Microalgae have been considered as one of the most promising biomass feedstocks for various industrial applications such as biofuels, animal/aquaculture feeds, food supplements, nutraceuticals, and pharmaceuticals. Several biotechnological challenges associated with algae cultivation, including the small size and negative surface charge of algal cells as well as the dilution of its cultures, need to be circumvented, which increases the cost and labor. Therefore, efficient biomass recovery or harvesting of diverse algal species represents a critical bottleneck for large-scale algal biorefinery process. Among different algae harvesting techniques (e.g., centrifugation, gravity sedimentation, screening, filtration, and air flotation), the flocculation-based processes have acquired much attention due to their promising efficiency and scalability.

Flocculation techniques for algal biorefinement process can be largely classified into five categories which are auto-flocculation, bio-flocculation, chemical flocculation, particle-based flocculation, and electrochemical flocculation. Here, these flocculation techniques and the key issues in their commercialization are introduced. Updated overview of the recent technical developments and progress in this field is provided. Further research directions have also been proposed to direct the development of flocculation harvesting processes suitable for large-scale algae applications.

- Microalgae

- harvesting

- flocculation

- biomass

- biofuel

- biorefienry

- Magnetic particle

- Electroflotation

1. Introduction

Please note: Below is an entry draft based on your paper, which is wrirren tightly around the entry title. Since it may not be very comprehensive, we kindly invite you to modify it (both title and content can be replaced) according to your extensive expertise. We believe this entry would be beneficial to highlight your work.

Microalgal biomass has attracted much attention in the academic and industrial fields due to its various industrial applications such as animal/aquaculture feeds, food supplements, nutraceuticals, and pharmaceuticals [1][2]. Recently, petroleum-fuel scarcity as well as global warming associated with greenhouse gas emissions (e.g., CO2) are obliging scientists and engineers to actively look for new and renewable sources of transportation fuels [3]. Various liquid and gaseous biofuels, such as diesel, aviation fuel, ethanol, butanol, hydrogen, and methane, can be produced from algal biomass through biological and thermochemical transformation technologies [4][5].

Microalgae can utilize CO2 as an inorganic carbon substrate using light energy and can be grown using diverse water resources, including freshwater, seawater, and even industrial/domestic wastewater. They can be also cultivated at a large-scale using different bioreactor systems such as open ponds and photobioreactors [6][7]. However, due to the low concentration (~5 g/L) in culture, small size (~5 μm) and negative surface charge (~−20 mV) of algal cells, external energy and/or chemicals are generally required to accelerate their recovery from base water [8][9]. Furthermore, other morphological and physiological characteristics of algal cells such as shape, cell wall structure, and extracellular organic matter (EOM) change significantly depending on the nutritional and environmental conditions including medium composition, light, temperature, pH, culture duration, and bioreactor type [10]. The algae harvesting costs are generally estimated at 20–30%, with the occasional rise to 60%, of the total biomass production cost, depending on the algal species and culture process used [11][12]. Therefore, the development of a high-efficiency and cost-effective harvesting process is key to achieving commercial scale algae-based process.

Definition

Algal biomass harvesting has been extensively studied with particular focus on centrifugation, gravity sedimentation, screening, filtration, air flotation, and flocculation techniques. However, there is no single universal harvesting method for all algal species and/or applications, which is both technically and economically viable [13][14]. For instance, centrifugation is based on a mechanical gravitational force that allows for efficient harvesting of suspended cells in a short time. However, due to the intensive energy requirement, it is recommended only for high-value algal products such as in foods and pharmaceuticals [14][15]. In the filtration process, micro-sized algal cells can be passed through a suitable membrane under high pressure to obtain a thick paste of algal biomass [16]. This size-exclusion method may be useful and scalable for algae harvesting only if problems in membrane blocking can be minimized or prevented [17][18]. The air flotation (or inverted sedimentation) harvesting process is based on the generation of up-rising gas bubbles that bind to algal cells and induce their flotation to the liquid surface [19]. However, due to differences in the surface hydrophobicity of algal cells, harvesting efficiency varies greatly depending on the species of algae [20]. It should also be noted that the high operation cost for producing small air bubbles can limit large-scale commercialization.

Microalgae have been considered as one of the most promising biomass feedstocks for various industrial applications such as biofuels, animal/aquaculture feeds, food supplements, nutraceuticals, and pharmaceuticals. Several biotechnological challenges associated with algae cultivation, including the small size and negative surface charge of algal cells as well as the dilution of its cultures, need to be circumvented, which increases the cost and labor. Therefore, efficient biomass recovery or harvesting of diverse algal species represents a critical bottleneck for large-scale algal biorefinery process. Among different algae harvesting techniques (e.g., centrifugation, gravity sedimentation, screening, filtration, and air flotation), the flocculation-based processes have acquired much attention due to their promising efficiency and scalability.

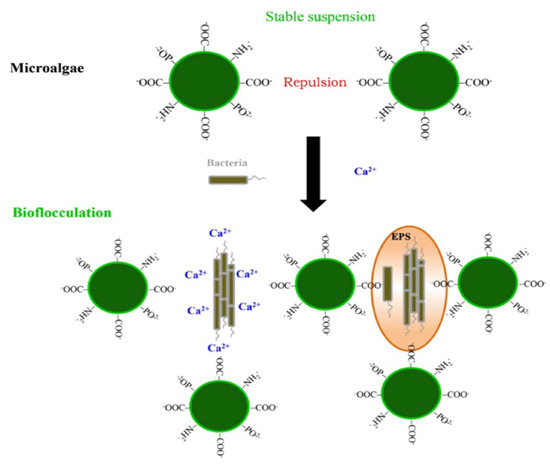

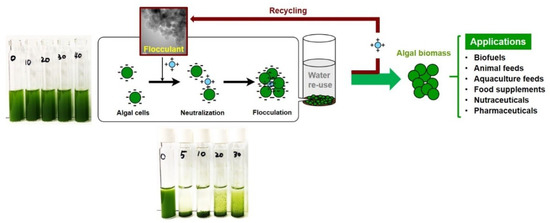

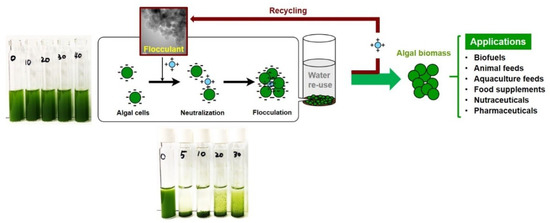

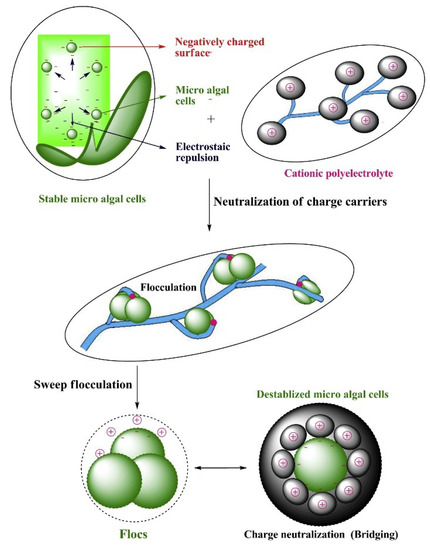

Flocculation refers to the aggregation of unstable and small particles through surface charge neutralization, electrostatic patching and/or bridging after addition of flocculants. Flocs formation allows for separation (or recovery) by simple gravity-induced settling or any other conventional separation method [21][22]. The flocculation process is simple and efficient, and has been extensively investigated as a promising strategy for harvesting various algal species [9][23]. Figure 1 shows the flocculation harvesting process of algal cells for algal biorefinery.

1. Introduction

Microalgal biomass has attracted much attention in the academic and industrial fields due to its various industrial applications such as animal/aquaculture feeds, food supplements, nutraceuticals, and pharmaceuticals [1,2]. Recently, petroleum-fuel scarcity as well as global warming associated with greenhouse gas emissions (e.g., CO2) are obliging scientists and engineers to actively look for new and renewable sources of transportation fuels [3]. Various liquid and gaseous biofuels, such as diesel, aviation fuel, ethanol, butanol, hydrogen, and methane, can be produced from algal biomass through biological and thermochemical transformation technologies [4,5].

Figure 1. Schematic diagram of the flocculation harvesting process of algal cells with a recyclable flocculant.

As the flocculant plays a major role in the flocculation harvesting process, the discovery of a highly efficient and cost-effective flocculant has forever remained a challenge in most studies. Nowadays, the use of conventional inorganic metal salts such as aluminum sulfate and ferric sulfate has been reduced due to high dosage and biomass contamination [9]. Various natural and synthetic organic flocculants have been designed and developed to improve flocculation efficiency. However, the former have high production cost and a short shelf-life while the latter have adverse effects on harvested biomass and non-biodegradability, due to their petroleum origins [24]. Metal cations released from the electrode under direct electric current condition are able to electrostatically attract almost all types of algal cells, resulting in efficient flocculation. Significant efforts are being directed to prevent electrode/biomass fouling and to reduce systemic/electric cost for large-scale algae harvesting. Nanoparticles in either single or hybrid forms decorated with various cationic chemicals have been employed for rapid algae separation and/or multi-functionalities such as cell disruption and lipid extraction [25]. This approach although highly efficient, is expensive and is mostly limited to laboratory-scale studies. Spontaneous aggregation of algal cells under specific conditions and the use of a self-flocculating microorganism can be considered as sustainable and environment-friendly [22][26]. However, species-specific reactivity, availability of low-cost bio-flocculant-microorganisms, and process scale-up should be properly considered for practical applications. Ideally, in addition to excellent harvesting efficiency and promising scalability, the industrial flocculant should satisfy the demands for recyclability, low toxicity, low-cost material, and massive production process.

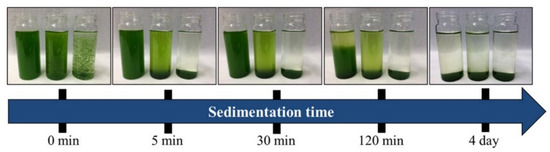

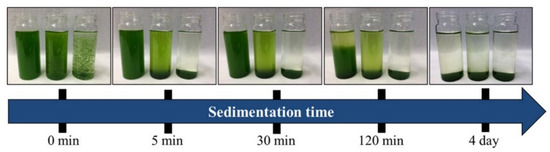

2. Auto-Flocculation

In auto-flocculation, suspended algal cells spontaneously aggregate, forming large flocs, which induce their simple gravitational sedimentation (Figure 2). This phenomenon has been observed in various algal species particularly under non-ideal culture conditions such as change in pH and cultural aging, as summarized in Table 1. Both alkaline and acidic conditions have been reported to reduce the intensities of the negative surface charge of algal cells, thereby promoting their self-aggregation [27]. Under alkaline conditions above pH 9, the changes in the surface charge of algal cells are mainly attributable to significant secretion of protective extracellular polymers [28]. Under acidic conditions, fluctuating dissociations of carboxyl and amine groups in the algal cell wall can cause changes in surface charge.

Microalgae can utilize CO2 as an inorganic carbon substrate using light energy and can be grown using diverse water resources, including freshwater, seawater, and even industrial/domestic wastewater. They can be also cultivated at a large-scale using different bioreactor systems such as open ponds and photobioreactors [6,7]. However, due to the low concentration (~5 g/L) in culture, small size (~5 μm) and negative surface charge (~−20 mV) of algal cells, external energy and/or chemicals are generally required to accelerate their recovery from base water [8,9]. Furthermore, other morphologigure cal and physiological characteristics of algal cells such as shape, cell wall structure, and extracellular organic matter (EOM) change significantly depending on the nutritional and environmental conditions including medium composition, light, temperature, pH, culture duration, and bioreactor type [10]. The algae harvesting costs are generally estimated at 20–30%, with the occasional rise to 60%, of the total biomass production cost, depending on the algal species and culture process used [11,12]. Therefore, the development of a high-efficiency and cost-effective harvesting process is key to achieving commercial scale algae-based process.

Algal biomass harvesting has been extensively stuto-died with particular focus on centrifugation, gravity sedimentation, screening, filtration, air flotation, and flocculation htechniques. However, there is no single universal harvesting ofmethod for all algal biomaspecies and/or applications, which is both technically and economically viable [13,14]. For instance, centrifugation is bas. Three vials ed on a mechanical gravitational force that allows for efficient harvesting of suspended cells in a short time. However, due to the intensive energy requirement, it is recommended only for high-value algal products such as in foods and pharmaceuticals [14,15]. In the filtration process, microntain algal s-sized algal cells can be passed through a suitable membrane under high pressure to obtain a thick paste of algal biomass [16]. This size-exclusion method may be useful and scalable for algae harvesting only if problemps in membrane blocking can be minimized or prevented [17,18]. The air flotation (or inves cultured rted sedimentation) harvesting process is based on the generation of up-rising gas bubbles that bind to algal cells and induce their flotation to the liquid surface [19]. However, due to differen different ces in the surface hydrophobicity of algal cells, harvesting efficiency varies greatly depending on the species of algae [20]. It should also be noted that the hitrate congh operation cost for producing small air bubbles can limit large-scale commercialization.

Flocculation rentrations: (lefers to the aggregation of unstable and small particles through surface charge neutralization, electrostatic patching and/or bridging after addition of flocculants. Flocs formation allows for separation (or recovery) by simple gravity-induced settling or any other conventional separation method [21,22]. The flocculat)ion process is simple and efficient, and has been extensively investigated as a promising strategy for harvesting various algal species [9,23]. Figure 1 shows the flocculation harvesting process of algal cells for algal biorefinery.

As the flocculant plays a major role in the flocculation harvesting process, the discovery of a highly efficient and cost-effective flocculant has forever remained a challenge in most 0studies.5×; (midd Nowadays, the use of conventional inorganic metal salts such as aluminum sulfate and ferric sulfate has been reduced due to high dosage and biomass contamination [9]. Various natural and synthetic organic flocculants have been designed and deve) 1× (original); and (rigloped to improve flocculation efficiency. However, the former have high production cost and a short shelf-life while the latter have adverse effects on harvested biomass and non-biodegradability, due to their petroleum origins [24]. Metal cations released from the elect) 2×. Reprinted fromrode under direct electric current condition are able to electrostatically attract almost all types of algal cells, resulting in efficient flocculation. Significant efforts are being directed to prevent electrode/biomass fouling and to reduce systemic/electric cost for large-scale algae harvesting. Nanoparticles in either single or hybrid forms decorated with various cationic chemicals have been employed for rapid algae separation and/or multi-functionalities such as cell disruption and lipid extraction [25]. This approach although Rhighly eferencefficient, is expensive and is mostly limited to laboratory-scale studies. Spontaneous aggregation of algal cells [29],under specific condistributed tions and the use of a self-flocculating microorganism can be considered as sustainable and environment-friendly [22,26]. However, species-specific reactivity, availability of low-cost bio-flocculander the terms ot-microorganisms, and process scale-up should be properly considered for practical applications. Ideally, in addition to excellent harvesting efficiency and promising scalability, the industrial flocculant should satisfy the demands for recyclability, low toxicity, low-cost material, and massive production process.

2. Auto-Flocculation

In auto-flocculation, the Creatisuspended algal cells spontaneously aggregate, forming large flocs, which induce their simple gravitational sedimentation (Figure 2). This phenomenon has been observed in Commvarious algal species particularly under non-ideal culture conditions such as change in pH and cultural aging, as summarized in Table 1. Both alkalinse and acidic conditions have been reported to reduce the intensities of the negative surface charge of algal cells, thereby promoting their self-aggregation [31]. Under alkaline conditions above pH 9, the Achanges in the surface charge of algal cells are mainly attribution Lable to significant secretion of protective extracellular polymers [32]. Under acidic conditions, fluctuating dissociations of carboxyl and amine groups in the algal censell wall can cause changes in surface charge.

|

Condition |

Alga (Cell Density) |

||||||||||||||||||||||||

Kind | Flocculant |

Optimal Harvesting |

Ref. |

||||||||||||||||||||||

Dosage | Alga (Cell Density) | Optimal Harvesting | Ref. |

Acidic pH |

pH 4.0 |

C. ellipsoideum (4.38 g/L) |

95% @ 15 min |

86% @ 30 min |

[27][31] |

||||||||||||||||

[ | ] | [64] |

|||||||||||||||||||||||

Aminoclay-based nanoparticle | Al-AC | 0.6 g/L | Chlorella sp. KR-1 (1.7 g/L) | 100% @ 30 min |

[74] |

[99] |

pH 4.0 |

Al2(SO4)3 (152 mg/L) |

C. nivale (4.17 g/L) |

94% @ 15 min |

[ |

Chlorella sp. (0.12 g/L) |

100% @ 60 min | ][31] |

|||||||||||

[ | ][65] |

||||||||||||||||||||||||

|

Al2(SO4)3 (180 mg/L) |

Scenedesmus sp. (0.20 g/L) |

90% @ 20 min |

[55][66] |

||||||||||||||||||||||

|

Al2(SO4)3 (20 mg/L) |

C. reinhardtii (0.31 g/L) |

90% @ 20 min |

[55][66] |

||||||||||||||||||||||

|

Al2(SO4)3 (438.1 μM) | |||||||||||||||||||||||||

AC-conjugated TiO2 | 3.0 g/L | Chlorella sp. KR-1 (1.5 g/L) |

pH 4.0 |

Scenedesmus sp. (6.94 g/L) |

98% @ 15 min |

[39] |

|||||||||||||||||||

3. Bio-Flocculation

Bio-flocculation is performed by adding a self-flocculating microorganism (or its extracellular biopolymer) to the culture broth to harvest non-flocculating, target algae (Figure 3). Bio-flocculants include bacteria, fungi, yeasts, or self-flocculating algae as well as their exudate-rich culture supernatants, as shown in Table 2. Since no chemical is required in this process similar to the case of auto-flocculation, the bio-flocculation method can also be considered as a sustainable and environmentally friendly technique for algal biomass harvesting [36][37][45,46]. A bio-flocculant-microorganism can be prepared by co-culturing with target algae or culturing separately in a different bioreactor, before performing the intended use [22][38][22,30]. Although the mechanism of bio-flocculation has not been clearly elucidated, it is believed that it is mainly a function of the reactivity of the extracellular biopolymer and/or the direct adsorption of the self-flocculating microorganisms on the target algae [23][39][23,27].

Flocculant (Dosage) | Alga (Cell Density, Volume or Amount) | Optimal Harvesting | Ref. | |||||||||||||||

Fungus | A. fumigatus | C. protothecoides | ~90% @ 24 h |

[40] |

[47] |

|||||||||||||

A. fumigatus (1.5–2.0 × 107 spores/L) | S. quadricauda (5–8 × 108 cell/mL) | ~97% @ 48 h |

[41] |

[49] |

||||||||||||||

~85% @ 10 min | [75] |

[100] |

A. fumigatus | |||||||||||||||

AC-induced humic acid | T. suecica | 5.0 g/L | Chlorella sp. (1.3 g/L)[27 |

~90% @ 24 h][31] | ||||||||||||||

[40] |

[47] |

~100% @ 30 min |

[76] |

[101] |

Alkaline pH |

pH 11.5 |

C. muelleri #862 (0.42 g/L) |

100% @ 30 min |

[ | |||||||||

A. lentulus (1.0 × 106 spores/mL) | Chroococcus sp. (1.58 g/L) | |||||||||||||||||

AC-templated nZVI | ][34] |

|||||||||||||||||

19.1 g/L | ~100% @ 24 h | Chlorella sp. KR-1 (1.5 g/L) |

[42] |

[48] |

~100% @ 3 min |

[77] |

[102] |

pH 11.0 |

||||||||||

Penicillium cells (1.92 g) |

C. vulgaris (0.5 g/L) |

95% @ 60 min |

[31 |

Chlorella sp. (3.84 g) |

N. oculata (1.7 g/L) |

92% @ 320 min |

||||||||||||

APTES-coated BaFe12O19 | 2.3 g/g cell | ][35] |

||||||||||||||||

~98% @ 2.5 h | Chlorella sp. KR-1 |

[43] |

[50] |

[28][32] |

||||||||||||||

99% @ 3 min | [78] |

[103] |

pH 12.0 |

Chlorococcum sp. R-AP13 |

94% @ 10 min |

[32][36] |

||||||||||||

Penicillium spores (1.1 × 104 cells/mL) |

Al2(SO4) | Chlorella sp. (3.84 g) | 3 | ~99% @ 28 h | (50 mg/L) |

[43] |

[50] |

S. limacinum (0.93 g/L) |

90% @ 20 min |

[55] |

pH 12.5 |

|||||||

[66] | Yeast |

Ettlia sp. YC001 (1.2 g/L) |

Extracellular protein of S. bayanus (0.1 g/L) |

94% @ 30 min |

C. reinhardtii (10 mL) |

[33][37] |

||||||||||||

95% @ 3 h | ||||||||||||||||||

Chitosan–Fe3O4 composite | 1.4 g/L | Chlorella sp. KR-1 (1.0 g/L) | ~99% @ 5 min |

[88] |

[112] |

|||||||||||||

Chitosan-coated Fe3O4-TiO2 | 0.07 g/g cell | C. minutissima (3.0 g/L) | 98% @ 2 min |

[89] |

[113] |

|||||||||||||

6. Electrochemical Flocculation

Electrochemical algae harvesting is generally carried out by passing a direct electrical current through electrodes into a culture broth wherein algal cells act as negatively charged colloids (Figure 5). There are two types of electrodes, “sacrificial electrodes”, whose metal ions are released into the aquatic environment, and “non-sacrificial electrodes” with non-reactive anodes and cathodes (Table 5). The electrical current in aqueous solution can cause a water-electrolysis reaction through either the sacrificial or non-sacrificial electrodes, which would release hydrogen and oxygen gases from the cathode and anode electrodes, respectively [90][91]. In this review, the electrochemical flocculation (ECF) process is discussed for the following three aspects: the sacrificial electrode, the non-sacrificial electrode, and electro-flotation.

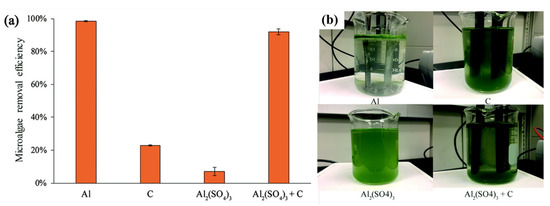

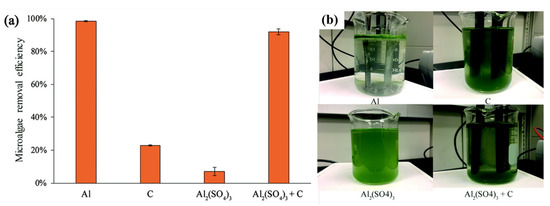

Figure 5. Electrochemical falocculationgae harvesting of microalgae uis generally carried out by passing aluminum direct electrical current through electrodes (Al), graphiinto a culture broth wherein algal cells act as negatively charged colloids (Figure 5). There are two types of electrodes (C), aluminum sulfate (Al2(SO4)3), “sacrificial electrodes”, whose metal ions are released into the aquatic environment, and g“non-sacraphiteificial electrodes” with aluminum sulfatenon-reactive anodes and cathodes (ATable 5). The electrical2(SO4)3 +current C): (a) microalgae removal efficiency; and (b) photograpin aqueous solution can cause a water-electrolysis reaction through either the sacrificial or non-sacrificial electrodes, which would release hydrogen and oxygen gases from the cathode and anode electrodes, respectively [124,125]. In this of the harvestingreview, the electrochemical flocculation (ECF) processes. Reprinted from Referenc is discussed for the following three [92], diaspectributed under the terms of the Creativs: the sacrificial electrode, the non-sacrificial electrode, and electro-flotation.

Figure 5. Electrochemical flocculation harvesting of microalgae using aluminum electrodes (Al), graphite electrodes (C), aluminum sulfate (Al2(SO4)3), and graphite electrodes with aluminum sulfate (Al2(SO4)3 + C): (a) microalgae removal efficiency; and (b) photographs of the harvesting processes. Reprinted from Reference [128], distributed under the terms of the Creative Commons Attribution License.

Figure 5. Electrochemical flocculation harvesting of microalgae using aluminum electrodes (Al), graphite electrodes (C), aluminum sulfate (Al2(SO4)3), and graphite electrodes with aluminum sulfate (Al2(SO4)3 + C): (a) microalgae removal efficiency; and (b) photographs of the harvesting processes. Reprinted from Reference [128], distributed under the terms of the Creative Commons Attribution License.

Table 5. Commons Attribution License.

parison of sacrificial and non-sacrificial electrodes for algae harvesting

Table 5. Comparison of sacrificial and non-sacrificial electrodes for algae harvesting

|

Electrode |

Alga (Cell Density) |

Optimal Harvesting (Energy Requirement) |

Ref. |

|||||||||||||||||||||||||

|

Sacrificial |

Al |

C. pyrenoidosa |

95.8% @ 1 min (0.3 kWh/kg cell) |

[93][126] |

||||||||||||||||||||||||

|

Al |

C. vulgaris |

98% @ 4 min (0.3 kWh/kg cell) |

[94][129] |

|||||||||||||||||||||||||

|

Al |

M. aeruginosa (1.3 × 109 cells/mL) |

100% @ 45 min (0.4 kWh/m3) |

[95][130] |

|||||||||||||||||||||||||

|

Al |

Nannochloropsis sp. (2.5 g/L) |

97% @ 10 min (0.06 kWh/kg cell) |

[96][131] |

|||||||||||||||||||||||||

|

Al |

Scenedesmus sp. |

~98.5% @ 20 min (2.3 kWh/kg cell) |

[92][128] |

|||||||||||||||||||||||||

|

Al |

P. tricornutum |

80% @ 30 min (0.2 kWh/kg cell) |

[97][132] |

|||||||||||||||||||||||||

|

Fe |

C. vulgaris |

80% @ 30 min (2.1 kWh/kg cell) |

[97] |

[44] |

[51] |

|||||||||||||||||||||||

|

pH 10.4 |

||||||||||||||||||||||||||||

Extracellular protein of S. bayanus (0.1 g/L) | N. oculate (2.27 × 105 cells/mL) |

90% @ 10 min |

[34 |

Picochlorum sp. (10 mL)][38] | ||||||||||||||||||||||||

75% @ 3 h |

[44] |

[51] |

pH 11.6 |

|||||||||||||||||||||||||

S. bayanus (1:1, v/v) |

S. quadricauda #507 (0.54 g/L) |

C. reinhardtii (10 mL) | 95% @ 30 min |

80% @ 6 h |

[30][34] |

|||||||||||||||||||||||

[ | ] |

[51] |

Culture aging |

16 days |

S. obliquus AS-6-1 (2.25 g/L) |

80% @ 30 min |

[35] | |||||||||||||||||||||

S. bayanus (1:1, v/v) | ||||||||||||||||||||||||||||

MgAC-Fe3O4 hybrid composites | 4.7 g/L | Chlorella sp. KR-1 (1.75 g/L) | 99% @ 10 min |

[79] |

[104] |

CaO (60 mg/L) |

C. vulgaris (1.5 g/L) |

85% @ 5min |

[56][67] |

|||||||||||||||||||

|

CaCO3-rich eggshell (80 mg/L) |

C. vulgaris (2.3 g/L) |

99% @ 20 min |

[57][68] |

Picochlorum sp. (10 mL) | ||||||||||||||||||||||||

Chlorella sp. KR-1 (1.7 g/L) | 100% @ 30 min |

[74] |

[99] |

FeCl3 (0.4 g/L) |

N. oculata (50 mL) |

94% @ 180 min |

||||||||||||||||||||||

Mg-APTES | 1.0 g/L |

[58][69] |

||||||||||||||||||||||||||

C. vulgaris (1.0 g/L) | 97% @ 125 min |

[ |

FeCl3 (143 mg/L) | 60% @ 6 h |

Chlorella sp. (0.12 g/L) |

100% @ 40 min | [ |

[54][65] |

||||||||||||||||||||

|

FeCl3 (438.1 μM) |

N. oculata (2.2 g/L) |

|||||||||||||||||||||||||||

Modified tannin (210 mg/L) | ||||||||||||||||||||||||||||

Scenedesmus sp. | ||||||||||||||||||||||||||||

97% @ 40 min |

[71][81] |

|||||||||||||||||||||||||||

|

Modified tannin (10 mg/L) |

N. oculate (400 mg/L) |

98% @ 30 min |

[72][82] |

|||||||||||||||||||||||||

MgAC-Fe3O4 hybrid composites | 4.3 g/L | S. obliquus (2.0 g/L) | 99% @ 10 min |

[79] |

[104] |

|||||||||||||||||||||||

[132] | Mg-APTES | 0.6 g/L | ||||||||||||||||||||||||||

|

Fe |

Chlorococcum sp. |

96% @ 15 min (9.2 kWh/kg cell) |

[98][133] |

|||||||||||||||||||||||||

|

Fe |

Green algae mixture (Scenedesmus, Kirchneriella, and Microcystis) |

~95.6% @ 24 h (4.4 kWh/kg cell) |

[99][134] | ] |

[98] |

44] |

[51] |

|||||||||||||||||||||

Mg-AC and Ce-AC | 0.2 g/L | |||||||||||||||||||||||||||

|

Fe | Cyanobacteria |

Tetraselmis sp.~100% @ 60 min |

94% @ 15 min (4.4 kWh/kg cell) |

[98][133] |

[81] |

[105] |

S. pastorianus (0.4 mg/g cell) | |||||||||||||||||||||

|

Non-sacrificial | C. vulgaris (5 g/L) | 90% @ 70 min | 78% @ 320 min | |||||||||||||||||||||||||

Magnetic particle |

[ |

Fe3O4 nanoparticle | C | 36] |

[45] |

|||||||||||||||||||||||

[ | ][32] |

|||||||||||||||||||||||||||

55.9 mg cell/mg particles |

C. sorokinianaB. braunii | 98% @ 1 min |

~95% @ 15 min (1.6 kWh/kg cell) |

[90][124] | [82] |

[106] |

Bacterium |

Fe2 | Flavobacterium, Terrimonas, and Sphingobacterium | C. vulgaris (6 × 106 cells/mL) | 94% @ 24 h | (SO4)3 (0.6 g/L) |

||||||||||||||||

Fe3O4 nanoparticle |

N. oculata (50 mL) | |||||||||||||||||||||||||||

|

C | 5.8 mg cell/mg particles |

C. pyrenoidosa | 87% @ 180 min |

79.2% @ 1 min (0.3 kWh/kg cell) |

[ [52] |

|||||||||||||||||||||||

] | [69] | |||||||||||||||||||||||||||

C. ellipsoidea | 98% @ 1 min | [126] |

[82] |

[106] |

Bio-flocculant secreted from S. silvestris W01 (3:1, w/w) |

Fe2(SO4)3 (1.0 g/L) |

||||||||||||||||||||||

Fe3O4 nanoparticle | N. oceanica DUT01 | Chlorella sp. KR-1 (1.52 g/L) |

0.12 g/L | 90% @ 10 min |

98% @ 30 min |

[46] |

[53] |

|||||||||||||||||||||

[ | ][70] |

|||||||||||||||||||||||||||

N. maritima | 95% @ 4 min |

[83] |

[107] |

Alga | S. obliquus AS-6–1 (1%, v/v) | S. obliquus FSP-3 (10 mL) | 83% @ 30 min |

|

Mg(OH)2 (1 mM) |

Chlorella sp. (0.1 g/L) |

90% @ 30 min |

[35] |

[39] |

|||||||||||||||

[ | ] | [71] |

||||||||||||||||||||||||||

|

Organic flocculant |

Cationic inulin (60 mg/L) | |||||||||||||||||||||||||||

Fe3O4 magnetic particle | 10 g/g cell | Chlorella sp. KR-1 | 99% @ 1 min |

[84] |

[108] |

Exudates-rich spent media of C. cf. pseudomicroporum (1:1, v/v) | S. ellipsoideus (15 mL) | 97% @ 4 h |

[47] |

[54] |

||||||||||||||||||

Phormidium sp. | Chlorella sp. | 100% @ 5 min |

[14] |

|||||||||||||||||||||||||

4. Chemical Flocculation

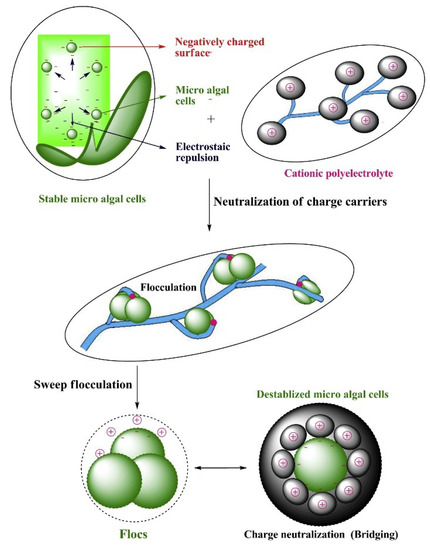

Chemical flocculation of algae occurs due to charge neutralization and electrostatic bridging between the suspended algal cells and the applied flocculant(s), resulting in floc formation and subsequent sedimentation (

Figure 4). Multivalent inorganic chemicals, biopolymers, or inorganic–organic hybrid polymers have been extensively used as algae-harvesting flocculants. Aluminum sulfate and ferric chloride are of the most popular inorganic flocculants for wastewater clarification and algal biomass recovery [48]. Chitosan, cationic starches, modified tannins, and polyacrylamides are examples of organic polymers that are widely used [28][49]. The harvesting efficiency of both organic and inorganic flocculants depends largely on their physicochemical properties such as solubility and electronegativity, as well as the operating conditions, such as dosage and algal solution characteristics (e.g., cell density, pH, and ionic strength) [50][51]. It should be noted that the sizes of the flocs formed through charge neutralization with conventional inorganic chemicals are generally small, requiring high dosage for algae flocculation. On the other hand, the bridging and sweeping reactions between polymeric flocculants and algal cells can lead to the formation of larger sized flocs, thereby promoting efficient biomass recovery at a relatively low dosage [24]. Table 3 briefly compares the different inorganic and organic chemical flocculants for algae harvesting.

F). Multivalent inorganic chemicals, biopolymers, or inorganic–orgure 4. A schematic diagram of chemicalanic hybrid polymers have been extensively used as algae-harvesting flocculants. Aluminum sulfate and ferric chloride are of the most popular inorganic flocculation harvents for wastewater clarification and algal biomass recovery [60]. Chitosan, cating of microalgae usonic starches, modified tannins, and polyacrylamides are examples of organic polymers that are widely used [32,61]. The harvesting efficiency of both orga cationic polynic and inorganic flocculants depends largely on their physicochemical properties such as solubility and electrolyte. Reprinted from Referencenegativity, as well as the operating conditions, such as dosage and algal solution characteristics (e.g., cell [52]density, pH, andistr ionic strength) [62,63]. It should be noted that the sibuzes of ted under the terms of the Creative Commons Attrihe flocs formed through charge neutralization with conventional inorganic chemicals are generally small, requiring high dosage for algae flocculation. On the other hand, the bridging and sweeping reactions between polymeric flocculants and algal cells can lead to the formation of larger sized flocs, thereby promoting efficient biomass recovery at a relatively low dosage [24]. Table 3 buriefly compares the differention License inorganic and organic chemical flocculants for algae harvesting.

Figure 4. A schematic diagram of chemical flocculation harvesting of microalgae using a cationic polyelectrolyte. Reprinted from Reference [29], distributed under the terms of the Creative Commons Attribution License.

Table 3. Comparison of inorganic and organic chemical flocculants for algae harvesting.

Figure 4. A schematic diagram of chemical flocculation harvesting of microalgae using a cationic polyelectrolyte. Reprinted from Reference [29], distributed under the terms of the Creative Commons Attribution License.

Table 3. Comparison of inorganic and organic chemical flocculants for algae harvesting.

|

Flocculant (Dosage) |

Alga (Cell Density or Volume) |

Optimal Harvesting |

Ref. |

||||||||||||||

|

Inorganic flocculant |

Al2(SO4)3 (1.2 g/L) |

Tetraselmis sp. KCTC12236BP (3 g/L) | |||||||||||||||

Botryococcus sp. | |||||||||||||||||

89% @ 15 min | |||||||||||||||||

Fe | |||||||||||||||||

3O4-embedded carbon microparticle | [ | 61][72] |

|||||||||||||||

~25 g/L | Chlorella sp. KR-1 (~2 g/L) | 99% @ 1 min |

[85] |

Cationic starches (0.01 g/L) |

S. dimorphus (0.12 g/L) |

95% @ 90 min |

[62][73] |

||||||||||

|

Cationic starches (1.4:1, w/w) |

S. obliquus |

90% @ 60 min |

[63][74] |

||||||||||||||

|

Cationic starches (119 mg/g cell) |

B. braunii (0.62 g/L) |

94% @ 20 min |

[64][75] |

||||||||||||||

|

Cationic starches (50 mg/L) |

S. limacinum (0.93 g/L) |

90% @ 20 min |

[55][66] |

||||||||||||||

[109] | |||||||||||||||||

Fe3O4–PEI nanocomposite | 0.02 g/L | C. ellipsoidea (0.75 g/L) | 97% @ 2 min |

[86] |

[110] |

||||||||||||

PEI-coated Fe3O4 | 0.2 g/L | S. dimorphus (1.8 g/L) | 82.7% @ 3 min |

[87] |

[111] |

Cationic starches (7.1 mg/L) |

C. vulgaris (0.75 g/L) |

90% @ 120 min |

[65][76] |

||||||||

|

Cationic starches (89 mg/g cell) |

C. pyrenoidosa (1.02 g/L) |

96% @ 20 min |

[64][75] |

||||||||||||||

|

Chitosan (10 mg/g cell) |

C. sorokiniana |

99% @ 45 min |

[66][77] |

||||||||||||||

|

Chitosan (120 mg/L)) |

C. vulgaris (1 g/L) |

99% @ 3 min |

[67][78] |

||||||||||||||

|

Chitosan (40 mg/L) |

Scenedesmus sp. A1 |

82% @ 60 min | |||||||||||||||

Fe3O4-carbon-microparticle | 10 g/L | Chlorella sp. KR-1 (2.0 g/L) | 99% @ 1 min |

[85] |

[109] |

[12] |

|||||||||||

|

Chitosan (30 mg/L) |

Chlorella sp. (3 × 107 cells/mL) |

97% @ 60 min |

[49][61] |

||||||||||||||

|

Chitosan (30 mg/L) + sodium alginate (40 mg/L) |

S. obliquus |

86% @ 60 min |

[68][40] |

||||||||||||||

|

Epichlorohydrin-n,n- diisopropylamine-dimethylamine (8 mg/L) |

Scenedesmus sp. (100 mL) |

>90% @ 30 min |

[69][79] |

||||||||||||||

|

Modified tannin (10 mg/L) |

M. aeruginosa (1 × 109 cells/L) |

97% @ 120 min |

[70][80] |

Poly-L-lysine (70–150 kDa, 0.5 mg/L) |

C. ellipsoidea (1 g/L) |

98% @ 75 min |

[73][83] |

||||||||||

5. Particle-Based Flocculation

Particle-based flocculation can potentially circumvent some drawbacks of conventional chemical flocculation such as bio-toxicity and difficulties related to chemical recovery. For these purposes, particle-based flocculants should be designed to be more efficient, recoverable, and/or have multi-functionalities other than algae recovery, such as cell disruption and lipid extraction [9]. Therefore, numerous research efforts have devoted effort towards the development of new and optimal nano/micro-particle-based flocculants. This section summarizes the recent progress in algae harvesting using the nano/micro-particle-based flocculants, namely aminoclay (AC)-based particles, magnetic particles (

), and more advanced multi-functional or recyclable particles.

Table 4. Comparison of particle-based flocculants for algae harvesting.

7. Conclusion

The importance of microalgae research is increasing in parallel with increasing demands for food, animal feeds, pharmaceuticals, and biofuels. However, moving from lab-scale to commercial-scale applications still requires extensive developments for reliable, cheap, and eco-friendly algae cultivation and harvesting processes. The specific flocculation process should be carefully selected and optimized comprehensively in consideration of various key factors such as efficiency, environmental impact, operating cost, value-added utilization of whole biomass, characteristics of algal species, and culture conditions.