The effect of adding alum water treatment residues (WTR) on the methanogenic activity in the digestion of primary domestic wastewater sludge was evaluated through laboratory experiments in sedimentation columns, using total suspended solids (TSS) concentrations from 0.37 to 1.23 g/L. The addition of WTR to primary clarifiers can benefit its effluent water quality in terms of colour, turbidity, chemical oxygen demand (COD), and TSS. However, the presence of WTR can negatively influence the production of methane gas during organic sludge digestion in primary clarifiers, for concentrations of TSS between 14.43 and 25.23 g/L and of VSS between 10.2 and 11.85 g/L. The activity of the Methanothrix sp., curved bacilli, methanococci, and Methanosarcina sp. decreases considerably after 16 days of anaerobic digestion, and methane production seems to only be associated with fluorescent methanogenic bacilli.

- alum sludge

- anaerobic bacteria

- methane production

- specific methanogenic activity

- water treatment residues

- methanogenic bacteria

2. Evaluation of the Sedimentation Performance of Primary Clarifiers

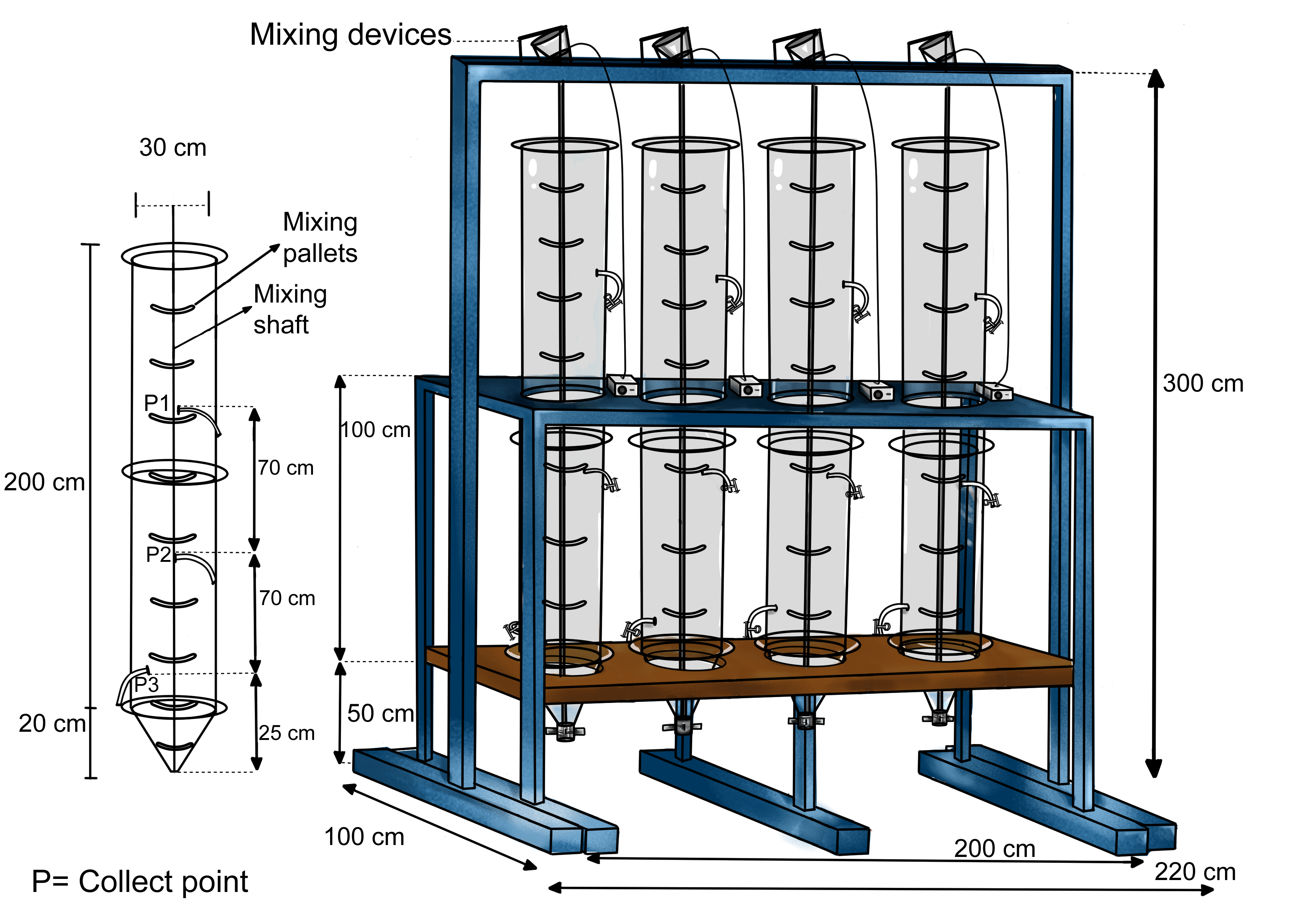

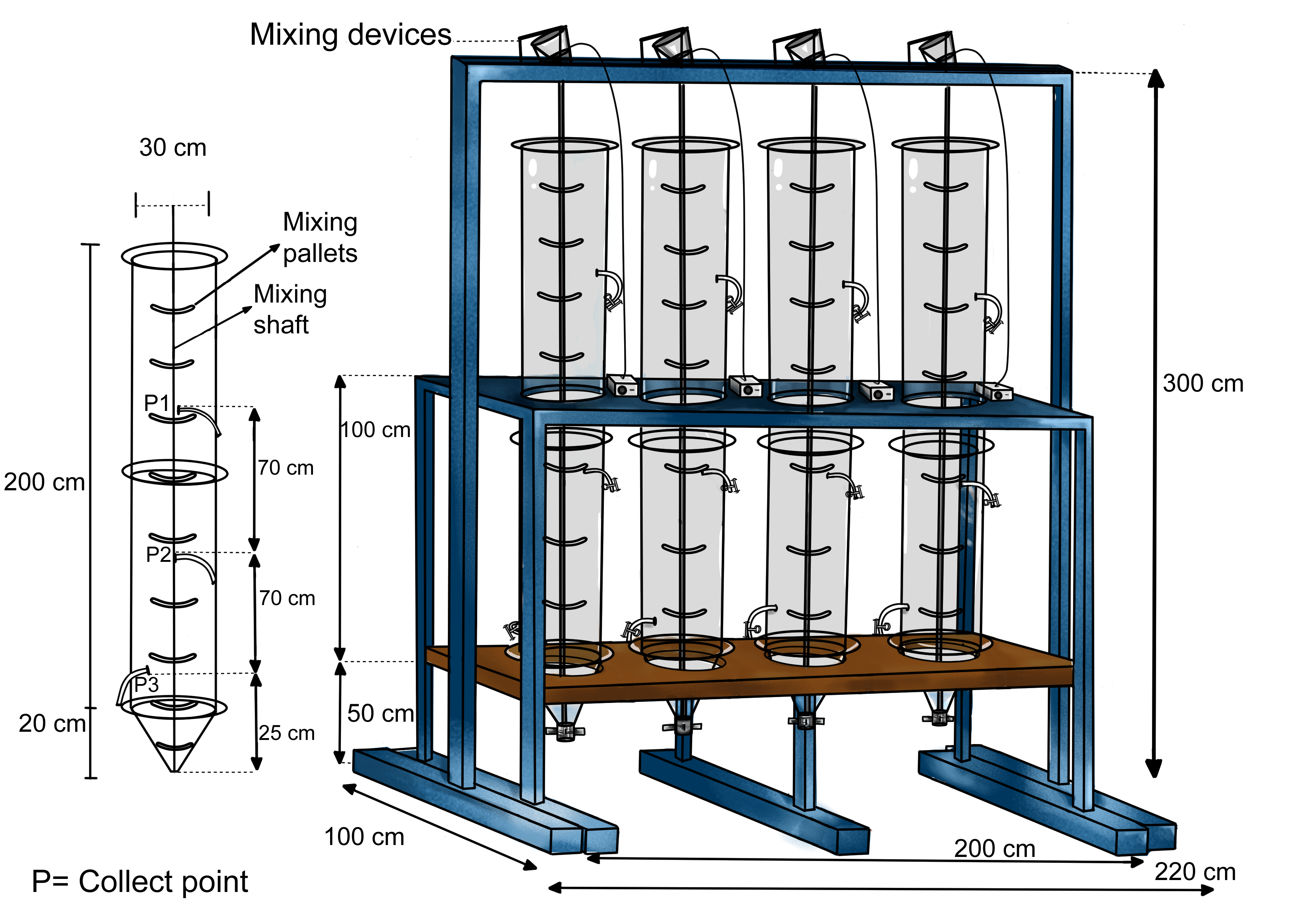

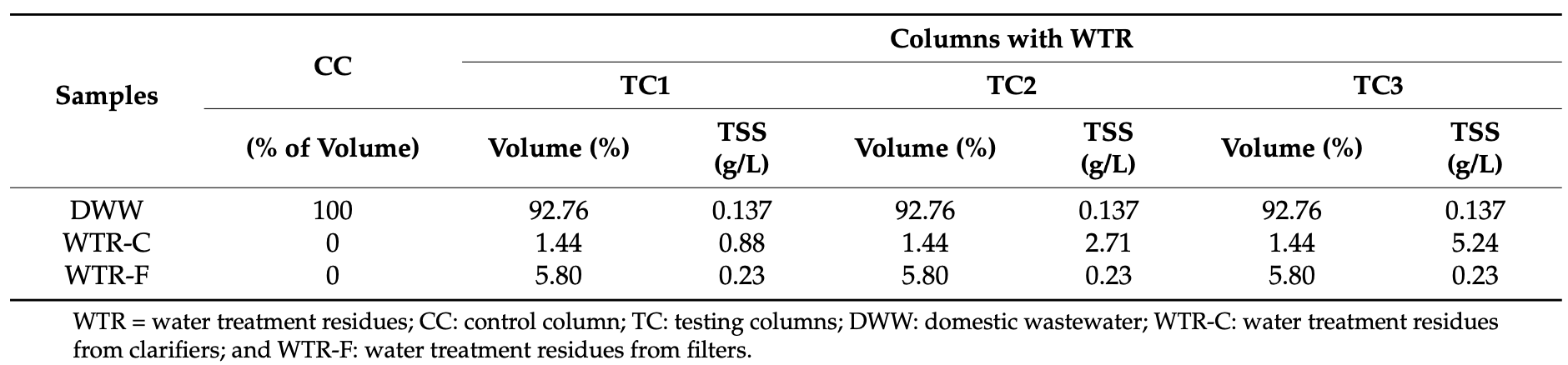

The experiments for evaluating the impact of WTR on the performance of primary clarifiers were set up in four sedimentation test columns (Figure 1). A mixture of WTR from a WTP clarifier (WTR-C, 19.9%) and from filters washing (WTR-F, 80.1%) from the WTP of S. Carlos (SP, Brazil) was used. Aluminium sulphate is the main coagulant for water treatment. Domestic wastewater (DWW) samples were collected at the sewer network of the city of S. Carlos (SP, Brazil). Table 1 shows the volumes used in the experiments.

Figure 1. Test columns: (a) picture and (b) schematic representation.

Table 1. Volumes of WTR and DWW used in the sedimentation experiments.

- Crittenden, J.; Trussell, R.; Hand, D.; Howe, K.; Tchobanoglous, G. Water Treatment: Principles and Design, 3rd ed.; John Wiley and Sons: Hoboke, NJ, USA, 2012; p. 1920.

- Reali, M. The main quantitative and qualitative characteristics of water treatment sludge. In General Notes on Water Treatment and Residuals Disposal from Water Treatment Plants; Reali, M.P., Ed.; ABES: Rio de Janeiro, Brazil, 1999; Chapter 2; pp. 21–39. (In Portuguese)

- Ren, B.; Zhao, Y.; Ji, B.; Wei, T.; Shen, C. Granulation of Drinking Water Treatment Residues: Recent Advances and Prospects. Water 2020, 12, 1400.

- Scalize, P. Disposal of Waste Generated in Water Treatment Plants in Sewage Treatment Plants. Ph.D. Thesis, University of Sao Paulo, São Paulo, Brazil, 2003; 146p. (In Portuguese).

- Kizinievicˇ, O.; Žurauskiene ̇, R.; Kizinievicˇ, V.; Žurauskas, R. Utilisation of sludge waste from water treatment for ceramicproducts. Constr. Build. Mater. 2013, 41, 464–473.

- Scalize, P.; Araujo, F.; Albuquerque, A.; Lima, F. New cement floor produced with water treatment residues. In Proceedings of the Annual Conference & Exposition 2015 (AWWA), Anaheim, CA, USA, 7–10 June 2015.

- Zhao, W.; Xie, H.; Li, J.; Zhang, L.; Zhao, Y. Application of Alum Sludge in Wastewater Treatment Processes: “Science” of Reuse and Reclamation Pathways. Process 2021, 9, 612.

- Park, S.; Kurosawa, K.; Yahata, H. Evaluation of water treatment residue as a soil substitute material compared to decomposed granite soil on the growth of greening trees. Bull. Inst. Trop. Agric. 2009, 32, 93–100.

- Oh, T.-K.; Nakaji, K.; Park, S.-G. Effects of the Application of Water Treatment Sludge on Growth of Lettuce (Lactuca sativa L.) and Changes in Soil Properties. J. Fac. Agric. Kyushu Univ. 2010, 55, 15–20.

- Albuquerque, A.; Scalize, P.; Neto, A. Water treatment sludge as potential soil amendment for native plants of the Brazilian Cerrado. Environ. Eng. Manag. J. 2018, 17, 1169–1178.

- Liu, R.; Zhao, Y.; Sibille, C.; Ren, B. Evaluation of natural organic matter release from alum sludge reuse in wastewater treatment and its role in P adsorption. Chem. Eng. J. 2016, 302, 120–127.

- Muisa, N.; Nhapi, I.; Ruziwa, W.; Manyuchi, M.M. Utilization of alum sludge as adsorbent for phosphorus removal in municipal wastewater: A review. J. Water Process. Eng. 2020, 35, 101187.

- Shen, C.; Zhao, Y.; Li, W.; Yang, Y.; Liu, R.; Morgen, D. Global profile of heavy metals and semimetals adsorption using drinking water treatment residual. Chem. Eng. J. 2019, 372, 1019–1027.

- USEPA. Drinking Water Treatment Plant Residuals Management; Technical Report, EPA 820-R-11-003; United States Environmental Protection Agency (USEPA): Washington, DC, USA, 2011; 377p.

- Zhou, Z.; Yang, Y.; Li, X.; Gao, W.; Liang, H.; Li, G. Coagulation efficiency and flocs characteristics of recycling sludge during treatment of low temperature and micro-polluted water. J. Environ. Sci. 2012, 24, 1014–1020.

- Scalize, P.S.; Souza, L.M.D.; Albuquerque, A. Reuse of alum sludge for reducing flocculant addition in water treatment plants. Environ. Prot. Eng. 2019, 45, 57–70.

- Carvalho, E. Disposal of Waste Generated at Water Treatment Plants in Sewage Treatment Plants with Primary Settling. Ph.D. Thesis, University of Sao Paulo, Sao Paulo, Brazil, 2000; 224p. (In Portuguese)

- Guan, X.-H.; Chen, G.; Shang, C. Re-use of water treatment works sludge to enhance particulate pollutant removal from sewage. Water Res. 2005, 39, 3433–3440.

- Soares, L.; Scalize, P.; Albuquerque, A. Water treatment sludge for post-treatment of effluents from stabilization pond. In Proceedings of the 10th IWA Specialist Ponds Conference, Cartagena, Colombia, 19–22 August 2013; 8p.

- Xu, D.; Lee, L.Y.; Lim, F.Y.; Lyu, Z.; Zhu, H.; Ong, S.L.; Hu, J. Water treatment residual: A critical review of its applications on pollutant removal from stormwater runoff and future perspectives. J. Environ. Manag. 2020, 259, 109649.

- Shanmugam, S. Granulation techniques and technologies: Recent progresses. BioImpacts 2015, 5, 55–63.

- Hussain, A.; Dubey, S.K. Specific methanogenic activity test for anaerobic degradation of influents. Appl. Water Sci. 2015, 7, 535–542.

- Ayres, R.; Mara, D. Analysis of Wastewater for Use in Agriculture: A Laboratory Manual of Parasitological and Bacteriological Techniques; World Health Organization: Geneva, Switzerland, 1996; 35p.

- Aquino, S.F.; Chernicharo, C.A.L.; Foresti, E.; Santos, M.D.L.F.D.; Monteggia, L.O. Metodologias para determinação da atividade metanogênica específica (AME) em lodos anaeróbios. Eng. Sanit. Ambient. 2007, 12, 192–201.

- APHA-AWWA-WEF. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association/American Waterworks Association/Water Environmental Federation: Washington, DC, USA, 2005.

- Da Silva, J.D.; Schneiders, D.; Till, A.; Lapa, K.R.; Pinheiro, A. Specific methanogenic activity (SMA) of industrial sludge from the aerobic and anaerobic biological treatment. Ambient. Agua Interdiscip. J. Appl. Sci. 2013, 8, 135–145.

- Ali, S.S.; Sun, J. Effective thermal pretreatment of water hyacinth (Eichhornia crassipes) for the enhancement of biomethanation: VIT® gene probe technology for microbial community analysis with special reference to methanogenic Archaea. J. Environ. Chem. Eng. 2019, 7, 102853.

3. Batch Experiments for Evaluating the Methanogenic Activity in Primary Sludge

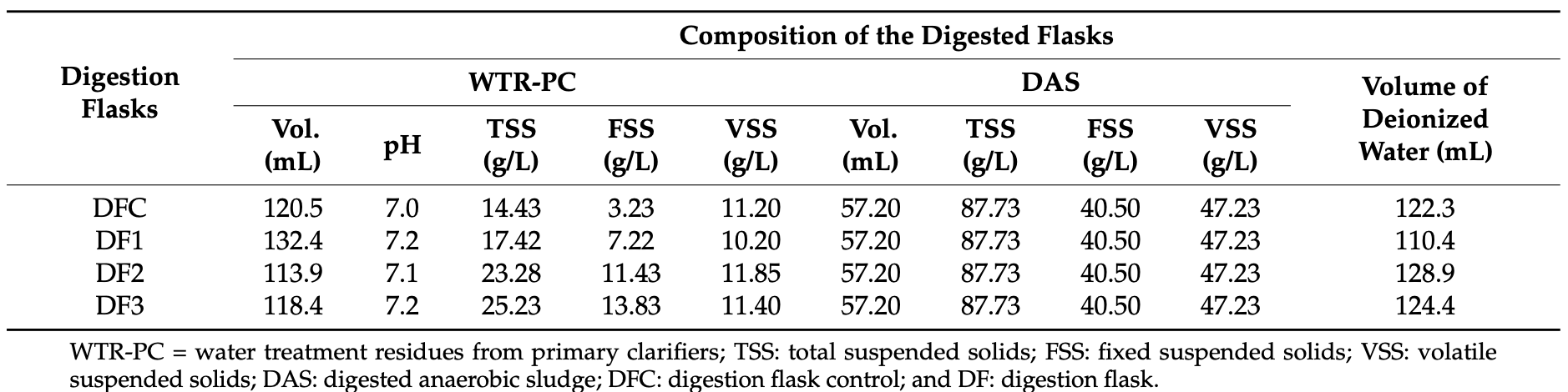

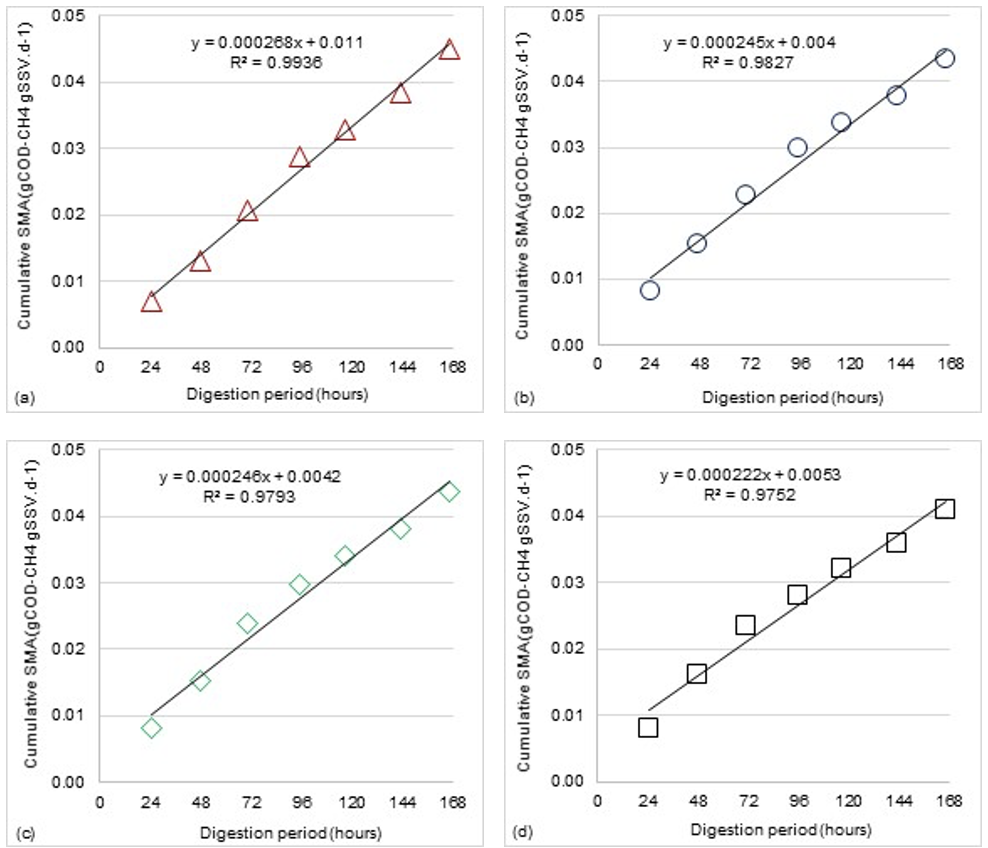

After the sedimentation experiments were finished, a sludge similar to that produced in primary clarifiers was obtained, which was designated by water treatment residues from primary clarifiers (WTR-PC), at the bottom of each column. The WTR-PC of each TC was then mixed with a digested anaerobic sludge (DAS), an inoculum with a SSV concentration of 9 g/L, collected from the anaerobic WWTP digester from the city of Piracicaba (SP, Brazil). The four mixtures were placed in four digestion flasks (DF) of 620 mL each, defined as DF1, DF2, DF3, and DFC for the WTR-PC, coming from the columns TC1, TC2, TC2 and CC, respectively. These experiments were used for evaluating the impact of the WTR-PC on the production of methane gas (methanogenic activity assay, with SMA calculation). The methodology proposed by Aquino [24] was followed, which included the determination of methane gas production, with duplicate tests at a thermostat- controlled temperature of 30 ◦C. The WTR-PC and DAS were characterized in terms of pH, COD, TS, TSS, FSS, and VSS, using the Standard Methods [25]. The concentration of methane gas produced was measured daily though chromatography, using an equipment Alpha MOS PR 2100 USA) equipped with FID detector and capillary column. During these experiments, samples were collected on the 8th and 16th days after incubation, using a needle and syringe, for optical microscopy analysis, at 10× and 40× through an Olympus BX 60 microscope (Japan). The SMA calculation was performed for each methane gas concentration. This was through the angular coefficient of the linear equation, obtained from the maximum slope curve, after plotting the volumes of methane, in terms of COD consumed, divided by the concentration of VSS of the inoculum (i.e., in gCOD-CH4 per gVSS.d), as mentioned in [22][24][26].4. Effect of WTR on the Sedimentation Characteristics of Primary Sludge and on the Effluent Water Quality of Primary Clarifiers

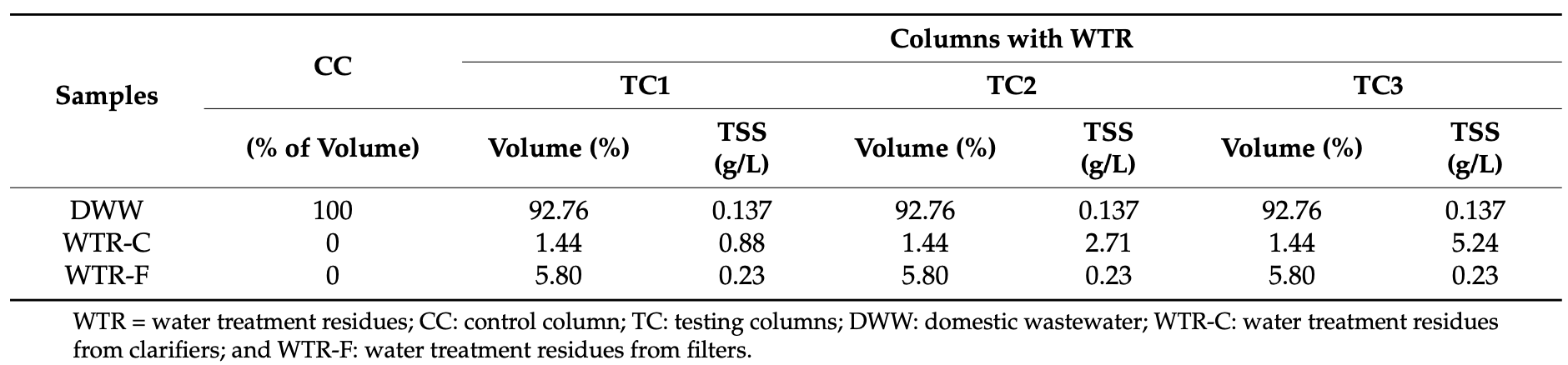

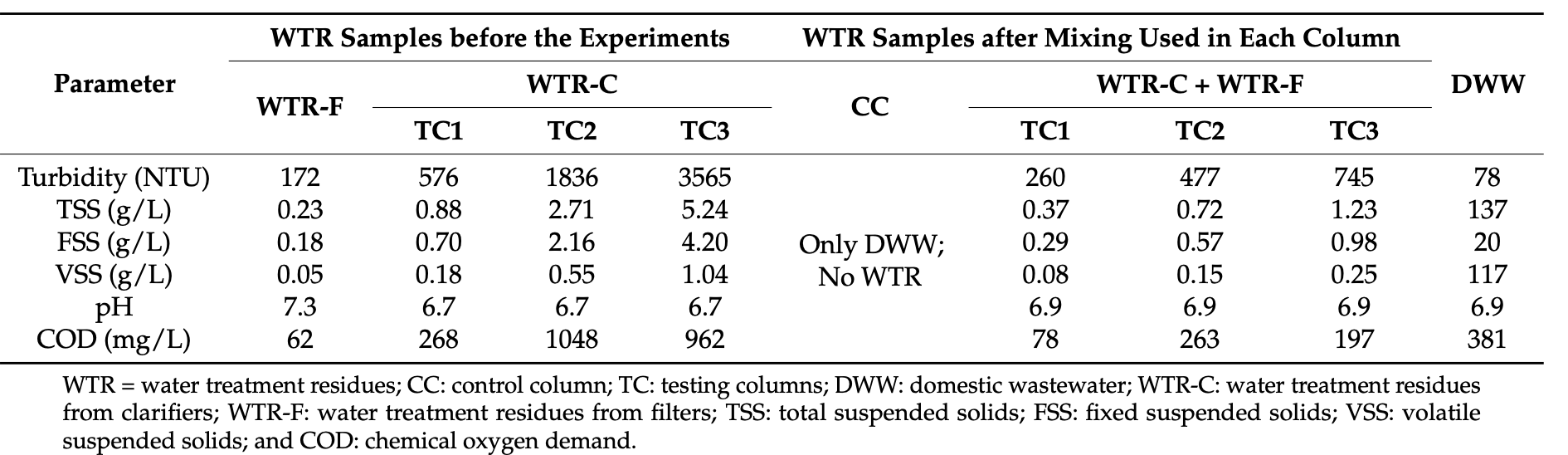

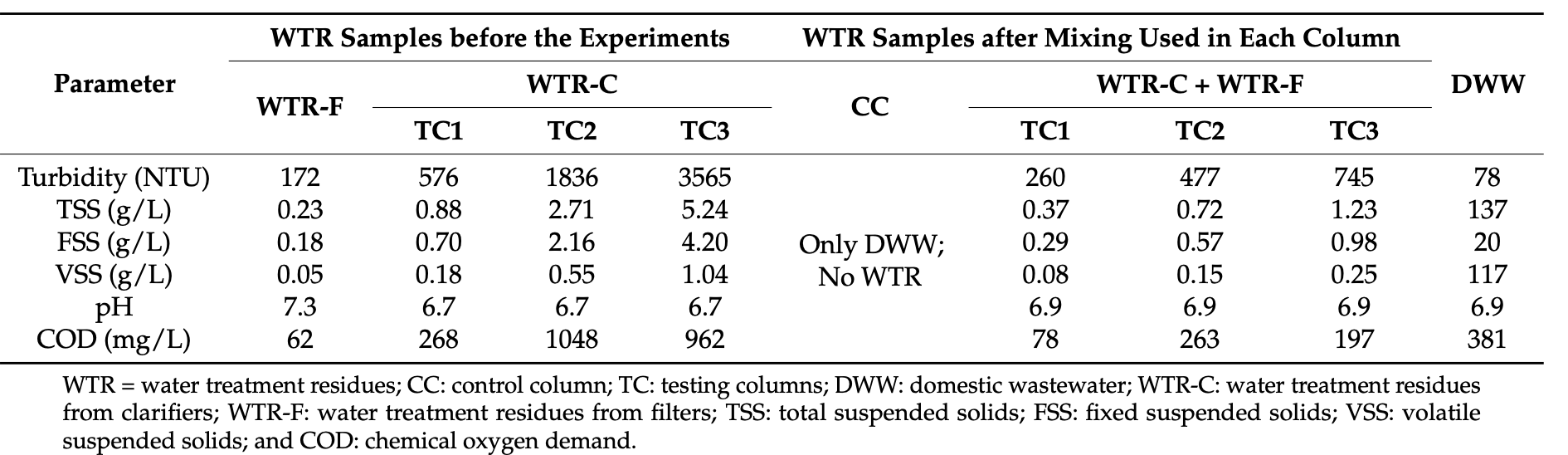

The characteristics of the WTR and the DWW samples used in the TC are shown in Table 2. For the WTR, between 78.3% and 80.2% of TSS is composed of fixed solids, i.e., most of the solid material is formed by inorganic substances (e.g., silt, sand, clay, and metal hydroxides). The fraction of VSS varied between 19.8% and 21.7%, which is contrary to that observed in the DWW samples, where 85.4% of the TSS is of the volatile type, due to the presence of organic matter. After mixing the WTR with the DWW, the TSS concentrations at the beginning of the experiments were 0.37, 0.72, and 1.23 g/L for TC1, TC2, and TC3, respectively. The results of Table 2 also show that the biomass (expressed in VSS), solids contents (as TSS), and the organic matter (expressed in COD) were diluted after joining the WTR-C, WTR-F, and DWW for the columns’ testing. The reduction of TSS was 58%, 73.4%, and 76.5% when both residues were mixed in TC1, TC2, and TC3, respectively, or COD was 70.9%, 74.9%, and 79.5%, and turbidity was 54.8%, 74% and 79,1%.

After the sedimentation period of 2 h, for the columns with WTR, an increase of the removal efficiency (RE) of solids in the liquid effluent, for any point P1, P2, and P3, as the TSS concentration was increased in the WTR-C, was seen. The final liquid effluent TSS at P3 was 104, 106, 90, and 120 mg/L for TC1, TC2, TC3, and CC, respectively. Therefore, the increase in WTR at primary clarifiers increases the sedimentation of the organic sludge and improves the effluent water quality in terms of TSS.

The RE of colour, TSS, and COD for the CC was below 20%, and the turbidity actually increased. The colour removal in the TC with WTR was 16.9%, 19.5%, and 33.3%, for TC1, TC2, and TC3, respectively, whilst for turbidity the RE was 15.9%, 17.2%, and 19%. For TSS, the RE was 22.6%, 28.5%, and 31.4%, and for COD, the RE was 17.8%, 21%, and 23.4%. The solid removal in the three columns was mainly in the form of VSS. There was a reduction of the total coliforms (TC) and E. coli content after contact with WTR, but the analysis was inconclusive for worms and eggs of parasitic helminths (PH).

After mixing the WTR with the DWW, the TSS concentrations at the beginning of the experiments were 0.37, 0.72, and 1.23 g/L for TC1, TC2, and TC3, respectively. The results of Table 2 also show that the biomass (expressed in VSS), solids contents (as TSS), and the organic matter (expressed in COD) were diluted after joining the WTR-C, WTR-F, and DWW for the columns’ testing. The reduction of TSS was 58%, 73.4%, and 76.5% when both residues were mixed in TC1, TC2, and TC3, respectively, or COD was 70.9%, 74.9%, and 79.5%, and turbidity was 54.8%, 74% and 79,1%.

After the sedimentation period of 2 h, for the columns with WTR, an increase of the removal efficiency (RE) of solids in the liquid effluent, for any point P1, P2, and P3, as the TSS concentration was increased in the WTR-C, was seen. The final liquid effluent TSS at P3 was 104, 106, 90, and 120 mg/L for TC1, TC2, TC3, and CC, respectively. Therefore, the increase in WTR at primary clarifiers increases the sedimentation of the organic sludge and improves the effluent water quality in terms of TSS.

The RE of colour, TSS, and COD for the CC was below 20%, and the turbidity actually increased. The colour removal in the TC with WTR was 16.9%, 19.5%, and 33.3%, for TC1, TC2, and TC3, respectively, whilst for turbidity the RE was 15.9%, 17.2%, and 19%. For TSS, the RE was 22.6%, 28.5%, and 31.4%, and for COD, the RE was 17.8%, 21%, and 23.4%. The solid removal in the three columns was mainly in the form of VSS. There was a reduction of the total coliforms (TC) and E. coli content after contact with WTR, but the analysis was inconclusive for worms and eggs of parasitic helminths (PH).

5. Effect of WTR on the Methane Production from Primary Sludge

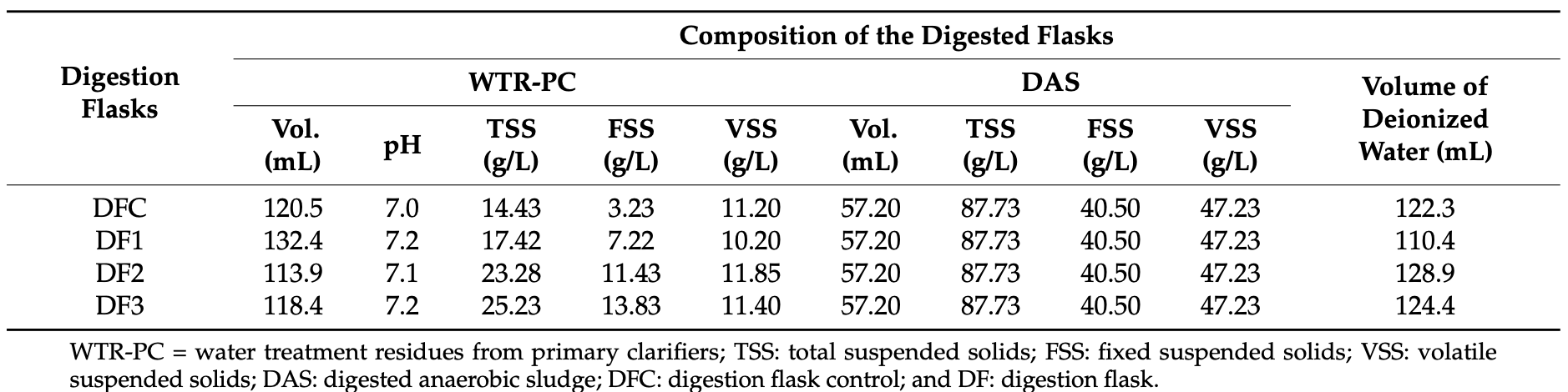

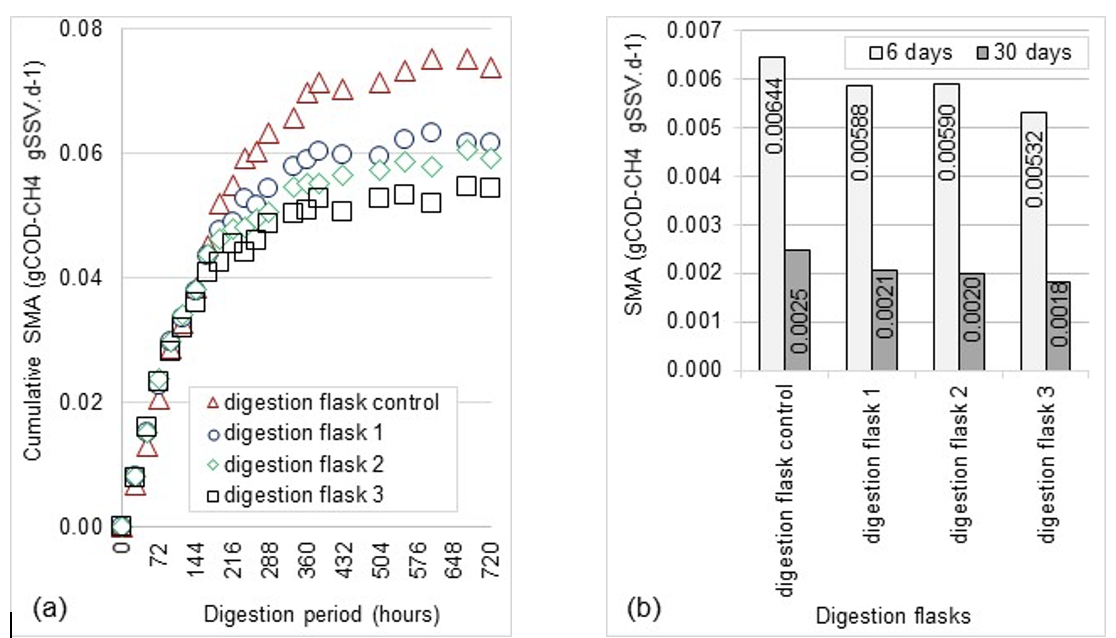

The characterization of the WTR-PC and the DAS for the SMA experiments is shown in Table 3. The fraction between biomass present in both materials (fraction VSSWTR-PC/VSSDAS) changed between 0.21 and 0.25 g/g. The cumulative SMA, throughout the 60 days of experiments, is presented in Figure 2a. It is noted that the highest amount of methane was produced in the DFC, which did not receive WTR (cumulative value of 0.077 gCOD-CH /gVSS.d). The DF with WTR showed a decrease in methane production as the TSS concentration increased, reaching a difference of 16.6%, 19.6%, and 26.4% between DF1, DF2, and DF3 and the control flask DFC, respectively. The cumulative values for the DF with WTR were 0.06 gCOD-CH /gVSS.d (DF1), 0.057 gCOD-CH /gVSS.d (DF2), and 0.052 gCOD-CH /gVSS.d (DF3). Therefore, negative interference can occur in methane production in sedimentation tanks, when WTR with TSS between 14.43 and 25.23 g/L, and VSS between 10.2 and 11.85 g/L are used.

The cumulative SMA, throughout the 60 days of experiments, is presented in Figure 2a. It is noted that the highest amount of methane was produced in the DFC, which did not receive WTR (cumulative value of 0.077 gCOD-CH /gVSS.d). The DF with WTR showed a decrease in methane production as the TSS concentration increased, reaching a difference of 16.6%, 19.6%, and 26.4% between DF1, DF2, and DF3 and the control flask DFC, respectively. The cumulative values for the DF with WTR were 0.06 gCOD-CH /gVSS.d (DF1), 0.057 gCOD-CH /gVSS.d (DF2), and 0.052 gCOD-CH /gVSS.d (DF3). Therefore, negative interference can occur in methane production in sedimentation tanks, when WTR with TSS between 14.43 and 25.23 g/L, and VSS between 10.2 and 11.85 g/L are used.

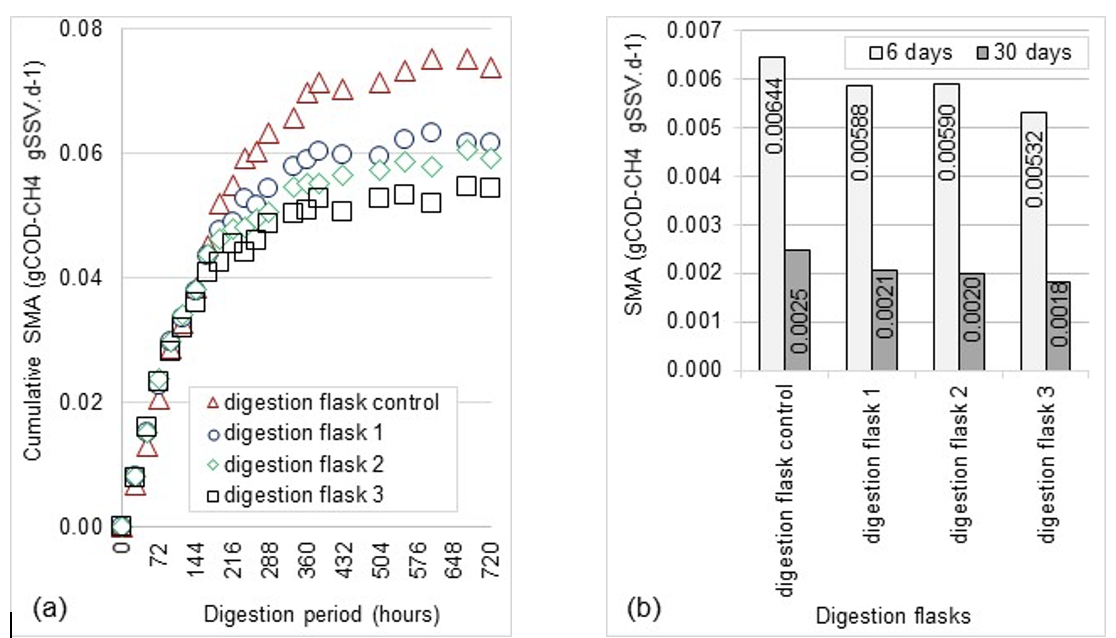

Figure 3. Determination of the angular coefficient of the curve section with the highest slope of the methane production: (a) DFC; (b) DF1; (c) DF2; and (d) DF3.

The values of SMA of Figure 2b show that there was negative interference of WTR in the production of methane gas along the two scenarios (6 and 30 days of digestion). However, production of gas still occurred, suggesting that some methanogenic microorganisms were physiologically active even in the presence of aluminium oxides.

For volumetric relationships between total sludge and anaerobic sludge up to 86%, there was no significant decrease in methane production. However, for higher volumetric ratios, a significant inhibitory effect was regimented. The temperature and the ratio between organic sludge and alum sludge seems to interfere in the production of methane and thus should be controlled in order to reduce the damage in anaerobic bacteria.

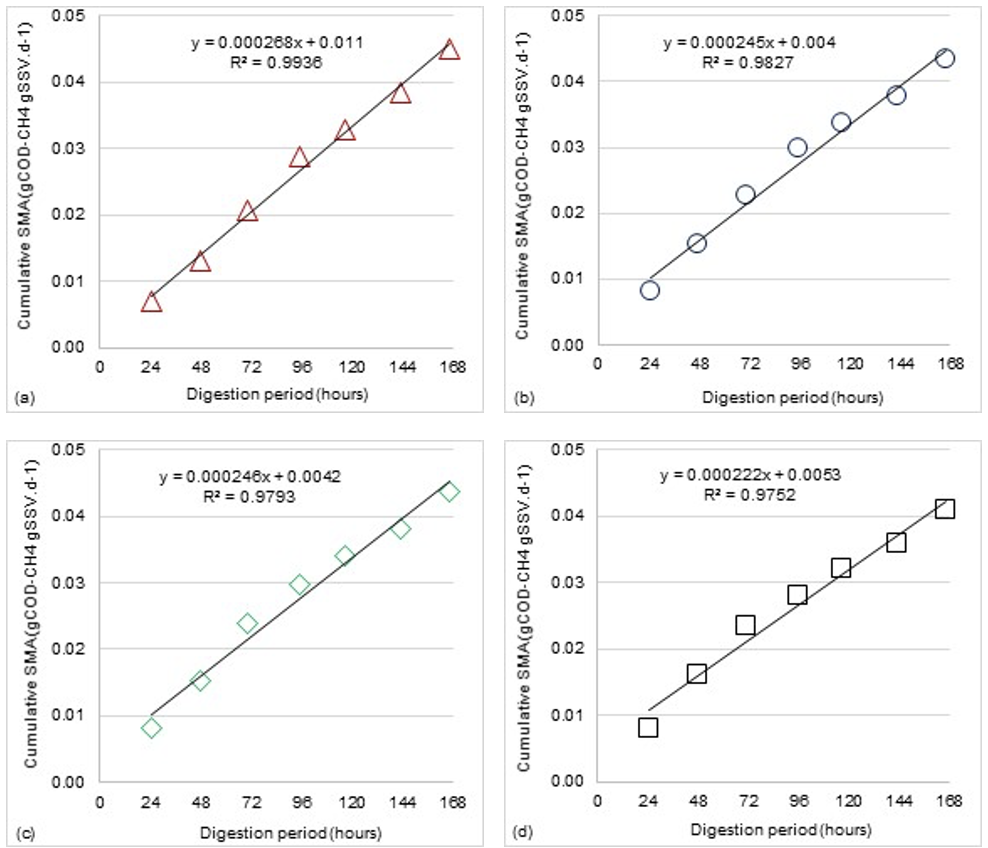

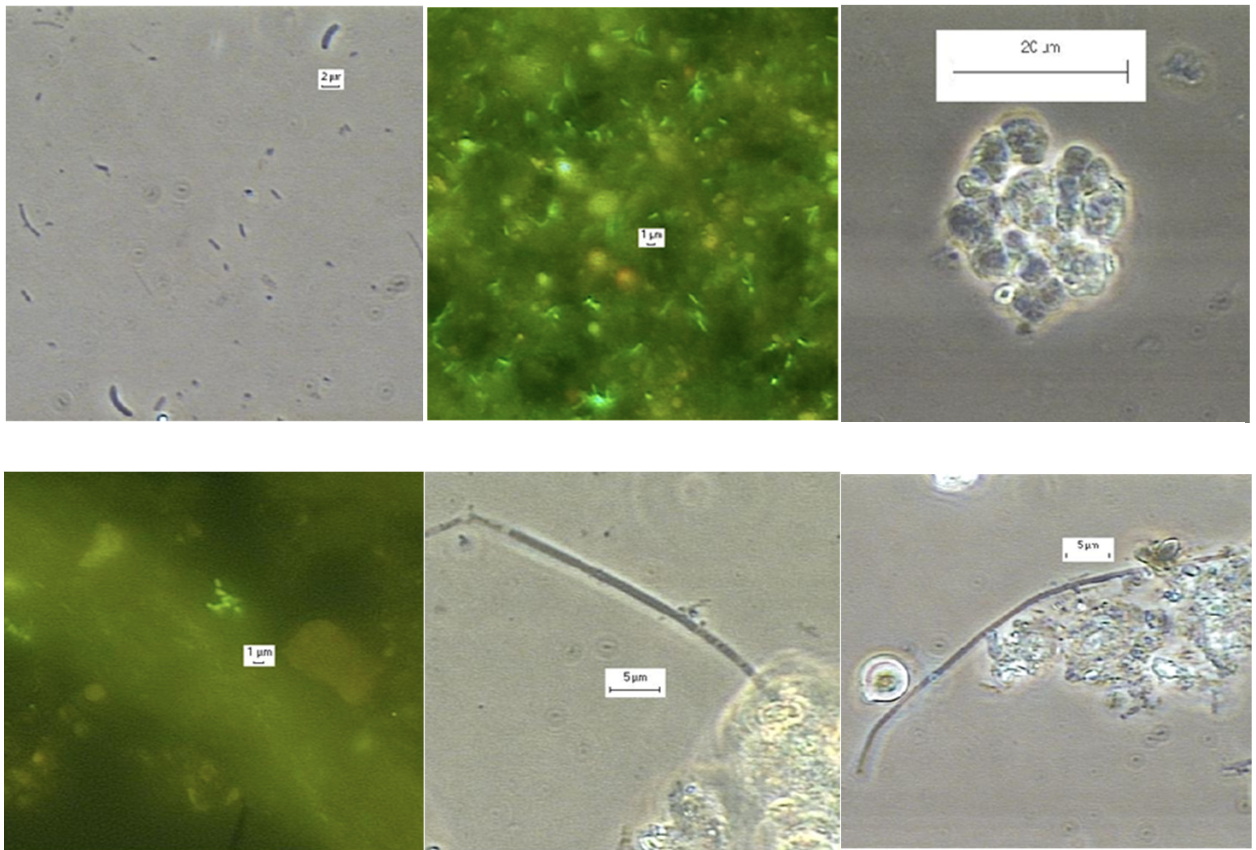

The microscopic analysis on the DF showed that, after 8 days of incubation, a predominance of methanogenic rod-shaped bacteria, which are fluorescent and produce methane via the hydrogenotrophic pathway (Figure 4).

Figure 3. Determination of the angular coefficient of the curve section with the highest slope of the methane production: (a) DFC; (b) DF1; (c) DF2; and (d) DF3.

The values of SMA of Figure 2b show that there was negative interference of WTR in the production of methane gas along the two scenarios (6 and 30 days of digestion). However, production of gas still occurred, suggesting that some methanogenic microorganisms were physiologically active even in the presence of aluminium oxides.

For volumetric relationships between total sludge and anaerobic sludge up to 86%, there was no significant decrease in methane production. However, for higher volumetric ratios, a significant inhibitory effect was regimented. The temperature and the ratio between organic sludge and alum sludge seems to interfere in the production of methane and thus should be controlled in order to reduce the damage in anaerobic bacteria.

The microscopic analysis on the DF showed that, after 8 days of incubation, a predominance of methanogenic rod-shaped bacteria, which are fluorescent and produce methane via the hydrogenotrophic pathway (Figure 4).

Figure 4. (a) Bacteria in the form of curved bacilli similar to sulphate reducing agents in DFC; (b) fluorescent bacteria in the form of rods; (c) methanosarcina sp. present in DF1; (d) few fluorescent methanococci; and (e,f) methanothrix sp present in DF2 and DF3.

Bacteria of the genus Methanothrix sp. were lower in relation to rod-shaped bacteria. Metanogenic bacteria of the genus Methanosarcina sp., metanococci, which are fluorescent, and bacteria in the form of curved bacilli, similar to the sulphate reducers, were also found in small quantities in al flasks. In the DF1, DF2, and DF3, a decrease in the bacteria of the genus Methanothrix sp. was observed, whilst the bacteria in the form of rods had a slight increase, with higher values for the DF1. In these three reactor flasks were found, in small quantity, methanogenic bacteria in the form of coconuts and Methanosarcina sp.

Methanosarcina species, such as Methanosarcina lacustris and Methanosarcina mazeii, are metabolically versa- tile with respect to substrate utilization for methane production, using different pathways and a variety of substrates for methanogenesis, such as H2 together with CO2, acetate, methanol, and methylamines [27].

After 16 days of incubation in the DFC, there was a predominance of fluorescent methanogenic bacilli and non-methanogenic bacilli; only a few Methanothrix sp. bacteria were found, and no methanococci and Methanosarcina sp. was detected. In DF1, DF2, and DF3, more fluorescent bacilli and only a few Methanothrix sp. was observed. The fluorescent bacilli were higher at the DF1. In the three flasks, some curved bacilli, similar to sulphate reducing agents, were found along with fungal hyphae and few nonfluorescent bacilli.

Microbiological analyses only confirm the existence of species and genus of bacteria, with participation in the reactions of methanogenesis. Although there was a decrease in the production of methane gas after adding aluminium-based WTR, probably due to the destruction and inhibition of part of the anaerobic consortium, anaerobic bacteria with methane gas capacity still remained in the DF after 16 days of anaerobic digestion. The genus Methanothrix sp. and the curved bacilli decreased considerably with the introduction of WTR, whereas the methanococci and Methanosarcina sp. no longer appear after 16 days of incubation.

Fluorescent methanogenic bacilli and non-methanogenic bacilli were detected in both samples and did not appear to have been affected by the introduction of WTR after 16 days of reaction. Overall, it seems the time of biodigestion influenced the diversity of bacteria and Archaea communities. The biodiversity of methanogenic microorganisms was significantly decreased over time, which indicate that Methanothrix sp. and curved bacilli seem susceptible to the addition of WTR in the long term. Therefore, fluorescent methanogenic bacilli seem to be the main bacteria responsible by keeping methane production, after adding WTR for 16 days of anaerobic digestion.

The results of this research seem to indicate that the use of WTR in wastewater treatment plants can be useful, either for improving the conditions for settling in primary settlers, or for improving the quality of the effluent for secondary biological treatment, or also for improving the production of methane.

Figure 4. (a) Bacteria in the form of curved bacilli similar to sulphate reducing agents in DFC; (b) fluorescent bacteria in the form of rods; (c) methanosarcina sp. present in DF1; (d) few fluorescent methanococci; and (e,f) methanothrix sp present in DF2 and DF3.

Bacteria of the genus Methanothrix sp. were lower in relation to rod-shaped bacteria. Metanogenic bacteria of the genus Methanosarcina sp., metanococci, which are fluorescent, and bacteria in the form of curved bacilli, similar to the sulphate reducers, were also found in small quantities in al flasks. In the DF1, DF2, and DF3, a decrease in the bacteria of the genus Methanothrix sp. was observed, whilst the bacteria in the form of rods had a slight increase, with higher values for the DF1. In these three reactor flasks were found, in small quantity, methanogenic bacteria in the form of coconuts and Methanosarcina sp.

Methanosarcina species, such as Methanosarcina lacustris and Methanosarcina mazeii, are metabolically versa- tile with respect to substrate utilization for methane production, using different pathways and a variety of substrates for methanogenesis, such as H2 together with CO2, acetate, methanol, and methylamines [27].

After 16 days of incubation in the DFC, there was a predominance of fluorescent methanogenic bacilli and non-methanogenic bacilli; only a few Methanothrix sp. bacteria were found, and no methanococci and Methanosarcina sp. was detected. In DF1, DF2, and DF3, more fluorescent bacilli and only a few Methanothrix sp. was observed. The fluorescent bacilli were higher at the DF1. In the three flasks, some curved bacilli, similar to sulphate reducing agents, were found along with fungal hyphae and few nonfluorescent bacilli.

Microbiological analyses only confirm the existence of species and genus of bacteria, with participation in the reactions of methanogenesis. Although there was a decrease in the production of methane gas after adding aluminium-based WTR, probably due to the destruction and inhibition of part of the anaerobic consortium, anaerobic bacteria with methane gas capacity still remained in the DF after 16 days of anaerobic digestion. The genus Methanothrix sp. and the curved bacilli decreased considerably with the introduction of WTR, whereas the methanococci and Methanosarcina sp. no longer appear after 16 days of incubation.

Fluorescent methanogenic bacilli and non-methanogenic bacilli were detected in both samples and did not appear to have been affected by the introduction of WTR after 16 days of reaction. Overall, it seems the time of biodigestion influenced the diversity of bacteria and Archaea communities. The biodiversity of methanogenic microorganisms was significantly decreased over time, which indicate that Methanothrix sp. and curved bacilli seem susceptible to the addition of WTR in the long term. Therefore, fluorescent methanogenic bacilli seem to be the main bacteria responsible by keeping methane production, after adding WTR for 16 days of anaerobic digestion.

The results of this research seem to indicate that the use of WTR in wastewater treatment plants can be useful, either for improving the conditions for settling in primary settlers, or for improving the quality of the effluent for secondary biological treatment, or also for improving the production of methane.

6. Conclusions

Adding alum WTR at primary clarifiers, for TSS concentrations between 0.37 and 1.23 g L−1, increases the sedimentation of the organic sludge and improves the effluent water quality in terms of colour, turbidity, COD, and TSS. The removal of pathogenic mi- croorganisms was not significant. It can cause negative interference in methane production when inorganic sludge with TSS between 14.43 and 25.23 g L−1 and VSS between 10.2 and 11.85 g L−1 are used for organic sludge digestion. The ratio between organic sludge and alum sludge seems to interfere in the production of methane and should be controlled, in order to inhibit anaerobic bacteria. The activity of Methanothrix sp. and the curved bacilli is considerably affected by the introduction of WTR, whilst methanococci and Methanosarcina sp. disappear after 16 days of incubation. Fluorescent methanogenic bacilli seem to be the main bacteria responsible for methanogenesis, after 16 days of anaerobic digestion.References

- Crittenden, J.; Trussell, R.; Hand, D.; Howe, K.; Tchobanoglous, G. Water Treatment: Principles and Design, 3rd ed.; John Wiley and Sons: Hoboke, NJ, USA, 2012; p. 1920.

- Reali, M. The main quantitative and qualitative characteristics of water treatment sludge. In General Notes on Water Treatment and Residuals Disposal from Water Treatment Plants; Reali, M.P., Ed.; ABES: Rio de Janeiro, Brazil, 1999; Chapter 2; pp. 21–39. (In Portuguese)

- Ren, B.; Zhao, Y.; Ji, B.; Wei, T.; Shen, C. Granulation of Drinking Water Treatment Residues: Recent Advances and Prospects. Water 2020, 12, 1400.

- Scalize, P. Disposal of Waste Generated in Water Treatment Plants in Sewage Treatment Plants. Ph.D. Thesis, University of Sao Paulo, São Paulo, Brazil, 2003; 146p. (In Portuguese).

- Kizinievicˇ, O.; Žurauskiene ̇, R.; Kizinievicˇ, V.; Žurauskas, R. Utilisation of sludge waste from water treatment for ceramicproducts. Constr. Build. Mater. 2013, 41, 464–473.

- Scalize, P.; Araujo, F.; Albuquerque, A.; Lima, F. New cement floor produced with water treatment residues. In Proceedings of the Annual Conference & Exposition 2015 (AWWA), Anaheim, CA, USA, 7–10 June 2015.

- Zhao, W.; Xie, H.; Li, J.; Zhang, L.; Zhao, Y. Application of Alum Sludge in Wastewater Treatment Processes: “Science” of Reuse and Reclamation Pathways. Process 2021, 9, 612.

- Park, S.; Kurosawa, K.; Yahata, H. Evaluation of water treatment residue as a soil substitute material compared to decomposed granite soil on the growth of greening trees. Bull. Inst. Trop. Agric. 2009, 32, 93–100.

- Oh, T.-K.; Nakaji, K.; Park, S.-G. Effects of the Application of Water Treatment Sludge on Growth of Lettuce (Lactuca sativa L.) and Changes in Soil Properties. J. Fac. Agric. Kyushu Univ. 2010, 55, 15–20.

- Albuquerque, A.; Scalize, P.; Neto, A. Water treatment sludge as potential soil amendment for native plants of the Brazilian Cerrado. Environ. Eng. Manag. J. 2018, 17, 1169–1178.

- Liu, R.; Zhao, Y.; Sibille, C.; Ren, B. Evaluation of natural organic matter release from alum sludge reuse in wastewater treatment and its role in P adsorption. Chem. Eng. J. 2016, 302, 120–127.

- Muisa, N.; Nhapi, I.; Ruziwa, W.; Manyuchi, M.M. Utilization of alum sludge as adsorbent for phosphorus removal in municipal wastewater: A review. J. Water Process. Eng. 2020, 35, 101187.

- Shen, C.; Zhao, Y.; Li, W.; Yang, Y.; Liu, R.; Morgen, D. Global profile of heavy metals and semimetals adsorption using drinking water treatment residual. Chem. Eng. J. 2019, 372, 1019–1027.

- USEPA. Drinking Water Treatment Plant Residuals Management; Technical Report, EPA 820-R-11-003; United States Environmental Protection Agency (USEPA): Washington, DC, USA, 2011; 377p.

- Zhou, Z.; Yang, Y.; Li, X.; Gao, W.; Liang, H.; Li, G. Coagulation efficiency and flocs characteristics of recycling sludge during treatment of low temperature and micro-polluted water. J. Environ. Sci. 2012, 24, 1014–1020.

- Scalize, P.S.; Souza, L.M.D.; Albuquerque, A. Reuse of alum sludge for reducing flocculant addition in water treatment plants. Environ. Prot. Eng. 2019, 45, 57–70.

- Carvalho, E. Disposal of Waste Generated at Water Treatment Plants in Sewage Treatment Plants with Primary Settling. Ph.D. Thesis, University of Sao Paulo, Sao Paulo, Brazil, 2000; 224p. (In Portuguese)

- Guan, X.-H.; Chen, G.; Shang, C. Re-use of water treatment works sludge to enhance particulate pollutant removal from sewage. Water Res. 2005, 39, 3433–3440.

- Soares, L.; Scalize, P.; Albuquerque, A. Water treatment sludge for post-treatment of effluents from stabilization pond. In Proceedings of the 10th IWA Specialist Ponds Conference, Cartagena, Colombia, 19–22 August 2013; 8p.

- Xu, D.; Lee, L.Y.; Lim, F.Y.; Lyu, Z.; Zhu, H.; Ong, S.L.; Hu, J. Water treatment residual: A critical review of its applications on pollutant removal from stormwater runoff and future perspectives. J. Environ. Manag. 2020, 259, 109649.

- Shanmugam, S. Granulation techniques and technologies: Recent progresses. BioImpacts 2015, 5, 55–63.

- Hussain, A.; Dubey, S.K. Specific methanogenic activity test for anaerobic degradation of influents. Appl. Water Sci. 2015, 7, 535–542.

- Ayres, R.; Mara, D. Analysis of Wastewater for Use in Agriculture: A Laboratory Manual of Parasitological and Bacteriological Techniques; World Health Organization: Geneva, Switzerland, 1996; 35p.

- Aquino, S.F.; Chernicharo, C.A.L.; Foresti, E.; Santos, M.D.L.F.D.; Monteggia, L.O. Metodologias para determinação da atividade metanogênica específica (AME) em lodos anaeróbios. Eng. Sanit. Ambient. 2007, 12, 192–201.

- APHA-AWWA-WEF. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association/American Waterworks Association/Water Environmental Federation: Washington, DC, USA, 2005.

- Da Silva, J.D.; Schneiders, D.; Till, A.; Lapa, K.R.; Pinheiro, A. Specific methanogenic activity (SMA) of industrial sludge from the aerobic and anaerobic biological treatment. Ambient. Agua Interdiscip. J. Appl. Sci. 2013, 8, 135–145.

- Ali, S.S.; Sun, J. Effective thermal pretreatment of water hyacinth (Eichhornia crassipes) for the enhancement of biomethanation: VIT® gene probe technology for microbial community analysis with special reference to methanogenic Archaea. J. Environ. Chem. Eng. 2019, 7, 102853.