Biofuel consists of non-fossil fuel derived from the organic biomass of renewable resources, including plants, animals, microorganisms, and waste. Energy derived from biofuel is known as bioenergy. The reserve of fossil fuels is now limited and continuing to decrease, while at the same time demand for energy is increasing. In order to overcome this scarcity, it is vital for human beings to transfer their dependency on fossil fuels to alternative types of fuel, including biofuels, which are effective methods of fulfilling present and future demands. The conversion of lignocellulosic feedstock is an important step during biofuel production. It is, however, important to note that, as a result of various technical restrictions, biofuel production is not presently cost efficient, thus leading to the need for improvement in the methods employed.

- biomass

- second-generation biofuel

- bioenergy

- bioethanol

- biodiesel

- non-fossil fuel

1. Introduction

- (i)

-

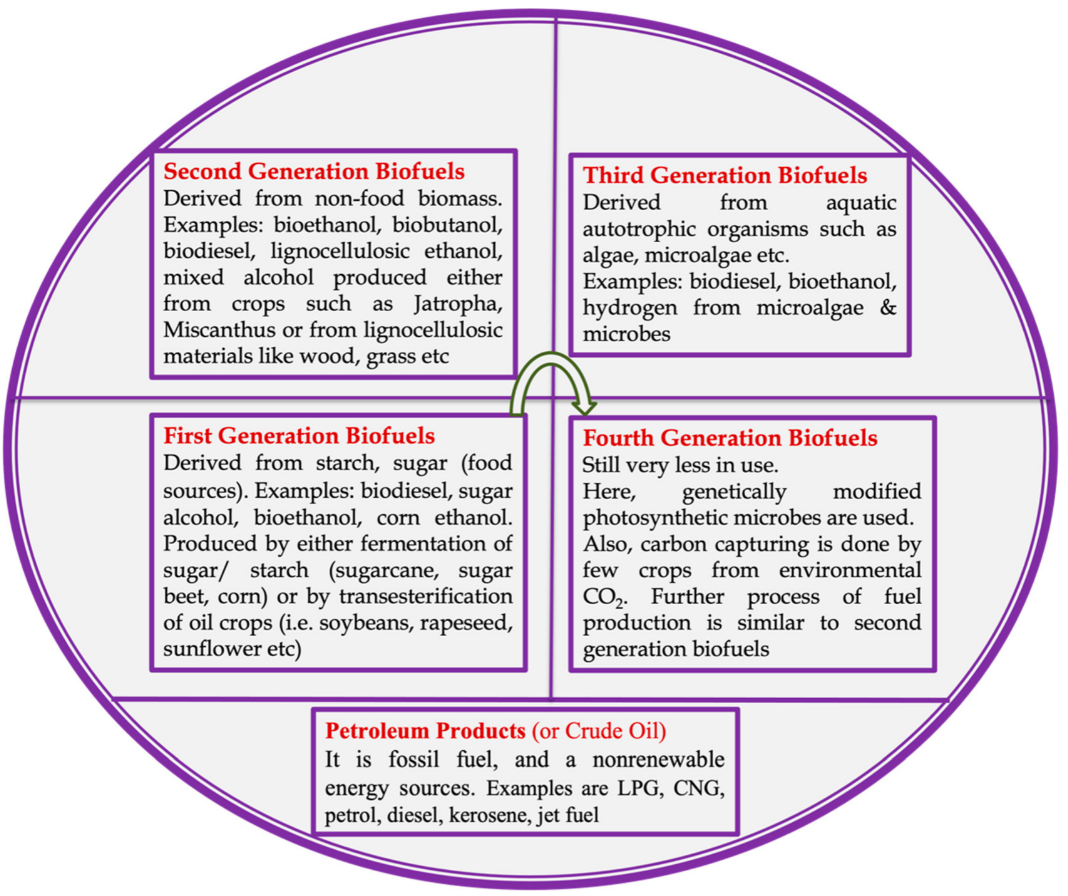

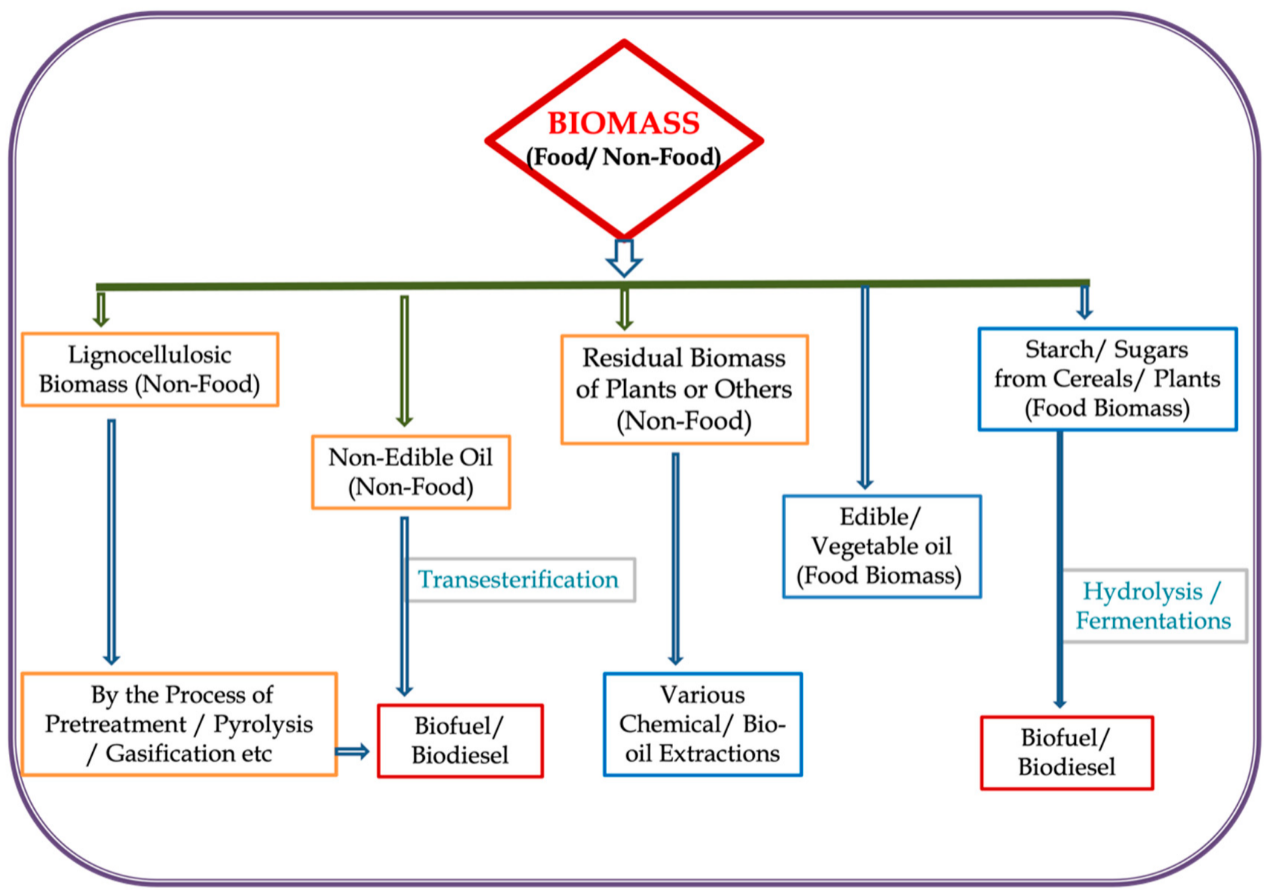

First-generation biofuel is primarily derived from parts of edible plants (i.e., grains and oilseeds). These types of fuel have derived from sugar, starch, vegetable oil, and fats. Examples of most popular first-generation biofuels are biodiesel, ethanol, biofuel gasoline, biogas, etc. [7,13,24,26][7][13][24][26]. Presently, first-generation biofuel (biodiesel and bioethanol) is mainly produced by using agricultural feedstock such as sugarcane, corn, sugar beets, etc. [23]. Economic feasibility of biofuel production using crops (such as oilseed crops) as feedstock is not cost effective presently, therefore, a more efficient approach is needed to enhance the biofuel production and convert it to an economically feasible stage. Additionally, more research work is needed to increase the biodiesel production using first-generation feedstock such as oil [23].

- (ii)

-

Second-generation biofuel is a comparatively advanced biofuel which is derived from various non-food biomass of plant/or animal. Second-generation (lignocellulosic) biofuel is derived from non-edible plants or non-edible parts of the plants. It is well known that non-edible lignocellulosic biomass (such as vegetable grasses, forest residues, agricultural waste, etc.) is present abundantly in the natural ecosystem, therefore, it could be used as a feedstock for biofuel production. Examples of second-generation biofuels are lignocellulosic ethanol, butanol, mixed alcohols, etc. [4,13,24,27][4][13][24][27].

- (iii)

-

Third-generation biofuel is derived from photosynthetic microbes, e.g., microalgae. They derived from autotrophic organism. Here, carbon dioxide, light, and other nutrient sources are used in the synthesis of feedstock (biomass) which is further used in biofuel production [8,24,25,28][8][24][25][28]. Biofuels obtained from third-generation sources (such as microalgae) might be a better energy substitute as compared to previous generation biofuels, due to their short life cycle and less requirement of valuable agricultural land and resources for their growth [25]. Algae have rapid growth and higher rate of the photosynthesis compared to terrestrial plants used in first- and second-generation biofuel production. Due to their use in biofuel production, photosynthetic microbes (such as algae/microalgae) have recently received more attention from researchers worldwide [12].

- (iv)

-

Fourth-generation biofuel is not common and at an under developmental stage since a few years ago. Here, genetically altered photosynthetic microbes (such as cyanobacteria, algae, fungi) are used as feedstock. Photosynthetic microbes have the ability to convert atmospheric CO2 to biofuel [24]. Some studies reported that carbon capturing is undertaken by some crops, taken from the atmosphere and further stored in their leaves, stems, etc., which is further converted into fuel using second-generation techniques [12]. Alalwan et al. [24] reported that, in the fourth-generation biofuels, genetically modified microorganisms are used to obtain more carbon (HC) yield and reduced carbon emissions [24].

2. Second-Generation Lignocellulosic Biofuels

3. Feedstock for Second-Generation Lignocellulosic Biofuels

-

Liu, Y.; Cruz-Morales, P.; Zargar, A.; Belcher, M.S.; Pang, B.; Englund, E.; Dan, Q.; Yin, K.; Keasling, J.D. Biofuels for a sustainable future. Cell 2021, 184, 1636–1647. [CrossRef]

-

Afolalu, S.A.; Yusuf, O.O.; Abioye, A.A.; Emetere, M.E.; Ongbali, S.O.; Samuel, O.D. Biofuel, a sustainable renewable source of energy—A review. IOP Conf. Ser. 2021, 665, 012040. [CrossRef]

-

Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [CrossRef]

-

Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [CrossRef]

-

Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status and prespective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [CrossRef]

-

Nazari, M.T.; Mazutti, J.; Basso, L.G.; Colla, L.M.; Brandli, L. Biofuels and their connections with the sustainable development goals: A bibliometric and systematic review. Environ. Dev. Sustain. 2021, 23, 11139–11156. [CrossRef]

-

Aro, E.-M. From first generation biofuels to advanced solar biofuels. Ambio 2016, 45, 24–31. [CrossRef]

-

Kumar, V.; Nanda, M.; Joshi, H.C.; Singh, A.; Sharma, S.; Verma, M. Production of biodiesel and bioethanol using algal biomass

harvested from fresh water river. Renew. Energy 2018, 116, 606–612. [CrossRef]

-

Muhammad, U.L.; Shamsuddin, I.M.; Danjuma, A.; Musawa, R.S.; Dembo, U.H. Biofuels as the starring substitute to fossil fuels.

Pet. Sci. Eng. 2018, 2, 44–49. [CrossRef]

-

Subramaniam, Y.; Masron, T.A.; Azman, N.H.N. Biofuels, environmental sustainability and food security: A review of 51 countries.

Energy Res. Soc. Sci. 2020, 68, 101549. [CrossRef]

-

Ganguly, P.; Sarkhel, R.; Das, P. The second-and third-generation biofuel technologies: Comparative perspectives. In Sustainable

Fuel Technologies Handbook; Academic Press: Cambridge, MA, USA, 2021; pp. 29–50. [CrossRef]

-

Dutta, K.; Daverey, A.; Lin, J.-G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy 2014, 69,

114–122. [CrossRef]

-

Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review.

Renew. Sustain. Energy Rev. 2010, 14, 578–597. [CrossRef]

-

Pandit, S.; Savla, N.; Sonawane, J.M.; Sani, A.M.; Gupta, P.K.; Mathuriya, A.S.; Rai, A.K.; Jadhav, D.A.; Jung, S.P.; Prasad,

R. Agricultural waste and wastewater as feedstock for bioelectricity generation using microbial fuel cells: Recent advances.

Fermentation 2021, 7, 169. [CrossRef]

-

Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and biorefineries: Development,

application and future perspectives emphasizing the environmental and economic aspects. J. Environ. Manag. 2021, 297, 113268.

[CrossRef]

-

Sindhu, R.; Binod, P.; Pandey, A.; Ankaram, S.; Duan, Y.; Awasthi, M.K. Biofuel production from biomass: Toward sustainable

development. In Current Developments in Biotechnology and Bioengineering; Kumar, S., Kumar, R., Pandey, A., Eds.; Elsevier:

Amsterdam, The Netherlands, 2019; pp. 79–92. [CrossRef]

-

Al Makishah, N.H.; Rai, A.K.; Neamatallah, A.A.; Mabrouk, A.M. Micrococcus luteus 2030: A novel lipolytic bacterial strain

isolated from local contaminated soil in Saudi Arabia. Sylwan 2019, 163, 132–152.

-

Sánchez, Ó.J.; Cardona, C.A. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol.

2008, 99, 5270–5295. [CrossRef]

-

Escobar, J.C.; Lora, E.S.; Venturini, O.J.; Yánez, E.E.; Castillo, E.F.; Almazan, O. Biofuels: Environment, technology and food

security. Renew. Sustain. Energy Rev. 2009, 13, 1275–1287. [CrossRef]

-

Jusakulvijit, P.; Bezama, A.; Thrän, D. The availability and assessment of potential agricultural residues for the regional development of second-generation bioethanol in Thailand. Waste Biomass Valor. 2021, 12, 6091–6118. [CrossRef]

-

EASAC. The Current Status of Biofuels in the European Union, Their Environmental Impacts and Future Prospects; German National Academy of Sciences Leopoldina: Haale, Germany, 2012; 47p, ISBN 978-3-8047-3118-9.

-

Oumer, A.N.; Hasan, M.M.; Baheta, A.T.; Mamat, R.; Abdullah, A.A. Bio-based liquid fuels as a source of renewable energy: A review. Renew. Sust. Energ. Rev. 2018, 88, 82–98. [CrossRef]

-

Hirani, A.H.; Javed, N.; Asif, M.; Basu, S.K.; Kumar, A. A review on first-and second-generation biofuel productions. In Biofuels: Greenhouse Gas Mitigation and Global Warming; Kumar, A., Ogita, S., Yau, Y.Y., Eds.; Springer: New Delhi, India, 2018; pp. 141–154. [CrossRef]

-

Alalwan, H.A.; Alminshid, A.H.; Aljaafari, H.A. Promising evolution of biofuel generations. Subject review. Renew. Energy Focus. 2019, 28, 127–139. [CrossRef]

-

Dragone, G.; Fernandes, B.; Vicente, A.A.; Teixeira, J.A. Third generation biofuels from microalgae. In Current Research, Technology and Education Topics in Applied Microbiology and Microbial Biotechnology; Mendez-Vilas, A., Ed.; FORMATEX: Badajoz, Spain, 2010; pp. 1355–1366.

-

Gumienna, M.; Szambelan, K.; Jelen, H.; Czarnecki, Z. Evaluation of ethanol fermentation parameters for bioethanol production from sugar beet pulp and juice. J. Inst. Brew. 2014, 120, 543–549. [CrossRef]

-

Sims, R.E.H.; Mabee, W.; Saddler, J.N.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2010, 101, 1570–1580. [CrossRef] [PubMed]

-

Hussain, F.; Shah, S.Z.; Ahmad, H.; Abubshait, S.A.; Abubshait, H.A.; Laref, A.; Manikandan, A.; Kusuma, H.S.; Iqbal, M. Microalgae an ecofriendly and sustainable wastewater treatment option: Biomass application in biofuel and bio-fertilizer production. A review. Renew. Sust. Energ. Rev. 2021, 137, 110603. [CrossRef]

-

Popp, J.; Harangi-Rakos, M.; Gabnai, Z.; Balogh, P.; Antal, G.; Bai, A. Biofuels and their co-products as livestock feed: Global economic and environmental implications. Molecules 2016, 21, 285. [CrossRef]

-

Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [CrossRef]

-

Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable environmental management and related biofuel technologies. J. Environ. Manag. 2020, 273, 111096. [CrossRef]

-

Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second Generation Biofuels: High-Efficiency Microalgae for Biodiesel Production. Bioenerg. Res. 2008, 1, 20–43. [CrossRef]

-

Eisentraut, A. Sustainable Production of Second-Generation Biofuels: Potential and Perspectives in Major Economies and Developing Countries; IEA Energy Papers, No. 2010/01; OECD Publishing: Paris, France, 2010; 221p. [CrossRef]

-

Scully, S.M.; Orlygsson, J. Recent advances in second generation ethanol production by thermophilic bacteria. Energies 2015, 8, 1–30. [CrossRef]

-

Gomez, L.D.; Clare, G.S.; McQueen-Mason, J. Sustainable liquid biofuels from biomass: The writing’s on the walls. New Phytol. 2008, 178, 473–485. [CrossRef]

-

Zabaniotou, A.; Ioannidou, O.; Skoulou, V. Rapeseed residues utilization for energy and 2nd generation biofuels. Fuel 2008, 87, 1492–1502. [CrossRef]

-

Dhiman, S.; Mukherjee, G. Present scenario and future scope of food waste to biofuel production. J. Food Process Eng. 2021, 44, e13594. [CrossRef]

-

Mizik, T.; Gyarmati, G. Economic and sustainability of biodiesel production- A systematic literature review. Clean Technol. 2021, 3, 19–36. [CrossRef]

-

Arefin, M.A.; Rashid, F.; Islam, A. A review of biofuel production from floating aquatic plants: An emerging source of bio- renewable energy. Biofuel. Bioprod. Biorefin. 2021, 15, 574–591. [CrossRef]

-

Badawy, T.; Mansour, M.S.; Daabo, A.M.; Aziz, M.M.A.; Othman, A.A.; Barsoum, F.; Basouni, M.; Hussien, M.; Ghareeb, M.; Hamza, M.; et al. Selection of second-generation crop for biodiesel extraction and testing its impact with nano additives on diesel engine performance and emissions. Energy 2021, 237, 121605. [CrossRef]

-

Pauly, M.; Keegstra, K. Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J. 2008, 54, 559–568. [CrossRef] [PubMed]

-

Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and challenges in lignocellulosic biofuel production technology. Renew. Sust. Energ. Rev. 2019, 111, 44–56. [CrossRef]

-

Aderibigbe, F.A.; Shiru, S.; Saka, H.B.; Amosa, M.K.; Mustapha, S.I.; Alhassan, M.I.; Adejumo, A.L.; Abdulraheem, M.; Owolabi, R.U. Heterogeneous catalysis of second generation oil for biodiesel production: A review. ChemBioEng Rev. 2021, 8, 78–89. [CrossRef]

-

Firouzi, S.; Allahyari, M.S.; Isazadeh, M.; Nikkhah, A.; van Haute, S. Hybrid multi-criteria decision-making approach to select appropriate biomass resources for biofuel production. Sci. Total Environ. 2021, 770, 144449. [CrossRef]

-

Narwane, V.S.; Yadav, V.S.; Raut, R.D.; Narkhede, B.E.; Gardas, B.B. Sustainable development challenges of the biofuel industry in India based on integrated MCDM approach. Renew. Energy 2021, 164, 298–309. [CrossRef]

-

Sarangi, P.K.; Nayak, M.M. Agro-Waste for Second-Generation Biofuels. In Liquid Biofuels: Fundamentals, Characterization, and Applications; Shadangi, K.P., Ed.; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 697–709. [CrossRef]

-

Shi, Y. China’s resources of biomass feedstock. Eng. Sci. 2011, 13, 16–23.

-

Wagner, A.O.; Lackner, N.; Mutschlechner, M.; Prem, E.M.; Markt, R.; Illmer, P. Biological pretreatment strategies for second-

generation lignocellulosic resources to enhance biogas production. Energies 2018, 11, 1797. [CrossRef]

-

Galbe, M.; Wallberg, O. Pretreatment for biorefineries: A review of common methods for efficient utilisation of lignocellulosic

materials. Biotechnol. Biofuels 2019, 12, 294. [CrossRef]

-

Machineni, L. Lignocellulosic biofuel production: Review of alternatives. Biomass Convers. Biorefin. 2020, 10, 779–791. [CrossRef]

-

Ab Rasid, N.S.; Shamjuddin, A.; Rahman, A.Z.A.; Amin, N.A.S. Recent advances in green pre-treatment methods of lignocellulosic

biomass for enhanced biofuel production. J. Clean. Prod. 2021, 321, 129038. [CrossRef]

-

Beig, B.; Riaz, M.; Naqvi, S.R.; Hassan, M.; Zheng, Z.; Karimi, K.; Pugazhendhi, A.; Atabani, A.E.; Chi, N.T.L. Current challenges

and innovative developments in pretreatment of lignocellulosic residues for biofuel production: A review. Fuel 2021, 287, 119670.

[CrossRef]

-

Gnansounou, E.; Dauriat, A. Techno-economic analysis of lignocellulosic ethanol: A review. Bioresour. Technol. 2010, 101,

4980–4991. [CrossRef] [PubMed]

-

Sivamani, S.; Baskar, R.; Chandrasekaran, A.P. Response surface optimization of acid pretreatment of cassava stem for bioethanol

production. Environ. Prog. Sustain. Energy 2020, 39, e13335. [CrossRef]

-

Dionísio, S.R.; Santoro, D.C.J.; Bonan, C.I.D.G.; Soares, L.B.; Biazi, L.E.; Rabelo, S.C.; Ienczak, J.L. Second-generation ethanol

process for integral use of hemicellulosic and cellulosic hydrolysates from diluted sulfuric acid pretreatment of sugarcane bagasse.

Fuel 2021, 304, 121290. [CrossRef]

-

Lima, D.R.S.; de Oliveira Paranhos, A.G.; Adarme, O.F.H.; Baêta, B.E.L.; Gurgel, L.V.A.; dos Santos, A.S.; de Queiroz Silva, S.;

de Aquino, S.F. Integrated production of second-generation ethanol and biogas from sugarcane bagasse pretreated with ozone.

Biomass Convers. Biorefin. 2022, 12, 809–825. [CrossRef]

-

Morales-Martínez, J.L.; Aguilar-Uscanga, M.G.; Bolaños-Reynoso, E.; López-Zamora, L. Optimization of chemical pretreatments

using response surface methodology for second-generation ethanol production from coffee husk waste. BioEnergy Res. 2021, 14,

815–827. [CrossRef]

-

Mund, N.K.; Dash, D.; Mishra, P.; Nayak, N.R. Cellulose solvent–based pretreatment and enzymatic hydrolysis of pineapple leaf

waste biomass for efficient release of glucose towards biofuel production. Biomass Convers. Biorefin. 2021, 1–10. [CrossRef]

-

Sinitsyn, A.P.; Sinitsyna, O.A. Bioconversion of renewable plant biomass. Second-generation biofuels: Raw materials, biomass

pretreatment, enzymes, processes, and cost analysis. Biochemistry 2021, 86, S166–S195. [CrossRef] [PubMed]

-

Talmadge, M.; Kinchin, C.; Chum, H.L.; de Rezende Pinho, A.; Biddy, M.; de Almeida, M.B.; Casavechia, L.C. Techno-economic analysis for co-processing fast pyrolysis liquid with vacuum gasoil in FCC units for second-generation biofuel production. Fuel

2021, 293, 119960. [CrossRef]

-

Lynd, L.R.; Weimer, P.J.; van Zyl, W.H.; Pretorius, I.S. Microbial Cellulose Utilization: Fundamental and Biotechnology.

Microbiol. Mol. Bio. Rev. 2002, 66, 506–577. [CrossRef] [PubMed]

-

Gregg, D.J.; Boussaid, A.; Saddler, J.N. Techno-economic evaluations of a generic wood-to-ethanol process: Effect of increased

cellulose yields and enzyme recycle. Bioresour. Technol. 1998, 63, 7–12. [CrossRef]

-

Weil, J.R.; Dien, B.; Bothast, R.; Hendrickson, R.; Mosier, N.S.; Ladisch, M.R. Removal of fermentation inhibitors formed during

pretreatment of biomass by polymeric adsorbents. Indust. Eng. Chem. Res. 2002, 41, 6132–6138. [CrossRef]

-

Sheehan, J.; Aden, A.; Paustian, K.; Killian, K.; Brenner, J.; Walsh, M.; Nelson, R. Energy and environmental aspects of using corn

stover for fuel ethanol. J. Indust. Ecol. 2004, 7, 117–146. [CrossRef]

-

Eggeman, T.; Elander, R.T. Process and economic analysis of pretreatment technologies. Bioresour. Technol. 2005, 96, 2019–2025.

[CrossRef]

-

Galbe, M.; Liden, G.; Zacchi, G. Production of ethanol from biomass-research in Sweden. J. Sci. Ind. Res. 2005, 64, 905–919.

-

Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for

Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [CrossRef]

-

Rocha–Meneses, L.; Raud, M.; Orupõld, K.; Kikas, T. Second-generation bioethanol production: A review of strategies for waste

valorization. Agron. Res. 2016, 15, 830–847.

-

Jutakridsada, P.; Saengprachatanarug, K.; Kasemsiri, P.; Hiziroglu, S.; Kamwilaisak, K.; Chindaprasirt, P. Bioconversion of

Saccharum officinarum leaves for ethanol production using separate hydrolysis and fermentation processes. Waste Biomass Valor.

2019, 10, 817–825. [CrossRef]

-

Azam, M.; Jahromy, S.S.; Raza, W.; Raza, N.; Lee, S.S.; Kim, K.-H.; Winter, F. Status, characterization and potential utilization of

municipal solid waste as renewable energy source: Lahore case study in Pakistan. Environ. Int. 2020, 134, 105291. [CrossRef]

-

Yang, B.; Wyman, C.E. Pre-treatment: The key to unlocking low cost cellulosic ethanol. Biofuel Bioprod. Biorefin. 2008, 2, 26–40.

[CrossRef]

-

Roy, P.; Dias, G. Prospects for pyrolysis technologies in the bioenergy sector: A review. Renew. Sustain. Energy Rev. 2017, 77, 59–69.

[CrossRef]

-

Djandja, O.S.; Wang, Z.C.; Wang, F.; Xu, Y.P.; Duan, P.G. Pyrolysis of municipal sewage sludge for biofuel production: A review.

Ind. Eng. Chem. Res. 2020, 59, 16939–16956. [CrossRef]

-

Fombu, A.H.; Ochonogor, A.E. Design and Construction of a Semi-batch Pyrolysis Reactor for the Production of Biofuel. In IOP

Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2021; p. 012041. [CrossRef]

-

Li, C.; Aston, J.E.; Lacey, J.A.; Thompson, V.S.; Thompson, D.N. Impact of feedstock quality and variation on biochemical and thermochemical conversion. Renew. Sustain. Energy Rev. 2016, 65, 525–536. [CrossRef]

-

Richardson, Y.; Joël, B.; Julbe, A. A short overview on purification and conditioning of syngas produced by biomass gasification: Catalytic strategies, process intensification and new concepts. Prog. Energy Combust. Sci. 2012, 38, 765–781. [CrossRef]

-

Cai, J.; Zeng, R.; Zheng, W.; Wang, S.; Han, J.; Li, K.; Luo, M.; Tang, X. Synergistic Effects of Co-Gasification of Municipal Solid Waste and Biomass in Fixed-Bed Gasifier. Process. Saf. Environ. Prot. 2021, 148, 1–12. [CrossRef]

-

Doliente, S.; Narayan, A.; Tapia, F.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation fuel: A comprehensive review and analysis of the supply chain components. Front. Energy Res. 2020, 8, 110. [CrossRef]

-

Furtado, A.; Lupo, J.S.; Hoang, N.V.; Healey, A.; Singh, S.; Simmons, B.A.; Henry, R.J. Modifying plants for biofuel and biomaterial production. Plant Biotechnol. J. 2014, 12, 1246–1258. [CrossRef] [PubMed]

-

Kalluri, U.C.; Yin, H.; Yang, X.; Davison, B.H. Systems and synthetic biology approaches to alter plant cell walls and reduce biomass recalcitrance. Plant Biotechnol. J. 2014, 12, 1207–1216. [CrossRef] [PubMed]

-

Ilmberger, N.; Streit, W.R. Screening for cellulase encoding clones in metagenomic libraries. In Metagenomics. Methods in Molecular Biology; Streit, W., Daniel, R., Eds.; Humana Press: New York, NY, USA, 2017; Volume 1539, pp. 205–217. [CrossRef]

-

Liu, G.; Qin, Y.; Li, Z.; Qu, Y. Development of highly efficient, low-cost lignocellulolytic enzyme systems in the post-genomic era. Biotechnol. Adv. 2013, 31, 962–975. [CrossRef] [PubMed]

-

Nimchua, T.; Thongaram, T.; Uengwetwanit, T.; Pongpattanakitshote, S.; Eurwilaichitr, L. Metagenomic analysis of novel lignocellulose-degrading enzymes from higher termite guts inhabiting microbes. J. Microbiol. Biotechnol. 2012, 22, 462–469. [CrossRef]

-

Rashamuse, K.; Tendai, W.S.; Mathiba, K.; Ngcobo, T.; Mtimka, S.; Brady, D. Metagenomic mining of glycoside hydrolases from the hindgut bacterial symbionts of a termite (Trinervitermes trinervoides) and the characterization of a multimodular beta-1,4-xylanase (GH11). Biotechnol. Appl. Biochem. 2017, 64, 174–186. [CrossRef]

-

Xie, S.; Syrenne, R.; Sun, S.; Yuan, J.S. Exploration of Natural Biomass Utilization Systems (NBUS) for advanced biofuel—From systems biology to synthetic design. Curr. Opin. Biotechnol. 2014, 27, 195–203. [CrossRef]

-

Liang, J.; Lin, Y.; Li, T.; Mo, F. Microbial consortium OEM1 cultivation for higher lignocellulose degradation and chlorophenol removal. RSC Adv. 2017, 7, 39011–39017. [CrossRef]

-

Wang, C.; Dong, D.; Wang, H.; Mueller, K.; Qin, Y.; Wang, H.; Wu, W. Metagenomic analysis of microbial consortia enriched from compost: New insights into the role of Actinobacteria in lignocellulose decomposition. Biotechnol. Biofuels 2016, 9, 22. [CrossRef]

-

Zhu, N.; Yang, J.; Ji, L.; Liu, J.; Yang, Y.; Yuan, H. Metagenomic and metaproteomic analyses of a corn stover-adapted microbial

consortium EMSD5 reveal its taxonomic and enzymatic basis for degrading lignocellulose. Biotechnol. Biofuels 2016, 9, 243.

[CrossRef]

-

Fu, Y.; Chen, L.; Zhang, W. Regulatory mechanisms related to biofuel tolerance in producing microbes. J. Appl. Microbiol. 2016,

121, 320–332. [CrossRef]

-

Dragosits, M.; Mattanovich, D. Adaptive laboratory evolution—Principles and applications for biotechnology. Microb. Cell Fact.

2013, 12, 64. [CrossRef] [PubMed]

-

Farwick, A.; Bruder, S.; Schadeweg, V.; Oreb, M.; Boles, E. Engineering of yeast hexose transporters to transport D-xylose without

inhibition by D-glucose. Proc. Natl. Acad. Sci. USA 2014, 111, 5159–5164. [CrossRef] [PubMed]

-

dos Santos, S.C.; Sá-Correia, I. Yeast toxicogenomics: Lessons from a eukaryotic cell model and cell factory. Curr. Opin. Biotechnol.

2015, 33, 183–191. [CrossRef] [PubMed]

-

King, Z.A.; Lloyd, C.J.; Feist, A.M.; Palsson, B.O. Next-generation genome-scale models for metabolic engineering.

Curr. Opin. Biotechnol. 2015, 35, 23–29. [CrossRef]

-

Nizami, A.S.; Rehan, M. Towards nanotechnology-based biofuel industry. Biofuel Res. J. 2018, 5, 798–799. [CrossRef]

-

Sekoai, P.T.; Ouma, C.N.M.; Du Preez, S.P.; Modisha, P.; Engelbrecht, N.; Bessarabov, D.G.; Ghimire, A. Application of nanoparti-

cles in biofuels: An overview. Fuel 2019, 237, 380–397. [CrossRef]

-

Elumalai, P.V.; Nambiraj, M.; Parthasarathy, M.; Balasubramanian, D.; Hariharan, V.; Jayakar, J. Experimental investigation to

reduce environmental pollutants using biofuel nano-water emulsion in thermal barrier coated engine. Fuel 2021, 285, 119200.

[CrossRef]

-

Bassalo, M.C.; Liu, R.; Gill, R.T. Directed evolution and synthetic biology applications to microbial systems. Curr. Opin. Biotechnol.

2016, 39, 126–133. [CrossRef]

-

Ghim, C.-M.; Kim, T.; Mitchell, R.J.; Lee, S.K. Synthetic biology for biofuels: Building designer microbes from the scratch.

Biotechnol. Bioprocess Eng. 2010, 15, 11–21. [CrossRef]

-

Sarkar, M.; Sarkar, B. How does an industry reduce waste and consumed energy within a multi-stage smart sustainable biofuel

production system? J. Clean. Prod. 2020, 262, 121200. [CrossRef]

100. Patel,A.;Shah,A.Integratedlignocellulosicbiorefinery:Gatewayforproductionofsecondgenerationethanolandvalueadded

products. J. Bioresour. Bioprod. 2021, 6, 108–128. [CrossRef]

101. Rosson,E.;Sgarbossa,P.;Pedrielli,F.;Mozzon,M.;Bertani,R.Bioliquidsfromrawwasteanimalfats:Analternativerenewableenergy source. Biomass Convers. Biorefin. 2021, 11, 1475–1490. [CrossRef]

102. AlHatrooshi,A.S.;Eze,V.C.;Harvey,A.P.Productionofbiodieselfromwastesharkliveroilforbiofuelapplications.Renew.Energy2020, 145, 99–105. [CrossRef]

-

-