You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Bruce Ren and Version 1 by Baojun Zhao.

Bottom-blowing copper smelting technology was initiated and developed in China in the 1990s. Injection of oxygen-enriched high-pressure gas strongly stirs the molten bath consisting of matte and slag. Rapid reaction at relatively lower temperatures and good adaptability of the feed materials are the main advantages of this technology. Development and optimisation of bottom-blowing copper smelting technology were supported by extensive studies on the thermodynamics of the slag and the fluid dynamic of the molten bath.

- copper smelting

- bottom-blowing

- SKS

- slag

- fluid dynamic

1. Introduction

Smelting is one of the important processes in the pyrometallurgical production of blister copper in which copper–iron sulphides are oxidised to form molten matte and slag. Flash smelting and bath smelting are the major smelting technologies in copper production. Copper concentrates react with oxygen directly in the flash smelting process which has the advantages of high capacity and automatic control. However, fine and dry feeds are required for the flash smelting furnace to enable fast reactions. As a result, considerable feed preparation is required, and the dust rate is relatively higher. It has limited ability to treat scrap and other copper-containing materials with large sizes. Bath smelting is an alternative technology to flash smelting which involves the reactions of copper concentrate with oxygen in the molten bath. Several technologies have been developed based on the bath smelting principles that include IsaSmelt/Ausmelt, Noranda/El Teniente, Vanyukov, Mitsubishi and recently developed bottom-blowing smelting (BBS) process [1,2,3,4][1][2][3][4]. Due to its unique technological features, such as good adaptability to raw materials, high oxygen utilisation and thermal efficiency, and flexible capacity, BBS technology has attracted strong interest from the copper industry [5,6,7,8,9,10,11,12,13,14][5][6][7][8][9][10][11][12][13][14]. In 2016, 13 BBS furnaces were constructed or were under construction with the capacity of 1600 kt/a copper production. The furnace size ranged from Ø3.8 m × 11.5 m to Ø5.8 m × 30 m [5,14][5][14]. The fundamental studies including thermodynamics of the slag and fluid dynamic of the molten bath have been extensively conducted in recent years to understand and support the new technology. This review summarises the development of the copper BBS including the history, features and relevant fundamental studies.

2. History of Technology Development

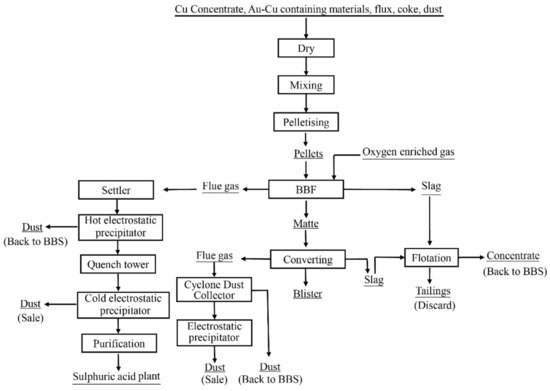

From November 1991 to June 1992, a plant trial was conducted at Shuikoushan (SKS) Smelter for a period of 217 days to smelt copper concentrate in a bottom-blowing furnace [15,16][15][16]. The name of SKS Smelting Technology was therefore used initially to represent the bottom-blowing copper smelting technology. Figure 1 below shows the flowsheet of the SKS trial [16]. It can be seen from the figure that carbon fuel was used during the trial, and the feeds were palletised during the trial. The smelting slag was treated by flotation process to recover copper and the concentrate from the flotation was sent back to the bottom-blowing furnace (BBF). Only the coarse flue dust from the BBF and PS converter was sent back to the BBF. The detailed operating parameters are given in Table 1. It can be seen from Table 1 that the BBF treated 50 t feeds per day during the trial and Cu in the concentrate was approximately 20%. Matte with 50% Cu was produced and Cu in the slag was in the range of 1–3%. Oxygen utilization at 100% was claimed and a lance life of 5000 h was estimated.

| Parameter | Unit | SKS |

|---|---|---|

| Capacity | t/d | 50 |

| Cu in Concentrate | % |

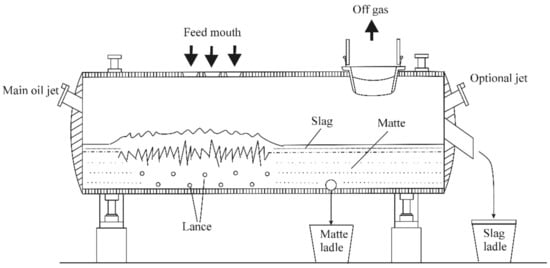

]. However, the BBF in Sin Quyen smelter seemed not operating properly as no operating details were reported. In 2008 the first real commercialised BBF started in Dongying Fangyuan Nonferrous Metals (Fangyuan) [7]. The main equipment was a horizontal cylindrical furnace shown in Figure 2. The size of the furnace was Φ 4.4 m × 16.5 m and it was lined with 380 mm thick chrome-magnesia bricks. The BBF had nine gas lances arranged in two rows on the bottom, five lances at 7 degrees and four lances at 22 degrees towards the outside. Each lance consisted of an inside tube and an external shroud. The inside tube injected pure oxygen and the shroud injected airflow as a coolant to protect the lance. The furnace operated with a rotation mechanism so the lances could be rolled above the molten bath during maintenance, repair, power failure or another emergency. Mixed feed materials with 7–10 wt% moisture were continuously transported by a belt conveyor into the high-temperature melt in the furnace through a feed mouth located above the reaction zone. High-pressure oxygen and air were blown constantly by the lances into the copper matte, in which iron and sulphur were rapidly oxidised. The by-product SO2 was sent to the acid plant and the slag was tapped regularly followed by the flotation process to recover copper. Matte was tapped regularly and sent to the PS converters by a ladle.

Figure 2. The bottom-blowing furnace at Dongying Fangyuan Nonferrous Metals. Reprinted with permission from ref. [7]. Copyright 2021 John Wiley and Sons.

Table 2 shows key process parameters in the Fangyuan smelting plant in January 2012 compared with the initial design. The effort made by the management and engineers enabled unexpected performance to be achieved in the first commercialised BBF. Differently from the trials in Shuikoushan, the following advantages were demonstrated in the Fangyuan BBF:

- (1).No carbon fuel was used—no CO2 was generated.

- (2).Feed preparation was not required—up to 100 mm size could be fed into the BBF directly.

- (3).High-grade matte with 70% Cu was produced—more concentrate could be treated.

- (4).Concentrate feed rate increased from 32 to 75 dry t/h—the furnace capacity was more than doubled.

Table 2. Typical process parameters for Fangyuan smelting plant in January 2012. Data derived from [7].

| Parameter | Unit | Design | January 2012 | |||||

|---|---|---|---|---|---|---|---|---|

| Maximum concentrate feed rate | dry t/h | 32 | 75 | |||||

| ~20 | ||||||||

| Average concentrate feed rate | dry t/h | 32 | 70 | Fe in Concentrate | % | ~26 | ||

| Average Cu content in concentrate | % | 25 | 22 | S in Concentrate | % | 25~30 | ||

| Average moisture of the feed | % | 8 | 7 | Matte grade | % | ~50 | ||

| Average silica flux feed rate | dry t/h | Cu in slag | % | 1~3 | ||||

| - | Slag clean | - | flotation | |||||

| 8 | ||||||||

| Average coal feed rate | dry t/h | 2.46 | 0–0.8 | |||||

| Total average feed to the furnace | wet t/h | - | 90 | Cu in tailing | % | 0.34 | ||

| Average copper matte grade | % | 55 | 70 | Fe/SiO | 2 | in slag | ||

| Average Fe/SiO | 2 | - | in slag | - | 1.5~1.7 | |||

| 1.7 | 1.8 | O | 2 | in gas | vol% | 60~70 | ||

| Average Cu in smelting slag | % | 4 | 2.6 | Oxygen pressure | Mpa | 0.5~0.7 | ||

| Average Cu in flotation tailing slag | % | 0.42 | 0.3 | O | 2 | utilisation | % | 100 |

| Lance life | hour | 5000 | ||||||

| Average oxygen + air flow rate | Nm | 3 | /s | - | 4.2 | |||

| Average oxygen enrichment | % | 70 | 72 | Production rate | % | 81.4 | ||

| Bath temperature range | °C | 1180–1200 | 1150–1170 | SO | 2 | in gas | vol% | >20 |

| Cu direct recovery | % | 93 | ||||||

| Cu total recovery | % | 98 | ||||||

| Furnace campaign life | day | >330 |

In 2005 the first industrial scope BBF was built in Sin Quyen smelter in Vietnam. The size of the furnace was Ø3.8 m × 11.5 m and the capacity was designed to be 10,000 t Cu per year [6,17][6][17

Compared with other bath smelting technologies, BBF shows several advantages:

- (1).Less preparation of feeds

Top blowing technology (Ausmelt and Isasmelt) requires pelletised feeds and side blowing technology (Teniente Converter) needs to inject dry and fine particle feeds. BBF can treat a wide range of size feeds up to 100 mm diameter with moisture up to 10%.

- (2).High gas pressure and long lance life

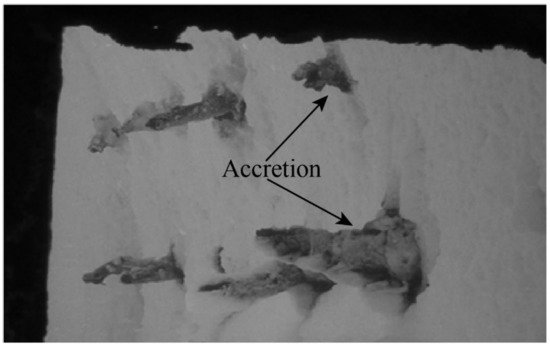

Much higher gas pressure in BBF has many advantages confirmed by Kapusta et al. [18,19,20,21,22,23][18][19][20][21][22][23]. As one of the significant developments at Fangyuan, a series of trials were undertaken to identify the optimum pressures of the oxygen and air in the lances. It was found that optimum gas pressures were related to the feeding rate, the viscosity of the slag, thicknesses of the slag and matte layers. The following requirements need to be met: (1) no backflow of matte into the lances; (2) enough stirring for rapid reactions and generation of the surface wave; (3) no strong splashing of the slag and matte to block the feed mouth and (4) a protection accretion is formed at the tip of the lance. Figure 3 shows the “mushroom” formed at the tip of the lances which enabled the lance life to be over 10 months [7]. These mushroom tips not only protect the lances but also distribute the injected gases to small bubbles.

Figure 3. “Mushroom” tips formed on the lances of the Fangyuan BBF. Reprinted with permission from ref. [7]. Copyright 2021 John Wiley and Sons.

- (3).Autogenous Smelting

Autogenous operation was achieved in the BBF at Fangyuan for smelting of normal copper concentrates. This operation reduced energy consumption and CO2 emission. The autogenous smelting was obtained by (1) low-temperature operation; (2) low slag rate resulting in a high Fe/SiO2 ratio; (3) low off-gas volume resulting in high oxygen concentration; (4) high thermal efficiency as most of the oxidisation reactions occur in the lower part of the bath, the heat generated from these reactions can be efficiently absorbed by the molten matte and slag.

- (4).Low-Temperature Smelting

The slag temperatures measured at the taphole of the Fangyuan BBF were usually in the range of 1150 to 1170 °C which was much lower than the liquidus temperature of the slag [7,24][7][24]. Approximately 20% solid spinel was present in the slag which increased the slag viscosity significantly. High-pressure gases injected from the bottom of the molten bath can generate surface waves that push the viscous slag out of the furnace through the taphole. The advantages of low-temperature smelting are (1) no extra fuels are required to maintain smelting temperature (although oil jets were available on both ends of the BBF, they were rarely used); (2) low consumption of the refractory. There was no significant erosion of the refractory on most parts of the furnace after one and a half years operation since spinel accretion was formed to protect the refractory [24,25,26,27][24][25][26][27]; (3) relatively higher viscosities of the matte and slag allowed higher pressures of the injected gases without strong splashing; (4) a higher-grade matte can be produced at a lower temperature at a given oxygen partial pressure.

References

- Schlesinger, M.; Sole, K.; Davenport, W.; Alvear, G. Chapter 5—Theory to practice: Pyrometallurgical industrial processes. In Extractive Metallurgy of Copper, 6th ed.; Elsevier: Oxford, UK, 2021; pp. 95–117. ISBN 9780128218754.

- Gonzales, T.W.; Walters, G.; White, M. Comparison of Smelting Technologies. In Proceedings of the 58th Annual Conference of Metallurgists (COM) Hosting the 10th International Copper Conference 2019, Vancouver, BC, Canada, 18–21 August 2019; p. 602421.

- Wang, J. Copper smelting: 2019 world copper smelting data. In Proceedings of the 58th Annual Conference of Metallurgists (COM) Hosting the 10th International Copper Conference 2019, Vancouver, BC, Canada, 18–21 August 2019; p. 592732.

- Watt, J.; Kapusta, J.P.T. The 2019 copper smelting survey. In Proceedings of the 58th Annual Conference of Metallurgists (COM) Hosting the 10th International Copper Conference 2019, Vancouver, BC, Canada, 18–21 August 2019; p. 595947.

- Cheng, L.; Wang, Z.; Jiang, J.; Huang, Q. The SKS copper smelting process in China. In Volume VI-Smelting, Technology Development, Process Modelling and Fundamentals, Proceedings of Copper 99-Cobre International Conference, Phoenix, AZ, USA, 10–13 October 1999; Diaz, C., Landolt, C., Utigard, T., Eds.; The Minerals, Metals, and Materials Society: Warrendale, PA, USA; pp. 83–91. ISBN 0873394356.

- Liang, S. A review of oxygen bottom blowing process for copper smelting and converting. In Proceedings of the 9th International Copper Conference (Copper 2016), Kobe, Japan, 13–16 November 2016; pp. 1008–1014.

- Zhao, B.; Cui, Z.; Wang, Z. A new copper smelting technology—Bottom blown oxygen furnace developed at Dongying Fangyuan Nonferrous Metals. In Proceedings of the 4th International Symposium on High-Temperature Metallurgical Processing, San Antonio, TX, USA, 3–7 March 2013; pp. 3–10.

- Cui, Z.; Shen, B.; Wang, Z.; Li, W.; Bian, R. New process of copper smelting with oxygen enriched bottom blowing technology. Nonferr. Met. Extr. Metall. 2010, 3, 17–20. (In Chinese)

- Chen, Z. The application of oxygen bottom-blown bath smelting of copper. China Nonferr. Metall. 2009, 5, 16–22. (In Chinese)

- Qu, S.; Li, T.; Dong, Z.; Luan, H. Plant practice of and design discussion on oxygen enriched bottom blowing smelting. Nonferr. Met. Extr. Metall. 2012, 3, 10–13. (In Chinese)

- Du, X.; Zhao, G.; Wang, H. Industrial application of oxygen bottom-blowing copper smelting technology. China Nonferr. Metall. 2018, 4, 4–6. (In Chinese)

- Wang, H.; Yuan, J.; He, R.; Wang, X. Plant practice of copper oxygen enrichment bottom blowing smelting. Nonferr. Met. Extr. Metall. 2013, 10, 15–19. (In Chinese)

- Su, G.L. Discussion on practice of “blowing oxygen at the end of the catch matte” smelting. China Nonferr. Metall. 2010, 4, 5–8. (In Chinese)

- Yan, J. Recent operation of the oxygen bottom-blowing copper smelting and continuous copper converting technologies. In Proceedings of the 9th International Copper Conference (Copper 2016), Kobe, Japan, 13–16 November 2016; pp. 13–16.

- He, S.; Li, D. Discussion on issues related to Shuikoushan Copper Smelting process. China Nonferr. Metall. 2005, 34, 19–22. (In Chinese)

- He, S.; Li, D. SKS copper smelting process. China Nonferr. Metall. 2006, 35, 6–9. (In Chinese)

- Liang, S.; Chen, Z. Application and development of oxygen enriched bottom-blowing copper smelting technology furnace. Energy Sav. Nonferr. Metall. 2013, 4, 16–19. (In Chinese)

- Kapusta, J.P.T. Implementation of air liquid shrouded injector (ALSI) technology at the Thai copper industries smelter. In 2007 International Copper Conference: The Carlos Diaz Symposium On Pyrometallurgy, Toronto, ON, Canada, 25–30 August 2007; Warner, A.E.M., Newman, C.J., Vahed, A., George, D.B., Mackey, P.J., Warczok, A., Eds.; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 2007; Volume 3, pp. 483–500. ISBN 1-894475-73-9.

- Kapusta, J.P.T.; Larouche, F.; Palumbo, E. Adoption of high oxygen bottom blowing in copper matte smelting: Why is it taking so long? In Proceedings of the Torstein Utigard Memorial Symposium, Toronto, Canada, 23–26 August 2015; The Materials and Metallurgical Society of CIM: Montreal, QC, Canada, 2015; pp. 1–25.

- Kapusta, J.P.T. Submerged gas jet penetration: A study of bubbling versus jetting and side versus bottom blowing in copper bath smelting. JOM 2017, 69, 970–979.

- Coursol, P.; Mackey, P.J.; Kapusta, J.P.T.; Cardona Valencia, N. Energy consumption in copper smelting: A new Asian horse in the race. JOM 2015, 67, 1066–1074.

- Kapusta, J.P.T. Gas jet penetration, smelting intensity, and oxygen efficiency in side blowing versus bottom blowing. In Proceedings of the 9th International Copper Conference (Copper 2016), Kobe, Japan, 13–16 November 2016; pp. 1282–1305.

- Kapusta, J.P.T.; Lee, R.G.H. The Savard-Lee shrouded injector: A review of its adoption and adaptation from ferrous to non-ferrous pyrometallurgy. In Proceedings of the 6th International Copper Conference (Copper 2013), Santiago, Chile, 1–4 October 2013; pp. 1115–1151.

- Chen, M.; Cui, Z.; Wei, C.; Zhao, B. Degradation mechanisms of refractories in a bottom blown copper smelting furnace. In Proceedings of the 9th International Symposium on High-Temperature Metallurgical Processing, Phoenix, AZ, USA, 11–15 March 2018; pp. 149–157.

- Chen, M.; Jiang, Y.; Cui, Z.; Wei, C.; Zhao, B. Chemical degradation mechanisms of magnesia–chromite refractories in the copper smelting furnace. JOM 2018, 70, 2443–2448.

- Chen, M.; Zhao, B. Investigation of the accretions in the bottom blown copper smelting furnace. In Proceedings of the 9th International Copper Conference (Copper 2016), Kobe, Japan, 13–16 November 2016; pp. 1184–1194.

- Xu, L.; Chen, M.; Wang, N.; Gao, S. Chemical wear mechanism of magnesia-chromite refractory for an oxygen bottom-blown copper-smelting furnace: A post-mortem analysis. Ceram. Int. 2021, 47, 2908–2915.

More