The textile branch includes mainly the processing of textile fibers, the production of yarns and various fabrics (fabrics, knitwear nonwovens and nano assmblies) and their use for clothing purposes and technical applications. This branch belonged, belongs and will probably continue to belong to fields using new technical solutions very quickly.The major factors involved in developement of textile branch are discussed. The main developement trends are presented.The selcted major breathrough in the field of textile machinery and their pactical benefits are shown.

- textile development

- human and civilization factors

- clothing and technical textiles

- open end spinning

- jet looms

- perpendicularrly laid noonvowen

- active lighting textiles

1. Introduction

The production of textiles and the construction of clothing are two of the oldest industries, with a traditionally high degree of automation and the use of new energy sources, new types of materials and new production facilities. It is interesting that the basic principles of yarn preparation by twisting and the production of fabrics by intertwining warp and weft threads do not actually differ in principle from the original manual procedures known for thousands of years. Textile machines enabled the realization of the first continuous technologies, and they used punched cards before the development of computer technology; very quickly, the elements of cognitive robots were applied to them when handling materials. Their speeds (with open end spinning up to 200,000 rpm) are extremely high and require the use of special solutions. On the other hand, textiles are directly connected with the three basic human needs, i.e., “food, housing and clothing.” Textile products that satisfy the need for clothing must, therefore, have both a functional (utility) and aesthetic aspect. The aesthetic aspect is related to the shape of the textile on the wearer and its changes when worn (characterized by drape) [1].

The need for textiles is generally related to the size of the human population (clothing textiles) and its maturity (technical textile structures). The question now turns to what locations and individuals can ensure this need. The current trend is to realize the production of textiles as close as possible to the sources of raw materials. Competition on world markets and a surplus of mass-produced products from Asian countries are causing a shift in production in Europe and USA towards customer-oriented textile products with new effects, quality and comfort [1].

2. Development of Textile Branch

The human population is in daily contact with clothing textiles, using home textiles and textiles for industrial applications (transport, composite structures, filtration and wastewater treatment, electronics, etc.). Thus, the main advantages of textiles as unique products are known, including the following: extremely low density due to high overall porosity (over 70%), unique drape, flexibility and easy formability, resistance to environmental influences (UV, humidity and temperature), abrasion, long-term heat and chemical resistance, low degradation under storage conditions and slow aging under conditions of use. The advantages are also the simple joining and cutting techniques enabling the preparation of “tailor-made” shapes; simple surface modification allowing changes in a number of properties related to interface behavior; layering and combining into structures with controlled geometry; and properties anisotropy, as well as easy maintenance, cleaning and easy reparation.

The developments of textiles and clothing are closely related to both human factors and the influence of civilization. Influences related to human factors can be divided into the following groups [3][2]: Earth’s population growth: The planet’s population is expected to increase to 8.9 billion by 2050. With an expected consumption of 20 kg of textiles per person per year, this amounts to a total of 178 billion tons of textiles per year in 2050 [1,2][1][3]; Prolongation of life expectancy: Based on a stochastic model, the expected life expectancy in 2050 was found in the range of 80–83 years (USA) and 83–91 years (Japan) [4]. This is also related to an increase in the relative share of seniors in society. The category of seniors will have other requirements for a number of textiles related mainly to ensuring their safety with limited mobility (e.g., improved visibility of objects, identifiable edges, etc.); Growth in the share of free time : Free time that can also be spent on activities requiring special textiles (FITNESS and WELNESS); A lifestyle that significantly changes the size range of clothing textiles and also affects the way they are purchased; Civilizational influences that usually have a negative effect on health and require the provision of special barrier functions (against microorganisms, allergies, environmental pollution, etc.); Protection and prevention of health (fitness sports and rehabilitation), which again require special textiles both in clothing and in some products (especially composites).

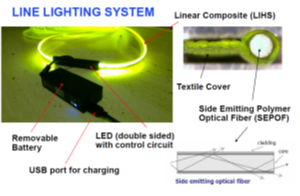

In the future, the predominant long-term trend can be expected to be the integration of development results in materials, chemistry, physics and engineering for the production of new textile structures for clothing textiles capable of adapting to changes in environmental conditions and special technical textiles with unique properties required for their applications. In the case of textiles for clothing purposes, the aspects of fashion, style and comfort have traditionally prevailed. From the consumer’s point of view, it will be necessary to ensure that these textiles will have the following abilities: Optimal humidity control; Heat flow control; Air breathability control; Improved thermal insulation properties; Water vapor permeability (diameter 0.4 μm), but not liquid water (diameter 100 μm) permeability; Protection against dangerous influences from the environment (microorganisms and ultraviolet UV radiation); Ecological production and disposal of used textiles (biodegradability); Self-cleaning effects and dust repellency; Improved wear resistance (abrasion); Support of health care (vital functions and healing processes); Support of cosmetic functions (regenerative processes on the skin); Easy maintenance including cleaning and ironing; Improved hand, aesthetic sensations and appearance even after several cycles of use and maintenance; Controlled active identifiability of textiles in conditions of low visibility. The new linear composite for line economic lighting (worldl patent WO 2014 / 071898A1) .is shown in fig.1.

Figure 1. Line economic lighting

In the field of technical textiles, the situation is usually simpler, as the requirements for their properties can often be precisely specified according to the intended purpose of use [5]. The general requirements for technical textiles for industrial use and composites include the following.

3. Production of Yarns and Fabrics

The weight of a typical cotton fiber with a length of 2.5 cm and a fineness of 1.5 dtex is only 3.8 micrograms. In one square meter (the area of human skin is about 1.5 m 2) of finer cotton fabric with a basis weight of 150 g/m 2, there are 39.5 million fibers. During the preparation for spinning and during the production of the yarn, this amount of fibers is handled (loosening, cleaning, mixing, carding, drawing and twisting). Similarly, in weaving, a relatively large length of yarn must be intertwined. It is, therefore, clear that machinery must be relatively sophisticated and, above all, capable of producing large quantities of textiles in a period of short time [9][6].

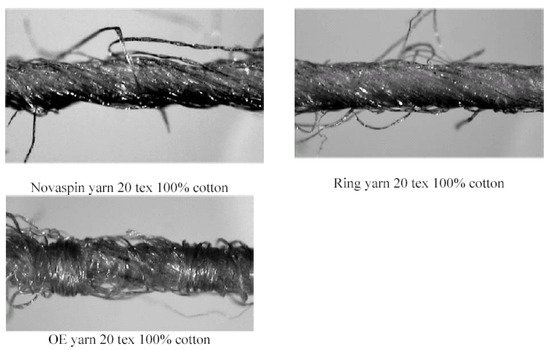

Ring spinning, based on the same principle as hand spinning on a spinning wheel, still remains the dominant method of yarn production worldwide [10][7]. The fibers are mechanically transformed (loosening, cleaning, mixing, carding, stretching and combing) into a linear structure— sliver. It is processed by drafting, twisted in the system ring—runner—spindle into the form of yarn, which is wound on a bobbin. The ring spinning yarn has a structure characterized in particular by the presence of protruding fibers (hairiness) (see Figure 2 ).

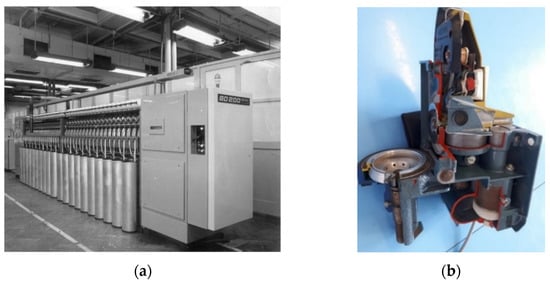

The core of the rotor spinning system is the rotor (see Figure 2 b). In the rotor, the fibers slide along its wall into the collecting groove where a fiber ribbon is formed. After introducing the free end of the yarn into the rotor, yarn is formed. It is, thus, a discontinuous system of disintegration into fibers, their transport and re-association with twisting [13,14][8][9]. The rotor spinning yarn has a structure with typical wraps, is stiffer and the yarn strength is usually 20 to 30% lower compared to ring spinning yarns [15][10] (see Figure 2 ). During fiber separation and their deformation in the rotor, the fiber breaks appear [16,17][11][12]. The mechanics of the functioning of rotor machine and the influence of some of the process parameters were comprehensively investigated [18][13]. Rotor technology is used mainly for manufacturing coarser yarns [10][7]. The main challenge was to use rotor spinning for the creation of cotton yarns and for the prediction of their properties. The influence of cotton fiber properties on selected properties of open-end yarn was investigated comprehensively in work [19][14]. The basic construction parameters of yarns were yarn count and yarn twist characterized by the Phrix twist coefficient. From these parameters, the structural characteristics such as packing density, orientation and mean surface helix angle were predicted. Total numbers of 180 cotton rotor yarns were prepared from seventeen kinds of cottons in five levels of yarn count and two levels of Phrix twist coefficient. For the prediction of yarn strength and mass unevenness based on fiber quality and yarn structural parameters, the dimension reduction approach combined with linear regression was used. It was found that yarn strength is critically dependent on fiber strength as was in accordance with the majority of models presented in work [20][15]. The simple models for yarn strength prediction based on the reduction in fiber strength by the multiplicative factors from orientation, Poisson ratio and volume fraction (see [21,22][16][17]) combined with linear regression was used as well. The influence of process parameters was “hidden” in yarn fineness, and process parameters were not as important as fiber strength. Yarn unevenness (mass variation between portions of yarn with lengths 0.8 mm) was critically dependent on yarn packing density, fiber helix angle in yarn, number of fibers in yarn and fiber length parameters (upper half mean length). The complex criterion of cotton fibers quality correlated significantly with yarn unevenness. Coarser yarns with lower packing density were more uneven. These results were not generalized due to practical range of technological parameters of yarn creation (yarn count and yarn twist), but they were in accordance with the conclusions obtained from experiments with other types of cotton yarns [23][18].The first prototype of the BD 200 rotor spinning device and rotor spinning unit are shown in Figure 3. [12].

At present time, the production of yarn on a ring spinning machine is about 20 m of yarn per minute and the range of processed fineness is 5–300 tex. On a rotor spinning machine, the yarn production is about 350 m of yarn per minute, and the range of fineness processed is 10–500 tex. There are also other principles of spinning (friction, Vortex, etc.), where the production of yarn is even higher, but their application (depending on the qualitative characteristics of the yarn) is so far only limited [24][19]. The principles of rotor and ring spinning will probably be maintained as the most applied in the future [25][20].

Major technigue for preparation of planar (2D) structures are weaving by usng of looms. In conventional shuttle looms, the weft threads are inserted with a shuttle (typical weight 300 g) carrying a spool of weft thread inside. The shuttle is given a high acceleration at the beginning and is stopped abruptly at the end (after the weft is inserted). This is followed by mechanical beating of the weft to the front of the fabric and contacting the warp at the contact points of the fabric by means of an impact mechanism weighing several hundred kilograms. The weaving sequence is thus discontinuous and the weft insertion takes place regularly from left to right and back during each weaving cycle. The weft is uninterrupted after inserting, so that solid edges are formed. The speed of weft insertion in modern shuttle looms is around 650 m / min and the noise level is around 92-107 dB. High speed air and water jets used for weft insertion were patented and realized at VÚTS Liberec. The first 45 cm wide air jet (see. Figure 4.) was demonstrated in December 1952.

Figure 4. The first air jet loom in the world.

Currently the most productive loom in the world CAMEL ADAPTIVE (speed 700 rpm) from the same institute is shown in Figure 5.

Figure 5. Air jet loom CAMEL ADAPTIVE.

The latest breakthrough solution in the field of jet weaving is the DIFA weaving loom for the production of 3D layered fabrics composed of two woven layers (distance between layers 12 - 50 cm) connected by binding threads.

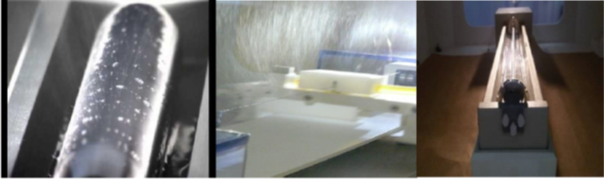

In the field of nanofibrous layers preparation (very thin special 2D) fabric a many of technologies based mainly on the principle of needle electrospinning and needle less electrospinning were invented.The original patented principle of production of nanofibrous assembly (US Patent 2005, Wo2005024101) realized under name Nanospider is currently further modified (especially on TUL), modifications are protected by a number of other patents and laboratory, pilot plant and operational equipment are implemented (Figure 6.).

Figure 6.

Modification of the NANOSPIDER system a) rotating cylindrical electrode with a pits on surface, b) wire electrode, c rotating wire electrode.

4. Future of the Textile Industry

The textile industry of the future will be focused on the following areas: Implementation of ecological production (not worsening the environment and not endangering life on earth); Reducing the share of waste from production (waste-free technologies, regeneration, recuperation and reuse); Reducing energy consumption (alternative reaction media, process optimization and alternative energy sources); Use of renewable resources (biotechnology and green chemistry); Elimination or replacement of toxic compounds (new solvents and replacement of heavy metals); Disposal of waste and used products (biodegradation, reuse of raw materials and special disposal).

In general, it is economical to use fewer machines with higher production speeds while maintaining product quality. That is why technologies with higher production speeds are developed and will be used. The two basic principles, i.e., rotor and ring spinning machines, will most probably be important for the production of yarns in the future [24][19]. Other principles will be used for special needs. This is the case of the most intensive yarn production system, Bobtex, using adhesive bonding (production speed around 700 m/min). The production speed of Bobtex is followed by the Dreft friction spinning system and the Vortex jet spinning system [10][7].

Textile technologies still have the potential to reduce energy consumption by up to 25% [3][2]. Thus, the search for new technologies with lower energy consumption (bio processes, catalytic processes and use of alternative energy sources), reduction in machine weight, reduction in reaction volumes, application of regulation and optimal control, effective insulation of machines and thermal energy transfer systems can be expected. The persisting basic and simple method for heat transfer by conduction using air and water is already supplemented by IR heating (many polymer fibers have absorption bands in the near IR region) and microwave heating (based on rapid changes in polarity-rotation of polar molecules). Microwave heating requires 10 to 100 times less energy than conventional heating. In IR heating, the surfaces of the materials are heated first and the edges and inner parts of the materials are heated first in microwave heating. By combining both types of heating, increasingly even heating of the entire volume can be obtained. Another possibility of intensive (local) heating of surfaces and thin subsurface layers is the use of plasma [38][21] or laser for local intensive heating until local surface destruction [39][22].

There is no universal solution yet, but water consumption will probably need to be severely reduced in the future [1]. During the solution of water consumption problems, the concept of “virtual water” should necessarily be focused on. Virtual water is defined as water that is only required for processing a fabric [43][23].

References

- Aneja, A. P. Caldwell, E.W. and Hietpas, P.B. Textile Business Strategies in the New Millennium, Proceedings of The Textile Institute’s 80th World Congress, Manchester, April 2000.

- Anonym: „European Technology Platform for the Future of Textiles and Clothing – a vision for 2020 “, Rept Euratex, December 2004

- Tuljapurkar S., Li N., and Boe C.: A universal pattern of mortality decline in the G7 countries, Nature 405, 789–792. (2000)

- Křemenáková D., Militký J., Mishra R.: Fibers for optical textiles, chap 23 of book Hu J., Kumar B., Lu J. eds. : Handbook of fibrous materials 2 , Wiley VCH, Weinheim 2020

- Křemenáková D., Militký J., Šašková J., Ledrová Z., Vydra J., Bubelová B.and Baxa M.: Testing of Emergency Line Light System in Radiation Therapy Rooms, Proc 18 th World Textile Conference, Istambul 2018

- Křemenáková D. et al.: Characterization of Side Emitting Polymeric Optical Fibers, Journal of Fiber Bioengineering & Informatics, 5, 423- 431, (2012)

- Křemenáková D., Militký J., Ibrahim S.: Cotton yarn and fabric production: future trends, chap 12 in book Wakelyn P. J. et all Cotton: Technology for the 21 st Century, International Cotton Advisory Committee 2010

- Lawrence C.A. Fundamentals of spun yarn technology, CRC Press, Boca Raton Florida 2003

- Basal G. ,Oxenham W.: Vortex spun yarn vs. air jet spun yarn, AUTEX Res. J., 3, 96 - 101(2003)

- Basal G. and Oxenham W.: Comparison of Properties and Structures of Compact and Conventional Spun Yarns, Res. J. 76, 567 - 575. (2006)

- Kašpárek J. V.: Future prospects of rotor spinning, Indian Journal of Fibre and Textile Research, 17 (December) 238-245, (1992)

- Rohlena V. et al.: Open end spinning, North Holland, Elsevier, Amsterdam(1975)

- Militký J., Křemenáková D. Ibrahim S.: Influence of fiber characteristics and yarn structure on OE yarn unevenness, The 86-th World Textile Conf. Hong Kong, November 2007.

- Militký, J., Křemenaková, D.: Some Ways of Technical Textiles Development, IVUZ Technol. Text. Prom. (Engl. Ed.). 317, 112-121 (2009)

- Seyam A. M.: Weaving technology, advances and challenges of Textile and Apparel, 3, 1-10 (2003)

- Nosek, S. (1996): Structure and geometry of fabric, Mineo, TU Liberec. ( in Czech)

- Hanuš J., Militký J., Arun Pal Aneja.: Local Compression of Corrugated Nonwoven Structures, In: Ninth International Conference on Composites Engineering, San Diego, July 1-6, USA, 2002

- Hanuš J., Jirsák O.: Twist May Produce Nonwovens, In: Textile Technology Forum ’95. Charlotte, N.C. USA, 1995.

- Hanuš J., Militký J.: Quasi-Yarn Applications in Nonwowen Production, In: HPTEX Coimbatore. July 7 -9, India, 2004

- Ramakrishna S. et al.: Electrospun nanofibers: solving global issues, Today 9, 40- 50 (2006)

- Ramakrishna S. et al.: An Introduction to Electrospinning and Nanofibers; World Scientific Publishing Company: Singapore, 2005

- R., Militký J. : Nanotechnology in Textiles - Theory and Application, Elsevier Woodhead Publishing, 2019

- Neckář, B.: Creation, structure, properties. SNTL Praha 1990 (in Czech).

- Militký J., Periyasamy A. P., Venkataraman M.: Textiles and Their Use in Microbial Protection, CRC Press Boca Raton 2021

- Neckář B., Das D.: Theory of Structure and Mechanics of Yarns, New Delhi, India, Woodhead Publishing 2018

- Elhawary I. A.: Mechanics of Rotor Spinning Machines, CRC Press, Boca Raton, 2017

- Militký J. et al.: Prediction of the selected properties of cotton type rotor yarns, Proc. of Beltwide Cotton Conferences, New Orleans January 2010

- Pan N., Hua T., Qiu, Y.: Relationship between Fibre and Yarn Strength, Textile Res. J.

- Pan N.: Prediction of statistical strength of twisted structure, J. Mater. Sci., 28, 6107-6114 (1993)

- Ghosh A., et al.: Predictive models for strength of spun yarns: an overview, AUTEX Research Journal, 5, 20-29 (2005).

- Lawrence C. A. ed.: Advances in yarn spinning technology, Woodhead Publishing, Philadelphia 2010

- Cormack D., et al.: The yarn twist inside the rotor in open-end spinning, The Journal of The Textile Institute, 70, 380-384 (1979)

- Salhotra K. R., Chattopadhyay R.: Incidence and mechanism of fiber breakage in rotor spinning, Textile Research Journal, 52, 317–320 (1982).

- Salhotra K. R., Chattopadhyay R.: Loss in fiber tenacity during separation in rotor spinning, Textile Research Journal, 54, 194–197 (1984)

- Soliman A.S.: Factors affecting rotor spinning of fine cotton yarns, PhD thesis, Texas Tech university, August 1985

- Oxenham W.: Current and Future trends in yarn production, JTATM 2,1-20 (2002)

- Gandhi K., ed: Woven Textiles, Elsevier, Oxford 2020

- Muthu S. S. ed.: Environmental Footprints of Recycled Polyester, Springer Nature Singapore 2020

- Poll H.V., Schladitz V., Schrenter, S.: Penetration of plasma effects into textile structures, Surface and Coat. Technol. 142, 489-493 (2001)

- Knittel D., Scholmeyer E.: Surface Structuring of Synthetic Fibres by UV Laser Irradiation, Part I : Phenomenological Report Polymer Int. 43, 231 - 239, (1997)

- Militký J.: Trends in the development of the textile and clothing industry, Implementation action plan of ČTPT, TUL Liberec 2011 (in Czech)

- Muthu S. ed.: Water in Textiles and Fashion, Woodhead Publ. Duxford, 2019

References

- Aneja, A.P.; Caldwell, E.W.; Hietpas, P.B. Textile Business Strategies in the New Millennium. In Proceedings of the Textile Institute’s 80th World Congress, Manchester, UK, 16–19 April 2000.

- Militký, J. Trends in the Development of the Textile and Clothing Industry, Implementation Action Plan of Czech Technology Platform (ČTPT); TUL: Liberec, Czech Republic, 2011. (In Czech)

- Rept Euratex. European Technology Platform for the Future of Textiles and Clothing—A Vision for 2020. December 2004. Available online: https://www.certh.gr/dat/141D2148/file.pdf (accessed on 6 October 2021).

- Tuljapurkar, S.; Li, N.; Boe, C. A universal pattern of mortality decline in the G7 countries. Nature 2000, 405, 789–792.

- Militký, J.; Křemenaková, D. Some Ways of Technical Textiles Development. IVUZ Technol. Text. Prom. 2009, 317, 112–121.

- Křemenáková, D.; Militký, J.; Ibrahim, S. Cotton yarn and fabric production: Future trends. In Cotton: Technology for the 21st Century; Wakelyn, P.J., Chaudhry, M.R., Eds.; International Cotton Advisory Committee: Washington, DC, USA, 2010; Chapter 12.

- Lawrence, C.A. Fundamentals of Spun Yarn Technology; CRC Press: Boca Raton, FL, USA, 2003.

- Lawrence, C.A. (Ed.) Advances in Yarn Spinning Technology; Woodhead Publishing: Philadelphia, PA, USA, 2010.

- Cormack, D.; Grosberg, P.; Ho, K.H. The yarn twist inside the rotor in open-end spinning. J. Text. Inst. 1979, 70, 380–384.

- Militký, J.; Křemenáková, D.; Ibrahim, S. Influence of fiber characteristics and yarn structure on OE yarn unevenness. In Proceedings of the 86-th World Textile Conference, Hong Kong, China, 18–21 November 2007.

- Basal, G.; Oxenham, W. Vortex spun yarn vs. air jet spun yarn. AUTEX Res. J. 2003, 3, 96–101.

- Basal, G.; Oxenham, W. Comparison of Properties and Structures of Compact and Conventional Spun Yarns. Text. Res. J. 2006, 76, 567–575.

- Elhawary, I.A. Mechanics of Rotor Spinning Machines; CRC Press: Boca Raton, FL, USA, 2017.

- Militký, J.; Křemenáková, D.; Krupincová, G.; Ibrahim, S. Prediction of the selected properties of cotton type rotor yarns. In Proceedings of the Beltwide Cotton Conferences, New Orleans, LA, USA, 5–7 January 2010.

- Ghosh, A.; Ishtiaque, S.; Rengasamy, S.; Mal, P.; Patnaik, A. Predictive models for strength of spun yarns: An overview. AUTEX Res. J. 2005, 5, 20–29.

- Pan, N.; Hua, T.; Qiu, Y. Relationship between Fibre and Yarn Strength. Text. Res. J. 2001, 71, 960–964.

- Pan, N. Prediction of statistical strength of twisted structure. J. Mater. Sci. 1993, 28, 6107–6114.

- Soliman, A.S. Factors Affecting Rotor Spinning of Fine Cotton Yarns. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, August 1985.

- Oxenham, W. Current and Future trends in yarn production. JTATM 2002, 2, 1–20.

- Neckář, B.; Das, D. Theory of Structure and Mechanics of Yarns; Woodhead Publishing: New Delhi, India, 2018.

- Poll, H.V.; Schladitz, V.; Schrenter, S. Penetration of plasma effects into textile structures. Surf. Coat. Technol. 2001, 142, 489–493.

- Knittel, D.; Scholmeyer, E. Surface Structuring of Synthetic Fibres by UV Laser Irradiation, Part I: Phenomenological Report. Polym. Int. 1997, 43, 231–239.

- Schwarzenbach, R.P.; Egli, T.; Hofstetter, T.B.; Von Gunten, U.; Wehrli, B. Global Water Pollution and Human Health. Annu. Rev. Environ. Resour. 2010, 35, 109–136.