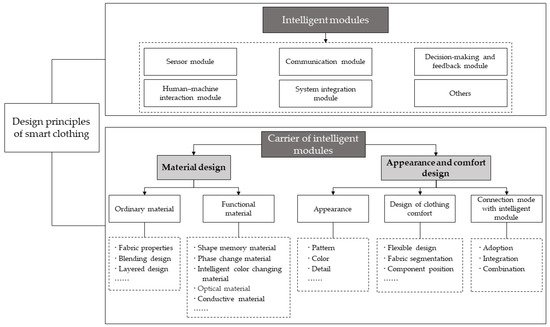

The difference between intelligent clothing and ordinary clothing is that it emphasizes people’s actual needs. In order to meet the requirement, smart clothing has a complicated manufacturing process, high cost and lots of design principles. In addition to style, color and fabric, designers focus on how to combine clothing with electronic information technology. Thus, the design principles can be summarized as intelligent module design and carrier design, in which carrier design includes material design and garments integral design (Figure 13).

3.1. Intelligent Modules

Intelligent module design is the core of its difference from traditional clothing design, which involves the frontier technologies in many fields. It can be divided into the following five aspects.

Sensor module is the key to realizing intelligent garments. It is used to convert non-electrical signals into electrical signals that are easy to process

[17][51]. Sensing technology can monitor heart rate, blood pressure, sweating rate and other physiological indexes, as well as the changes of environmental information such as temperature, pressure, location, etc. For example, baby pajamas developed by Rest Devices can sense the baby’s breathing and temperature through multiple built-in sensors, and the family can view the baby’s condition on an app to facilitate nursing

[18][52]. An Italian team Andretta developed a gas sensor and applied it to work clothes, achieving a great effect on gas safety monitoring

[19][53].

- 2.

-

Communication module

Communication module transmits the data and information collected by sensors. Communication technology greatly reduces the use of wires and facilitates data transmission. The communication between smart clothing and the data terminal is mainly based on Bluetooth, WiFi, NFC and other technologies. For example, a smart shirt launched by Arrow uses NFC to realize sending electronic business cards and playing music

[20][54]. Japanese researchers designed intelligent clothing that prevents the elderly from getting lost by combining WiFi with GPS, which is convenient for families to know the elderly’s location in real time and ensure travel safety for the old

[21][55].

- 3.

-

Decision-making and feedback module

Decision-making and feedback module is a unit for information collection, processing and transmission. In smart clothing, it is mainly used to extract, transform and analyze the collected physiological or environmental signals, make judgments according to default information and trigger further reactions

[22][56]. Smart clothing can realize communication with people, no matter what the communication form is (e.g., text display, voice feedback, image presentation, etc.). The decision-making and feedback module is essential to process signals and improve reasonable services and guidance.

- 4.

-

Human–machine interaction module

Human–machine interaction module builds a communication bridge between users and clothing. Human–machine interaction technology, originated from the computer field, is a technology that produces an interactive relationship with the surrounding environment and other organisms through language or behavior based on the needs of users

[23][57]. At present, human–machine interaction technology generally achieves speech recognition, face recognition, gesture analysis and other functions by identifying and analyzing sound, image and other signals.

- 5.

-

System integration module

System integration module integrates separated modules and function into an interrelated and unified system through computer network technology so as to achieve resource sharing and efficient management

[24][58]. System integration technology includes module integration and function integration. Module integration is the integration of electronic components into a single package, mainly relying on packaging and miniaturization technologies. Function integration refers to the connection and interaction between devices to make function configuration reasonable, which mainly relies on wireless body area network technology, a technology that transmits data to an intelligent terminal by wireless communication technology

[25][59]. For example, users’ ECG, pulse, respiration and blood oxygen are monitored at the same time.

3.2. Carrier of Intelligent Modules

In addition to the advanced technologies, the intelligence of garments cannot be realized without the design of a carrier. Carrier design can be roughly divided into material design and garment integral design.

The materials used in smart clothing include ordinary fabrics and functional material. The former are used as functional carriers to ensure the basic wearing performance of clothing, whereas the latter is used to improve the functionality of clothing based on the unique properties of fibers.

The adaptability of intelligent components, clothing comfort and usage scenarios should be considered for fabric design. Because the properties (e.g., rigidity and extensibility) of electronic devices such as sensors and processors are quite different from ordinary yarns, the fabric yarns should be selected flexibly according to the position, embedding mode and functional requirements of electronic components. For example, the fabric for emergency rescue should have high strength, high toughness, good permeability and water resistance

[5][42]. In order to improve the comfort of clothing, combining intelligent materials with ordinary yarns through blending or knitting is a common way. For example, phase-change materials are added to underwear fabric to regulate body temperature, and conductive yarn is blended with ordinary cotton yarn to improve the feel and look of the fabric. In addition, fabric layered design is also commonly used in smart clothing, for example, physiological monitoring intelligent clothing applied in fire protection and military. In order to accurately perceive the changes in workers’ health condition, the intelligent module should be in close contact with the skin, and thus it is generally placed in the inner layer, which should have the properties of moisture absorption, ventilation, heat transmission and fast drying. The second layer of fabric is used for thermal insulation and minimizing external signal interference. Finally, in order to improve the protection capability further, a third layer can be added to improve the performance in wind resistance, water repellency, temperature resistance and acid resistance

[26][60].

Functional materials have the functions of sensing information, processing information, self-diagnostics, self-repair and so on

[27][61]. The common materials used in intelligent clothing include shape-memory materials, phase-change materials, intelligent color-changing materials, optical materials and conductive materials. Shape-memory material is able to return to its original shape with the right thermal, optical, etc., stimuli

[28][62]. It is mainly applied in clothing for fitness and posture adjustment. Phase-change material enables garments to regulate temperature by sensing ambient temperature

[29][63]. The material is usually applied in pockets, necklines and other positions and is suitable for athletes, sanitation workers, smelting workers, etc. Intelligent color-changing material is divided into photochromic and thermochromic, mainly applied for leisure and recreation, as well as acting as a warning. Optical material is used to sense and transmit data and provide real-time and accurate system information and is widely applied in all kinds of sensors

[30][64]. Conductive material is able to connect various electronic modules to ensure the system works properly

[28][62]. In addition to serving as a connection, conductive fibers are also widely used in flexible sensors. For example, American Circuitex weaved conductive fibers into clothing as sensors to monitor the health status of patients

[31][65]. In addition, with the development of biochemical technology, more new intelligent materials have been developed, such as antibacterial material

[32][66] and anti-impact material

[33][67]. Wang et al.

[34][68] tried to improve the tensile properties and conductivity of fibers applied to smart textiles. Tokyo University developed an invisibility cloak based on visual camouflage, which is made of retro-reflective fibers

[30][64].

- 2.

-

Appearance and comfort design

The style design of smart clothing requires designers to improve the fashion sense while ensuring garment practicability. Similar to ordinary clothing, the characteristics of targeted consumers should be considered. For example, in terms of color selection, simple and elegant color matching are suitable for the elderly while bright and bold colors are better for the young. In pattern design, children’s clothing needs to emphasize fun and novelty. For example, most children prefer vivid and lovely patterns such as cartoon, letter and bionic figures. It is suggested that the concealment of intelligent components be considered in the pattern design. It is necessary to reduce the presence of electronic components through proper arrangement of pattern color, position and shape. In addition, the feedback mode of smart clothing also affects the design. For example, the LED display screen is generally placed on the back, and the light-emitting module is generally built in hems and cuffs. Other detailed designs such as laces and folds can not only play a decorative role but also enhance the concealment of electronic components.

For smart clothing, it is difficult to balance functionality and comfort. For example, the hardness, rigidity and volume of electronic components may cause foreign body feeling or even tingling. At present, flexible electronic technologies (e.g., flexible sensor, skin electronic patch, thin-film battery, flexible screen) tend to be used for improving the comfort of intelligent clothing. For example, Coosemans et al.

[35][69] integrated sensors made of mixed textile materials into baby pajamas. In addition, fabric segmentation design is also a widely used method to improve the comfort of intelligent clothing. Different fabrics should be selected according to the contact area with the skin. For example, fabric close to the neck and the elbow should be soft and elastic

[36][70]. In addition, the position of intelligent components also affects the wearing comfort; thus the areas susceptible to large activity and dirt such as cuffs and necklines should avoid electronics. For example, Liu

[37][71] designed a zipper on the front of the T-shirt to place the locators.

The connection manner between the carrier and the intelligent module is a vital part in smart clothing design. The traditional method makes intelligent components separate from textiles, that is, textiles as a platform for embedded electronics (e.g., pockets)

[38][72]. Pockets are generally located in side seams, hems, hats, etc. As the technology develops, intelligent materials are better integrated with textiles, and thus softer connection modes emerged. For example, the electronic devices are embedded in zippers and buttons

[39][73] or with seamless connection between the intelligent elements and ordinary fabrics by knitting

[40][74], embroidery

[41][75] and coating

[42][76]. Recently, the progress of biochemical technology has inspired designers to directly adopt textile materials with inherent functionalities without considering the connection mode. For example, Solar Active developed yarns that are able to change into orange, blue, red and other colors under ultraviolet irradiation, which can be directly used to make intelligent color-changing clothing

[43][77]. Berzowska et al.

[44][78] designed a shape-memory material in the shape of flowers to decorate the shoulder of a dress, with flowers blooming and closing to the change of temperature.

Various intelligent wearable devices are sprouting up with technological advancements. Wearable devices are the combination of microelectronic devices with daily wearable products

[2][39], such as glasses, watches, backpacks, etc. However, these products have long-term discomfort, insufficient accuracy and many other disadvantages; thus health monitoring through traditional wearable devices is difficult to sustain. In addition, due to the small contact area between wearable devices and the skin, the types and accuracy of collected physiological parameters are relatively limited

[45][79], resulting in the functions being unable to meet the requirements of consumers. As a kind of intelligent wearable device, clothing is in direct contact with about 90% of the skin

[46][80], which has a wider monitoring range and gains more accurate results. Thus, the key to achieving continuous innovation and vitality for smart clothing is to integrate functional components into daily textiles in a softer way, which not only meets the basic needs of consumers for covering and keeping warm but also satisfies the functional needs of physiological monitoring, health protection, leisure and recreation.