Cellulose nanomaterials from plant fibre provide potential applications in biomedical. The biomedical application of nanocellulose isolated from plant fibre, which is a carbohydrate-based source, is very viable in the 21st century. The essential characteristics of plant fibre-based nanocellulose, which include its molecular, tensile and mechanical

properties, as well as its biodegradability potential, have been widely explored for functional

materials in the preparation of aerogel. Plant cellulose nano fibre (CNF)-based aerogels are novel

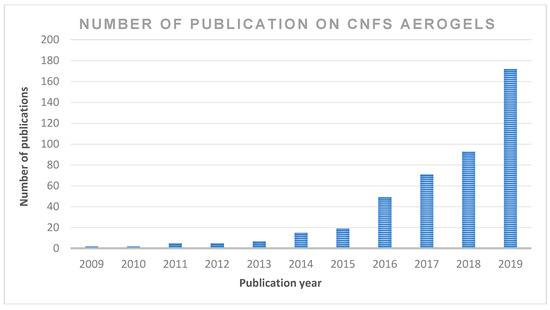

functional materials that have attracted remarkable interest. In recent years, CNF aerogel has been

extensively used in the biomedical field due to its biocompatibility, renewability and biodegradability.

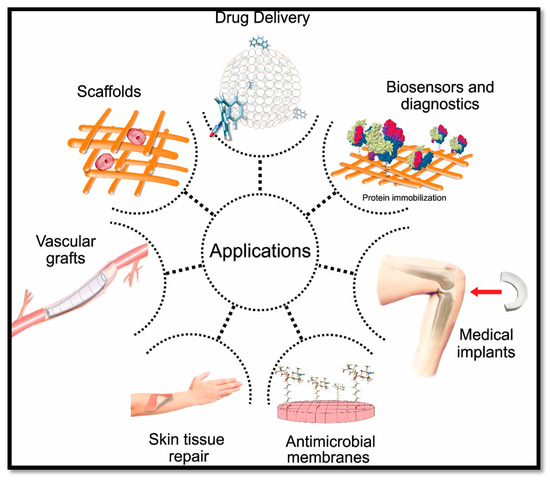

The effective surface area of CNFs influences broad applications in biological and medical studies such

as sustainable antibiotic delivery for wound healing, the preparation of scaffolds for tissue cultures,

the development of drug delivery systems, biosensing and an antimicrobial film for wound healing.

Many researchers have a growing interest in using CNF-based aerogels in the mentioned applications.

The application of cellulose-based materials is widely reported in the literature. However, only a few

studies discuss the potential of cellulose nanofibre aerogel in detail. The potential applications of CNF

aerogel include composites, organic–inorganic hybrids, gels, foams, aerogels/xerogels, coatings and

nano-paper, bioactive and wound dressing materials and bioconversion.

- Biomaterials

- Cellulose nanofibre

- Aerogel

- Nanotechnology

- Drug delivery

- Biomedical application

- Biopolymers

1. Introduction

Cellulose fibres derived from plant fibre have been widely used as reinforcements in polymers for packaging and biomedical applications. The use of aerogel in the biomedical application is on the increase, especially in tissue repair. The reparation of aerogel is difficult, time consuming and a major challenge in this research phase. However, extensive studies to develop materials of cheaper and better properties with high prospects and effectiveness for many applications are the focus of the present work. Aerogel contains more than 99% air and is a lightweight material, often prepared and manufactured in multi-shape structures depending on the required application. It has been manufactured from many inorganic and organic sources [1][2].

The majority of nanomaterials used in the manufacturing of aerogels are biopolymers. Biopolymers have been preferably used in biomedical and environmental applications due to their abundance, renewable source, low toxicity, biocompatibility and biodegradability. Various plant and animal biopolymers have been used in the preparation of aerogels. This includes cellulose, collagen, chitosan, alginate, etc. However, plant biopolymers are preferred due to their availability, biocompatibility, biodegradability and renewability potential. Cellulose has been reported as the most abundant natural polymer, and is mostly used in the preparation of aerogels more than other biopolymers. Cellulose is mainly derived from biomass, and it is the main composite of the plant cell walls [4]. It has also been widely isolated from other living organisms such as bacteria [4]. Bacterial cellulose does not contain impurities such as wax, lignin, pectin, and hemicelluloses, which were commonly present in cellulose derived from plants [4]. Plant cellulose can be isolated from different plants, parts of a plant or plant waste. According to the literature, the most used plants are soybean hulls, wheat straw, sugarcane, rice straw and husks, palm oil residue, pineapple, banana leaf fibre, bagasse, hemp and flax straws [5][6][7].

Figure 1.

Figure 2.

2. Cellulose Nanofibre (CNF) Aerogels in Medical Application

Table 1). CNF aerogel has been tested in diverse medical applications such as biosensing, tissue engineering [12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][

Table 14.

Material | Advantage | Method | Application | Reference | |||||||||||||

Super critically dried silica sol-gel discs | Facilitate the detection of chemicals and organisms | Use of viruses to trigger a response in immobilised bacteria and chemicals | Biosensors and diagnostics |

[14]. |

[96]. |

||||||||||||

Cellulose-based hydrogel | Superabsorbent capacity and satisfying biodegradability | Tested for biodegradability and antibacterial activity against E.coli | Antibacterial activity |

[15] |

[97] |

||||||||||||

Ultrafine cellulose acetate fibres with silver nanoparticles | Very strong antimicrobial activity | Direct electrospinning of a CA solution with small amounts of AgNO3 and then photoreduction |

(e) uncoated Polyvinyl alcohol (PVA)/CNF aerogel, | Antimicrobial film |

(f) coated PVA/CNF aerogel. |

[58][135] |

[16] |

[98] |

|||||||||

Cellulose acetate nanofibre | Inhibit the growth of G+ and G- bacteria | cellulose acetate nanofibre membrane using supercritical carbon dioxide | Strong antibacterial film |

[17] |

[99] |

||||||||||||

Hydroxyapatite/bacterial cellulose (HAp/BC) nanocomposite | Better adhesion and activity and faster proliferated | HAp/BC nanocomposite scaffolds were prepared to utilise the biomimetic technique | Bone tissue engineering. |

[18] |

[100] |

||||||||||||

Bacterial cellulose (BC) aerogel | Easily equipped | No aide interactions | BC aerogel matrix loaded with drug and the release behaviour from the matrix were studied | Drug delivery |

[19] |

[101] |

|||||||||||

Bacterial CNF incorporated with gold nanoparticles | Biocatalytic activity and fast response in low conc. of H2O2 | Immobilisation of heme proteins and enzymes | Fabrication of H2O2 biosensors. |

[20] |

[102] |

||||||||||||

Hydrophobic nanocellulose aerogels | Increase oral availability of drugs | Physical adsorption of a drug to aerogel for oral administration | Drug delivery system |

[21] |

[103] |

||||||||||||

Nanofibrillated cellulose (NFC) aerogels | Controlled drug delivery | NFC hydrogels are incorporated with the drug then convert it to aerogel | Drug delivery system |

[22] |

[104] |

||||||||||||

NCF/collagen composite aerogels | Strong absorption | Biocompatible | High proliferation. | Di-aldehyde NCFs and collagen were cross-linked together and formed the composite aerogels. | Tissue engineering and wound dressing |

[23] |

[105] |

||||||||||

Nanocellulose aerogel (NCA) | Significant increase in cell count. | Cultured NIH 3T3 cells for two weeks on NCA. | Scaffolds for 3D cell culture |

[24] |

[106] |

||||||||||||

Nanocellulose aerogel (NA) | Monitor the level of protease in chronic wounds | The complex of polypeptide-NA (PepNA) to detect the sensitivity of PepNA for human neutrophil. | Biosensors |

[25] |

[107] |

||||||||||||

Antibacterial cellulose-based aerogel | Bacterial inhibition rate of >99.99%. | Fixing antibacterial substances on the surface of cellulose aerogels. | Bacterial growth inhibition |

[26] |

[108] |

||||||||||||

CNF composite aerogel | Significant increase in cell count. | Cultured 3T3 NIH cells on poly (vinyl alcohol). | Scaffolds for 3D cell culture |

[27] |

[90] |

||||||||||||

NFC aerogel | Noticeable increase in drug release | Loaded of NFC aerogel with alkylating antineoplastic agent. | Cancer treatments |

[28] |

[109] |

||||||||||||

Nanocellulose derivate aerogel | Complete inhibition of tested bacteria. | Loading lysozymes and silver nanoparticles on CNF aerogel. | Bacterial growth inhibition |

[29] |

[110] |

||||||||||||

Strain-sensing protonated CNF aerogel | Stretchable and sensitive | Cross-linking CNF surface with PSS in PEDOT/PSS generated PEDOT/PSS/CNF aerogels | Biosensors |

[30] |

[111] |

||||||||||||

Nanocellulose/gelatine composite cryogels | Controllable porosity, and good biocompatibility | Used cross-linked di-aldehyde starch as carriers for controlled 5-fluorouracil (5-FU) release. | Controlled drug release |

[31] |

[112] |

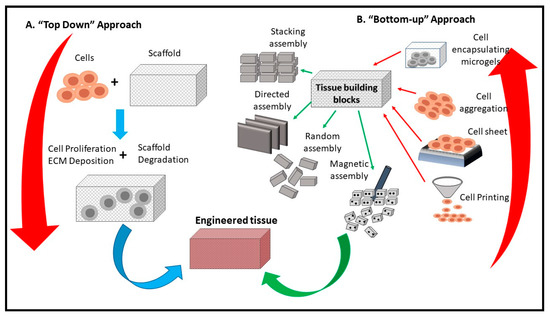

2.1. Tissue Engineering

In tissue engineering technologies, to maintain regular growth of tissue, the cells must have a 3D scaffold to permit a proper exchange of waste or nutrients for the growing cells [24]. CNF aerogels have been used as a scaffold for tissue engineering and are proven to enhance the growth and the proliferation of cells [23][32][33]. The high porosity (more than 99%) of CNF-based aerogels allows high oxygen permeability and accelerates the exchange of metabolic requirements in growing cells, leading to enhanced cell activities, better adhesion, and increased proliferation. Unlike the other scaffolds, CNF and bio-based scaffolds have less cytotoxicity to growing cells, and their biocompatibility has proved to be higher. Liu et al. [32] reported that CNF and bio-based scaffolds had less than 5% cell death after 72 h of cell growth.

Similarly, Cai et al. concluded that CNF aerogel microspheres significantly facilitated the growth and proliferation of fibroblasts [24]. Scaffolding is an essential part of tissue engineering, besides giving the oxygen, adhesion and metabolic requirements to cells, it also directs the shape and structure of the tissue.

Figure 3 presents a schematic diagram of a CNF-based scaffold and its usage in tissue engineering. Scaffolds can be designed based on the needed tissue, thus allowing the target cells to proliferate accordingly. Numerous composite aerogels have been prepared recently, containing different materials; Lu et al. [23] prepared composite aerogels using cellulose and collagen as precursors to reduces the influence of protease, thereby curing chronic wounds. This is because collagen is biocompatible, biodegradable and has strong adhesive characteristics on the skin. Hence, it is applicable for wound dressing.

Figure 37. Schematic diagram of the use of CNF in tissue engineering (adapted from Tingli Lu et al. [34]. Copyright 2013. Reproduced with permission from the Dove Medical Press publisher.

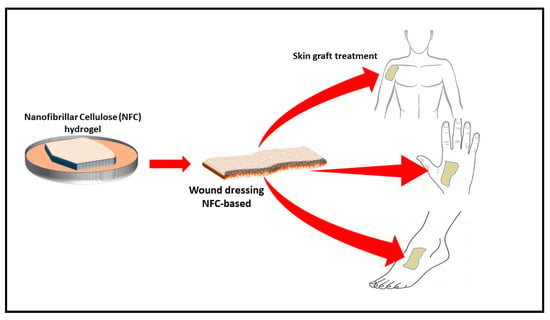

2.1.1. Wound Healing

The process of wound healing requires normal cellular function, moisture control, and optimal oxygen permeability [35][36][37]. The effective surface area of filamentous biomaterials has been explored to develop nanoparticle-based cellulose. For example, a nanocellulose polymer was developed for cellular uptake. Similarly, a synthesised polymer was used as a folate receptor for the testing of cancer [38]. However, CNF aerogel can be incorporated with an antimicrobial material during the preparation process and can be used as a wound dressing material (

Figure 4). Many plant extracts have been investigated for their antimicrobial activity. An evaluation of the effect of aqueous and alcoholic extracts of the peels of Punica granatum showed better activity than some of the common antibiotics. Similar materials can be incorporated in the aerogel to generate an antimicrobial aerogel for wound dressing [39].

Figure 48. Schematic drawing of production of biodegradable antimicrobial wound dressing material (adapted from T. Hakkarainen [40] et al., 2016). Copyright 2016. Reproduced with permission from Elsevier Ltd.

Antimicrobial-incorporated CNF aerogel prevents infection and provides moisture and optimal oxygen permeability to the cells for proliferation. CNF aerogel has an advantage in that regular wound dressing sheets may not provide oxygen permeability or microbial control. The use of cellulose nanofibre aerogels with their high porosity and surface area provide oxygen permeability, thereby preventing the growth of anaerobic bacteria. Moreover, they can be incorporated with an antibacterial ingredient to inhibit aerobic bacterial as well. Wang et al. [36] investigated CNF and copper-containing mesoporous bioactive glass as antibacterial ingredients in aerogel composites for the potential treatment of chronic wounds. The obtained aerogel completely inhibited the growth of

E. coli

Clostridium perfringens

2.1.2. Biosensing and Diagnostics

A biosensor is known as an analytical device that detects low concentrations of a desirable parameter, and it combines a biological component with a physicochemical detector. Nowadays, with the development of nanotechnology, the use of 3D frame materials like bioaerogels is a crucial strategy to overcome the challenges of the low instability and sensitivity associated with 1D and 2D materials. Low-density nanocellulose aerogel from cotton has been applied as a transducer biosensor surface for protease wound dressing (Edward et al., 2016). Bacterial CNFs incorporated with gold nanoparticles have been used to immobilise heme proteins and enzymes due to the extensive surface area and biocompatibility of nanofibres. This matrix of bacterial CNF incorporated with gold nanoparticles was used to fabricate hydrogen peroxide biosensors. The findings revealed that they have the capability of detecting low concentrations of hydrogen peroxide [41].

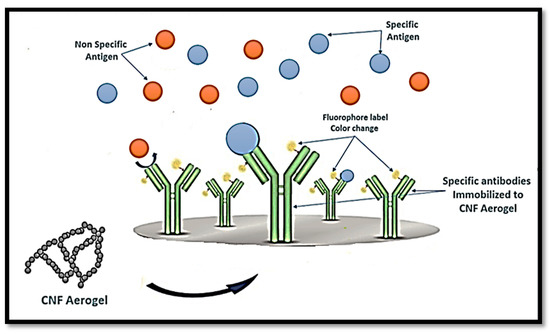

Similarly, Weishaupt et al. [42] developed a biosensor for heavy metals. The sensing of cyanobacterial biomolecule C-phycocyanin (CPC) was enhanced with genetic modified bacteria and integrated into CNF films as a carrier material, after which CPC–CNF films were able to detect free copper ions in human blood serum, and heavy metal sensitive fluorescent emission was observed. CNFs in aerogels can also be linked to either immobilised antigen or antibodies that conjugate to an enzyme or fluorophore label used to detect the specific antibody or antigen, respectively, as presented in

Figure 59.

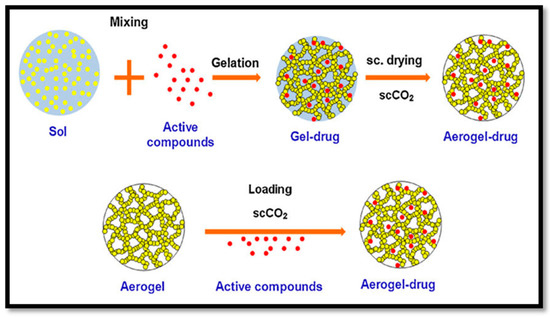

2.1.3. Drug Delivery

In recent decades, wide varieties of novel delivery systems were developed and reported on in relation to the prolonged and controlled release of pharmaceuticals and other bioactive compounds through different routes of administration. Hydrophobic nanocellulose aerogels are one of these controlled systems, and can increase drug bioavailability compared to the intravenous and oral bioavailability of the pure drug solution. Moreover, the other advantages include the mucoadhesive properties and the floating tendency of cellulose bioaerogel [21]. The use of CNFs has been explored in drug formulations due to their unique physicochemical properties. These unique properties include their rheological and barrier properties. These properties are responsible for the stability of CNFs in oil–water and air–water interfaces. This unique characteristic can also be attributed to their large surface area to volume ratio, which means that molecular interactions will require less soluble drugs. However, by varying the porous structure of CNF aerogels, and controlling the interactions between them and the desired drug to be delivered, the drug release profile can be tuned [22][43].

Figure 6. The drug delivery system can be controlled by controlling the size of the pores, surface area and drug and aerogel interactions. This approach could be a novel treatment for type one diabetes. Beta cell (β cell) pancreatic islets found in the pancreas that synthesise and secrete insulin could be immobilised in CNF aerogel and masked from our bodies’ immune systems. These aerogel-immobilised β cells could be introduced to the human body as a potential biosynthetic pancreas.

Figure 610. Fabrication process of drug delivery aerogel (cited from García-González et al. [44]. Copyright 2011. Reproduced with permission from Elsevier Ltd.

2.1.4. Antimicrobial Immobilisation

Cellulose nanofibre incorporated with natural or synthetic antimicrobial material can be immobilised inside the nanocellulose fibres (NCFs) based aerogels. This complex can be fabricated and then applied as an antimicrobial film for wound dressing. Many studies have been carried out regarding the incorporation of CNFs with silver and zinc as antibacterial inhibitors acting on different targets inside the microbial cell. Uymin et al. [29] have incorporated lysozymes and silver nanoparticles on the surface of CNF aerogels, resulting in the inhibition of the growth of 99.9% of all tested microbes.

Table 2 summarises some examples of the immobilisation of antimicrobial materials inside the NCFs. In the study conducted by Xiao et al. [45]], the authors investigated the efficacy of antibacterial nanocellulose-based sponges through the covalent immobilisation of gentamicin. The result obtained revealed that the incorporation of 0.33 wt% gentamicin in the CNF sponge has a non-leaching effect and a durable contact-active antibacterial effect. Although there was no significant effect on the surface morphology, the findings revealed that cross-linkages slightly influenced the mechanical properties.

Table 5.

|

Antimicrobial Agent |

Function |

Reference |

|

Silver nanoparticles (average size of 21 nm) incorporated into the cellulose acetate nanofibre |

Excellent antibacterial action against Gram-positive S. aureus and Gram-negative E. coli, K. pneumonia, and P. aeruginosa |

[46][124] |

Prepared CNF film even with low Mw of chitosan exhibited antibacterial activity against | ||

L. innocua |

2.2. Potential and Challenges of with CNF Aerogel in Biomedical Application

Table 3. Their morphological characteristics, as illustrated by the SEM images, show a good porous nested network, which promotes the growth of damaged tissue when they are used as implants.

Table 36.

|

SEM Images of CNF-Based Aerogels |

Type |

Reference |

||||

|

(a) and (b) pure CNF aerogels. |

[56][133] |

|||||

|

Silver nitrate (size ranging from 10 to 20 nm) incorporated into the cellulose acetate nanofibre |

Very strong antimicrobial activity against S. aureus, K. pneumonia, E. coli, and P. aeruginosa |

[47][125] |

||||

|

(c) neat CNF, (d) CNF/ carbon nanotubes (CNTs) (75/25 wt%). |

[57][134] |

Composition of nanofibrillated Cellulose with silver nanoclusters (NFC/AgNC) |

Antibacterial activity against E. coli |

[48][126] |

||

|

ZnO incorporated into the cellulose acetate nanofibre |

Exhibited strong antibacterial activity against S. aureus, E. coli, and Citrobacter |

[49][127] |

||||

and | ||||||

E. coli. | ||||||

|

Silver nanoparticles incorporated into bacterial cellulose nanofibres |

Strong antimicrobial potential against E. coli and S. aureus bacteria |

[50][68] |

||||

|

T4 bacteriophage incorporated into core/shell electrospun fibres of polyethene oxide, cellulose diacetate (CDA) and their blends |

Prevent bacterial growth on contaminated food surfaces |

[51][128] |

||||

|

Porous CNFs with biomass tar, polyacrylonitrile (PAN), and silver nanoparticles |

Excellent antimicrobial performance against Gram-positive S. aureus and Gram-negative E. coli, |

[52][129] |

||||

|

Chitosan adsorbed cellulose nanofibre (CNF) films |

[53][130] |

|||||

|

Covalent grafting of gentamicin to nanocellulose-based sponge |

Excellent antibacterial performance against E. coli and S. aureus, with bactericidal rates of over 99.9% |

[45][123] |

||||

|

Ag nanoparticle/cellulose nanofibre (Ag NP/CNF) composite aerogels |

The aerogel exhibited good antibacterial (for E. coli) and antifungal (for A. niger) activity. |

[54][131] |

||||

|

Cellulose nanofibres (CNFs) and thyme essential oil (EO) |

Sustained antibacterial release for fresh food preservation. |

[55][132] |

||||

According to the Cryogel Safety Data Sheet (2007), from a health perspective, aerogel may irritate the eyes and skin of some people. Furthermore, the nanosized particles of aerogels can cause silicosis in the respiratory tract if inhaled. The particles may also cause dryness in the eyes, mucous membranes and even skin. Other challenges such as CNFs’ toxicity, their environmental impact and the high-energy consumption of their production route need to be researched in detail. Furthermore, the biological and environmental toxicity of CNF-based materials’ remediation may be the greatest obstacle for their application and marketability, as the eco-toxicology studies on CNF-based materials are still limited and are at the primary stage [59]. However, more research needs to be performed to confirm whether CNF-based materials have any toxicity to humans, animals, or even microorganisms.