||

Unfilled |

ENR |

Combined intrinsic |

||||||

|

Polyamide ionene | Hydrogen bonds + Transesterification reactions |

Graphene oxide |

[65] |

3.2. Self-Healing Synthetic Elastomers

Combined intrinsic |

Ionic interactions + Hydrogen bonds + π-π stacking |

Unfilled |

[82] |

|

|

Ionic elastomer |

Non-covalent intrinsic |

Ionic interactions |

Unfilled |

[83] |

|

SBR |

Covalent intrinsic |

Disulfide exchange |

GTR 1 |

|

|

SBR |

Covalent intrinsic |

Disulfide exchange |

dGTR 2 |

[85] |

|

XNBR |

Non-covalent intrinsic |

Ionic interactions |

GTR |

[79] |

|

Silicone elastomer |

Covalent intrinsic |

Thiol exchange |

Ag nanoparticles |

[86] |

1 Ground tire rubber (GTR) from end-of-life tires. 2 Devulcanized ground tire rubber (dGTR) from end-of-life tires.

4. Challenges, perspectives, and outlook

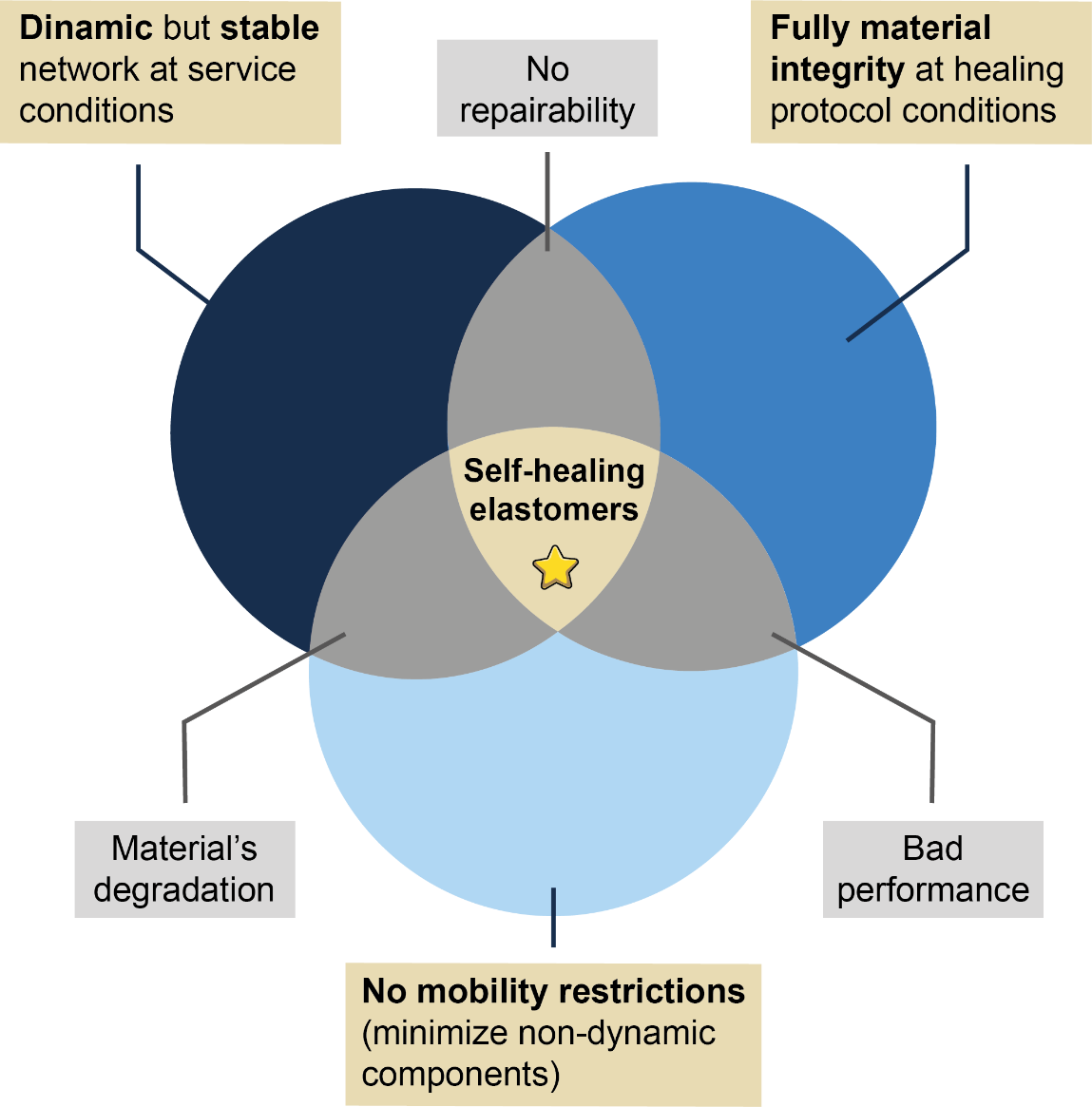

Until now, different matrices (natural and synthetic) with potential industrial applications have been studied. However, there is still much work to be done. Although it is true that efforts point towards the scalability of self-healing concepts in commercial applications, a comprehensive understanding of the underlying self-healing mechanisms, as well as the optimization of its conditions, is still pending. The redesign of elastomeric compounds to exhibit this capability requires the consideration of three main conditions (Figure 1):

- The construction of a dynamic but stable and robust network at service temperatures to guarantee excellent mechanical performance,

- The minimization of components that can hinder the mobility necessary to achieve healing (e.g., secondary irreversible networks) and,

- The optimization of the appropriate conditions (temporality and external stimulus) for each repair mechanism. In turn, these conditions must be compatible with the material stability, to avoid its deterioration during the healing protocols.

Figure 1. Venn diagram illustrating optimal healing conditions.

Figure 1. Venn diagram illustrating optimal healing conditions.

On this road it is important not overlooking the economic viability, the commercial prospect, and the corresponding life cycle assessment (LCA) that corroborates its environmental impact. When all these conditions are matched, the massive scalability of self-healing materials will be an irreversible fact, and we will have taken one of the definitive steps towards the consolidation of a truly sustainable society.

References

- Alan M. Wemyss; Chris Bowen; Cédric Plesse; Cédric Vancaeyzeele; Giao T.M. Nguyen; Frédéric Vidal; Chaoying Wan; Dynamic crosslinked rubbers for a green future: A material perspective. Materials Science and Engineering: R: Reports 2020, 141, 100561, 10.1016/j.mser.2020.100561.

- Yuxin Zhang; Zhen Zhang; Alan Matheson Wemyss; Chaoying Wan; Yongtao Liu; Pan Song; Shifeng Wang; Effective Thermal-Oxidative Reclamation of Waste Tire Rubbers for Producing High-Performance Rubber Composites. ACS Sustainable Chemistry & Engineering 2020, 8, 9079-9087, 10.1021/acssuschemeng.0c02292.

- Łukasz Zedler; Marta Przybysz-Romatowska; Józef Haponiuk; Shifeng Wang; Krzysztof Formela; Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites. Journal of Composites Science 2019, 4, 2, 10.3390/jcs4010002.

- Łukasz Zedler; Xavier Colom; Javier Cañavate; Mohammad Saeb; Józef T. Haponiuk; Krzysztof Formela; Investigating the Impact of Curing System on Structure-Property Relationship of Natural Rubber Modified with Brewery By-Product and Ground Tire Rubber. Polymers 2020, 12, 545, 10.3390/polym12030545.

- Adeel Ahmad Hassan; Zhen Zhang; Krzysztof Formela; Shifeng Wang; Thermo-oxidative exfoliation of carbon black from ground tire rubber as potential reinforcement in green tires. Composites Science and Technology 2021, 214, 108991, 10.1016/j.compscitech.2021.108991.

- Krzysztof Formela; Maria Kurańska; Mateusz Barczewski; Recent Advances in Development of Waste-Based Polymer Materials: A Review. Polymers 2022, 14, 1050, 10.3390/polym14051050.

- Soumyajit Ghorai; Satyaban Bhunia; Madhusudan Roy; Debapriya De; Mechanochemical devulcanization of natural rubber vulcanizate by dual function disulfide chemicals. Polymer Degradation and Stability 2016, 129, 34-46, 10.1016/j.polymdegradstab.2016.03.024.

- Karima Aoudia; Saïd Azem; Nourredine Aït Hocine; Michel Gratton; Valeria Pettarin; Saïd Seghar; Recycling of waste tire rubber: Microwave devulcanization and incorporation in a thermoset resin. Waste Management 2017, 60, 471-481, 10.1016/j.wasman.2016.10.051.

- Fabiula D.B. de Sousa; Carlos Scuracchio; Guo-Hua Hu; Sandrine Hoppe; Devulcanization of waste tire rubber by microwaves. Polymer Degradation and Stability 2017, 138, 169-181, 10.1016/j.polymdegradstab.2017.03.008.

- Saïd Seghar; Lucia Asaro; Morena Rolland-Monnet; Nourredine Aït Hocine; Thermo-mechanical devulcanization and recycling of rubber industry waste. Resources, Conservation and Recycling 2019, 144, 180-186, 10.1016/j.resconrec.2019.01.047.

- X. Colom; J. Cañavate; K. Formela; Alireza Shadman; Mohammad Reza Saeb; Assessment of the devulcanization process of EPDM waste from roofing systems by combined thermomechanical/microwave procedures. Polymer Degradation and Stability 2020, 183, 109450, 10.1016/j.polymdegradstab.2020.109450.

- Alan M Wemyss; Christopher Ellingford; Yoshihiro Morishita; Christopher Bowen; Chaoying Wan; Dynamic Polymer Networks: A New Avenue towards Sustainable and Advanced Soft Machines. Angewandte Chemie International Edition 2021, 60, 13725-13736, 10.1002/anie.202013254.

- Nikola Bosnjak; Meredith N. Silberstein; Pathways to tough yet soft materials. Science 2021, 374, 150-151, 10.1126/science.abl6358.

- Nikola Bosnjak; Meredith N. Silberstein; Pathways to tough yet soft materials. Science 2021, 374, 150-151, 10.1126/science.abl6358.