Peach tree canopy architecture is manipulated by producers via pruning, training and rootstock selection to achieve various goals. An ideal peach training system maintains optimal levels of light interception, uniform light distribution and facilitates high yields of high-quality fruit.

- training systems

- orchard design

- high-density planting

- HDP

- preharvest factors

1. Introduction

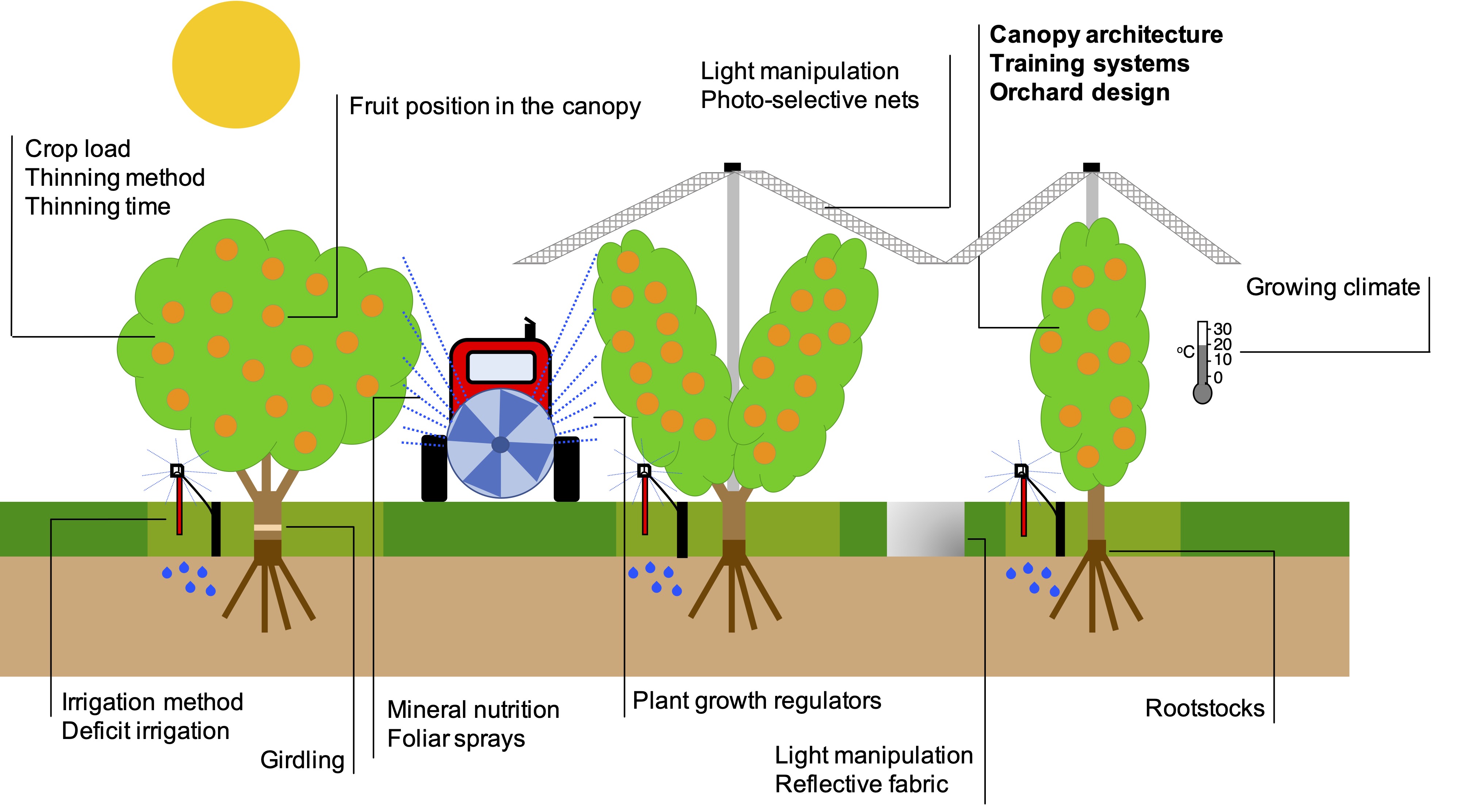

Peach production remains a significant industry in the global agricultural economy. However, peach consumption is in decline due to poor fruit quality, threatening the profitability and sustainability of the peach industry. Therefore, optimizing management for high fruit quality must be the focus of peach production, as consumers are willing to pay more for a superior product. Fruit quality can only be developed in the orchard through optimizing preharvest factors, such as orchard design and training systems (Figure 1). With the development of dwarfing rootstocks comes the opportunity for peach production to transition, like apple and cherry, to high-density planting systems to maximize land use efficiency, light, yields and fruit quality.

Figure 1. Overview of key orchard factors that influence preharvest peach tree and fruit physiology and affect harvest quality (Adapted from Minas et al. [1]).

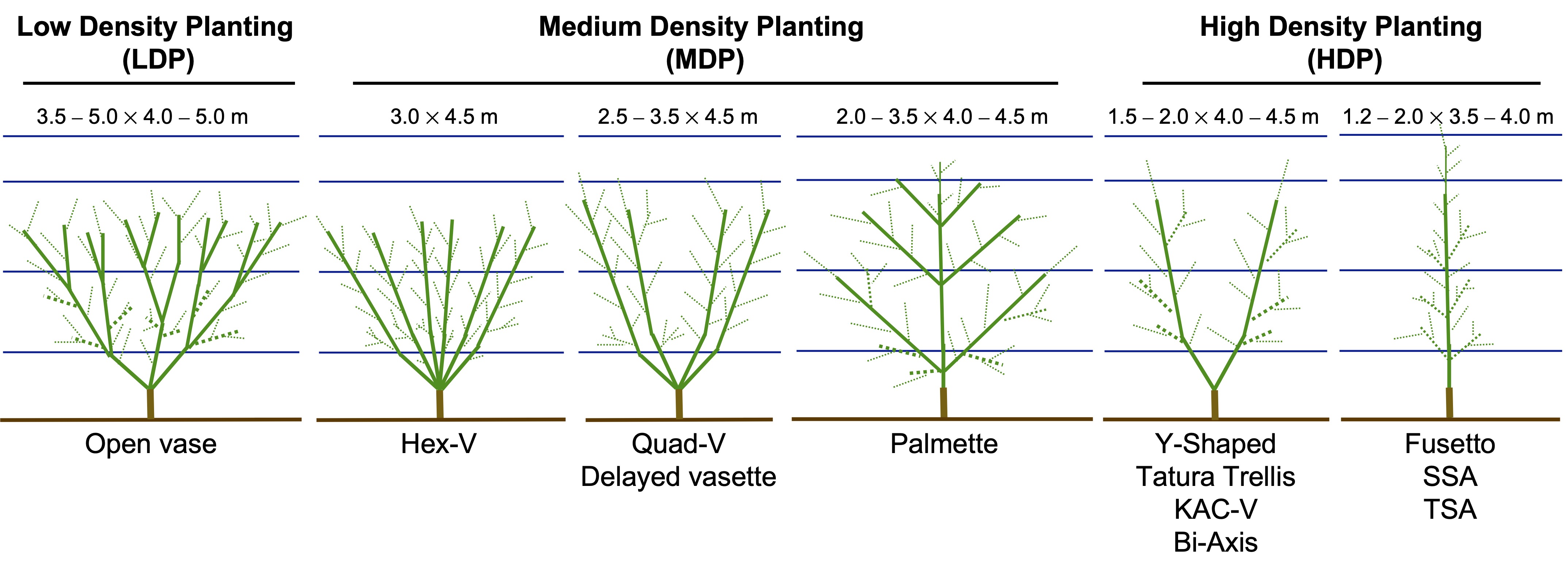

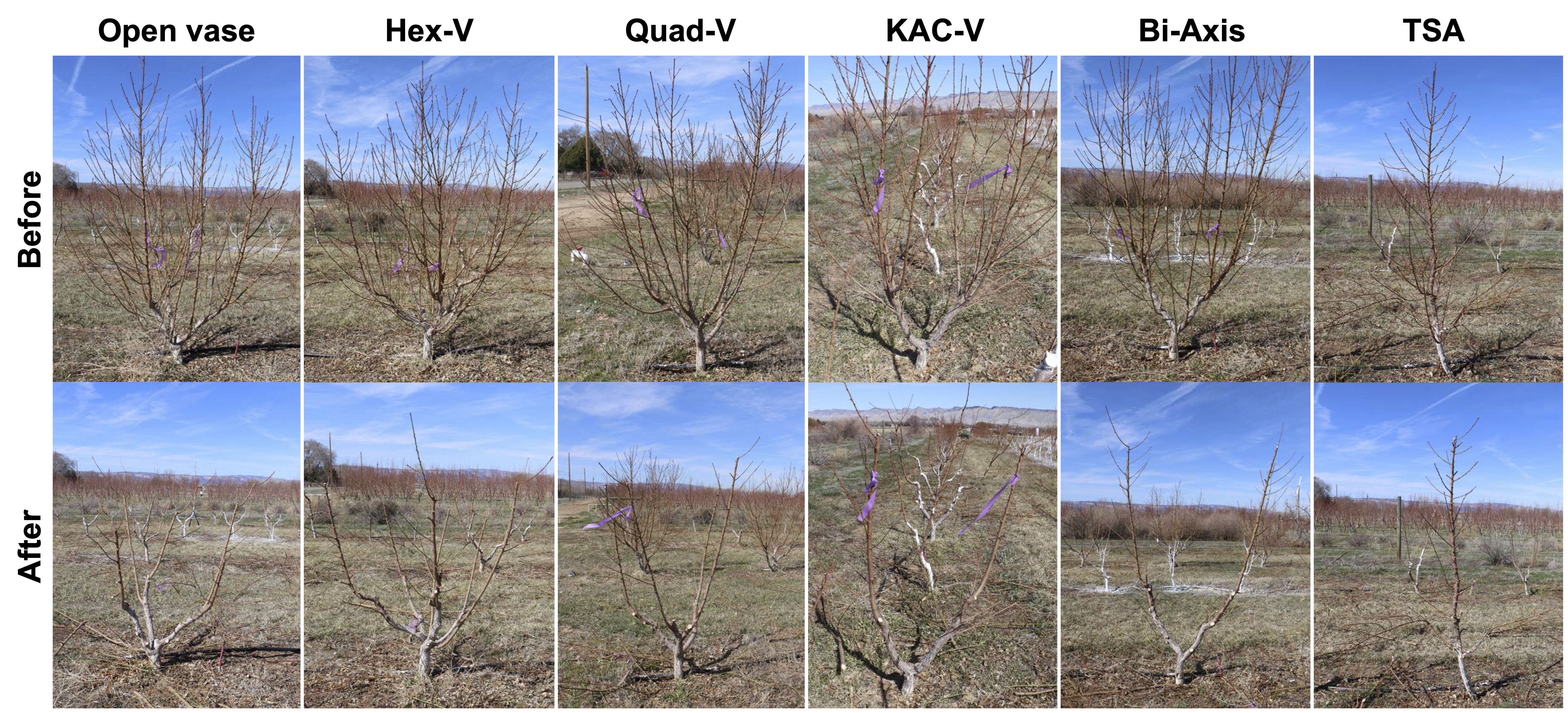

Several training systems have been developed over recent decades to improve economic, resource and labor characteristics of peach production. Peach training systems span from traditional, complex 3D canopy architectures, with multiple leaders per tree, to more modern high-density, simple/planar designs with single or multiple leaders per tree. The shift to modern orchard design is facilitated by genetic and horticultural manipulations that control vigor (e.g., low-vigor cultivars, dwarfing rootstocks, pruning/training, etc.) in order to increase planting density, production per hectare, light interception, light distribution and fruit quality [2 – 3][2][3]. Historically, low-density planting (LDP) training systems such as the open vase has been and continues to be widely used given a lack of dwarfing rootstocks and its ease of management. However, LDP systems do not achieve maximum light, yield nor quality potentials in an orchard. Now, with the increasing availability of dwarfing rootstocks, higher-density plantings have been pursued. However, when size-controlling rootstocks are not available, multi-leader systems (or cordons with several uprights) can be used to diffuse vigor horticulturally. In the pursuit of increased densities, medium-density planting (MDP) systems have been developed, such as the delayed vasette, palmette, Quad-V and Hex-V. The goal of MDP systems include: increasing light interception, increasing yields and reducing tree heights. Unfortunately, the complex 3D architecture of these LDP and MDP systems limit light distribution and can promote intra-tree shading. High-density planting (HDP) systems such as Y-shaped (e.g., Kearney Agriculture Center-V (KAC-V), bi-axis) or central leaders (e.g., Fusetto, Tall Spindle Axe (TSA), Slender Spindle Axe (SSA)) and its iterations have been developed to further increase yields and quality across the totality of the canopy, as light distribution is a key objective with these systems. These HDP training systems can generate homogenous fruiting walls to promote the use of mechanization/robotics to reduce labor costs (Figure 2, Figure 3) [1, 4][1][4].

Figure 2. Canopy architectures of the most widely used training systems in peach and their planting densities. Spacings listed as: intra-row x inter-row.

Traditional multi-leader 3D systems, like the open vase and delayed vassette, can yield a higher amount of fruit per tree, given the larger canopy volume, but these systems produce less on a per land area basis given their lower densities [3]. Additionally, these canopies may intercept a higher amount of light at the top/exterior portions of the tree, but often the bottom/internal portions are shaded. This is especially true for peach trees, as 80% of leaves are located in the top 40% of the tree in these 3D systems [5]. Génard and Baret [6] [6] demonstrated the variability of light distribution in open vase systems, reporting that 30% of shoots received <30% of available light, which is below the critical threshold for floral bud induction [4]. The result of shade in these interior/basal portions of the canopy, especially in high vigor cultivars/rootstocks, leads to reduced tree performance, yields and fruit quality (reduced color and SSC) [7]. Subsequently, this can lead to lower crop loads in the lower/interior parts of the canopy and an excessive vegetative vigor response, which can only exacerbate the problem of poor light distribution, unless summer pruning (or other vigor control) interventions are used. Grossman and DeJong [3] reported that open vase systems intercepted less light and produced less (Mt · ha-1) than higher density 2D cordon and KAC-V systems. Furthermore, these smaller tree, high-density planting (HDP) training systems facilitate better light distribution, so interior/basal portions of the canopy do not decline in yields and can maintain higher crop loads [8]. Nuzzo et al. [9] confirms this trend, reporting that when comparing a Y-system with an open vase system in peach, the Y-system resulted with higher levels of leaf area index (LAI, leaf area : ground area), light interception (LI, %) and yields. However, it is important to note that training system selection, along with its pruning/management, must be contextualized to cultivar/rootstock selection [10].

The ideal system will vary from farm to farm, but the overall goal of training system selection and orchard design should be: 1) to optimize light interception (60 – 70 %) and yields, 2) promote thin canopies (70 – 90 cm) with reduced leaf density for high light distribution and enhanced/uniform fruit quality and 3) find a balance between maximum yield potential and maximum fruit quality potential.

Figure 3. Orchard appearance of six canopy architectures of the most widely used training systems in ‘O’Henry’ peach trees (grafted on Krymsk®86 rootstock) before and after dormant pruning following the 3rd leaf from planting at the Colorado State University’s Experimental Orchard at Western Colorado Research Center - Orchard Mesa (WCRC-OM) located in Grand Junction, CO, USA.

References

- Minas, I.S., Tanou, G. and Molassiotis, A. Environmental and orchard bases of peach fruit quality. Sci. Hortic. 2018, 235, 307-322.

- Faust, M. Physiology of temperate zone fruit trees. John Wiley & Sons, Inc., 1989

- Grossman, Y.L. and DeJong, T.M. Training and pruning system effects on vegetative growth potential, light interception, and cropping efficiency in peach trees. J. of the Am. Soc. for Hortic. Sci. 1998, 123(6), 1058-1064.

- Corelli-Grappadelli, L. and Marini, R.P. Orchard Planting Systems. In The Peach: Botany, Production and Uses, DR Layne, & D. Bassi; CABI, Cambridge, MA, USA, 2008; p.264.

- Chalmers, D.J., Mitchell, P.D. and Jerie, P.H. The physiology of growth control of peach and pear trees using reduced irrigation. In International Workshop on Controlling Vigor in Fruit Trees 1983; 146, pp. 143-150.

- Génard, M. and Baret, F. Spatial and temporal variation of light inside peach trees. J. of the Am. Soc. for Hortic. Sci. 1994, 119(4), 669-677.

- Gullo, G., Motisi, A., Zappia, R., Dattola, A., Diamanti, J. and Mezzetti, B. Rootstock and fruit canopy position affect peach [Prunus persica (L.) Batsch](cv. Rich May) plant productivity and fruit sensorial and nutritional quality. Food Chem. 2014, 153, 234-242.

- Robinson, T.L. Interaction Of Tree Form And Rootstock On Light Interception, Yield And Efficiency Of 'Empire', 'Delicious' and 'Jonagold' apple Trees Trained To Different Systems. In VI International Symposium on Integrated Canopy, Rootstock, Environmental Physiology in Orchard Systems 451, 1996; pp. 427-436.

- Nuzzo, V., Dichio, B., Palese, A.M. and Xiloyannis, C. Productivity and fruit quality in peach trees [Prunus persica (L.) Batsch]. The effect of the training system and light availability. Atti VI Giornate Scientifiche SOI, Italy, 2002

- Lauri, P.E. and Corelli Grappadelli, L. December. Tree architecture, flowering and fruiting-thoughts on training, pruning and ecophysiology. In X International Symposium on Integrating Canopy, Rootstock and Environmental Physiology in Orchard Systems 1058, 2014; 291-298.