Definition

Since the beginning of the nuclear industry, graphite has been widely used as a moderator and reflector of neutrons in nuclear power reactors. Some reactors are relatively old and have already been shut down. As a result, a large amount of irradiated graphite has been generated. Although several thousand papers in the International Nuclear Information Service (INIS) database have discussed the management of radioactive waste containing graphite, knowledge of this problem is not common.

- graphite

- irradiated graphite

- graphite processing

- radioactive waste

- waste management

- waste disposal

- spent TRISO fuel

Please note: Below is an entry draft based on your paper, which is wrirren tightly around the entry title. Since it may not be very comprehensive, we kindly invite you to modify it (both title and content can be replaced) according to your extensive expertise. We believe this entry would be beneficial to highlight your work.

Definition

Since the beginning of the nuclear industry, graphite has been widely used as a moderator and reflector of neutrons in nuclear power reactors. Some reactors are relatively old and have already been shut down. As a result, a large amount of irradiated graphite has been generated. Although several thousand papers in the International Nuclear Information Service (INIS) database have discussed the management of radioactive waste containing graphite, knowledge of this problem is not common.

1. Introduction

As of December 31, 2018, 451 nuclear power reactors were in operation and produced 392,779 MWe of electricity. Fifty-five reactors, with a net capacity of 57,441 MWe, were under construction, while 172 reactors were permanently shut down [1]. At the turn of the millennium, scientists from several centers around the world started working on the development of new nuclear energy systems, called Generation IV systems, that will deliver energy at a relatively low cost and will work with a high level of safety. Most of the reactors use moderators and/or reflectors made from graphite.

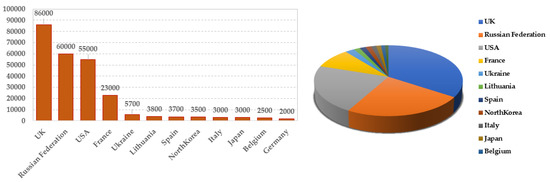

Like any other industry, nuclear power plants (NPP) generate waste; however, compared with other industries, the mass of this waste is relatively small. According to the recent data published by the International Atomic Energy Agency (IAEA), the global volume of solid radioactive waste is about 35 million m3, of which 28.5 million m3 (82%) has been permanently disposed of, and another 6.3 million m3 (18%) is in storage awaiting final disposal. Over 98% of this is classified as waste with a very low or low radioactivity level, and the majority of the remaining waste is at an intermediate level [2]. Much of the waste comes from the dismantling of nuclear installations, which are the main source of the irradiated graphite (called i-graphite) originating from the reactor’s structural material, as well as from other irradiated carbonaceous (i-carbonaceous) waste, non-graphitized carbon bricks, or fuel coatings (pyrocarbon, silicon carbide). It has been estimated that as a result of the decommissioning of one water-cooled graphite-moderated reactor, about 1500–2000 tons of radioactive graphite waste is produced [3]. According to data published in 2010 by the IAEA, the world resources of i-graphite at that time were approximately 250,000 tons (160,000 cubic meters). Handling i-graphite and i-carbon poses a particularly large problem for Great Britain (containing about 86,000 tons of i-carbons), the Russian Federation (60,000 tons), the USA (55,000 tons), and France (over 23,000 tons) (Figure 1) [4,5,6]. The resources of several other countries range from 6000 to 2000 tons each.

Figure 1. World resources of irradiated graphite waste by country (tons).

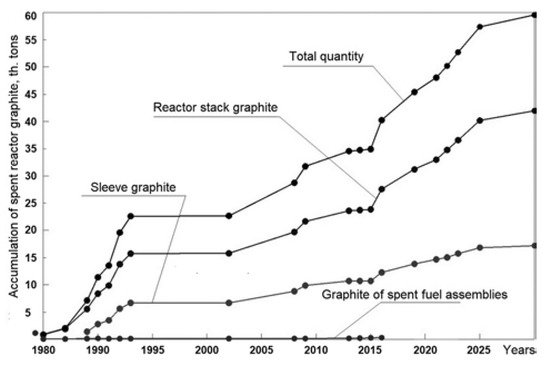

The increasing trend of global graphite reserves can also be seen from the data published by Pavlyuk (Figure 2) [7]: in Russia, from 2010–2020, the total amount of radioactive graphite waste increased by about 15,000 tons, and it is expected to reach roughly 60,000 tons in 2030.

Figure 2. Forecasted dynamics of collecting radioactive graphite waste in Russia. Reproduced from [7] with permission.

An initiative to select the optimum method for the disposal of radioactive waste graphite started in the frame of the IAEA conference Solutions for Graphite Waste: A Contribution to the Accelerated Decommissioning of Graphite-Moderated Nuclear Reactors (Manchester, UK, 2007) and the presented papers along with records of the discussion sessions may be found in IAEA-TECDOC-1647, published in 2010 [9]. In order to follow up on the activities related to i-graphite management, the IAEA has launched two more projects: establishing a repository for data and reports within the IMMONET knowledge network (accessible via the IAEA ‘Nucleus’ portal) [11] and a new project called Irradiated Graphite Processing Approaches (GRAPA) in which experts from the following countries participate: Belgium, France, Germany, India, Italy, the Democratic People’s Republic of Korea, Lithuania, the Netherlands, the Russian Federation, Spain, Switzerland, Ukraine, the United Kingdom, and the United States of America [12]. The common goal of both of these initiatives was to encourage an international debate and collaborative work aimed at optimizing and facilitating the treatment of irradiated graphite. In turn, the European Commission, under the Seventh Framework Programme (2007 to 2011) of the Euratom has established a network of experts which is designed to ensure the best available and most environmentally acceptable technologies have been identified for the characterization, retrieval, treatment, reuse/recycling and disposal of irradiated graphite [13]. In light of the planned development of nuclear energy in Poland, and probably the earlier installation of HTGR reactors, the problems associated with irradiated graphite management are important not only for Poland but also for all countries introducing this type of energy production method.

2. Carbonaceous Components of Nuclear Power Plant Installations

Nuclear graphite (defined as graphite having a purity level < 5 ppm (boron equivalent) and with a density greater than 1.50 g/cm3 [14]) is produced from selected pitch or petroleum coke, which are either natural or industrial products. In traditional nuclear reactors (Generation I, most of them being already excluded from use) and operating commercial power reactors (Generations II and III), graphite is used to produce large-scale reflectors and neutron stream moderators.

Apart from the above, HTGR nuclear fuel (e.g., of the TRISO type) is also fabricated in the form of pyrolytic carbon/porous and carbon/silicon carbide-coated fuel particles with extremely high mechanical strength that are highly resistant to irradiation. Such fuel particles, like the graphite blocks in which they are packed, can survive high temperatures up to ~1600 °C. In pebble bed reactors, more than 8000 TRISO small fuel pellets are packed inside spherical graphite packages with diameters of 60 mm [15]. The core of the HTR-10 HTGR-type reactor is loaded with more than 25,000 fuel spheres, so this type of HTGR pebble bed reactor may produce large amounts of graphite material.

Graphite for use in nuclear reactors should not contain neutron-absorbing elements, particularly boron, which has a large neutron capture cross-section. The boron content of thermally purified graphite (such as AGOT graphite, known to be a good non-conductor but currently commercially unavailable) is usually smaller than 0.4 ppm [16], but in chemically purified nuclear graphite, this may be lower than 0.06 ppm.

Despite the high chemical and mechanical stability of graphite, during NPP operation, the graphite elements of an installation may be oxidized and/or cracked. These processes determine when the items must be decommissioned. In addition, as a result of neutron irradiation, both the chemical composition and physical properties of graphite elements are significantly altered. For example, if irradiated with a very high radiation dose, the size of the graphite elements increases, which increases their fragility. These changes may lead to the destruction of nuclear installation components and, ultimately, to their removal as radioactive waste.

When graphite is irradiated by a flux of neutrons, defects may form in its crystal lattice in which atoms are displaced from their normal positions, accompanied by energy storage (the Wigner effect). It was found that the amount of this energy stored due to irradiation depends on the neutron energy that crosses a unit area (i.e., neutron fluence) and the temperature of the irradiation process. Thus, the thermal conductivity of graphite decreases upon increasing its stored energy. By increasing the temperature of the irradiated graphite, e.g., by external heating or by the heat supplied by irradiation, dislocated atoms may return to vacancies in the graphite lattice, which induces the release of stored energy in the form of heat. In uncontrolled conditions, the accumulated energy may result in the auto-ignition of graphite-containing waste.

Furthermore, radioactively contaminated i-graphite spontaneously emits significant amounts of often radioactive gases and, as a result, reveals significant weight loss. During the reactor’s operating life, it can even exceed 20% and occurs fairly uniformly within the whole graphite portion. Moreover, fast neutron irradiated graphite exposes a significant differentiation in the materials’ properties, such as the Young’s modulus, thermal conductivity, etc. [17]. In the formed methane, carbon dioxide, or hydrogen, a non-radioactive atom is exchanged by its radioactive isotope. The most important radioactive gases that may be released from cemented waste are methane-14C and tritiated hydrogen (HT) [18]. Additionally, even if a large portion of the formed carbon-14C dioxide is immobilized within a landfill, a significant part of this gaseous product may be released into the atmosphere.

Radioactive contamination of i-graphite arises either from the irradiation of impurities within graphite or from contamination by the corrosion products within the operating reactor loop. The former, arising from the activation of atoms within the graphite structure by rapid neutron capture, occurs in naturally occurring 13C and also the impurities introduced into graphite during its production (e.g., chlorine, nitrogen, cobalt, and lithium isotopes). The latter generally comes from contact with the reactor cooling water and generates 14C from nitrogen or oxygen irradiation. The deposited heavy metal radionuclides (uranium, transuranic elements, and fission products) come from inside reactor installations and may contaminate graphite elements due to nuclear fuel crashes that may occur during reactor operation [19].

In terms of i-graphite management, short-lived radionuclides are important only immediately after reactor shutdown. If the recovery and treatment are delayed for tens of years after shutdown, their activity significantly decreases due to their decay. About 95% of the radioactivity concentration emitted by i-graphite, however, comes from carbon 14C and can achieve a value of more than 3·1011 Bq/m3. This value approaches the upper limit of 14C permitted for storage as long-leaved waste (LLW) waste (i.e., a low-level Class C according to the U.S. Regulatory Commission on Nuclear Safety, NRC) [20,21,22]. Since this radionuclide has a relatively long half-life (~5730 years), if it is released into the atmosphere, it may produce potentially long-term health risks due to the emitted radiation. Thus, long-living radionuclides (14C, but also 36Cl) are the most important radioisotopes to consider when choosing a management strategy for radioactive waste containing i-graphite.

3. Management Strategies of Waste Containing Irradiated Graphite

Radioactive waste is defined by the International Atomic Energy Agency, IAEA as “any material that contains or is contaminated by radionuclides at concentrations or radioactivity levels greater than the exempted quantities established by the competent authorities and for which no use is foreseen” [25]. This waste is generated by any human activity that uses radioactive materials, either as part of the process (e.g., nuclear medicine, science, tracking certain industrial processes) or by using radioactive materials as equipment or instruments for the process (defectoscopes, fume detectors, tank fill meters containing closed radioactive sources, etc.).

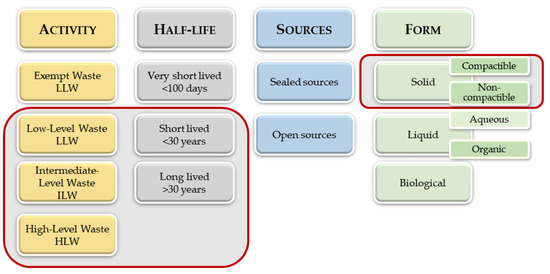

Several attempts have been made to classify radioactive waste, and some are presented in Figure 3. The left part of the figure contains the categorization proposed by the IAEA [26]. Currently, most countries base their national systems of categorization on this IAEA scheme.

Figure 3. Different categorizations of radioactive waste based on [27]; radioactive waste containing graphite is shown.

4. Management of Graphite-Containing Waste—Special Cases

As stated above, the generally accepted methods of irradiated graphite disposal may be categorized into one of the following groups:

-

(1). Removal of large elements from nuclear installations as solid graphite and prolonged (or permanent) storage with or without crushing.

-

(2). Decomposition of graphite elements, e.g., by thermochemical methods (incineration).

-

(3). Recovery of graphite (regeneration) for reuse, e.g., by decontamination.

5. Disposal of Spent Graphite-Containing HTGR Fuel

There are currently many methods available for preparing spent HTGR fuel into a form suitable for long-term storage. The method selection should be based on the criteria used for waste storage, ease of removal from the nuclear installation, and efficiency of reducing the mass of carbon in the waste. In such cases, processing the waste into a form acceptable for repositories should also be accompanied by the lowest cost and minimal risk.

6. Decontamination of Graphite Elements

There are three types of elements made from graphite in high-temperature reactors that, if contaminated, should be cleaned:- ✓ fuel blocks,

- ✓ solid neutron reflectors,

- ✓ neutron moderators.

7. Conclusions

Irradiated nuclear graphite, as well as radioactive waste containing graphite components, are difficult to handle. Graphite blocks from Magnox or AGR reactors are huge and heavy, and therefore represent a serious problem for operations typically used to treat radioactive waste. In many cases, nuclear graphite is combined with other materials—metallic or ceramic—which make it significantly difficult to recycle. The greatest challenge is related to the contamination of irradiated graphite by long-lived radioisotopes such as 14C, 36Cl, and 60Co, and the possible emission of radioactive gases. As in the case of other radioactive waste containing long-living isotopes, this is associated with the public fear of processing and long-term disposal of these materials. Hence, there is a lack of social acceptance for facilities such as deep geological repositories.