Thermally modified wood (TMW) is a material derived from a treatment that combines temperature and moisture, avoiding harmful substances while providing better energy efficiency and drying quality. Such types of processes can considerably improve the performance of timber in several aspects. The treatment is usually achieved at temperatures between 120 °C and 260 °C, depending on the industrial process and desired end-product characteristics ().

- degradation

- abiotic and biotic factors

- thermal modification

- weathering

- wood

1. Introduction

There are a wide variety of applications of wooden structures, and nobody questions the value of the majority of these products [1][2][2,3] for building materials, including indoor and outdoor products, structural frames, window and door frames, floors, and façade systems [3][4][5][4,5,6]. However, wood is a complex biological tissue composed of different cell types [6][7]. This cellular diversity, with a diverse molecular structure, largely determines the physical and mechanical properties and profoundly influences the performance of wood as a construction material and its demand as such [7][8]. Therefore, knowledge of the wood structure and species identification is essential [8][9][1,9].

For outdoor use, wood is exposed to many abiotic and biotic factors, such as weather conditions and biodegradation, which negatively affect the wood material’s physical, biological, chemical, and mechanical properties [10][12].

Due to the environmental problems associated with chemicals, many industries, including the wood industry, are looking for environmentally friendly wood treatments to improve wood durability.

2. Wood Modification

Thermally modified wood (TMW) is a material derived from a treatment that combines temperature and moisture, avoiding harmful substances while providing better energy efficiency and drying quality [1][2]. Such types of processes can considerably improve the performance of timber in several aspects. The treatment is usually achieved at temperatures between 120 °C and 260 °C, depending on the industrial process and desired end-product characteristics ( Table 1 ).

Table 1. Different thermal modification industrial processes (adapted from Sandberg et al. [11]).

|

Process |

App. Year |

Temperature |

Process Duration (h) |

Pressure |

Atmosphere |

System Type |

|

FWD |

1979 |

120–180 |

≈15 |

0.5–0.6 |

Steam |

Closed system |

|

Plato |

1980 |

150–180/ |

4–5/70–120 |

Super |

Saturated steam/ |

A four-stage |

|

ThermoWood |

1990 |

130/185–215/80–90 |

30–70 |

Atmospheric |

Steam |

Continuous steam flow through the wood under processing removes volatile degradation products. |

|

Le Bois |

1990 |

200–230 |

12–36 |

Atmospheric |

Steam |

The process |

|

Retification |

1997 |

160–240 |

8–24 |

- |

Nitrogen or other gas |

The nitrogen |

|

OHT |

2000 |

180–220 |

24–36 |

- |

Vegetable oils |

Closed system |

This kind of treatment is widely used, established by several company trademarks and patents around the globe [12][13][14][19,20,21]. The first process we studied was carried out by Burmester, who studied the effects of temperature, pressure, and moisture in a closed system, then named Feuchte-Wärme-Druck (FWD) [11][18]. Throughout this technology development, several commercial processes were created, such as Lignostone ® and Lignifol ® in Germany, and Staypak ® and Staywood ® in the United States of America. More recently, other commercial methods were introduced in Europe: the Thermowood ® process in Finland, the Plato ® process in The Netherlands, and the Perdure ® process and Retification ® in France [15][16][17][18][22,23,24,25]. During the 2000s, other thermal modification processes were created: those using vegetable oils, such as OHT ® (oil heat treatment) and those using a vacuum system, such as VacWood ® (Thermo vacuum-treated wood) [11][18]. In Europe, the ThermoWood process is the one most commonly used commercially [11][18]. Table 2 shows the wood species that are widely used in Finland and other countries.

| Softwood Species | Hardwood Species |

|---|---|

| Pine (Pinus sylvestris) | Birch (Betula pendula) |

| Spruce (Picea abies) | Aspen (Populus tremula) |

| Radiata pine (Pinus radiata) | Ash (Fraxinus excelsior) |

| Maritime pine (Pinus pinaster) | Larch (Larix sibirica) |

| Alder (Alnus glutinosa) | |

| Beech (Fagus sylvatica) | |

| Eucalyptus (Eucalyptus sp.) |

Thermal modification treatments alter the structure and chemical composition of the wood cell walls [19][20][21][26,27,28]. These changes are responsible for modifying physical and mechanical properties. The main effects are improvement of dimensional stability, reduction of hygroscopicity (due to a decrease in the equilibrium moisture content and wettability), and the improvement of resistance to biological attack [12][16][19,23]. On the downside, these treatments can cause a reduction in some mechanical and physical properties, namely, in the modulus of elasticity (MOE), the modulus of rupture (MOR), impact toughness, abrasion resistance, hardness, and roughness [16][22][23][24][25][23,29,30,31,32], depending on the wood species ( Table 3 ).

| Species | Thermal Modification |

Time | MOE (MPa) |

MOR (MPa) |

Roughness (µm) |

Hardness (kg) |

Reference |

|---|---|---|---|---|---|---|---|

| Ash (Fraxinus excelsior) |

Control | 90 min in steam atmosphere | 7760 (850.94) | 90.68 (5.78) | - | - | [26] |

| 212 °C | 9990 (1838.94) | 74.04 (7.59) | |||||

| Iroko (Milicia excelsa) |

Control | 90 min in steam atmosphere | 11960 (1719.88) | 121.90 (18.85) | - | - | |

| 212 °C | 12860 (960.73) | 114.83 (16.14) | |||||

| Scots pine (Pinus sylvestris) |

Control | 90 min in steam atmosphere | 9644 (498.33) | 89.54 (7.45) | - | - | |

| 190 °C | 8808 (1219.58) | 74.18 (9.77) | |||||

| Spruce (Picea orientalis) |

Control | 90 min in steam atmosphere | 7618 (320.66) | 75.20 (3.00) | - | - | |

| 190 °C | 8985 (1244.55) | 72.50 (8.92) | |||||

| Black Alder (Alnus glutinosa) |

190 °C | 3 h | - | - | 36.08 (1.5) | 341.6 (26.1) | [24] |

| 35.35 (1.6) | 361.29 (24.3) | ||||||

| Red Oak (Quercus rubra) |

190 °C | 3 h | - | - | 57.82 (6.5) | 662.00 (73.7) | |

| 54.28 (3.1) | 533.72 (38.3) | ||||||

| Southern Pine (Pinus taeda) |

190 °C | 3 h | - | - | 27.16 (1.4) | 263.44 (28.4) | |

| 27.00 (1.4) | 270.97 (29.5) | ||||||

| Yellow Poplar (Liriodendron tulipifera) | 190 °C | 3 h | - | - | 44.08 (1.8) | 352.34 (50.8) | |

| 44.01 (1.4) | 354.65 (46.3) | ||||||

| Maritime pine (Pinus pinaster) |

Control | 2 h | 1110 (13.5%) | 130 (21.5%) | - | - | [27] |

| 200 °C | 1130 16.4%) | 127 (17.4%) | |||||

| 240 °C | 1070 (17.2%) | 104 (12.2%) | |||||

| 260 °C | 1130 (34.9%) | 76 (24.2%) | |||||

| 300 °C | 7800 (<2%) |

51 (11.0%) | |||||

| Eucalyptus (Eucalyptus globulus) |

Control | 2 h | 1440 (5.5%) | 129 (5.9%) | - | - | |

| 200 °C | 1580 (14.9%) | 105 (21.7%) | |||||

| 240 °C | 1260 (14.9%) | 86 (25.6%) | |||||

| 260 °C | 1410 (8.6%) | 91 (13.9%) | |||||

| 300 °C | 4600 (< 2%) |

28 (8.2%) | |||||

| Beech (Fagus sylvatica) |

Control | 2 h | 1190 (24.0%) | 146 (26.6%) | - | - | |

| 200 °C | 1230 (18.5%) | 167 (6.5%) | |||||

| 240 °C | 9600 (25.8%) | 124 (11.5%) | |||||

| 260 °C | 1040 (20.2%) | 105 (21.6%) | |||||

| 300 °C | 8140 (<2%) |

52 (12.0%) | |||||

| Acacia (Acacia melanoxylon) |

Control | 2 h | 1610 (4.1%) | 138 (6.7%) | - | - | |

| 200 °C | 1640 (7.5%) | 141 (2.8%) | |||||

| 240 °C | 1040 (14.9%) | 83 (9.7%) | |||||

| 260 °C | 1300 (5.9%) | 82 (2.8%) | |||||

| 300 °C | 8400 (13.8%) | 47 (28.9%) | |||||

| Oak (Quercus faginea) |

Control | 2 h | 1130 (9.9%) | 102 (9.2%) | - | - | [27] |

| 200 °C | 1150 (13.3%) | 91 (12.6%) | |||||

| 240 °C | 1090 (16.4%) | 83 (20.2%) | |||||

| 260 °C | 1120 (5.2%) | 74 (3.0%) | |||||

| 300 °C | 1010 (12.8%) | 68 (12.8%) | |||||

| Pedunculate Oak (Quercus robur) |

Control | 11731 (4219) | - | - | - | [28] | |

| 160 °C | 11021 (350) | ||||||

| 180 °C | 10846 (1168) | ||||||

| 200 °C | 11639 (1028) |

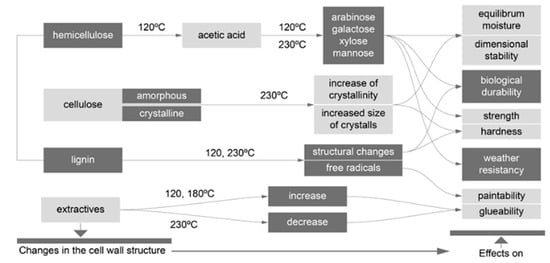

According to the literature, different reactions occur during thermal treatments [29][36]. Figure 1 summarizes the chemical changes that occur during thermal modification. Even at lower temperatures, hemicelluloses are the first structural components affected by depolymerization and hydrolysis. Cellulose is the next to be affected: hydrolysis and recrystallization of the amorphous region increase the crystallinity index in cellulose [11][18][30][18,25,37]. Finally, lignin reductions occur, with homolytic cleavage and polycondensation as the main reactions. Other reactions, such as extractive flow from inside the wood and a decrease in pH, have also been reported [18][25].

3. Weathering

In the last years, several studies have been conducted to evaluate the impact of weathering in thermally modified wood. Studies on the exposure of wood to natural weathering conditions (urban environments) [4][10][31][32][33][34][35][36][37][5,12,42,51,52,53,54,55,56] or artificial exposure through the use of climatic chambers (UV radiation, temperature, and humidity) [38][39][40][41][42][43][57,58,59,60,61,62] were conducted.

Natural weathering modifies the molecular structure of wood through a complex combination of chemical, mechanical, biological, and light-induced changes that coincide and affect each other [44][41].

The authors evaluated the changes in color and moisture content during a two-year exposure period in Ljubljana (Slovenia). They concluded that blue-stain fungi changes in color and growth on façade and decking correlated with solar radiation and water condensation. Unmodified wood underwent a greater color change than modified wood, but modified wood became grey faster than unmodified wood. They also noticed that decking of modified wood had a higher moisture content than that of unmodified wood, except for modified larch, which was altered at lower temperatures. The authors theorized that this happened because thermally modified wood has a higher permeability [37][56]. Finally, after the treatment, the formation of microcracks occurs, as well as degradation from tylosis.

In all UV resistance studies found in the literature, the researchers evaluated the color stability of thermally modified wood under artificial weathering, using UV radiation at different exposure times (between 75 and 835 h).

4. Conclusions

This entry allowed us to draw the following conclusions: The main factors with a significant impact on thermally modified wood degradation were moisture content and UV radiation. The UV radiation promotes color loss and photodegradation of the wood surface, leading to cracks in the wood structure in both unmodified and modified wood. The moisture content promotes mold, blue stain, and fungal growth, affecting the wood color. The advantages and disadvantages of thermally modified wood were identified. Benefits were the improvement of dimensional stability with thermal modification, promoting some weathering protection. The disadvantages were that thermal change was not beneficial in some wood species, and the modified wood can be sensitive to UV radiation. Species are structurally different, with notable performances in particular environments. It will be essential to consider more studies with a wider range of species (temperate and tropical) and environments, for example, in industrial and maritime environments where the effect of the salinity and pollutant gases are very aggressive for metallic materials; the same effects are unknown for modified wood. In addition, more studies on thermally modified wood are needed for wooden constructions in coastal areas (urban centers with a higher population density). It is necessary to conduct long-term weathering exposure to know how thermally modified woods will be affected by atmospheric contaminants and to predict their behavior under current climatic change scenarios. More field and laboratory tests, including different thermal modification settings and weathering factors, should be conducted to identify which environmental parameters affect wood the most.

The lack of information mentioned in our review can be an opportunity for future work; that is, to understand the degradation mechanisms caused by the weathering factors and to search for other forms of wood protection to promote the improvement of its lifetime service in various weathering contexts.