Regenerative medicine is one of the most attractive topics of research worldwide. Different strategies are proposed, and a range of materials of various forms and compositions tailored for tissue engineering are developed, but this approach just started to emerge in clinics. Biodegradable microparticles (MPs) made from degradable and biocompatible polymers, with a mean diameter of ~200 μm, are attractive not only as 3D matrices to multiply cells but also as a scaffold to support tissue rebuilding.

1. Introduction

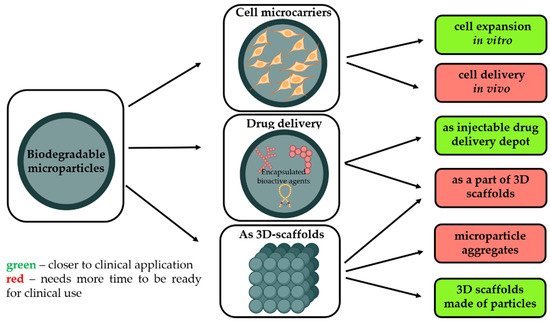

Regenerative medicine is one of the most attractive topics of research worldwide. Different strategies are proposed, and a range of materials of various forms and compositions tailored for tissue engineering are developed, but this approach just started to emerge in clinics [1]. As schematically presented in Figure 1

, biodegradable microparticles (MPs) made from degradable and biocompatible polymers, with a mean diameter of ~200 μm, are attractive not only as 3D matrices to multiply cells but also as a scaffold to support tissue rebuilding [2]. Being injectable and made from safe materials, they could be implanted into the tissue defect adopting one of the three possible clinical approaches:

Different strategies of microparticles usage for regenerative medicine and perspective of their clinical application. Created by

(accessed on 25 January 2022).

- As a temporary microcarrier to support expansion of cells initially cultivated in vitro [3]. Biodegradability is a crucial characteristic to avoid main technological issues related to cell multiplication on non-degradable microcarriers, i.e., poor yield of cell detachment, contamination related to enzymes requested to harvest cells, and difficulties to separate microparticle debris from free cells. Moreover, as these microcarriers are made from safe and degradable polymers, these cell microcarriers could be injected into the targeted tissues to restore them.

- Without pre-culture with cells in order to provide a sustained and local release of growth factors selected to promote tissue rebuilding while also offering a large surface to enhance in vivo cell adhesion.

- As a part of other types of 3D scaffolds for tissue engineering, including the application of biodegradable microparticles as starting building blocks to generate 3D scaffolds with well-defined architecture, adopting additive technologies or other techniques.

Despite the potentialities of these microparticles in tissue engineering today, there are no commercial biodegradable microcarrier-based products available on the market. However, it is worth reminding that the technologies requested to produce pharmaceutical-grade biodegradable microparticles have already been developed and validated for several applications in the pharmaceutical area. Indeed, these microparticles have been first designed to achieve a sustained release of (bio)pharmaceutical actives on an extended period [4]. Most of the difficulties of translation of all these R&D efforts and clinical trials on the application of biodegradable microparticles into the clinical reality come from several challenges and bottlenecks general issues of the cell-based products for regenerative medicine [5][6]. Indeed, several barriers have been identified, which can be classified according to technological, clinical, and administrative criteria. Despite the potentialities of these microparticles in tissue engineering today, there are no commercial biodegradable microcarrier-based products available on the market. However, it is worth reminding that the technologies requested to produce pharmaceutical-grade biodegradable microparticles have already been developed and validated for several applications in the pharmaceutical area. Indeed, these microparticles have been first designed to achieve a sustained release of (bio)pharmaceutical actives on an extended period [4]. Most of the difficulties of translation of all these R&D efforts and clinical trials on the application of biodegradable microparticles into the clinical reality come from several challenges and bottlenecks general issues of the cell-based products for regenerative medicine [5,6]. Indeed, several barriers have been identified, which can be classified according to technological, clinical, and administrative criteria.

Regarding the technological challenges, in comparison to classical drugs made from a single molecular entity, cells are a viable complex material that can change quickly in response to any subtle variations of their environment. Accordingly, the validation of a cell-based therapy product adopting the standards typically imposed in the pharmaceutical industry is impossible due to the intrinsic variation in the cell sampling and the difficulty of establishing standard reference products. The costs associated with the production, storage, and distribution of, for example, stem cells are today so expensive that their clinical use at a worldwide level remains mostly unrealistic [7]. Indeed, in contrast to classical molecular drugs, stem cells, once collected, purified, and multiplied, have to be either administrated just after or stored in liquid nitrogen to maintain their viability. The worldwide repartition of the ongoing clinical trials highlights that these biotherapies are limited to countries where harvesting cells or tissues of human origin can be performed in health centers under strict controls and accredited by Public Authorities.

A critical issue of cell therapy is the in vitro large-scale expansion of allogeneic cells according to Good Manufacturing Practice (GMP) standards which allows combining product quality, purity, reliability, and good yields [7]. In this perspective, biodegradable microparticles could be a better solution for the in vitro cultivation of substrate-dependent cells than 2D substrates. Mostly under the shape of plastic plates and T-flasks, these two surfaces are mainly coated by bioadhesive proteins such as Matrigel ® (Corning Inc., New York, NY, USA), gelatin, collagen, or even mouse embryonic fibroblasts (MEF) to enhance cell adhesion [8][9]. The total surface area required for cell expansion to satisfy a single therapeutic dose in the clinical assay is nearly 4.5 m (Corning Inc., New York, NY, USA), gelatin, collagen, or even mouse embryonic fibroblasts (MEF) to enhance cell adhesion [8,9]. The total surface area required for cell expansion to satisfy a single therapeutic dose in the clinical assay is nearly 4.5 m 2, corresponding to 600 standard T-75 culture plates. Nowadays, the most promising alternative approach relies on the cultivation of cells in suspension in closed and controlled stirred bioreactors in which the solid surface required for the anchorage of adherent cells is provided by microbeads suspended in the culture medium [8][9]. , corresponding to 600 standard T-75 culture plates. Nowadays, the most promising alternative approach relies on the cultivation of cells in suspension in closed and controlled stirred bioreactors in which the solid surface required for the anchorage of adherent cells is provided by microbeads suspended in the culture medium [8,9].

2. Fabrication and Modification of Polymeric-Based Microparticles (MPs)

2.1. Materials for MPs Fabrication

There is a variety of materials that can be used for microparticles fabrication, as depicted in

2. Fabrication and Modification of Polymeric-Based Microparticles (MPs)

2.1. Materials for MPs Fabrication

There is a variety of materials that can be used for microparticles fabrication, as depicted in

Table 1. Material selection should be made according to key technical features, such as degradation and diffusion features, thermal and mechanical properties, and suitable structural form for cell adhesion and tissue integration [10]. However, in terms of clinical application, the materials used for the microparticle fabrication should be safe and approved for biomedical use as the main criterion.

Biodegradable synthetic aliphatic polyesters are the main class of raw materials reported for the fabrication of polymeric scaffolds and drug delivery systems [10][11][12]. Being approved for more than 30 years by regulatory bodies, e.g., FDA or EMA, aliphatic polyesters, such as poly(lactic acid) (PLA), poly(glycolic acid) (PLGA), polycaprolactone (PCL), and their copolymers, have received the most considerable attention. The main requirements for their biomedical applications are biodegradability, tolerability, and non-toxicity. These polymers undergo hydrolytic degradation in the human body, releasing no cytotoxic byproducts. Thanks to the possibility to adjust their chemical structure, e.g., molecular weight, stereoregularity, macromolecule topology, copolymer composition, etc., these synthetic polymers are more reliable and flexible in terms of microparticle fabrication conditions and final properties. However, their lack of bioactivity, i.e., the inability to interact specifically with cells to promote and control cell adhesion, proliferation, and differentiation, limits their functionalities in tissue engineering. Thereby, to extend the functionality of microparticles based on synthetic polymers, they could be blended with natural polymers or inorganic components. Such types of microparticles are mainly interesting for the fabrication of microparticles without pre-cultured cells or as building blocks for additive technologies, i.e., selective laser sintering.

The main advantage offered by natural polymers relies on their ability to better mimic biological macromolecules and enhance specific cell adhesion. These materials are indeed more likely to stimulate cell attachment and proliferation due to specific integrin molecular recognition [13]. Their natural chemistry allows them to degrade through natural enzymatic pathways releasing no cytotoxic byproducts. However, being from natural sources, their purity level can raise several concerns in terms of reliability, homogeneity, stability, and potential immunogenicity [10].

Some polysaccharides and collagen are the most commonly studied natural polymers for microparticles processing [14]. Alginates are natural gel-forming polysaccharides of algal or bacterial origin and have been used in the food and pharmaceutical industries since 1881. In clinics, these polysaccharides are most specifically used daily as a material for wound dressings thanks to their hemostatic properties and biocompatibility. Alginate alone, or in combination with other natural polymers, has been mostly reported for cell encapsulation for several decades now [14][15][16][17][18]. However, due to their high hydrophilicity combined with a high negative charge density, alginates are suffering from the main drawback for tissue engineering, i.e., cell repulsion properties that counteract any cell adhesion and proliferation. For this reason, alginates functionalized with peptides with cell adhesion properties are today proposed for tissue engineering applications [19].

Chitosan is a linear polysaccharide produced via deacetylation of chitin (a primary component of cell walls in fungi, insects, and crustaceans). With a chemical structure similar to glycosaminoglycan, an important component of the human extracellular matrix and cell signaling pathways [20], its safety has been reported in several scientific papers. Furthermore, chitosan-based materials have antimicrobial properties and can stimulate angiogenesis [21]. However, till now, if some clinical trials have reported on the adoption of chitosan-based materials for tissue repair [22], these materials still need formal approval of legal authorities to be used in clinical practice.

Collagen is the most important protein of the extracellular matrix in the human body. Hence it has been widely adopted for tissue engineering applications [13][23]. Collagen shows high biocompatibility, low immunogenicity, cell adhesion, and proliferation. Products from its degradation absorb easily in the body and are not cytotoxic [24]. Collagen microparticles enable the delivery of both bioactive compounds and stem cells [25]. Gelatin, resulting from mild degradation of collagen, is also disclosed to be biodegradable and safe while forming gels very easily. Some studies have shown efficient cell growth and differentiation using gelatin hydrogel microspheres [15][26]. Further, gelatin is commonly used in combination with alginates in the form of hydrogels.

Polyanhydrides are a class of degradable synthetic biopolymers widely used as carriers for controlled drug delivery. Despite being easy and cheap to synthesize, polyanhydrides have a short shelf life. Thus, there are few polyanhydride products available on the market compared to polyester-based products, and a very low number of works explore their use in tissue engineering [27].

Polyhydroxyalkanoates (PHAs) are other biopolymers of bacterial nature produced under stress conditions as an energy reservoir. Such representatives, as homopolymer poly(3-hydroxybutyrate) or the poly(3-hydroxybutyrate-co-hydroxyvalerate) copolymer, may be efficiently used in biomedicine, e.g., drug delivery [28]. Their biocompatibility and biodegradability, along with good controllable mechanical properties, stimulate the research and allow to refer to PHAs as «green plastics» [29][30]. PHAs may promote cell growth and enable their adhesion and proliferation [30][31].

Silk fibroin has also been suggested as a material for microparticle fabrication. This natural protein derived from silkworms exhibits cell-binding moieties enabling stem cells differentiation [32]. Silk fibroin can be tailored to control its biodegradation and its mechanical strength [24]. This material can also contribute to drug delivery [33]. Despite high biocompatibility and several advantages, low mechanical strength, and batch-to-batch variability have been disclosed as the main limitations of these natural products for tissue engineering applications. In this perspective, at the present moment, synthetic polymers are more promising for the fabrication of microparticles for real clinical application. The novel research projects are mostly devoted to hybrid microparticles with the aim of combining the most beneficial properties of different materials. Synthetic materials, e.g., PLA, PGA, PCL, and their copolymers, contribute to their mechanical properties and controlled formation, whereas natural materials, e.g., chitosan, collagen, increase the microparticles’ compatibility with the native extracellular matrix. In this way, the limitations of each individual material can be overcome, and biomedical needs can be met. There are a few works dealing with the fabrication of microparticles based on copolymers of synthetic and natural polymers, which gives a combination of advantages of both polymer types as well as flexibility in terms of fabrication conditions [34][35][36]. However, such copolymers could be considered as new polymers and needed to be firstly approved for biomedical application, which is complicated from the regulatory point of view.

Inorganic components could also be used for microparticles fabrication, but are mostly used as filling materials and stabilizers for dispersions. Nevertheless, scientific works describe inorganic materials as the main building material for microparticles [37]. Some materials which are similar to natural components may mimic human tissue structure and therefore promote cell differentiation. For example, bone is a highly organized natural nanocomposite consisting of collagen fibers mineralized with hydroxyapatite nanocrystals [38]. Hence, the application of biodegradable microparticles containing hydroxyapatite (HA) is beneficial for bone regeneration.

. Material selection should be made according to key technical features, such as degradation and diffusion features, thermal and mechanical properties, and suitable structural form for cell adhesion and tissue integration [11]. However, in terms of clinical application, the materials used for the microparticle fabrication should be safe and approved for biomedical use as the main criterion.

Biodegradable synthetic aliphatic polyesters are the main class of raw materials reported for the fabrication of polymeric scaffolds and drug delivery systems [11,12,13]. Being approved for more than 30 years by regulatory bodies, e.g., FDA or EMA, aliphatic polyesters, such as poly(lactic acid) (PLA), poly(glycolic acid) (PLGA), polycaprolactone (PCL), and their copolymers, have received the most considerable attention. The main requirements for their biomedical applications are biodegradability, tolerability, and non-toxicity. These polymers undergo hydrolytic degradation in the human body, releasing no cytotoxic byproducts. Thanks to the possibility to adjust their chemical structure, e.g., molecular weight, stereoregularity, macromolecule topology, copolymer composition, etc., these synthetic polymers are more reliable and flexible in terms of microparticle fabrication conditions and final properties. However, their lack of bioactivity, i.e., the inability to interact specifically with cells to promote and control cell adhesion, proliferation, and differentiation, limits their functionalities in tissue engineering. Thereby, to extend the functionality of microparticles based on synthetic polymers, they could be blended with natural polymers or inorganic components. Such types of microparticles are mainly interesting for the fabrication of microparticles without pre-cultured cells or as building blocks for additive technologies, i.e., selective laser sintering.

The main advantage offered by natural polymers relies on their ability to better mimic biological macromolecules and enhance specific cell adhesion. These materials are indeed more likely to stimulate cell attachment and proliferation due to specific integrin molecular recognition [14]. Their natural chemistry allows them to degrade through natural enzymatic pathways releasing no cytotoxic byproducts. However, being from natural sources, their purity level can raise several concerns in terms of reliability, homogeneity, stability, and potential immunogenicity [11].

Some polysaccharides and collagen are the most commonly studied natural polymers for microparticles processing [15]. Alginates are natural gel-forming polysaccharides of algal or bacterial origin and have been used in the food and pharmaceutical industries since 1881. In clinics, these polysaccharides are most specifically used daily as a material for wound dressings thanks to their hemostatic properties and biocompatibility. Alginate alone, or in combination with other natural polymers, has been mostly reported for cell encapsulation for several decades now [15,16,17,18,19]. However, due to their high hydrophilicity combined with a high negative charge density, alginates are suffering from the main drawback for tissue engineering, i.e., cell repulsion properties that counteract any cell adhesion and proliferation. For this reason, alginates functionalized with peptides with cell adhesion properties are today proposed for tissue engineering applications [20].

Chitosan is a linear polysaccharide produced via deacetylation of chitin (a primary component of cell walls in fungi, insects, and crustaceans). With a chemical structure similar to glycosaminoglycan, an important component of the human extracellular matrix and cell signaling pathways [21], its safety has been reported in several scientific papers. Furthermore, chitosan-based materials have antimicrobial properties and can stimulate angiogenesis [22]. However, till now, if some clinical trials have reported on the adoption of chitosan-based materials for tissue repair [23], these materials still need formal approval of legal authorities to be used in clinical practice.

Collagen is the most important protein of the extracellular matrix in the human body. Hence it has been widely adopted for tissue engineering applications [14,24]. Collagen shows high biocompatibility, low immunogenicity, cell adhesion, and proliferation. Products from its degradation absorb easily in the body and are not cytotoxic [25]. Collagen microparticles enable the delivery of both bioactive compounds and stem cells [26]. Gelatin, resulting from mild degradation of collagen, is also disclosed to be biodegradable and safe while forming gels very easily. Some studies have shown efficient cell growth and differentiation using gelatin hydrogel microspheres [16,27]. Further, gelatin is commonly used in combination with alginates in the form of hydrogels.

Polyanhydrides are a class of degradable synthetic biopolymers widely used as carriers for controlled drug delivery. Despite being easy and cheap to synthesize, polyanhydrides have a short shelf life. Thus, there are few polyanhydride products available on the market compared to polyester-based products, and a very low number of works explore their use in tissue engineering [28].

Polyhydroxyalkanoates (PHAs) are other biopolymers of bacterial nature produced under stress conditions as an energy reservoir. Such representatives, as homopolymer poly(3-hydroxybutyrate) or the poly(3-hydroxybutyrate-co-hydroxyvalerate) copolymer, may be efficiently used in biomedicine, e.g., drug delivery [29]. Their biocompatibility and biodegradability, along with good controllable mechanical properties, stimulate the research and allow to refer to PHAs as «green plastics» [30,31]. PHAs may promote cell growth and enable their adhesion and proliferation [31,32].

Silk fibroin has also been suggested as a material for microparticle fabrication. This natural protein derived from silkworms exhibits cell-binding moieties enabling stem cells differentiation [33]. Silk fibroin can be tailored to control its biodegradation and its mechanical strength [25]. This material can also contribute to drug delivery [34]. Despite high biocompatibility and several advantages, low mechanical strength, and batch-to-batch variability have been disclosed as the main limitations of these natural products for tissue engineering applications. In this perspective, at the present moment, synthetic polymers are more promising for the fabrication of microparticles for real clinical application. The novel research projects are mostly devoted to hybrid microparticles with the aim of combining the most beneficial properties of different materials. Synthetic materials, e.g., PLA, PGA, PCL, and their copolymers, contribute to their mechanical properties and controlled formation, whereas natural materials, e.g., chitosan, collagen, increase the microparticles’ compatibility with the native extracellular matrix. In this way, the limitations of each individual material can be overcome, and biomedical needs can be met. There are a few works dealing with the fabrication of microparticles based on copolymers of synthetic and natural polymers, which gives a combination of advantages of both polymer types as well as flexibility in terms of fabrication conditions [35,36,37]. However, such copolymers could be considered as new polymers and needed to be firstly approved for biomedical application, which is complicated from the regulatory point of view.

Inorganic components could also be used for microparticles fabrication, but are mostly used as filling materials and stabilizers for dispersions. Nevertheless, scientific works describe inorganic materials as the main building material for microparticles [38]. Some materials which are similar to natural components may mimic human tissue structure and therefore promote cell differentiation. For example, bone is a highly organized natural nanocomposite consisting of collagen fibers mineralized with hydroxyapatite nanocrystals [39]. Hence, the application of biodegradable microparticles containing hydroxyapatite (HA) is beneficial for bone regeneration. Biodegradable biomaterials for MPs fabrication.

|

| Material |

|

| Chemical Nature, Crystallinity, Thermal Properties |

|

| Range of Degradation Rate and the Main Route of Degradation |

|

| Functionality |

|

| Advantages |

|

| Drawbacks |

|

| Approval Status |

|

| Ref. |

|

|

| Synthetic polymers |

|

|

| PCL |

|

| Aliphatic polyester; |

| Semi-crystalline; |

| Tg: −60 °C; Tm: 60 °C |

|

| >1 year |

| Ester hydrolysis |

|

| Hydrophobic material; |

| Limited to aliphatic ester functions; |

| Residual organic solvent content; |

|

| Macromolecular features and purity are well-controlled and reliable; |

| Chemical purity is under control; |

| Degradation rate can be easily adjusted in function of the Mw, tacticity, and crystallization %; |

| Easy processability. |

|

| Lack of cell adhesion moieties; |

| Release of acidic by-products during degradation. |

|

| FDA-approved |

|

[39]

|

[40]

|

|

| PLA |

|

| Aliphatic polyester; |

| Semi-crystalline or amorphous; |

| Tg: 40 °C; Tm: 180 °C |

|

| >0.6 year |

| Ester hydrolysis |

|

[40]

|

[41]

|

|

| PLGA |

|

| Aliphatic polyester; |

| Semi-crystalline or amorphous; |

| Tg: 40 °C; Tm: 180 °C |

|

| >0.3 year |

| Ester hydrolysis |

|

[41]

|

[42]

|

|

| Natural polymers |

|

|

| Alginates |

|

| Anionic polysaccharides copolymers |

|

| Enzymatic degradation pathway |

|

| Carboxyl groups; |

| Polyelectrolyte. |

|

| Gel-forming ability; |

| Hydrophilicity. |

|

| No cell adhesion characteristics; |

| Lack of control of the macromolecular features (Mw, polydispersity, purity). |

|

| FDA-approved |

|

[42]

|

[43]

|

|

| Collagen |

|

| Natural protein present in the extracellular matrices of tissues |

|

| Enzymatic degradation pathway |

|

| Carboxyl and amino groups |

|

| Cell adhesion and proliferation enhancement; |

| Hydrophilicity. |

|

| Risk of allergic reactions; |

| Low mechanical properties. |

|

| FDA-approved |

|

[13]

|

[14]

|

|

| Chitosan |

|

| Cationic polysaccharides copolymers. |

|

| Enzymatic degradation pathway |

|

| Primary amino-groups |

|

| Positive charge; |

| Cell adhesion enhancement; |

| Hydrophilicity. |

|

| Lack of control of the macromolecular features (Mw, polydispersity, purity); |

| Difficulty of processing (not soluble in aqueous medium at neutral pH). |

|

| Not approved as pharmaceutical excipient; |

| Under clinical testing as an implant. |

|

[43]

|

[44]

|

|

| PHAs |

|

| Polymers with high structural diversity; Semi-crystalline. |

|

| Enzymatic and hydrolytic degradation |

|

| Ester functions |

|

| Cell proliferation stimulation; |

| Hydrophilicity; |

| Controllable mechanical and thermal properties. |

|

| Low mechanical properties |

|

| Not approved |

|

[44]

|

[45]

|

|

| Silk |

| fibroin |

|

| Natural protein isolated from animals. |

|

| Enzymatic degradation pathway |

|

| Carboxyl and amino groups |

|

| Cell proliferation stimulation; |

| Hydrophilicity; |

| Gel-forming material |

|

| High risk of allergic reactions. |

|

| Not approved |

|

[45]

|

[46]

|

2.2. Methods of MPs Fabrication

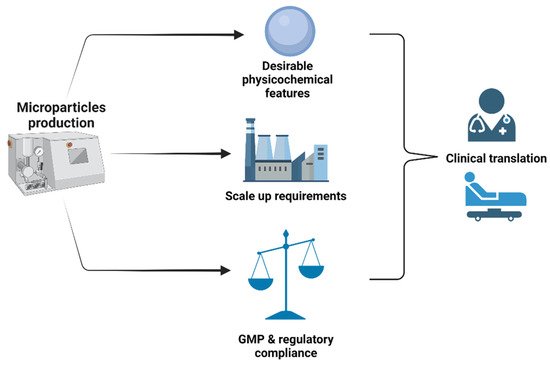

Microparticles are well-established tools in pharmaceutical and biomedical fields with attractive applications, particularly in drug delivery and recently in regenerative medicine [28][46]. These particles provide several advantages, including the possibility of tailoring their properties to improve the efficiency of available biomedical applications that rely on them. They can be made from both degradable and non-degradable materials [47]. Over the last decades, successful developments in the polymers chemistry and processing field have catalyzed the design of microparticles with fine-tune characteristics. Currently, there is a wide range of techniques that have been developed for the production of microparticles [46][48][49][50][51]. The choice of the proper production method depends on such factors as particle composition, desired physical features, and optimal biochemical functionalities that need to be achieved with microparticles. Typically, the ideal manufacturing process should have control over critical microparticles features such as size, shape, surface topography, porosity, sustained and/or controlled release of encapsulated bioactive agents, and so forth. These characteristics are prerequisites for different applications, including cell therapy and tissue engineering, as they may impact cell attachment, spreading, morphology, and behavior during an in vitro expansion culture of cells or an in situ scaffold formation. The scalability of the process is also an important aspect that should be put under consideration. Indeed, commercial production of microparticles to be used for both pharmaceutical and cell products should comply with GMP conditions which require the use of fully characterized materials and well-defined equipment, as depicted in

2.2. Methods of MPs Fabrication

Microparticles are well-established tools in pharmaceutical and biomedical fields with attractive applications, particularly in drug delivery and recently in regenerative medicine [29,47]. These particles provide several advantages, including the possibility of tailoring their properties to improve the efficiency of available biomedical applications that rely on them. They can be made from both degradable and non-degradable materials [48]. Over the last decades, successful developments in the polymers chemistry and processing field have catalyzed the design of microparticles with fine-tune characteristics. Currently, there is a wide range of techniques that have been developed for the production of microparticles [47,49,50,51,52]. The choice of the proper production method depends on such factors as particle composition, desired physical features, and optimal biochemical functionalities that need to be achieved with microparticles. Typically, the ideal manufacturing process should have control over critical microparticles features such as size, shape, surface topography, porosity, sustained and/or controlled release of encapsulated bioactive agents, and so forth. These characteristics are prerequisites for different applications, including cell therapy and tissue engineering, as they may impact cell attachment, spreading, morphology, and behavior during an in vitro expansion culture of cells or an in situ scaffold formation. The scalability of the process is also an important aspect that should be put under consideration. Indeed, commercial production of microparticles to be used for both pharmaceutical and cell products should comply with GMP conditions which require the use of fully characterized materials and well-defined equipment, as depicted in . In addition to the plethora of conventional methods (emulsions, spray-drying, coacervation, etc.) that have been proposed to prepare microparticles, there is a remarkable research effort towards the development of innovative techniques capable of challenging many limitations encountered with conventional methods. Schematic illustration representing the main three aspects to be taken under consideration while selecting a fabrication technology for microparticles. Created by

BioRender.com (accessed on 23 February 2022).

2.3. Microparticle-Based and Microparticle-Contained 3D Structures

Biodegradable microparticles are well-established tools in the pharmaceutical and biomedical fields with attractive applications. They are especially interesting as injectable drug/cell microcarriers, but they could also be successfully used for the fabrication of larger scaffolds using one of the three possible strategies:

(accessed on 23 February 2022).

2.3. Microparticle-Based and Microparticle-Contained 3D Structures

Biodegradable microparticles are well-established tools in the pharmaceutical and biomedical fields with attractive applications. They are especially interesting as injectable drug/cell microcarriers, but they could also be successfully used for the fabrication of larger scaffolds using one of the three possible strategies:

- Aggregation of cell-free microparticles via polymer/polymer aggregation or assembly of microparticles with pre-cultured cells through cell/cell interactions;

- Microparticles as filling material to other types of matrices, including the application of them as drug depot, functional fillers to regulate the physico-mechanical properties of the matrix as well as cell-seeded microcarriers within bioinks;

- Microparticles without cells as building blocks for the fabrication of 3D scaffolds.

3. Biomedical Applications of MPs

3.1. Microparticles as Drug Delivery Depot to Promote Tissue Reconstruction

Those microparticles should be designed in order to guarantee the sustained release of growth factors for at least several days or weeks. Accordingly, they should be essentially non-porous and made from polymers and according to a process that maintains the activity of these proteins during the whole duration of the release kinetics. Several growth factors have been proposed in the literature to enhance tissue repair and regeneration. Some of them, e.g., BMP-2 and BMP-6, are today accepted by legal authorities in order to assist bone reconstruction [52][53]. However, if the local delivery of these growth factors has highlighted promising results in pre-clinical studies, their success rate in clinic remains very limited [54]. Amongst the reasons explaining this lack of efficiency can be certainly mentioned the very short half-life of these biopharmaceutical agents, their rapid escape from the injected site, and also their high prices in comparison to their efficiency. These main limitations could be solved using degradable microparticles tailored to protect and progressively deliver one or a defined cocktail of growth factor(s) locally in the injured tissue. An additional advantage offered by this strategy will be that these microparticles will multiply the surface requested to support cell proliferation and differentiation. In terms of perspectives of valorization, this strategy also seems very attractive, taking into account the following aspects:

3. Biomedical Applications of MPs

3.1. Microparticles as Drug Delivery Depot to Promote Tissue Reconstruction

Those microparticles should be designed in order to guarantee the sustained release of growth factors for at least several days or weeks. Accordingly, they should be essentially non-porous and made from polymers and according to a process that maintains the activity of these proteins during the whole duration of the release kinetics. Several growth factors have been proposed in the literature to enhance tissue repair and regeneration. Some of them, e.g., BMP-2 and BMP-6, are today accepted by legal authorities in order to assist bone reconstruction [123,124]. However, if the local delivery of these growth factors has highlighted promising results in pre-clinical studies, their success rate in clinic remains very limited [125]. Amongst the reasons explaining this lack of efficiency can be certainly mentioned the very short half-life of these biopharmaceutical agents, their rapid escape from the injected site, and also their high prices in comparison to their efficiency. These main limitations could be solved using degradable microparticles tailored to protect and progressively deliver one or a defined cocktail of growth factor(s) locally in the injured tissue. An additional advantage offered by this strategy will be that these microparticles will multiply the surface requested to support cell proliferation and differentiation. In terms of perspectives of valorization, this strategy also seems very attractive, taking into account the following aspects:

- Their local administration is minimally invasive and feasible into limited accessible sites;

- Their high surface/volume ratio is favorable and reported to be particularly suited as cell supporting microcarriers;

- Being made from well-known biocompatible and biodegradable polyesters, such as PLGA;

- Their degradation rate can be easily adjusted to balance growth factor release kinetics, cell supporting amplification, and mechanical support [55];

- Their degradation rate can be easily adjusted to balance growth factor release kinetics, cell supporting amplification, and mechanical support [107];

- The large scale GMP production of these drug delivery microparticles is already known and applied for several years;

- They are simple products, free of animal cells, and easy to submit to regulatory bodies;

- There is an opportunity to physically combine these microparticles with autologous stem cells just before implantation on a patient.

This approach was already suggested several years ago by Perez et al. [56] or J.P. Karam [57]. However, and despite all the advantages cited above highlighting the attractiveness of this approach, no microparticles are commercially available to trigger the sustained release of growth factors for tissue engineering.

Several reasons could be suggested to explain the reluctance of pharmaceutical industries to invest in this direction, in particular cost/efficiency. However, more importantly, supraphysiological concentrations of growth factors have been correlated with local and systemic adverse events, such as edema, tissue resorption, atypic remolding tissue, and also an increased risk of cancer development [58][59].

To counteract these issues and improve efficacy, chimeric growth factors have been recently developed and evaluated in vitro and in vivo for bone repair [60].

On the other hand, it is also worth reminding that tissue rebuilding is not only dependent on the presence of a specific growth factor, but is under the influence of several biological agents which regulate the proliferation, migration, and invasion of mesenchymal stem cells, according to a time sequence and concentration ratio which are not well defined [61].

Regarding these limitations, a concurrent strategy relies on the adoption of platelet concentrates which gain interest in clinical practice for both soft and hard tissue engineering. This autologous material, which does not require any specific regulatory requirements in the actual status of the legislation to be used by clinicians, allows a sustained release of concentrated growth factors as well as fibrin and platelets, and these compounds are known to be essential in wound healing [62].

3.2. Microcarriers for Cell Expansion

To be able to obtain a sufficient number of cells for cell therapy, whether it is about autologous or allogeneic stem cells, in vivo cell expansion is an essential step in the development process. Indeed, the final therapeutic dose of differentiated mesenchymal stem cells (MSC) varies according to application. It is reported that a therapeutic dose should contain between 2 and 3 million MSC/kg

This approach was already suggested several years ago by Perez et al. [126] or J.P. Karam [127]. However, and despite all the advantages cited above highlighting the attractiveness of this approach, no microparticles are commercially available to trigger the sustained release of growth factors for tissue engineering.

Several reasons could be suggested to explain the reluctance of pharmaceutical industries to invest in this direction, in particular cost/efficiency. However, more importantly, supraphysiological concentrations of growth factors have been correlated with local and systemic adverse events, such as edema, tissue resorption, atypic remolding tissue, and also an increased risk of cancer development [128,129].

To counteract these issues and improve efficacy, chimeric growth factors have been recently developed and evaluated in vitro and in vivo for bone repair [130].

On the other hand, it is also worth reminding that tissue rebuilding is not only dependent on the presence of a specific growth factor, but is under the influence of several biological agents which regulate the proliferation, migration, and invasion of mesenchymal stem cells, according to a time sequence and concentration ratio which are not well defined [131].

Regarding these limitations, a concurrent strategy relies on the adoption of platelet concentrates which gain interest in clinical practice for both soft and hard tissue engineering. This autologous material, which does not require any specific regulatory requirements in the actual status of the legislation to be used by clinicians, allows a sustained release of concentrated growth factors as well as fibrin and platelets, and these compounds are known to be essential in wound healing [132].

3.2. Microcarriers for Cell Expansion

To be able to obtain a sufficient number of cells for cell therapy, whether it is about autologous or allogeneic stem cells, in vivo cell expansion is an essential step in the development process. Indeed, the final therapeutic dose of differentiated mesenchymal stem cells (MSC) varies according to application. It is reported that a therapeutic dose should contain between 2 and 3 million MSC/kg

−1 body weight, bearing in mind that repeated doses are typically requested [63]. It is therefore not surprising that most indications have production requirements that cannot be met by traditional static tissue culture methods. In this context, the development of microparticle-based cell expansion technologies has gained momentum lately since they enable larger-scale production to ensure the continued progression of cell therapy through clinical trials [64][65].

Microcarriers are support matrices that enhance the growth of anchorage-dependent cells in bioreactor systems. In microcarrier (MC) culture, cells can grow as monolayers on the surface of small spheres but also as multilayers in the pores of microporous structures usually suspended in culture medium by gentle stirring. Since the introduction of this interesting approach by Van Wezel in 1967, several optimization works have followed, in particular, to improve the physicochemical properties of MC [66][67][68]. Those investigations have led to different microcarriers with varying surfaces, charges, structures, and other properties, allowing the customization of microcarriers’ surface properties based on cell types. They are now commercially available, although a significant proportion of the total investigated materials are still under development.

There are some advantages with this manufacturing procedure which include the improvement of morphological aspects, mechanosensing properties, and cellular yield of the cultured cells [69]. The selection of a suitable microcarrier depends on the cell types and applications. Further engineering efforts are directed towards the design of MC with different formats that replicate signaling cues and the 3D network found in the native tissues of cells [68]. In this framework, MC surface features are key parameters that need to be controlled as they possess a huge impact on the cell fate [65][70]. The functionalization of the MC surface can be achieved through both physical and chemical means. Physical features of MC are related to topography, rugosity, stiffness, and elastic modulus, whereas chemical features include the use of various coating moieties. These characteristics are critical for attachment and detachment of cells to or from MC and may also dictate cells behavior (morphology, differentiation, biological functions, etc.). Cell culture on the microparticles could be additionally optimized in terms of dynamic culture conditions, i.e., stirring regime, microparticle/medium ratio.

Cell expansion carried out with non-degradable microcarriers still suffers from many drawbacks, for instance, poor yield of cell detachment, contamination issues related to proteolytic enzymes requested to harvest cells, and difficulties to separate microparticles debris from free cells [64]. Several strategies have been explored to improve harvest efficiency. Many of them rely on the use of stimuli-responsive polymers whose properties can be drastically altered either by a physical trigger (light, temperature, etc.) or a specific chemical reaction. For instance, poly N-isopropylacrylamide (PNIPAM) is one of the most studied thermoresponsive polymers used for its low critical solution temperature (LCST), which is in the range of 28–32 °C. It has been used for coating the surface of various MCs, including some commercially available ones, for thermal-induced cell detachment [71]. Recently, Narumi et al. assessed the use of a microcarrier coated with an innovative zwitterionic thermoresponsive polymer which had a lower critical solution temperature in the same range as PNIPAM for human mesenchymal stem cells growth. Compared to PNIPAM, this new polymer showed not only superior cell adhesion efficiency and growth rate, but also a higher cell recovery rate [72]. In another study, C. Li et al. reported alginate/PEG-based MC with cleavable cross-linkage for expansion and non-invasive harvest of human umbilical cord blood MSCs. Here, a contently cross-linked alginate network MC is degraded via cleaving of the S-S bonds using reductant, e.g., dithiothreitol. The cells harvested from this system had excellent viability and maintained the stemness and differentiation potential [73].

3.3. Microparticle-Containing 3D Scaffolds for Regenerative Medicine

Large scaffolds made of microparticles via the assembly of cell-free polymeric particles through various types of polymer/polymer interactions could be considered as a specific scaffold fabrication technique [74]. Aggregation of cell-seeded microparticles through the cell interactions is limited by issues coming from cell culture highlighted within previous sections and low control over the microparticle aggregation process.

An application of microparticles as an additional component of large 3D scaffolds refers to their usage as a drug depot, functional filling material, and cell-laden microcarriers. Works on the fabrication of scaffolds containing cell-seeded microparticles are mostly focused on technological issues. Indeed, this complex fabrication strategy is very promising but still requires a lot of processing optimization [75][76]. Thus, PLA microparticles functionalized with human recombinant collagen type I were seeded by mesenchymal stromal cells and cultured using either static or dynamic conditions before the loading of a bioink by the microparticles. The viability of cells seeded on the microparticles was monitored after the UV-induced crosslinking of the bioink made of gelatin methacrylamide. Microcarrier-laden bioink was successful in the fabrication of a composite scaffold. The application of the microparticles allowed to increase cell density in the bioink, preserve cell viability, and the microparticles also acted as mechanical reinforcement. Microparticles without preliminary cell culture could also be used as a part of a larger scaffold to regulate its properties (as functional filling material) or to provide sustainable release of bioactive compounds (as drug depot). In terms of biomedical application, the first approach is mostly aimed at the enhancement of biocompatibility of scaffolds made of synthetic polymers via filling them with naturally derived silk microparticles [77][78]. Such types of research are mainly focusing on bone tissue engineering, while the addition of microparticles as drug depots within larger scaffolds could be more diverse in terms of the final goal. Liu et al. reported that drug-loaded microparticles were successfully used as fillers within hydrogel inks for 3D extrusion printing of cartilage tissue scaffold [79]. Further, microparticles could be used as BMP depots to enhance osteogenesis [80] or as prolonged antibiotic release systems [16][79].

body weight, bearing in mind that repeated doses are typically requested [133]. It is therefore not surprising that most indications have production requirements that cannot be met by traditional static tissue culture methods. In this context, the development of microparticle-based cell expansion technologies has gained momentum lately since they enable larger-scale production to ensure the continued progression of cell therapy through clinical trials [134,135].

Microcarriers are support matrices that enhance the growth of anchorage-dependent cells in bioreactor systems. In microcarrier (MC) culture, cells can grow as monolayers on the surface of small spheres but also as multilayers in the pores of microporous structures usually suspended in culture medium by gentle stirring. Since the introduction of this interesting approach by Van Wezel in 1967, several optimization works have followed, in particular, to improve the physicochemical properties of MC [136,137,138]. Those investigations have led to different microcarriers with varying surfaces, charges, structures, and other properties, allowing the customization of microcarriers’ surface properties based on cell types. They are now commercially available, although a significant proportion of the total investigated materials are still under development.

There are some advantages with this manufacturing procedure which include the improvement of morphological aspects, mechanosensing properties, and cellular yield of the cultured cells [139]. The selection of a suitable microcarrier depends on the cell types and applications. Further engineering efforts are directed towards the design of MC with different formats that replicate signaling cues and the 3D network found in the native tissues of cells [138]. In this framework, MC surface features are key parameters that need to be controlled as they possess a huge impact on the cell fate [135,140]. The functionalization of the MC surface can be achieved through both physical and chemical means. Physical features of MC are related to topography, rugosity, stiffness, and elastic modulus, whereas chemical features include the use of various coating moieties. These characteristics are critical for attachment and detachment of cells to or from MC and may also dictate cells behavior (morphology, differentiation, biological functions, etc.). Cell culture on the microparticles could be additionally optimized in terms of dynamic culture conditions, i.e., stirring regime, microparticle/medium ratio.

Cell expansion carried out with non-degradable microcarriers still suffers from many drawbacks, for instance, poor yield of cell detachment, contamination issues related to proteolytic enzymes requested to harvest cells, and difficulties to separate microparticles debris from free cells [134]. Several strategies have been explored to improve harvest efficiency. Many of them rely on the use of stimuli-responsive polymers whose properties can be drastically altered either by a physical trigger (light, temperature, etc.) or a specific chemical reaction. For instance, poly N-isopropylacrylamide (PNIPAM) is one of the most studied thermoresponsive polymers used for its low critical solution temperature (LCST), which is in the range of 28–32 °C. It has been used for coating the surface of various MCs, including some commercially available ones, for thermal-induced cell detachment [141]. Recently, Narumi et al. assessed the use of a microcarrier coated with an innovative zwitterionic thermoresponsive polymer which had a lower critical solution temperature in the same range as PNIPAM for human mesenchymal stem cells growth. Compared to PNIPAM, this new polymer showed not only superior cell adhesion efficiency and growth rate, but also a higher cell recovery rate [142]. In another study, C. Li et al. reported alginate/PEG-based MC with cleavable cross-linkage for expansion and non-invasive harvest of human umbilical cord blood MSCs. Here, a contently cross-linked alginate network MC is degraded via cleaving of the S-S bonds using reductant, e.g., dithiothreitol. The cells harvested from this system had excellent viability and maintained the stemness and differentiation potential [143].

3.3. Microparticle-Containing 3D Scaffolds for Regenerative Medicine

Large scaffolds made of microparticles via the assembly of cell-free polymeric particles through various types of polymer/polymer interactions could be considered as a specific scaffold fabrication technique [153]. Aggregation of cell-seeded microparticles through the cell interactions is limited by issues coming from cell culture highlighted within previous sections and low control over the microparticle aggregation process.

An application of microparticles as an additional component of large 3D scaffolds refers to their usage as a drug depot, functional filling material, and cell-laden microcarriers. Works on the fabrication of scaffolds containing cell-seeded microparticles are mostly focused on technological issues. Indeed, this complex fabrication strategy is very promising but still requires a lot of processing optimization [115,154]. Thus, PLA microparticles functionalized with human recombinant collagen type I were seeded by mesenchymal stromal cells and cultured using either static or dynamic conditions before the loading of a bioink by the microparticles. The viability of cells seeded on the microparticles was monitored after the UV-induced crosslinking of the bioink made of gelatin methacrylamide. Microcarrier-laden bioink was successful in the fabrication of a composite scaffold. The application of the microparticles allowed to increase cell density in the bioink, preserve cell viability, and the microparticles also acted as mechanical reinforcement. Microparticles without preliminary cell culture could also be used as a part of a larger scaffold to regulate its properties (as functional filling material) or to provide sustainable release of bioactive compounds (as drug depot). In terms of biomedical application, the first approach is mostly aimed at the enhancement of biocompatibility of scaffolds made of synthetic polymers via filling them with naturally derived silk microparticles [112,113]. Such types of research are mainly focusing on bone tissue engineering, while the addition of microparticles as drug depots within larger scaffolds could be more diverse in terms of the final goal. Liu et al. reported that drug-loaded microparticles were successfully used as fillers within hydrogel inks for 3D extrusion printing of cartilage tissue scaffold [155]. Further, microparticles could be used as BMP depots to enhance osteogenesis [110] or as prolonged antibiotic release systems [17,155].