The kinetics of the oxygen evolution reaction (OER) are generally slower relative to chlorine evolution reaction (CER) due to the requirement for the transfer of four electrons and protons per oxygen molecule, while the CER is a two-electron process. At pH > 3, chloride can be oxidized to form hypochlorous acid (HOCl, pH 3–7), and at pH > 7, hypochlorite is formed (OCl

−)

[4]. Most research on maximizing oxygen evolution activity to date has focused on highly acidic

[5][6][7][8][5,6,7,8] or alkaline

[9][10][11][12][9,10,11,12] media, and information regarding the selectivity toward chlorine evolution often stems from the chlor-alkali industry in acidic environments where CER is preferred

[13]. Although precious metal oxides (e.g., IrO

2) are highly active for OER in acidic media, such materials are similarly highly active for CER in chloride-containing media

[14][15][14,15].

In the neutral conditions of seawater

[16][17][18][16,17,18], electrolysis studies are scarce and, instead, often incorporate additional buffering

[19]. Historically, research in such media has focused on metal oxides primarily composed of Mn

[20][21][22][20,21,22], Ni

[16][23][16,23], and Co

[19][20][24][19,20,24], often with additional elements, such as Fe or W. Considering abundance and a promising price point

[24],

we focus here

on Mn-based oxides

are focused, which are stable and have demonstrated good Faradaic efficiency in a wide range of electrolyte pH. MnOx electrocatalysts (often supported on an IrO

2/Ti substrate

[25]) have demonstrated good selectivity (>90%) toward OER in chlorine-containing electrolyte, with the remainder of the current going toward CER and oxidative dissolution in the form of MnO

4− [21]. However, these electrodes suffered from mechanical instability during cycling at appreciable current densities. The incorporation of Mo

6+ improved durability and Faradaic efficiency

[26]. The further incorporation of W

6+ maintained this performance while improving OER activity (lowering overpotential), which has been attributed in part to its enhancement of oxide conductivity

[23]. However, numerous other potential metals may serve a similar role, perhaps with better efficacy and stability.

2. Electrode Fabrication and Structure

The electrodeposition process produced electrodes with a cracked mud structure, with the Mn-Mo-X catalyst deposited on top of a sub-layer of thermal decomposition-produced IrO2. The IrO

2 layer prevents insulation of the titanium substrate by oxidation

[25]. The thermal decomposition process deposited ~0.0020 g/cm

2 of IrO

2. To ensure the complete coverage of, first, the IrO

2 layer on the Ti and, then, the Mn-Mo catalyst, important for analysis of Faradaic efficiency toward OER, deposition conditions were tailored to achieve complete attenuation by EDS (information depth on the order of ~microns). Three sequential electrodeposition cycles of 20 min each at 80 °C were used to generate a homogenous catalyst layer.

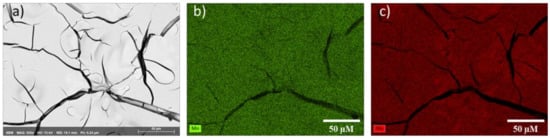

Figure 1 shows the resulting catalyst layer yielding complete coverage of the electrode surface by EDS, similar to prior work

[22]. Electrodeposition at room temperature or with a continuous deposition at 80 °C generated incomplete and heterogeneous catalyst layers on the electrode surface. Beyond three cycles, flaking from over-deposition was observed. The deposition cycles resulted in ~0.0500 g/cm

2 of catalyst deposited.

Figure 1. (a) SEM micrograph and the corresponding EDS maps for (b) Mn and (c) Mo for a 0.2 M Mn-0.003 M Mo catalyst with three 20 min electrodeposition cycles at 80 °C. There was no signal from the underlying Ti or Ir layers.

The inclusion of dopants at various levels in the Mn-Mo-X catalyst did not distort the overall cracked mud structur

e (see

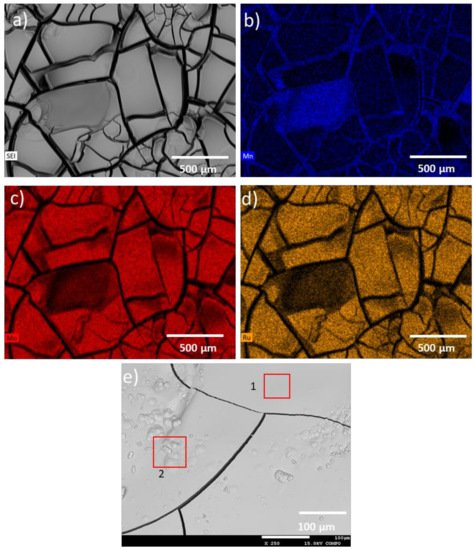

SEM images in Figure S1). Some heterogeneous distribution of the catalyst elements was observed as small “bumps” on the catalyst surface. EDS mapping highlighted the variations in element distribution through the catalysts. As an example,

Figure 2a shows the SEM image of a Mn-Mo-0.006 M Ru electrode. While the composition appeared generally uniform across the film, there is also a Mn-rich region (

Figure 2b) that is depleted in Mo (

Figure 2c) and Ru (

Figure 2d). The “cracks” in the microstructure gave a stronger Mn signal, suggesting the Mn distribution may vary with electrode thickness. While the distribution of the Ru in

Figure 2d appeared homogenous, magnification of the catalyst surface in

Figure 2e showed “bumps” on the catalyst surface. EDS spot analysis showed that the flat region contained only Mn and Mo, whereas the bumps also contained Ru (

Table 1). As a result of this heterogenous composition profile, the quantification of the dopant level and Mn/Mo/X ratios was limited with EDS. Thus, electrodes are referred to by the starting electrodeposition solution concentration, where increased solution concentration results in increased electrode dopant concentration.

Figure 2. (a) SEM micrograph and corresponding EDS maps for (b) Mn, (c) Mo, and (d) Ru showing a Mn-rich region. (e) SEM micrograph at higher resolution on the Mn-Mo-0.006 M Ru electrode showing the heterogeneous bumps on the sample surface. The red boxes denote the regions quantified in Table 1.

Table 1. Composition of the regions analyzed by EDS in Figure 2e.

| Spectrum |

O (at%) |

Mn (at%) |

Mo (at%) |

Ru (at%) |

| 1 |

58.23 |

41.49 |

0.28 |

0.00 |

| 2 |

58.17 |

41.29 |

0.40 |

0.15 |

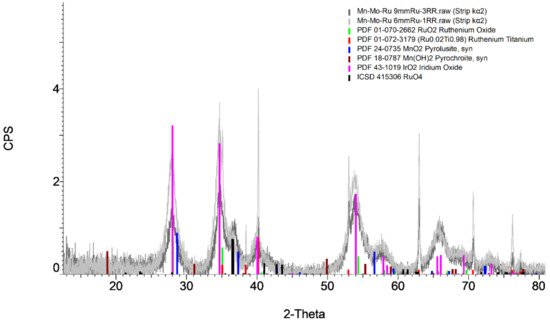

The XRD pattern of both the Mn-Mo-0.006 M Ru and Mn-Mo-0.009 M Ru electrodes showed the majority of the pattern arising from MnO

2 with a strong signal from the underlying IrO

2 layer (

Figure 3). The low concentration of Ru and the overlap in the XRD features of its oxides make it challenging to assess potential phase segregation.

Figure 3. XRD patterns of the Mn-Mo-0.006 M Ru and Mn-Mo-0.009 M Ru electrodes and associated peak fits. CPS = counts per second.

3. OER Efficiency in Saline and Seawater Environments

The performance of the electrodes was assessed on efficiency toward the OER over the CER, represented as the faradaic efficiency (FE) for OER, and the overall catalytic performance, represented as total charge passed at a given applied potential for 30 min (normalized by electrode geometric area). Electrodes that suppress the CER while facilitating the rate of OER are promising candidates for further development. In a 30 min exposure at 1.4 V vs. Ag/AgCl, an IrO

x had a faradaic efficiency of only 18% toward OER (14.7 C/cm

2), while a Mn-Mo electrode measured 91% faradaic efficiency (31 C/cm

2).

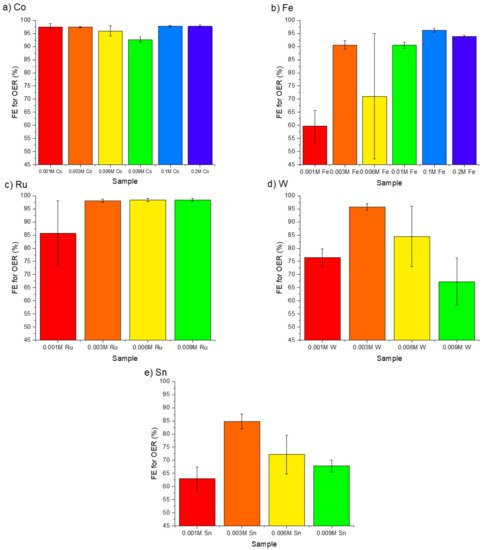

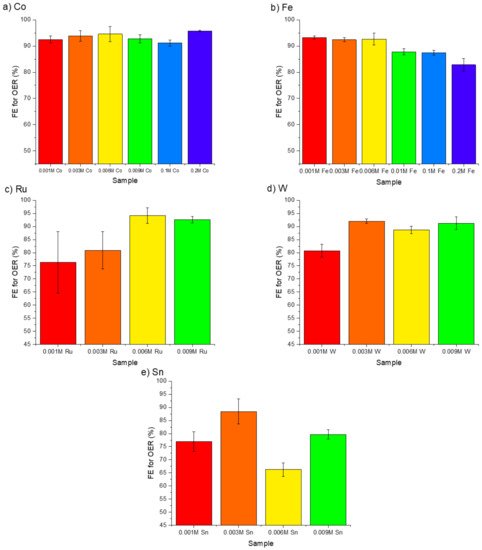

The influence of various dopant levels on the Mn-Mo electrodes on OER faradaic efficiency in neutral chloride (0.5 M NaCl) environments is shown in

Figure 45. In

Figure 45a, the addition of Co to the Mn-Mo provided efficiencies >95% relatively consistently for the tested compositions, with the exception being 0.009 M Co. Increasing to Mn-Mo-0.1 M Co created a more physically stable electrode. For the inclusion of Fe (

Figure 45b), the best performance was measured for electrodes Mn-Mo-0.01 M Fe, Mn-Mo-0.1 M Fe, and Mn-Mo-0.02 M Fe. Below 0.01 M Fe addition, stability and efficiency were compromised. A Mn-Mo-0.003 M W electrode was the best performing of the W set with consistent >94% efficiency for OER (

Figure 45d).

We Aobserved a drop in pH over time

was observed in the unbuffered neutral chloride electrolyte, possibly due to the inability of the Nafion

® membrane to exchange the protons at the proton generation/consumption rate. The Ru electrodes with >0.003 M Ru addition all had strong OER efficiency (

Figure 45c). The Mn-Mo-0.001 M Ru electrodes had poor physical stability leading to the large deviation between runs. The addition of Sn as a dopant led to a decrease in OER compared with the other dopants, with the Mn-Mo-0.003 M Sn electrode providing ~88% efficiency (

Figure 45e). Out of the electrodes evaluated, the inclusion of Ru provided the best efficiency toward OER in 0.5 M NaCl (

Figure 45).

Figure 45. Comparison of the average OER faradaic efficiencies (3 subsequent measurements) following 30 min at 1.5 V (vs. Ag/AgCl) in 0.5 M NaCl for electrodes doped with (

a) Co, (

b) Fe, (

c) Ru, (

d) W, and (

e) Sn.

When testing in filtered raw seawater, most of the electrodes saw a slight decrease in OER faradaic efficiency compared with the neutral chloride solution. The differences may originate from the increased ionic concentration in seawater and the application from a higher kinetic overpotential (V vs. RHE) given the increased buffering in seawater and, correspondingly, the higher pH in the anolyte compared to 0.5 M NaCl. A summary of these tests is shown in

Figure 56. The inclusion of Co (

Figure 56a) generally maintained high OER faradaic efficiency, somewhat greater for the Mn-Mo-0.2 M Co electrode. Surprisingly, for Fe-containing electrodes (

Figure 56b), the OER faradaic efficiency in seawater was notably greater than in 0.5 M NaCl for 0.001 M Fe, generally decreasing with Fe content and reaching OER efficiencies notably lower than in 0.5 M NaCl. This switch may be due to buffering occurring in seawater improving the Fe’s stability in the electrode. Elucidation of this behavior change at low Fe doping levels will be a focus of future work. The Ru electrodes also performed well, >90% efficiency for the electrodes at 0.003 M Ru and 0.009 M Ru (

Figure 56c). For W-containing electrodes, OER faradaic efficiencies were also somewhat higher in seawater, marginally greater for the Mn-Mo-0.003 M W (

Figure 6d), which also had similar performance in artificial seawater

(Figure S2). The Mn-Mo-0.003 M Sn electrode again had the best performance from the Sn set (

Figure 56e).

Figure 56. Comparison of the OER faradaic efficiency for replicate electrode samples following 30 min at 1.5 V (vs. Ag/AgCl) in raw filtered seawater for electrodes doped with (

a) Co, (

b) Fe, (

c) W, (

d) Ru, and (

e) Sn.

4. The Effectiveness of Doping Transition Metals on CER Suppression

The doping transition metals into Mn-Mo-X catalysts can effectively suppress the CER and improve overall catalytic activity. The best-performing dopant was Ru in terms of efficiency for OER over CER and catalytic activity. However, despite previous reports of this doping approach being successful for CER suppression, little mechanistic discussion is present in the literature. With the similar response of multiple dopants (Fe, Sn, W, and Co) and the enhanced activity of a known catalytically active species, Ru, dopants may play a role in manipulating the coating density and stability in addition to serving as active catalytic sites. Evidence on both mechanistic roles exists. Ru and Ir are industrial benchmark catalysts for efficient oxygen and chlorine evolution (in the chlor-alkali process), sitting high on the volcano curve for both OER [27][33] and CER [28][34]. In the case of IrOx, the OER is not suppressed or influenced by the CER occurring on the same surface, showing scaling between the two reactions on active catalysts [29][35]. Targeting selective OER over CER can present a challenge but may be realized through a combination of processes.

The adsorbed intermediates generated for the CER can also influence selectivity. Surfaces that form a M-Cl intermediate can efficiently sustain the CER, while the generation of the M-OCl intermediate will suppress the CER [30][38]. The OCl intermediate route further suppresses the CER on RuO2 with increasing pH due to the change in Gibbs free energy loss. Studies of preferential OER in halide-containing environments on NiB and CoP catalysts suggest that the edge sites on the metalate clusters are crucial to sustaining the OER, as H2O will out compete halides for these sites, increasing the likelihood of OER over CER. With the small locations and disordered distribution of the Ru dopants in this study, a higher number of edge sites may dictate an added preference to OER over CER via oxygen-containing intermediates [31][39].