Theis vertical disintegration of companies has increased the complexity ofpaper aims to assess the relationship between Industry 4.0 (I4.0) and the circular economy that could contribute to supply chain management in terms of time and quality and increased uncertainty in the markets, making it impossible today for companies to compete effectively if they are isolated from their suppliers and other stakeholders. In this context, adopting the concept of supply chains (SCs) is increasingly essential for aperformance. To achieve this, a combination of the interpretative structural modelling (ISM) and (cross-impact matrix multiplication applied to classification) MICMAC approach was used to establish the interrelationships between these topics. The developed analysis reveals that there are 19 constructs capable of elucidating this relationship and that there is a hierarchy between these constructs, which are presented in a structural model. Further, the different levels of dependency and driving power are company’s performance. Moreover, two themes are being increasingly discussed in the context of SCs,red in a cluster diagram. As the main result, it was found that there is a strong mutual relationship between the basic technologies. The use of Internet of Things and cloud computing technologies influences the circular economy (CE) and Industry 4.0 (I4.0). The CE paradigm consists of a possible way to achieve environmental objectives and economic sustainability by developing systemic changes that go beyond the individual company and involvollection of large amounts of data, leading to big data, which in turn influence the use of data analytics tools to obtain competitive advantages. These outcomes may contribute to managers’ more assertive decision-making regarding the selection, implementation, and evaluation of projects adopting Industry 4.0 technologies and circular economy approaches in supply chains. Moreover, our study could be the other actors in the SC, contributing to adding value to a product and/or servicebasis for future empirical research to investigate how companies incorporate Industry 4.0 technologies into their processes and how this influences the quest for sustainable supply chains.

1. Introduction

The vertical disintegration of companies has increased the complexity of management in terms of time and quality and increased uncertainty in the markets, making it impossible today for companies to compete effectively if they are isolated from their suppliers and other stakeholders

[1][2][1,2]. In this context, adopting the concept of supply chains (SCs) is increasingly essential for a company’s performance. Moreover, two themes are being increasingly discussed in the context of SCs, the circular economy (CE) and Industry 4.0 (I4.0)

[3]. The CE paradigm consists of a possible way to achieve environmental objectives and economic sustainability by developing systemic changes that go beyond the individual company and involve the other actors in the SC, contributing to adding value to a product and/or service

[4][5][4,5]. On the other hand, I4.0 refers to an industrial revolution based on the deployment of automation technologies and information and communication technologies, which can be helpful to meet current SC needs, such as flexibility, increased productivity, reducing waste, resource optimisation, and more sustainable production processes

[2]. Consequently, the CE can be used to minimise resource usage and decrease waste generation in a high-tech manufacturing environment, integrating sustainable resource management and transforming SCs in the I4.0

[6][7][6,7].

Previous research has assessed the relationship between these themes. For example, some researchers have linked the CE to I4.0

[7][8][7,8], while others have linked, separately, the implementation of I4.0 or the CE to SC performance

[1][2][9][10][11][1,2,9,10,11]. However, a systematic analysis from the perspective of experts concerning the relationship between these three topics is still missing. Many articles do not provide insight into the realization of initiatives to introduce Sustainable Industry 4.0 in the supply chain context. Our paper uses combined Interpretive structural modelling (ISM) and the MICMAC approach was used as a systematic methodology to establish the interrelationships between these topics. However, there is still a lack of studies that analyse this relationship more deeply, to create a consensus between the relationships between the different strategies of I4.0 and CE in the supply chain

[12][13][12,13].

To clarhify our research gap, Table 1 was study aims developed to contrastidentify the research gap with the studies already published.

The dlati

scussion

on sustainable development and the CE has been highlighted worldwide since the 1980s, recognising that natural resources are limited and are suffering significant and irreversible damage from human activity [4].ship between I4.0 technologies and the CE and present This new perspect

ive has created pressure from several stakeholders (consumers, investors, governments, etc.) for companies to reduce their negative impact on the environment [4]. Therefore, orhe effect of adopting

anisations have been working on improving their environmental performance to obtain competitive advantages (such as increased market share and product differentiation) capable of improving financialboth approaches concerning SC performance

without significantly increasing (or even reducing) costs [13]. At t. Then, this research

e same time, I4.0 has been impacting the development of the global industry as it has been providing solutions for computerisation and digitalisation. In other words, the CE and I4.0 are seen as having the potential to increase the efficiency and competitiveness of organisations and, consequently, to offer performance improvements for SCs. Sustainable development depends on its is an attempt to fill this gap and aims to answer the two research questions: (1) what are the relationship

with technological developments between [14]. The I4.0

, t

hrough technologi

cal pillars, has the potential for transition to CE, by maximizing the use of available resources and minimizing waste and emission [2][15].

2. The Importance of the CE and I4.0 for SC Performance

Poes and the CE? (2) What is the p

ulatio

n growth linked to economic and technological development has led to changes in the types of production and consumption, making SCs increasingly dependent and unsustainable [4]. Growing tential effect of these constructs on SC performance? As a starting point, a systema

rket

competitiveness, environmental changes, public pressure, and environmental legislation have generated the need for organizations to change their production systems’ operations to ensure the coexistence of industrial development and environmental protection [16]. For theic literature review (SLR) was developed, resulting in 19 constructs. Subsequently, the interactions

e changes to occur, it is necessary to redefine the basic between these construct

ure of SCs to include environmental issues [17]. As recommes and

ed by the

CE literature [5], strength

e first step of this change is to migrate from a linear SC to a closed-loop one. When SCs extend environmental concerns to their operof the driving and dependence power of this relations

, they are characterized as a circular supply chain (CSC)hip were proposed using a [6]. Acco

rmbined

ing to Srivastava [18] (p. 54), ci interpretive str

uc

ular supply chain management (CSCM) can be defined as “the integtural modelling (ISM) and fuzzy MICMAC (Matrice d’Impacts Croisés Multiplication Appliqués à un Classement (cr

atio

n of environmental thinking with supply chain management, including product design, material selecss-impact matrix multiplication a

nd supply, manufacturing processes, delivery of the final product to consumers and the management of the entire product life cycle, even after the end of its useful life”pplied to classification) analysis.

T

2. Theoretical Background

Alth

e ado

ption of the CSCM requires a paradigm shiftugh [13][18]. Spemuc

ifically,h organisations need to stop seeing environmental issues as external restrictions that impose limits, increase the costs of their operation, and reduce their competitivenesswork has been done on sustainable SCs, the relationship between the [19]CE and

SCs st

art instead to see them as an opportunity to generate economic and financial gains [18], ill needs to be explored, especially to identify th

use improving their performancemethods and [13]. Ttoo

ls achieve this, several practicesthat need to be adopted

, including: circular projects; designing products and operations in across the SC t

aking into account environmental protection and health throughout the product’s life cycle; reverse logistics (planning and controlling the flow of raw materials, inventories, and products from the point of consumption to the point of origin to recapture value or ensure proper disposal); recycling and remanufacturing operations; the recovery, reuse,o support efficient CE adoption, enabling a “complete” transition from a linear to a circular SC due to its increased complexity [5]. aIn

d reforming of products and packaging; waste management and minimisation; and the substitution of hazardous materials or processes with less problematic ones [20] this context, I4.0 technologies can be of great value [2,7].

The S

C invo

lves coordinating, planning, and controlling products and services through integrated activitieme proposals for relationships between

suppliers and customers. However, despite being connected, many of these activities are carried out independently by each member organisation of the chain [21].these two approaches can be found in Thus, the

results obtained in the traditional SC structure are no longer sufficient and do not match current technologicalliterature, with ReSOLVE [16] dbe

velopments [21]. In thi

s con

text, the conceptg one of the

integration and digitisation of the SC emerges to add value, strengthen the competitive potential of organisations, and improve the corporate performance of intra-organisational and inter-organisational processes [22].

A dimost cited methods. However, empirical studies are scarce, resulting

itised SC is an intelligent system of networks, hardware, and software that requires a massive amount of data, as well as cooperation and communication, to support and synchronise interaction between organisations to provide higher value and more accessible services based on agility, consistency, and effectivenessin the effect of this relationship on companies’ performance, especially in the [3]. S

everalC, technologies and innovative solutions are used for digitising and integrating of SCs, including I4.0 technologieis poorly studied. It is

[21][23], sucth

ais

: flexible and digitally integrated production systems; inter-organisational information integration, synchronisation and communication systems; worker support technologies; the Internet of Things (IoT); cloud computing; big data; and data analytics. Further, as Vacchi et al. [7] (p. 1) stat gap that the present study aims to address. The intersection literature betwee

d,n “Industry 4.0 pushes manufacturing industries to make their processes minimise waste: tthese areas is presented.

3. Research Method

This

tr

ansition to efficiency links Industry 4.0 with the goals of the circular economy”. Therefore, there is an opportunity to investigateesearch aims to identify the relationship

s between

these three themes.

3. The Literature Regarding the Relationship between the CE and I4.0 and Its Effect on SC Performance

The need to optimise SCs due to the competitive pressures of the market promotes and encourages the adoption of I4.0 technologies

, in parallel with CE approaches

, [15]. Accorand

ing to Rajput [24], thSC pe

CE irforman

tegration with I4.0 is a way to achieve sustainability, as it reduces barriers such as lack of information regarding the life cycle of products and uncertainty about the return on investmentsce. For this, the ISM approach was chosen to identify and classify relationships between [25]. Fovar

exia

mple, asbles [10]. T

hi

waris [8] (p. 2) statme

d, “th

e advent and adoption of digital technologies based on the principles of Industry 4.0 may help toodology involves four steps [10,31,32]: overcome(1) the barriers to the adopidentification of

CE”. In other words, if organisations want to maintain and strengthen their competitive potential, they need to embrace technological and environmental changes together [12]. In thelements that relate the three research topi

cs

context, Jabbour et al.through a [15] proposys

ed t

he relationship between the CE business actions and I4.0 technologiesematic literature review (

Table 1SLR)

.

Table 1. Relationship between the ReSOLVE framework and I4.0 technologies.

More recently,

some studies have simultan

eously addressed all these three themes Laskurain-Iturbe et al.d this generated a [12] showed evidence of the p

otre

ntial impacts of additive manufacturing and robotics by integrating industry 4.0 and the CE. Rajput and Singhliminary list; (2) data collection [24] used DEMATEL t

hro

identify enablers and barriers to the relationship between these topics. Dev et al. [26] sugh expert interviews to vali

muldate

d a reverse logistics model to propose a roadmap for the joint implementation of I4.0 principles using the ReSOLVE model. Further, Yadav et al. [27] this list from an empirical perspective; (3) de

veloped a framework to overcome challenges in SCs through solutions based on I4.0 and the CE, subsequently validating it through a case study in the automotive industry. Various researchers have used other perspectives to examine this relationship [28][29]. Althlaboration of the structural model; and (4) fuzzy MICMAC development with a cluster diagram sho

ugh thwe

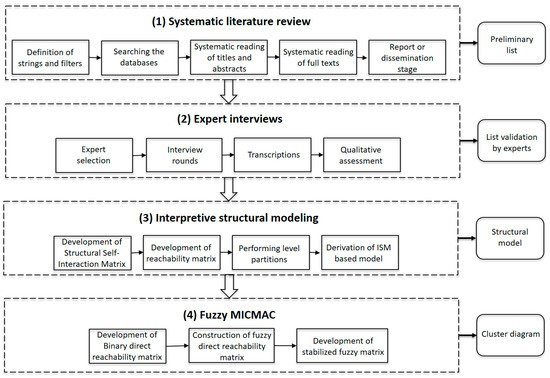

theme’s relevance in the literature has been highlighted, no research was identified in the SLR assessing the relationship between the themes systematically from the perspective of expertsd the elements driver and dependence power. The following subsections describe these steps, as summarised in Figure 1.

Figure 1. Research method.

4. Conclusions

The main contribution of this research is to present the relationships between the different constructs of the studied themes. The ISM model, the reachability matrix, and the strength matrix of relationships are, together, valuable tools for understanding the direction, order, and power of the complex relationships between I4.0, the CE, and SC performance. Using these tools, managers can make more proactive and consistent decisions regarding implementing I4.0 technologies and CE approaches. They can also select the main performance measures associated with this implementation, allowing the evaluation of the performance of projects with greater accuracy.