A new metallurgical strategy was introduced to develop advanced materials with outstanding performance—high-entropy alloys (HEAs). THigh-entroday, HEAs contain five or more multiple principle metallic elements in equal or near-equal atomic percentages. HEAs’ four core effects—high configurational entropy, sluggish diffusion, severe lattice distortion, and the cock-tail effect—are mainly responsible for their various physical and mechanical properties. HEAs present promising properties, such as high strength and fracture toughness at room temperature and high temperatures and have excellent wear resistance, and corrosion resistance, along with high-temperature oxidationpy alloys (HEAs) prefer to form single-phase solid solutions (body-centered cubic (BCC), face-centered cubic (FCC), or hexagonal closed-packed (HCP)) due to their high mixing entropy.

1. Introduction

A new metallurgical strategy was introduced to develop advanced materials with outstanding performance—high-entropy alloys (HEAs). Today, HEAs contain five or more multiple principle metallic elements in equal or near-equal atomic percentages

[1]. HEAs’ four core effects

[2]—high configurational entropy, sluggish diffusion, severe lattice distortion, and the cock-tail effect—are mainly responsible for their various physical and mechanical properties. HEAs present promising properties, such as high strength and fracture toughness at room temperature

[3][4][5][6][3,4,5,6] and high temperatures

[2][7][2,7] and have excellent wear resistance

[4], and corrosion resistance

[8][9][10][11][8,9,10,11], along with high-temperature oxidation

[8].

HEAs are more likely to generate a simple solid solution (typically body-centered cubic (BCC), face-centered cubic (FCC), or hexagonal closed-packed (HCP) phases) despite containing many components

[12][13][14][15][12,13,14,15]. Up to now, the development of HEAs has mainly gone through three stages: quinary equal-atomic single-phase solid-solution alloys; quaternary or quinary non-equal-atomic multiphase alloys; medium-entropy alloys, high-entropy fibers, high-entropy films and lightweight HEAs (LWHEAs)

[16][17][16,17]. HEAs mainly include two categories: refractory elements (such as V, Cr, Ti, Mo, Nb, Ta, W, Zr, and Hf) and commodity metals (such as Cr, Co, Fe, Ni, Mn, and Cu)

[18]. HEAs in the first category consist of many refractory elements, so-called refractory high-entropy alloys (RHEAs)

[13], and mostly form BCC structures

[19][20][19,20]. The second category of HEAs mostly forms FCC structures

[21][22][21,22], a combination of FCC and BCC structures

[23][24][25][23,24,25] or BCC structures alone

[26][27][26,27].

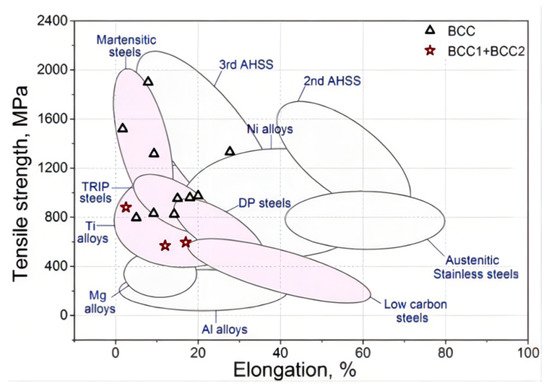

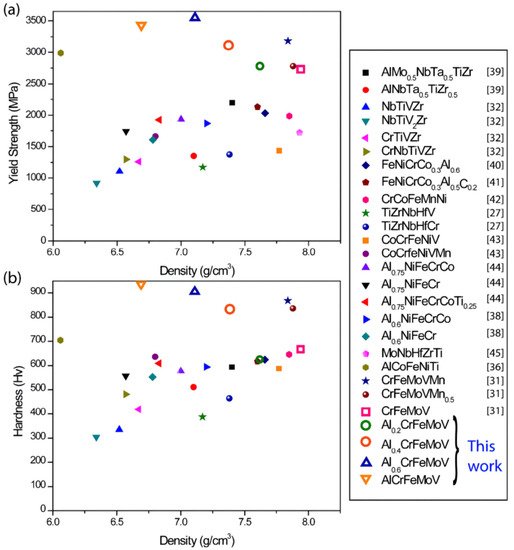

However, FCC structures or “FCC-based” structure HEAs show excellent ductility high plasticity, but its yield strength is not considerable in a large number of studies reported so far

[28][29][28,29]. It needs to be strengthened by a series of thermomechanical treatments before industrial application, which requires an additional cost. In contrast to FCC HEAs, BCC HEAs exhibit relatively high intrinsic yield strengths

[30][31][30,31]. Besides, RHEA systems have excellent high-temperature mechanical properties but insufficient toughness at room temperature

[32][33][32,33]. Developing BCC HEAs with high strength and good ductility is a key to making them potential structural materials in technological applications.

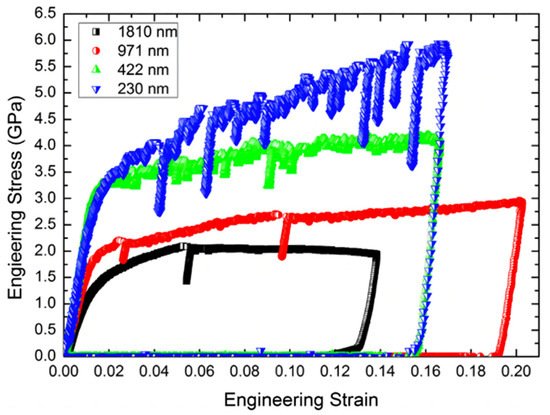

However, it is still weak to regulate the plastic deformation behavior of BCC HEAs via the strengthening methods of FCC HEAs. BCC HEAs can only deal with liquid-solid phase transformation by some processing technology, such as melt purification, homogenization, directional solidification (DS), powder metallurgy (PM) and additive manufacturing (AM).

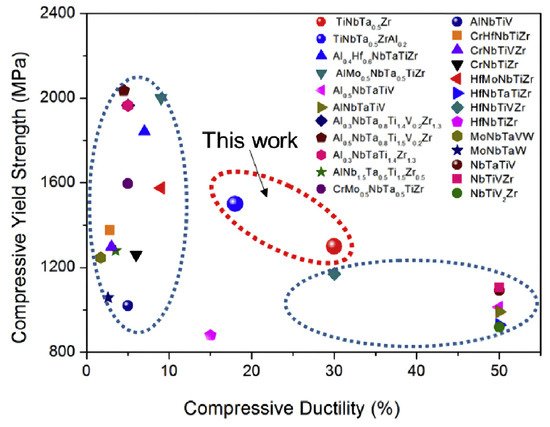

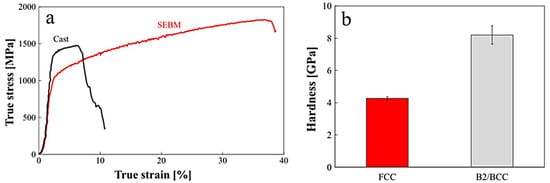

Nowadays, BCC HEAs have typically been fabricated via simple arc-melting and casting, which has been confirmed to be a highly efficient technique for more than five metals. For instance, the AlCrFeCoNi HEA with a single-phase BCC solid solution exhibits excellent compressive properties of yield stress (1250.96 MPa) and plastic strain (32.7%)

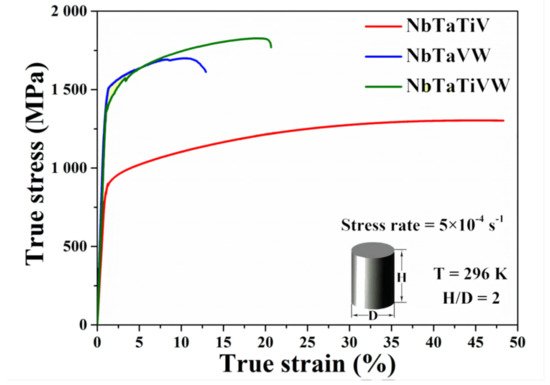

[27]. VNbMoTa RHEAs exhibit excellent room-temperature ductility with a fracture strain > 25% and high-temperature strength (compressive yield strength of 811 MPa at 1000 °C)

[34]. However, the cast product has some drawbacks including many structural defects, such as voids, porosity, chemical segregation and grain coarsening.

Powder metallurgy (PM), a forming technology that allows significant compositional accuracy can completely prevent chemical segregation, can obtain a homogeneous microstructure, can produce nanocrystalline materials and can develop metal matrix composites

[35][36][35,36]. Lightweight RHEAs of CrNbVMo exhibited superior compressive specific yield strengths compared to cast RHEAs at 25 °C and 1000 °C

[37]. TiNbTa

0.5Zr and TiNbTa

0.5ZrAl

0.2 RHEAs were successfully prepared without any cracks or fractures by PM, and with Al addition, the compressive peak stress increased from 508 MPa to 603 MPa at 800 °C

[38]. The PM process is not only suitable for preparing RHEAs but is also suitable for preparing small and precise components.

In contrast to the conventional process, additive manufacturing (AM) is based on an incremental layer-by-layer fabrication process

[39]. Because local process control can be realized in the AM process, it has extremely rapid solidification cooling rates, production with unrivaled design freedom, and shorter production cycles

[40][41][40,41]. The AM process can overcome the inherent complexity and achieve the high levels of control required to produce homogeneous bulk alloys. Due to the immanent advantages of AM, it has attracted much attention in the last decade. At present, the process for preparing HEAs mainly includes direct laser deposition (DLD), selective laser melting (SLM) and selective electron beam melting (SEBM)

[42][43][44][45][42,43,44,45]. The phases, crystal features, mechanical properties, functionalities and potential applications of these products have been discussed. Because the high density, low ductility at room temperature and poor resistance to oxidation are the main drawbacks of RHEAs, it is a challenge to prepare powder for the AM process.

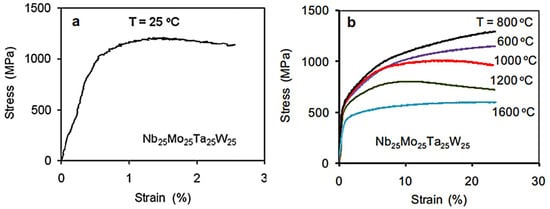

2. Mechanical Properties of BCC-Structured HEAs at Various Temperatures