Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Jino Ramson and Version 2 by Jason Zhu.

As a consequence of swiftly growing populations in the urban areas, larger quantities of solid waste also form rapidly. Since urban local bodies are found to be unable to manage this perilous situation effectively, there is a high probability of risks relative to the environment and public health. A sudden change is indispensable in the existing systems that are developed for the collection, transportation, and disposal of solid waste, which are entangled in turmoil. However, Smart sensors and wireless technology enable cyber-physical systems to automate solid waste management, which will revolutionize the industry.

- Internet of Things

- solid waste management

- trash bin

- LoRaWAN

1. Introduction

Everyday, the generation of waste increases and is paving the way for serious negative environmental impacts all over the world [1]. It is incontrovertible that all human activities end up generating a considerable quantity of waste in all forms of matter [2]. There is a huge impact on theour environment due to undesigned modernization along with industrialization, which leads to a sudden increase in solid waste, nuclear waste, and other perilous wastes [3].

Waste management refers to the reduction in the amount of waste being produced and the disposal of the same products by using adequate measures [4][5][4,5]. Waste may come in many shapes and forms, including solid waste being produced from domestic sources, infectious waste produced from hospitals, and radioactive waste produced by nuclear reactors [6][7][6,7]. Waste management includes the collection, transportation, recycling or disposal, and analysis of waste materials. Moreover, waste management is relatively new as an industry, which is flourishing day-by-day because of its extreme impact on the ecosystem.

Amusingly, the rate of waste produced is linked to towering economic growth, and it is really an attribute of advanced countries. However, the quantity of waste generated depends on the region, season, and many other factors, which show the difficulty in proper waste disposal.

The management of waste is a complex multi-level process that involves government policy making, legal, financial, administrative, and research facilities [8][9]. The high cost associated with the safe and efficient management of waste makes investing in this industry difficult [9][10]. Therefore, a lot of research and development in this sector is required to establish efficient waste management systems [10][11]. The conventional waste management process begins with the disposal of waste in trash bins near the place of origination. At predetermined times, municipal or private enterprise vehicles pick up waste and move it to temporary collection units. However, these approaches may result in improper waste management due to the following circumstances.

The collection of solid waste on a daily basis constitutes a loss of time, fuel, and labor in cases where trash bins are empty. Alternatively, the collection of solid waste once a week may lead to a risk of overflowing the trash bins. Consequently, solid waste spreads across the region, causing possible heath problems and environmental pollution. Moreover, when cities are large in size, an effective solid waste management system is of great importance. However, the technological developments in the field of sensors and wireless communications pave the way to automate solid waste management systems. Several automation techniques are available that begin with RFID technology relative to the latest Internet of Things (IoT)-based models. Nevertheless, for an efficient solid waste management system, a challenging task is to determine the appropriate mix of sensor and communication technologies with optimum solutions.

2. RFID Based Solid Waste Management Systems

RFID technology is an automated identifying system that is primarily based on RF microwave transmission and is seen as a natural extension of previous identification systems such as bar codes, magnetic cards, and smart cards [11][17]. Despite the fact that the RFID system’s theory of operation was conceived at the beginning of the radio frequency communications era, its use is steadily increasing today [12][18]. RFID is a technology that allows users to read information from tags and communicate it to an information-processing system over a radio frequency range without the need for a physical connection. An antenna, a tag, and a reader are the three parts of an RFID system. The antenna transmits a signal that activates the transponder using radiofrequency waves. When the tag is engaged, it sends data back to the antenna. The transmission ranges of low-frequency RFID systems are short, while those of high-frequency RFID systems are longer. Contactless payments [13][19], automobile [14][20], library [15][21], retail supply chain management [16][22], pharmaceutical [17][23], industry [18][24], ticketing [19][25], and solid waste management systems [20][26] are only a few of the applications where RFID technology is used.

The main objectives of RFID based solid waste management systems are as follows:

-

To obtain information on the waste collection area and the respective collecting time;

-

To develop a system for monitoring and tracking of waste collection trucks and waste bins;

-

To obtain information on the quantity of solid waste inside the bin and the surroundings.

2.1. System Architecture

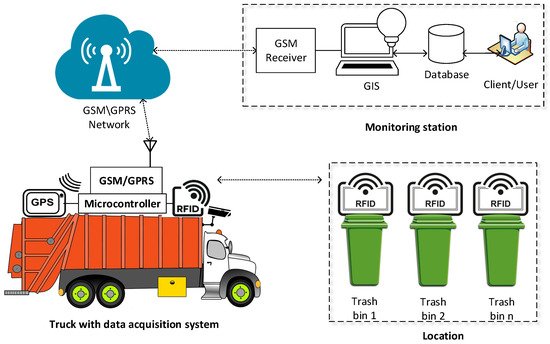

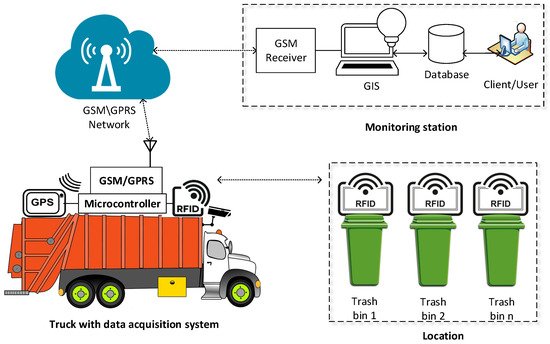

A typical system architecture of the RFID-based solid waste handling system is shown in Figure 1. Communication technologies such as general packet radio service (GPRS), global positioning system (GPS), radio frequency identification (RFID), and geographic information system (GIS) including camera have been integrated for developing the system [21][27].

Figure1. A typical system architecture for RFID-based Solid Waste Handling System.

An RFID tag is attached to all the bins to provide unique identity. The truck, which is used to collect waste from the bins, is mounted with a data acquisition system comprising an RFID reader, camera, GPS, and GSM Module. Once the truck approaches the bin area, the RFID reader detects the RFID tag installed on the bin, the GPS module obtains the real-time location, and the camera captures images prior to and subsequent to waste collection in order to determine the waste in the bin and its surroundings. The data from the truck’s data acquisition system are recorded and sent to a central monitoring station by using a GSM or GPRS network. The monitoring station comprises a receiver, GIS, database and a monitoring terminal for providing user interface.

RFID-Enabled Trash Bin Level Monitoring Systems

Numerous trash bin level monitoring systems have been developed using RFID technology. The work presented in [21][22][27,28] is a purely RFID-based system, which is not using any sensors for bin level measurement. The camera-equipped on the truck is capturing images of the trash bins, which will be sent to the central monitoring station for verifying the waste collection process. Moreover, the system is not using any routing methods to optimize waste collection. The system presented in [23][29] used an additional infrared sensor for measuring the trash bin’s filled level. This system is not using any camera, since sensors are equipped to assess the emptiness of trash bins. In [24][30], a series of sensors was used to assess the unoccupied level and pressure of trash bins. A camera is also equipped in the system for the establishment of GIS for assisting the truck driver to execute optimized waste collection from the trash bins. In [25][31], an outdoor trash bin monitoring system based on RFID is presented. This system used a load-cell sensor to measure the weight of the trash bins. Threshold levels are set according to the filled and empty trash bin’s weight.

The RFID-based system presented in [26][32] is integrated with photoelectric and image sensors to obtain the filled status of the trash bins. A GPS module is also equipped to obtain the accurate locations of the bins to define optimized routing for the waste collection truck. An RFID-based smart trash bin is proposed in [27][33]. This system performs waste material classification with a web-based information system running on the remote server. The trash bins are equipped with RFID tags and each tag is mapped to particular waste material. This approach helps in waste material classification for proper and efficient recycling and disposal.

From the study performed on the RFID enabled trash bin level monitoring systems, the following inferences are obtained:

-

RFID-based systems are unable to provide continuous real-time monitoring of the bin’s filled level;

-

Trash bins are monitored only when the truck is within the range of RFID tags;

-

RFID tags are using to identify the bins uniquely and they do not provide any data on the filled levels of the bins;

-

Additional infrastructure is required to obtain the filled levels of the trash bins.

3. Wireless Sensor Networks Based Solid Waste Management Systems

A Wireless Sensor Network (WSN) is a network of a large number of wireless sensors that are installed ad hoc to monitor the physical or environmental parameters of the system. Sensor nodes with an onboard CPU are used in WSN to monitor the environment in a specific area. The sensor nodes are connected to a central node called the coordinator node and all the coordinator nodes are connected to the base station, which serves as WSN’s processing unit. The base station is connected to the internet to share data. WSN already showcased its applications in various domains such as home automation, environmental monitoring, agriculture, industry, waste management, health, and fitness monitoring. Among the aforementioned applications, WSN presents a key role in designing and deploying real-time solid waste management systems. Some of the main characteristics of WSN based monitoring systems are as follows:

-

Capacity for dealing with node failures;

-

Optimal for nodes equipped with batteries;

-

Nodes mobility and heterogeneity;

-

Scalability to a vast distribution scale.

3.1. Network Architecture

The architecture mainly consists of clusters, base station, and central monitoring station. Each cluster includes several trash bins equipped with sensor nodes, and all these sensor nodes are connected to a coordinator node. The coordinator nodes of various clusters are connected to the base station, which will act as WSN’s processing unit. Furthermore, the base station will share data to the internet for establishing remote monitoring facilities.

WSN-Based Trash Bin Level Monitoring Systems

The advancements in wireless technologies face-lifted solid waste management systems that were bound to the limitations of establishing real-time monitoring and wide-range deployments. This section presents a comparative analysis of various WSN-enabled trash bin level monitoring systems. A WSN architecture for solid waste management based on Zigbee networking protocol is presented in [28][34]. The architecture comprises three modules: data collecting, data processing, and notification. The end nodes mounted on the trash bins measure the unfilled level and update the server through a Zigbee coordinator. Moreover, to save time and money, notifications are sent to the garbage pickup unit using the Telegram messaging service. An intelligent trash bin monitoring system with Zigbee network architecture is presented in [29][35]. The smart nodes enabled with the Zigbee networking protocol transmit the sensed data (filled level of trash bin) to the Zigbee coordinator. The Zigbee coordinator node receives data from all smart nodes and send data to the cloud server when sensed data crosses the threshold level. The cloud server will assess the degree of fullness of trash bins for optimal route planning for waste collection. In addition, the sensor nodes are designed for harvesting energy by using solar energy to extend the lifetime of the nodes. However, the system fails to provide a real-time visualization of the trash bin’s filled level.

A network architecture employed with ArgosD sensor nodes is presented in [30][36]. The nodes are enabled with CC2420 RF transceivers, MSP430F1611 microprocessor, and a sensor. The graphical user interface displays the bin level but not the organizational level. In addition, as compared to conventional approaches, the current consumption and wake-up speed of the devices used are high.The modeling of a wireless sensor network to monitor the unfilled level of bins through a central monitoring station is presented in [31][37]. The wireless monitoring device comprises an ultrasonic sensor, MSP430F2274 microcontroller, and a CC2500 radio that uses the simpliciTI network protocol. The sensor nodes that run on battery power would last around 288 days for a 10,400 mAh power bank. Moreover, to send unfilled data to the remote monitoring station, this model requires a personal computer or a personal digital assistant that increases the overall cost of the system.

The design and development of a wireless sensor network powered by a solar energy harvesting system to monitor the unfilled level of the trash bin is presented in [32][38]. Each bin has a node called Solar Powered Wireless Monitoring Unit (SPWMU), which contains a sensor that measures the unfilled level of the bins and transmits data to the Solar Powered Wireless Access Point Unit (SPWAPU). Experiments have been carried out to verify the proposed system. The battery charging time and life expectancy of the SPWMU were calculated, and the average charging time was determined to be 6.26 h, with the charge lasting 27 days and 17 h. Even on rainy days, the unfilled level of bins can be monitored perfectly without interruption. Furthermore, this system does not require additional PC or PDA for sending data to the monitoring station, which ultimately reduces the effective deployment cost of the system.

A self-powered, simply connected WSN-based solid waste management system is presented in [33][39]. The sensor nodes attached to the trash bins measure the unfilled level of the bins and send it to the wireless access point. The data received from several sensor nodes will be forwarded to the central monitoring station for analysis and visualization. The nodes are equipped with solar panels for energy harvesting. Significant experiments were carried out to validate the system in terms of sensor accuracy, the lifetime of the node, and the maximum range between nodes and the wireless access point. Moreover, the Graphical User Interface (GUI) is designed with progressive bars to represent the dynamic unfilled levels of the trash bins.

4. IoT-Enabled Solid Waste Management Systems

IoT has emerged as one of the most crucial technologies of the twenty-first century in recent years [34][40]. The advances in technologies such as low power sensors, long-range connectivity, cloud computing, and machine learning made the practical establishment of IoT systems faster. An IoT environment consists of a network of web-centric smart devices that use embedded electronic devices such as communication hardware, sensors, and CPUs to collect, send, and process the data from their surroundings. Connecting IoT devices to any edge device such as an IoT gateway allows the sharing of sensor data that can be sent to the cloud for examination. Sometimes, these devices interact among themselves and carry out action on the data they receive. Despite the fact that the users can interact with devices such as setting them up, providing instructions, and extracting data, a greater part of the work is handled by IoT devices alone, eliminating human intervention.

IoT already showcased its robustness and efficiency in various domain-specific applications especially in wearables, smart home, healthcare, smart cities, agriculture, industrial automation, etc. The solid waste management system is one of the most important IoT-based services provided in smart cities. The main features of IoT-enabled solid waste management systems are as follows:

-

No missed pickups: The data recorded from the smart bins assist in reducing missed pickups. The authorities will be automatically notified if the sensors detect that the garbage container is full. Then, the IoT waste management system enables the scheduling of next pickup for this location. This simplifies the process of waste management and reduces overflowing garbage cans.

-

Waste production analysis: Throughout the day, the connected devices keep track of how quickly the bins fill up and how often they empty in different locations. The analysis of these data opens the possibilities of better trash bin distribution, elimination of improper disposal techniques, and even waste reduction at the landfill.

-

Route Optimization: The real-time data provided by the smart trash bins can be used to determine the best paths for garbage collection by prioritizing the most required regions.

4.1. Network Architecture

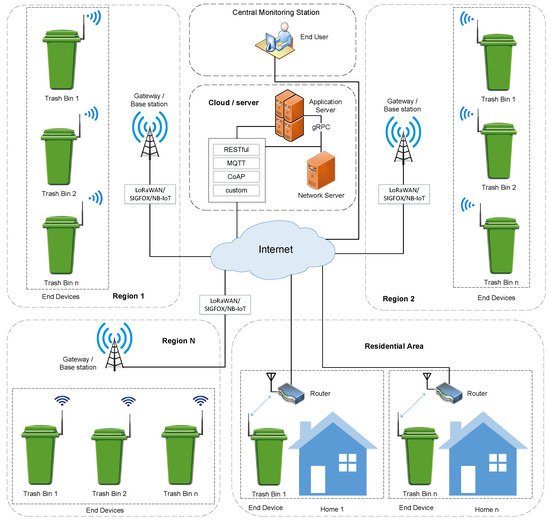

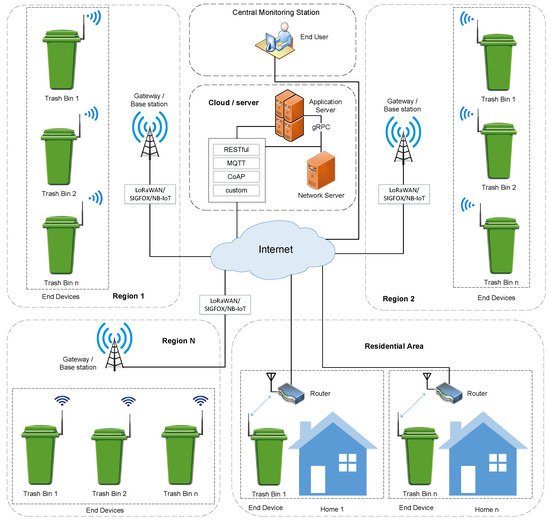

A generic IoT architecture for solid waste handling system is shown in Figure 2. The architecture comprises four sections namely IoT end device, gateways or base station, cloud server, and end-user.

Figure 2. A generic IoT architecture for solid waste handling system.

- IoT end device: It consists of sensors to measure the unfilled level or weight of the trash bins, a microcontroller to perform local processing, and a radio device to establish wireless connectivity with gateways or base stations.

-

Gateway or Base stations: Several communication technologies are available to establish connectivity between the end devices and the cloud server. According to the adopted wireless technology, the gateway or base station will act as a bridge between the end devices and the cloud server. For instance, a gateway for LoRaWAN devices, a base station for Sigfox and NB IoT devices, and a wireless router for Wi-Fi devices.

-

Cloud Server: For IoT applications, cloud servers are preferred due to their flexibility, scalability, and secure authentication process.

-

End-user: Remotely monitoring a system can be performed by the end-user. The end-user may be an employee of the solid waste management company or a person in charge of the solid waste collection department in a municipality or corporation. A hierarchical view of trash bins’ filled level can be obtained through a web page or application software.

Furthermore, automated route optimization for waste pickup trucks is another part of waste management operations. To collect trash, these trucks usually follow a certain path every day. Drivers are often unaware of how full a trash bin is filled until they come across it. IoT solutions in waste management are helping to improve this situation by providing truck drivers with real-time information of the actual fill level of trash bins.

IoT Embedded Trash Bin Level Monitoring Systems

IoT-embedded trash bin level monitoring systems are the latest approach towards building smart cities. A wide range of IoT-based systems, starting from general trash bin monitoring to waste sorting and recycling is available in the literature. This section provides a comparative analysis of various IoTp-embedded trash bin level monitoring systems.

An approach for the optimized handling of solid wastes in urban areas is proposed in [35][41]. A combination of proximity and weight sensors is incorporated to obtain the status of trash bins (i.e., weight/filled level). A Raspberry Pi microcomputer is acting as the gateway to transmit the measured data to the smart-M3 platform. However, this system requires additional gateways to increase its wireless range. Cloud-based smart waste management for waste collection and recycling is proposed in [36][42]. This system consists of separate trash bins for different types of wastes such as organic, plastic, bottles, etc. However, the study has not specified the details of the sensors and wireless technology adopted for deployment. In [37][43], the researchersuthor describes various waste disposal methods in which IoT-based systems can be implemented. A smart box that is powered with solar energy is proposed in this system for bin level measurement. However, this work fails to present the architecture in detail. A system for screening and sorting plastic resin is proposed in [38][44]. After removing plastic wastes, the remaining wastes are used for biogas plants. In [39][45], the researchersuthor describes a smart bin system that uses a mesh network to monitor the degree of fullness of the trash bin. The network is deployed using low-power radio at the 2.4 GHz band. The collected data are sent to a remote server for the analysis and waste collection route optimization. A smart garbage bin for streets is presented in [40][46]. This system sends the sensor ID and geolocation of the almost-filled bins to authorized persons. However, the design of the nodes and other technical details were not presented clearly. In [41][47], an IR sensor-based smart waste management system using IoT is presented. The trash bins’ filled levels are sent to an Intel Galileo Gen 2 board through RF modules. This work also presented a comparison with some of the existing systems.

Most of the systems discussed here use short-range communication technologies such as Wi-Fi, Zigbee, RF, etc. These short-range communication technologies require repeaters to increase their wireless range and are not suited for the low power consumption nature of IoT nodes. The evolution of low power wide area networks (LPWAN) addresses the above limitations by introducing communication technologies that are capable of transmitting data in long-range with low power consumption. The LoRa Alliance maintains LoRaWAN, which is an open specification that primarily serves as a network layer protocol for handling communication between LPWAN gateways and end-node devices [42][48]. Sigfox [43][49] is a software-based communication system that manages all networks and computes complexity in the cloud rather than on the devices themselves. When all of this is taken into account, connected devices’ energy consumption and prices are reduced considerably. The Third Generation Partnership Project (3GPP), which is responsible for the standardization of cellular systems, has launched NB-IoT [44][50] to address the needs of very low data rate devices that must connect to mobile networks and are often powered by batteries.

Among the aforementioned LPWAN technologies, LoRaWAN is preferred for the deployment of IoT-based trash bin level monitoring systems because of the following features:

-

LoRaWAN is an open specification, whereas NB-IoT and Sigfox are proprietary network protocols.

-

LoRaWAN allows the establishment of private networks in which sensor nodes, gateways, and backhaul can be deployed by the user for a specific application. This is in contrast to NB-IoT and Sigfox, where a user needs to pay for connecting their sensor to the networks.

-

LoRaWAN supports firmware upgrade over the air (FUOTA) that enables the remote firmware update of the multiple devices deployed over the network.

-

LoRaWAN supports the Adaptive Data Rate mechanism for the optimization of power consumption, airtime, and data rates, whereas NB-IoT and Sigfox do not support this feature.

IoT-based trash bin level monitoring systems. Automated waste management systems using sensors to monitor bin state, TensorFlow-based object detection for garbage identification and categorization, and the LoRa communication protocol for long-range, low-power data transmission were presented in [45][51]. Due to its lightweight nature, the pre-trained object identification model SSDMobilnetV2 can operate well with Raspberry Pi 3 Model B+. The model could detect and classify waste into different categories such as paper, plastic, and metal. Nevertheless, the accuracy of the model can be enhanced by increasing the frequency of training data, the frequency of captured images of waste, and the training period. The work in [46][52] discusses the suitability of waterproof ultrasonic sensors for measuring the level of waste within a trash bin. The proposed sensing node has been evaluated in the laboratory, demonstrating its efficacy. The value of the waste level inside the bin is determined with a precision of 2–3 cm; this value is sufficient since waste is not spread uniformly inside the bin. Following this initial testing, a network comprising five sensor nodes coupled to a single-channel LoRa gateway is constructed and implemented in real-time. The implementation of an Internet of Things (IoT) architecture for waste management optimization in the context of Smart Cities is presented in [47][53]. This work describes a novel sensor node topology based on the utilization of low-cost and low-power components. All the sensor nodes are equipped with a single-chip microprocessor, an ultrasound-based sensor for measuring the fill level of trash bins, and a LoRa transmission module. A LoRaWAN network is established to evaluate the performance of the proposed system. Moreover, it evaluates the end node in detail by focusing on energy-saving technologies and strategies, intending to increase battery life by reducing power consumption via hardware and software optimization.

A waste monitoring and management system for rural areas is presented in [48][54]. A low-power wireless node prototype is built to determine the weight, filling level, and temperature of the trash bin. This form of monitoring enables the collection and analysis of progressive filling data for each trash bin, as well as the generation of notifications in the event of an incident. The system enables a module for determining the most efficient waste collection routes. This module constructs routes dynamically based on data acquired from deployed nodes, saving energy, time, and, ultimately money. In [49][55], an IoT system based on the LoRa network is deployed and evaluated for feasibility in the development of an economically viable digital waste management system for Industry 4.0 and smart cities. As identified in this work, the primary challenge to successful commercialization is the cost of the sensor accessories, which is essentially driven by the ultrasonic distance sensing portion, where dependable waterproof sensors suitable for outdoor circumstances are expensive to deploy via the LoRa network.