Natural polymers like polysaccharides and proteins, i.e., alginate; carrageenan; chitosan; starch; pea protein, are important materials obtained from renewable plant, algae and animal sources, as well as from agroindustrial residues. Historically, some of them have been widely used by ancient populations for food packaging until these were replaced by petroleum-based plastic materials after World War II. Nowadays, biobased materials for food packaging have attracted attention. Their use was boosted especially because of the environmental pollution caused by inappropriate disposal of plastic packaging. Biobased materials are welcome to the design of food packaging because they possess many advantages, such as biodegradability, biocompatibility and low toxicity. Depending on the formulation, certain biopolymer-based packaging may present good barrier properties, antimicrobial and antioxidant activities Thus, polysaccharides and proteins can be combined to form diverse composite films with improved mechanical and biological behaviors, making them suitable for packaging of different food products.

1. Introduction

Plants, algae and marine seafoods are important resources to obtain natural polymers that can be used for designing sustainable packaging. Historically, different natural materials, e.g., plant and animal parts, shells, ceramics, and others, were the firstly used materials by the ancient populations for food packaging

[1]. The Industrial Revolution and the World War II were significant events that boosted the discovery, design of new packaging materials and novel processing strategies. Aluminum cans by canning operation and the coming up of petroleum-based plastics are some typical examples

[2][3][2,3]. Afterwards, conventional plastics were extensively used for packaging. As their majority has a single use only, usually ends up polluting landsites and aquatic environments. It was estimated that, only in 2015, around five billion tons of plastic waste ended up in natural sites

[4]. Because of this problem, reducing petroleum-based pollution should be top priority of all nations around the world. More than 170 United Nations Member States have committed to reduce the use of plastics until 2030

[4]. In this way, replacing conventional plastics for biobased materials is a sustainable approach that contributes to reducing plastic pollution. Consequently, the synthesis and use of biobased materials for packaging design has increased over the past few years.

Besides being environmentally friendly and emitting low greenhouse gases, natural materials can be obtained from different renewable sources, such as plants, animals, microorganisms and their residues, making them extensively available

[5]. This is also an advantage when compared to conventional plastic polymers, since the latter are petroleum-based, a nonrenewable resource. Natural polymeric materials, such as plant- or marine-based polysaccharides and proteins, are naturally biodegradable, which means that they can be degraded by local microorganisms and return to nature

[6]. Natural polymers have important technological and biological properties, which allow their utilization for food packaging. Generally, these materials display good film-forming and gelling properties, which leads to consider them distinguishable and sustainable choices to prepare edible films and coatings. When applied to this end, biopolymeric films may exhibit some processing challenges. They present brittleness, low water and gases barrier properties, inferior mechanical behavior, characteristic of their nature

[7]. The incorporation of hydrophobic substances or blending two or more biopolymers to form composites consist of alternative approaches to overcome these technological issues

[8].

2. Some Natural and Renewable Macromolecules Used to Prepare Edible Films and Coatings

A wide range of natural polymers from renewable sources has been used in the development of biobased food packaging. The main natural sources for this purpose are derived from polysaccharides, proteins, lipids, or blends of these macromolecules

[9][10][36,37] (

Figure 13). The utilization of these natural materials is partly linked to its biodegradability and renewability. However, some other advantages are expected when used for food packaging, e.g., as these materials can act as carriers of functional substances adding well-being benefits, incorporating flavorings and colorings aspects, enhancing organoleptic characteristics, improving mechanical and barrier resistance, and others

[8].

Figure 13. Major natural biological materials used in food biobased packaging.

Polysaccharides are known to possess good oxygen barrier and to have sites for hydrogen bonding formation, which can be used for incorporation of functional substances, e.g., coloring, flavoring, and antioxidants agents. By contrast, these materials do not exhibit good barrier to water vapor, which can be overcome by blending with other hydrophobics macromolecules, such as lipids

[7][8][7,8]. Polysaccharides have been used to develop natural-based packaging

[7][9][7,36].

Plant-derived proteins have gained remarkable attention of food manufactures and consumers in search for natural food resources and alternative materials to vegetarian, vegan, and food allergy diet restrictions. Protein-based film packaging exhibit extraordinary mechanical and barrier properties, especially to oxygen and carbon dioxide gases, when compared to polysaccharides

[7][11][7,38]. Besides being eco-friendly materials, these films can nutritionally improve food quality and preservation. Moreover, the amphiphilic attribute of proteins contributes to their utilization as emulsifiers by stabilizing oil/water interface due to changes in interfacial tension

[12][39]. Nowadays, a great variety of plant proteins have been used in food industry and packaging, such as from soybean, wheat, corn, sunflower, and pea

[13][40].

Edible films can be defined as a thin layer of a material coating or placed between foods, in which act as a barrier ad that can be consumed without any health risk

[8][11][8,38]. Both are a primary food packaging and can be thought similar, although they differ substantially. Mainly, films are solid laminates, separately prepared, dried, processed and then used to cover food surface, placed between food parts, or used as an edible sealed bag

[7][14][7,41]. Differently, coatings are prepared as a solution, directly sprayed or dipped on the food surface and then dried

[15][42]. Thus, coatings can be considered as a part of the food product, since they are not made to be removed

[8]. Moreover, films can be prepared as a mono, bi or multilayers. The latter provide a better water barrier to food but are less commonly used as they need two or more processing steps of casting and drying

[7].

Both films and coatings should be composed only by food-grade components, GRAS (Generally Recognized as Safe), including any additives, such as plasticizers

[15][42]. As any other packaging, these materials must protect the food integrity and maintain its quality

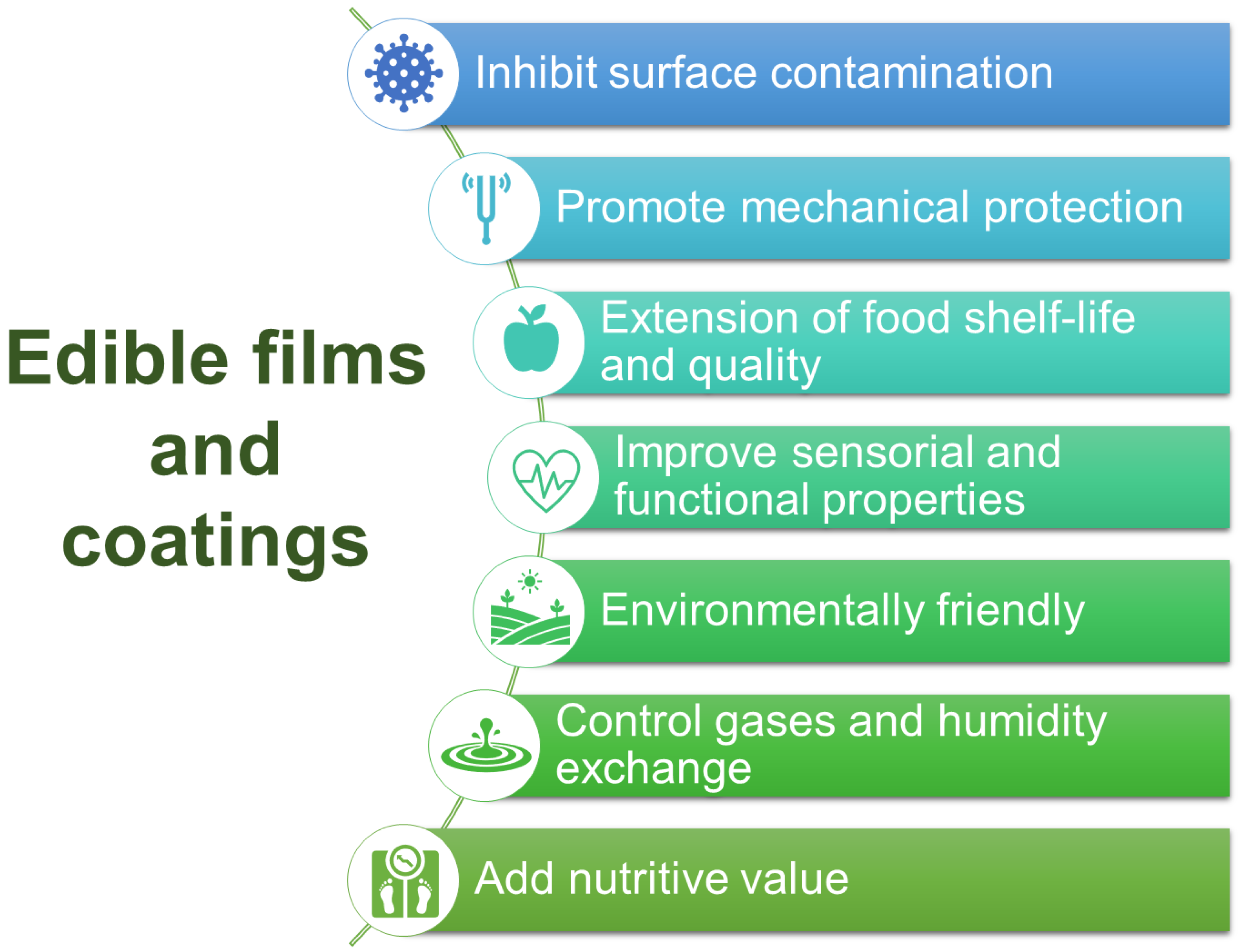

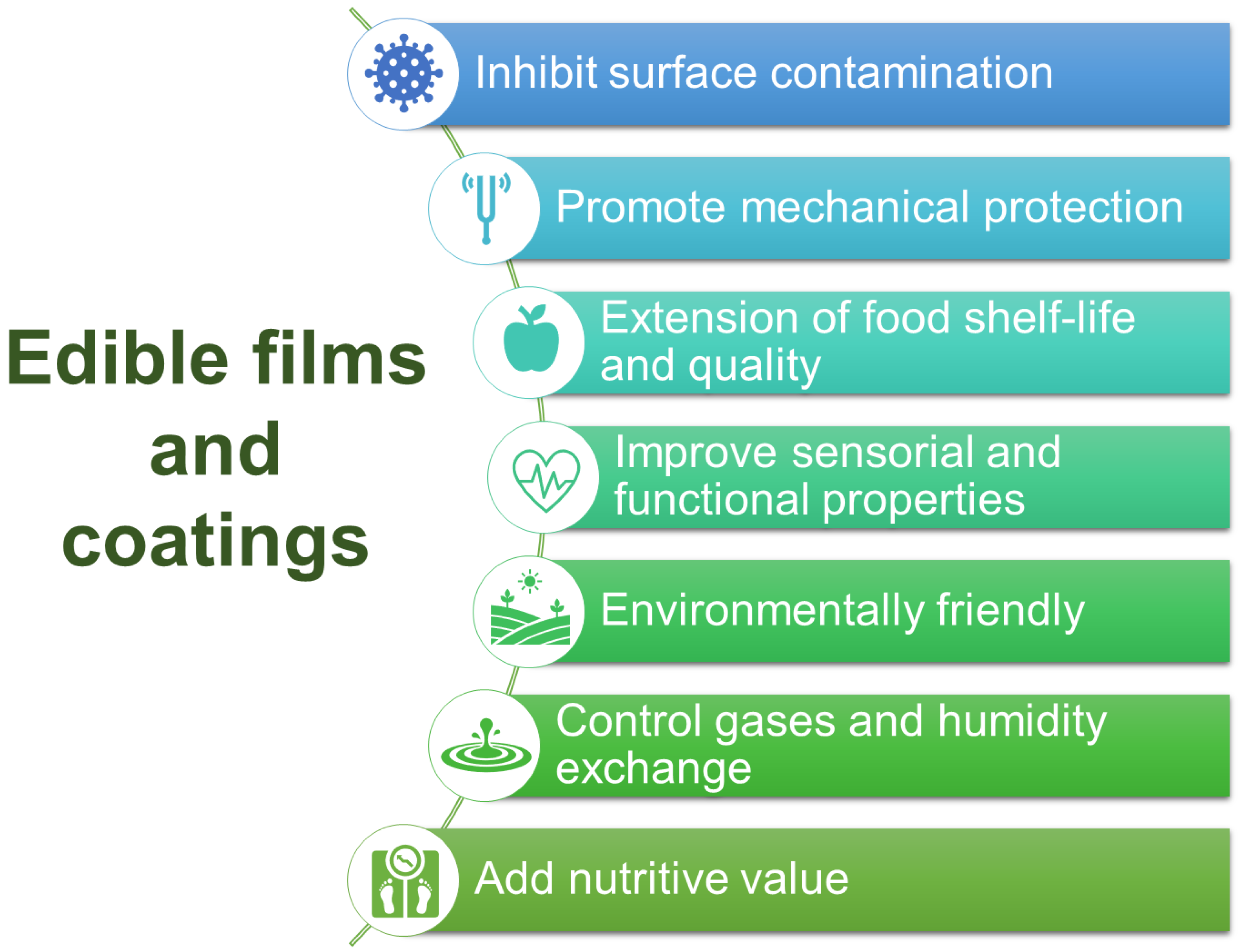

[8][14][15][8,41,42]. In

Figure 24 is presented the main purposes of edible food packaging. Although, it is not expected that the edible films could replace completely all conventional packaging, they can be used to significantly reduce the use of petroleum-based plastics, decrease food losses, and reduce the environment pollution over a long-term.

Figure 24. Main purposes of edible food packaging.

Edible films and coatings may have in their composition two main based materials, a biomacromolecule matrix and additives, such as plasticizers, cross-linkers, other reinforcements substances and functional ingredients

[16][14]. These materials can be used alone or blended. Edible packaging composed by natural-based materials can be classified as a subgroup of biobased and biodegradable packaging

[8]. Generally, polysaccharides, proteins, lipids, and their mixtures are used for the development of edible films and coatings. The classification and some examples of these natural materials commonly used for this purpose are presented in

Table 1.

Table 1.

Natural materials used in edible films and coatings.

| Biomacromolecules |

Raw Materials |

References |

| Polysaccharides |

Agar |

[17][43] |

| Alginate |

[18][44] |

| [ | 43 | ] | [ | 69] |

Cellulose |

[19][45] |

| Κ-carrageenan |

0.2–0.8% (w/v) |

0–1% glycerol (w/v) |

Papaya (Carica papaya) |

[22][48] |

Chitosan |

[20][46] |

| Sodium alginate |

0, 1 and 3% (w/v) |

20% glycerol (v/v) |

Plum (Prunus salicina) |

[44][70] |

Gums |

[21][47] |

| Sodium alginate |

1.5% (w/v) |

Ficus hirta extract, 0.7% citric acid and 1.0% sucrose ester (w/v) |

Nanfeng mandarin (Citrus reticulata) |

[45][71] |

K-carrageenan |

[22][23][48,49 |

| Starch/chitosan | ] |

| 2%/0.5–1.0% ( | w/v) |

2% glycerol (w/v) |

Apples Fuji cultivar |

[27][53] |

Pectin |

[24][50] |

| Starch/gelatin |

3–5%/10% (1:1) |

10% sorbitol |

Red Crimson grapes |

[46][ |

Pullulan |

[25][51] |

| Starch |

[26][27][52,53] |

| Proteins |

Casein |

[28][54] |

| Collagen |

[29][55] |

| Corn zein |

[30][56] |

| ] |

| [ |

| 62 |

| ] |

Edible coatings can be used to decrease weight loss, color changing, inhibit ethylene production and delay softening related to the postharvest ripening of fruits

[42][68]. Different natural polymers, such as chitosan, carrageenan, alginates, gums, starches, their blends, and a wide range of additives can be used to prepare edible coatings and to be applied on fruits, as listed in

Table 2.

Table 2.

Edible coatings applied on fruits.

| Matrix |

Concentration |

Additives |

Food Product |

Reference |

| Carboxymethyl chitosan/pullulan |

Different mixing ratio of 5:0, 4:1, 3:2, 2.5:2.5, 2:3 and 1:4 (w/w) |

8% galangal essential oil and 20% glycerol (w/w) |

Mangoes |

[25][51] |

| Chitosan |

1% (w/v) |

40 mmol L−1 of ascorbic acid |

Plums (Prunus salicina) |

| 72 |

| ] |

| Xantham gum |

| 2.5 g L | −1 |

1.0 g L−1 cinnamic acid |

Pears (Pyrus pyrifolia and P. communis) |

[ |

| Gelatin |

| [ |

| 19 | ][45] |

| Pea protein |

[31][57] |

| Sodium caseinate |

[24][50] |

| Soy protein |

[32][58] |

| Wheat gluten |

[33][59] |

| Whey protein |

[34][60] |

| Lipids |

Candelilla wax |

[35][61] |

| 21 | ] | [ | 47 | ] |

Bee wax |

[36 |

| Vegetable oils |

[37][63] |

| Composites |

Blends |

[5][25]51[28],54[29],55[34][5,,60] |

| Residues and by-products from agriculture |

[38][39][40][64,65,66] |

| Fruit pulps |

[41][67] |

3. Conclusions

Research on novel biobased food packaging has been growing over the last decade mainly boosted because of concern with the global environmental plastic pollution. Innovative strategies to develop biodegradable and sustainable packaging materials based on natural resources are welcome to reduce the use of plastics. The present review highlighted a historical timeline, functionality and application trends of alginate, carrageenan, chitosan, starch and pea protein, as natural biopolymers for the design of food packaging. Using these polymers from agroindustrial residues to this end are also an interesting strategy to close the wheel of a circular and sustainable economy. These materials have valuable potential in the chemistry and packaging industries, especially due to its renewability, biodegradability, compatibility, as well as good technological and functional properties. Therefore, many challenges related to its processability, proper ways of disposal and legislations need to be overcome to increase their industrial application. It is known that a full replacement of plastics for biobased packaging is not quite easy and is far from being a reality in many countries, though any degree of substitution is welcome to achieve a significant reduction of environmental pollution. This replacement is a challenge to be overcome by packaging industries, especially because there is lack of legislation about it, the adequacy of industrial processing facilities is costly and the disposal of packaging residues is not well known by consumers or not available to all, especially in low-income countries. Despite those difficulties, replacing petroleum-based plastics should be top priority of all food packaging industry around the world.