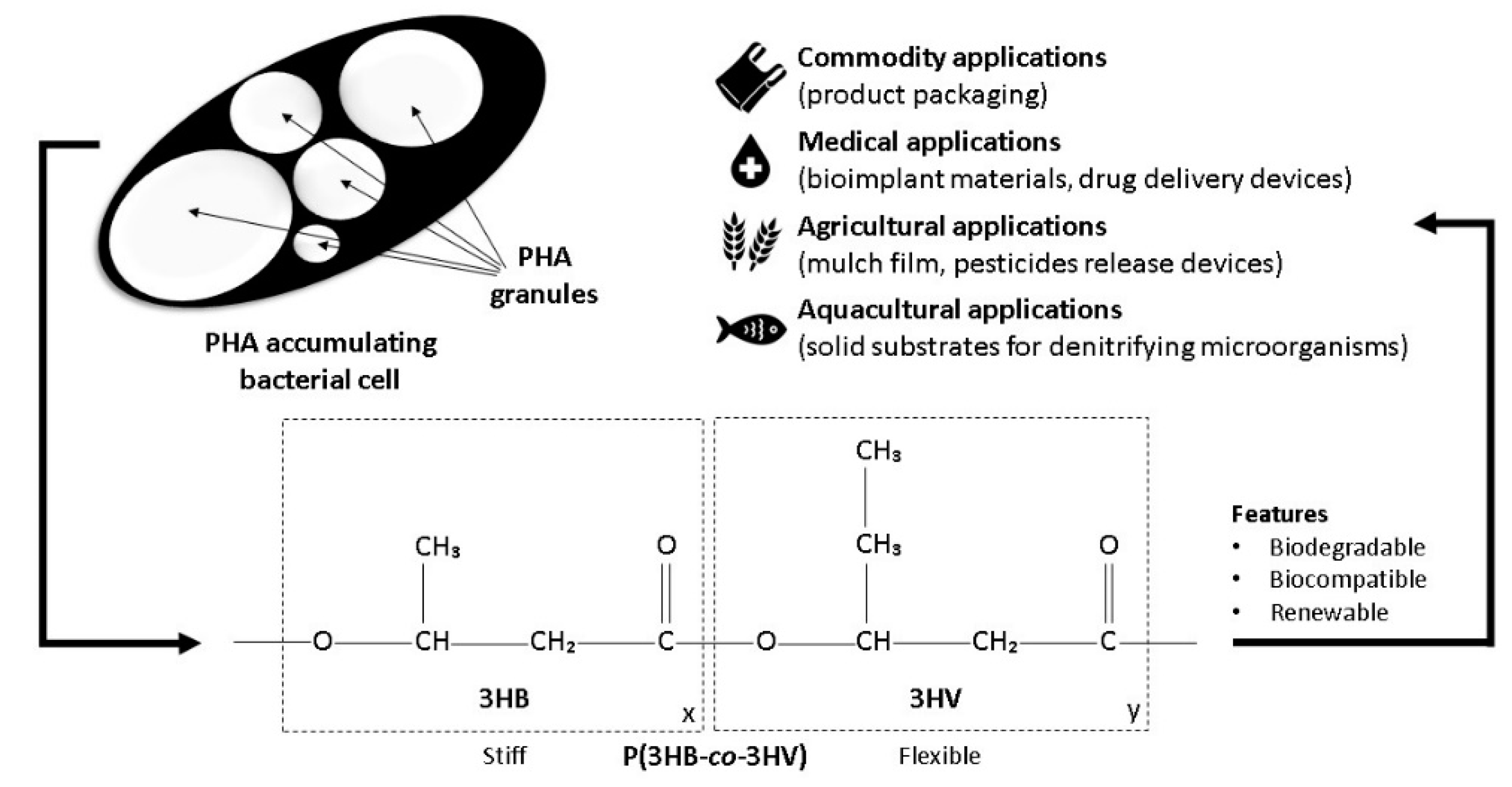

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P(3HB-co-3HV)) is the most studied short-chain-length polyhydroxyalkanoates (PHA) with high application importance in various fields owing to its biodegradability, biocompatibility, renewability and thermoplastic properties. PHA are biopolyesters with plastic-like properties accumulated by microorganisms as a reserved energy source in the form of granules under carbon-excess and nitrogen-limited conditions. P(3HB-co-3HV) can be produced through microbial fermentation and has great potential as an alternative for non-biodegradable synthetic plastics.

- Applications

- Biodegradable

- Biocompatible

- Biopolymer

- Biosynthesis

- Thermoplastic

- Polyhydroxyalkanoates (PHA)

- Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

- P(3HB-co-3HV)

- Properties

1. Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (P(3HB-co-3HV)) Properties and Applications

2. Bioconversion of Alkyl Alcohols and Organic Acids into P(3HB-co-3HV)

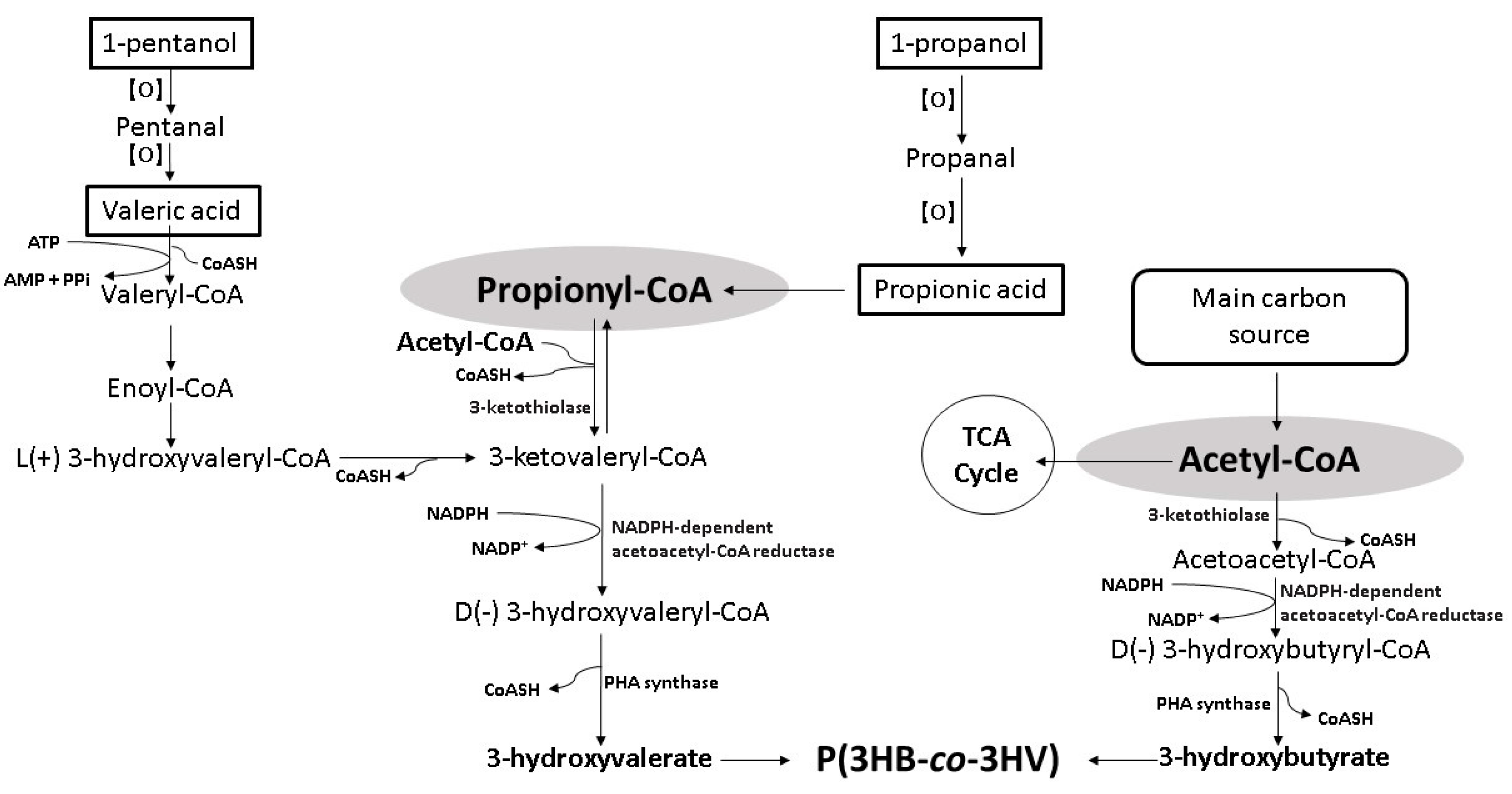

The most common way to incorporate 3HV monomers is by employing a precursor carbon source as a co-substrate along with the main carbon source that contributes to the 3-hydroxybutyrate (3HB) monomer. Precursor carbon sources such as organic acids, alcohols, or some amino acids were studied thoroughly to clarify the metabolic pathways involved and to search for promising precursors of greater potential. Organic acids, especially propionic acid, valeric acid, and their respective salts, are the standard 3HV precursors owing to their wide acceptance among PHA-producing bacteria. However, organic acids can only be added in low concentrations due to their high toxicity to the bacteria, and their high substrate cost causes lower profitability. Although levulinic acid is way more cost-effective than propionic acid and valeric acid, it seems to be a privilege for Cupriavidus necator, and the production mechanism is yet to be clarified [120][221]. Although some amino acids such as threonine, valine, and isoleucine could be employed as 3HV precursors, metabolic engineering of the amino acid biosynthetic pathways is required to convert amino acids into propionyl-CoA, which is essential for 3HV formation. The rare occurrence of alcohols-utilizing ability among PHA-producing bacteria hinders the employment of alkyl alcohols as 3HV precursors despite their potential as cost-effective substitutes for organic acids [322]. In addition to the merit in lowering the substrate cost, naturally occurring carbon sources such as glucose and glycerol or organic wastes can be converted by microorganisms into alkyl alcohols, thus are promising as cost-effective and sustainable bioresources for P(3HB-co-3HV) production [423].

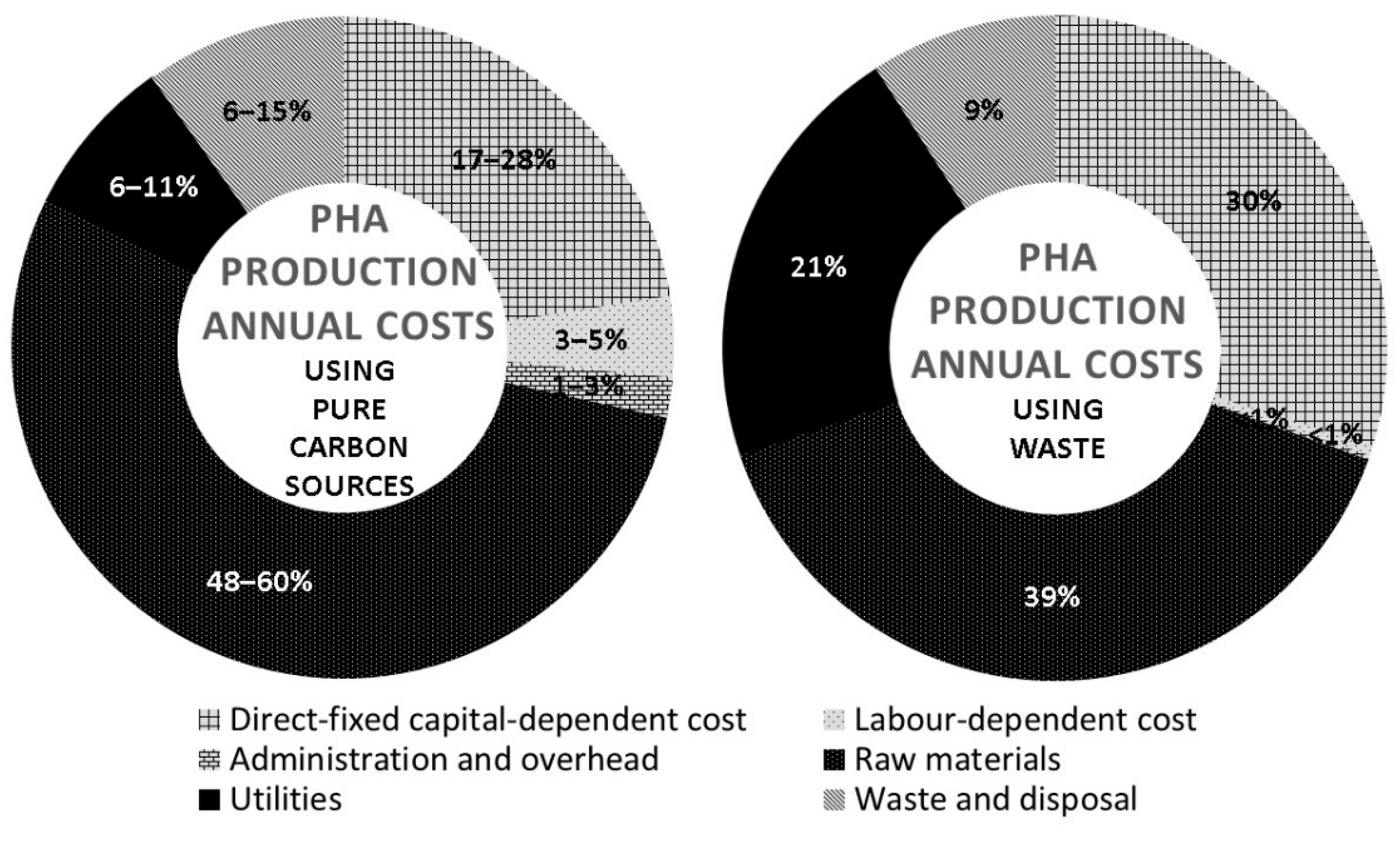

3. Techno-Economic and Sustainability Assessment

References

- Nathalie Berezina; Enhancing the 3-hydroxyvalerate component in bioplastic PHBV production by Cupriavidus necator. Biotechnology Journal 2011, 7, 304-309, 10.1002/biot.201100191.Strong, P.J.; Laycock, B.; Mahamud, S.N.S.; Jensen, P.D.; Lant, P.A.; Tyson, G.; Pratt, S. The opportunity for high-performance biomaterials from methane. Microorganisms 2016, 4, 11.

- Ivana Novackova; Dan Kucera; Jaromir Porizka; Iva Pernicova; Petr Sedlacek; Martin Koller; Adriana Kovalcik; Stanislav Obruca; Adaptation of Cupriavidus necator to levulinic acid for enhanced production of P(3HB-co-3HV) copolyesters. Biochemical Engineering Journal 2019, 151, 107350-107360, 10.1016/j.bej.2019.107350.Liu, Q.; Zhang, H.; Deng, B.; Zhao, X. Poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate): Structure, property, and fiber. Int. J. Polym. Sci. 2014, 2014, 1–11.

- Grazia Policastro; Antonio Panico; Massimiliano Fabbricino; Improving biological production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) co-polymer: a critical review. Reviews in Environmental Science and Bio/Technology 2021, 20, 479-513, 10.1007/s11157-021-09575-z.Shishatskaya, E.I.; Kamendov, I.V.; Starosvetsky, S.I.; Vinnik, Y.S.; Markelova, N.N.; Shageev, A.A.; Khorzhevsky, V.A.; Peryanova, O.V.; Shumilova, A.A. An in vivo study of osteoplastic properties of resorbable poly-3-hydroxybutyrate in models of segmental osteotomy and chronic osteomyelitis. Artif. Cells, Nanomed. Biotechnol. 2014, 42, 344–355.

- Stanislav Obruca; Ivana Marova; Ondrej Snajdar; Ludmila Mravcova; Zdenek Svoboda; Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Cupriavidus necator from waste rapeseed oil using propanol as a precursor of 3-hydroxyvalerate. Biotechnology Letters 2010, 32, 1925-1932, 10.1007/s10529-010-0376-8.Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196.

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2013, 38, 536–583.

- Ali, I.; Jamil, N. Polyhydroxyalkanoates: Current applications in the medical field. Front. Biol. 2016, 11, 19–27.

- Wu, L.P.; Wang, D.; Parhamifar, L.; Hall, A.; Chen, G.Q.; Moghimi, S.M. Poly(3-hydroxybutyrate-co-R-3-hydroxyhexanoate) nanoparticles with polyethylenimine coat as simple, safe, and versatile vehicles for cell targeting: Population characteristics, cell uptake, and intracellular trafficking. Adv. Healthc. Mater. 2014, 3, 817–824.

- Catoni, S.E.; Trindade, K.N.; Gomes, C.A.; Schneider, A.L.; Pezzin, A.; Soldi, V. Influence of poly(ethylene grycol)-(PEG) on the properties of influence of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)-PHBV. Polímeros 2013, 23, 320–325.

- Li, Z.; Loh, X.J. Water soluble polyhydroxyalkanoates: Future materials for therapeutic applications. Chem. Soc. Rev. 2015, 44, 2865–2879.

- Shah, M.; Naseer, M.I.; Choi, M.H.; Kim, M.O.; Yoon, S.C. Amphiphilic PHA–mPEG copolymeric nanocontainers for drug delivery: Preparation, characterization and in vitro evaluation. Int. J. Pharm. 2010, 400, 165–175.

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Mat. Today Proc. 2021; in press.

- Sen, S.K.; Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 2015, 3, 462–473.

- Kader, M.A.; Senge, M.; Mojid, M.A.; Ito, K. Recent advances in mulching materials and methods for modifying soil environment. Soil Tillage Res. 2017, 168, 155–166.

- Sarkar, D.J.; Barman, M.; Bera, T.; De, M.; Chatterjee, D. Agriculture: Polymers in crop production mulch and fertilizer. In Encyclopedia of Polymer Applications; Routledge: England, UK, 2018; Volume 1, pp. 1–20.

- Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable polymers with a range of applications. J. Chem. Technol. Biotechnol. 2007, 82, 233–247.

- Yogesh, C.; Pathak, B.; Fulekar, M.H. PHA-production application and its bioremediation in environment. Res. J. Environ. Sci. 2012, 1, 46–52. Available online: http://www.isca.in/IJENS/Archive/v1/i2/9.ISCA-JEvsS-2012-009.pdf (accessed on 15 January 2022).

- Krasnits, E.; Beliavsky, M.; Tarre, S.; Green, M. PHA based denitrification: Municipal wastewater vs. acetate. Bioresour. Technol. 2013, 132, 28–37.

- Santorio, S.; Fra-Vázquez, A.; Del Rio, A.V.; Mosquera-Corral, A. Potential of endogenous PHA as electron donor for denitrification. Sci. Total Environ. 2019, 695, 133747–133753.

- Hiraishi, A.; Khan, S.T. Application of polyhydroxyalkanoates for denitrification in water and wastewater treatment. Appl. Microbiol. Biotechnol. 2003, 61, 103–109.

- Schulz, H. Beta oxidation of fatty acids. Biochim. Biophys. Acta Lipids Lipid Metab. 1991, 1081, 109–120.

- Yamane, T.; Chen, X.; Ueda, S. Growth-associated production of poly(3-hydroxyvalerate) from n-pentanol by a methylotrophic bacterium, Paracoccus denitrificans. Appl. Environ. Microbiol. 1996, 62, 380–384.

- Azira, T.F.; Nursolehah, A.A.; Norhayati, Y.; Majid, M.I.A.; Amirul, A.A. Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) terpolymer by Cupriavidus sp. USMAA2-4 through two-step cultivation process. World J. Microbiol. Biotechnol. 2011, 27, 2287–2295.

- Chen, Q.; Wang, Q.; Wei, G.; Liang, Q.; Qi, Q. Production in Escherichia coli of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with differing monomer compositions from unrelated carbon sources. Appl. Environ. Microbiol. 2011, 77, 4886–4893.

- Huijberts, G.N.; Eggink, G.; De Waard, P.; Huisman, G.W.; Witholt, B. Pseudomonas putida KT2442 cultivated on glucose accumulates poly(3-hydroxyalkanoates) consisting of saturated and unsaturated monomers. Appl. Environ. Microbiol. 1992, 58, 536–544.

- Majid, M.I.A.; Akmal, D.H.; Few, L.L.; Agustien, A.; Toh, M.S.; Samian, M.R.; Najimudin, N.; Azizan, M.N. Production of poly(3-hydroxybutyrate) and its copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Erwinia sp. USMI-20. Int. J. Biol. Macromol. 1999, 25, 95–104.

- Bingham, E.; Cohrssen, B.; Powell, C.H. Patty’s Toxicology Volume 1–6, 6th ed.; John Wiley & Sons: New York, NY, USA, 2012.

- Klabunde, J.; Bischoff, C.; Papa, A.J. Propanols. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2018; pp. 1–14. Available online: https://onlinelibrary.wiley.com/doi/10.1002/14356007.a22_173.pub3 (accessed on 15 January 2022).

- Mallat, T.; Baiker, A. Oxidation of alcohols with molecular oxygen on solid catalysts. Chem. Rev. 2004, 104, 3037–3058.

- Steinbüchel, A.; Lütke-Eversloh, T. Metabolic engineering and pathway construction for biotechnological production of relevant polyhydroxyalkanoates in microorganisms. Biochem. Eng. J. 2003, 16, 81–96.

- Berezina, N. Enhancing the 3-hydroxyvalerate component in bioplastic PHBV production by Cupriavidus necator. Biotechnol. J. 2012, 7, 304–309.

- Novackova, I.; Kucera, D.; Porizka, J.; Pernicova, I.; Sedlacek, P.; Koller, M.; Kovalcik, A.; Obruca, S. Adaptation of Cupriavidus necator to levulinic acid for enhanced production of P(3HB-co-3HV) copolyesters. Biochem. Eng. J. 2019, 151, 107350–107360.

- Berezina, N.; Yada, B. Improvement of the poly(3-hydroxybutyrate-co-3-hydroxyvalerate)(PHBV) production by dual feeding with levulinic acid and sodium propionate in Cupriavidus necator. New Biotechnol. 2016, 33, 231–236.

- Chung, S.H.; Park, G.G.; Kim, H.W.; Rhee, Y.H. Effect of levulinic acid on the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Ralstonia eutropha KHB-8862. J. Microbiol. 2001, 39, 79–82.

- Kim, D.Y.; Park, D.S.; Kwon, S.B.; Chung, M.G.; Bae, K.S.; Park, H.Y.; Rhee, Y.H. Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolyesters with a high molar fraction of 3-hydroxyvalerate by an insect-symbiotic Burkholderia sp. IS-01. J. Microbiol. 2009, 47, 651–656.

- Koller, M.; Hesse, P.; Fasl, H.; Stelzer, F.; Braunegg, G. Study on the effect of levulinic acid on whey-based biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Hydrogenophaga pseudoflava. Appl. Food Biotechnol. 2017, 4, 65–78.

- Choi, J.; Lee, S.Y. Factors affecting the economics of polyhydroxyalkanoate production by bacterial fermentation. Appl. Microbiol. Biotechnol. 1999, 51, 13–21.

- Saratale, R.G.; Cho, S.K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Kumar, G.; Kim, D.S.; Mulla, S.I.; et al. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685–124699.

- Bhattacharyya, A.; Jana, K.; Haldar, S.; Bhowmic, A.; Mukhopadhyay, U.K.; De, S.; Mukherjee, J. Integration of poly-3-(hydroxybutyrate-co-hydroxyvalerate) production by Haloferax mediterranei through utilization of stillage from rice-based ethanol manufacture in India and its techno-economic analysis. World J. Microbiol. Biotechnol. 2015, 31, 717–727.