Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Conner Chen and Version 1 by Ramez Abdallah.

Composite materials are composed of two or more different materials having considerably different physical and/or chemical characteristics that, when merged, produce a material with attributes that differ from the separate elements. Composite materials are extensively utilized in the automobile, construction, transportation, aerospace, and renewable energy applications due to their durability, high strength, great quality, minimal maintenance, and low weight.

- recycling

- reinforced composites

- pyrolysis

- CFRC

- GFRC

- carbon fiber

- glass fiber

- sustainability

- Composite

1. Aerospace

Over the next ten years, the International Air Transport Association (IATA) estimates that 11,000 aircraft will be retired [5][1]. The COVID-19 pandemic has severely curtailed aviation travel, and this is likely to hasten the decommissioning of these planes, emphasizing the importance of recycling. Moreover, composite utilization in airplanes has increased dramatically, as is clear in the commercial aircraft produced by Airbus and Boeing. Take, for example, the usage of composites in the Airbus commercial aircraft A300 (4.5 wt%, 1971–2007) and B787 (50 wt%, 2007–present) [10][2]. By weight, the B787 body is 50% composites, 10% steel, 15% titanium, 20% aluminum (Al), and 5% other. Meanwhile, the composite material in B787 consists mainly of carbon sandwich structures, CFRP laminates, and fiberglass [1][3]. In the aircraft sector, Al has long been one of the most utilized materials. However, its utilization rate has dropped from 50% in the Boeing B777 to barely 20% in the Boeing B787 [11][4]. Comparisons of tensile modulus and strength characteristics of E-glass fibers (72 GPa, 3.5 GPa) against Al (68.9 GPa, 0.31 GPa) offer another explanation for the tendency toward composites [11][4].

2. Automotive

Because their light weight allows for the maximum possible performance, composites have been utilized in sports vehicles. Electric propulsion and self-guiding technologies have been made possible by recent advancements in mobility. These vehicles require lightweight materials to achieve higher ranges between recharging (i.e., electric automobiles), which has driven the need for high-volume composite manufacturing and EoL disposal. Another driving force behind the push for recycling is the fact that the automobile and aerospace industries, which produce large quantities of carbon fiber parts, also waste large percentages of the raw materials used (sometimes as much as 20–40%). One of the goals of the automobile industry is to have vehicles that are both fuel-efficient and lightweight. The use of CFRC in automotive components decreases the weight of a typical vehicle by 30% [2][5]. The importance of environmental stewardship cannot be overstated. EU law in the automobile sector mandates that 85% of a car can be recycled. CF scrap may be collected and transformed into new components with less than 10% of the energies used to manufacture virgin carbon fiber (CF), meeting legal and environmental goals [2][5]. CFRC help to reduce greenhouse gas emissions by reducing fuel usage, since they are utilized to make lighter automobile and airplane bodies [2][5]. Cost reduction is a significant motivator in the composites field [12][6].3. Marine

Composites have proven to be a game-changer in the offshore business. At present, glass fiber (GF) and carbon fiber (CF) composite materials play a huge role in marine energy development, shipbuilding, and marine engineering repair. Composite materials have slowly and steadily replaced upper metal (above water level) in more and more marine installations, whether new installations or in renovations of existing structures. Carbon fiber has several advantages in marine engineering construction [13,14,15[7][8][9][10][11],16,17], including lighter weight, high strength, and wear resistance. Most installations use structural parts to replace traditional building materials, reducing the high freight weight, seawater corrosion, and the problems arising from rebar materials [18,19][12][13]. The following are the primary advantages of GRP for maritime applications: environmental resistance, durability, cost-effectiveness, the ability to mold complex, seamless objects, the ability to adjust strength to load circumstances, excellent strength-to-weight ratio, light weight (about half that of similar steel constructions), low maintenance/repairability, and excellent long-term durability [18,19][12][13].4. Wind Energy

Composites are used in wind turbines because of their high specific strength. According to the GWEC, the total number of utility-scale wind turbines installed throughout the world has surpassed 330,000, most of which are projected to last 20–25 years. The first significant group of wind turbines made of composite materials will approach their EOL in the 2020s [20][14]. As a result of the approaching challenge of recycling wind turbine blades, roughly two gigawatts are expected to be replaced in 2019 and 2020 [21][15]. Denmark, for example, was a significant participant in the initial implementation of wind turbines, and has now become one of the first countries to tackle the mass disposal problem [20][14]. Some EU nations have prohibited the disposal of composite blades in landfills for environmental reasons [4][16], necessitating the development of novel EOL solutions for composites in this industry. The used scrap blade materials are anticipated to double in the next decade, from 1,000,000 t in 2020 to 2,000,000 t in 2030 [22][17]. An estimated 25% of all EOL trash will be generated in the EU, according to estimates [12][6]. The majority of turbine rotors feature three blades, with sizes ranging from 12 m to 80 m or more. Several of these blades are expected to be phased out shortly [20][14]. Siemens Gamesa Renewable Energy (SGRE) has a capacity of 14 MW wind turbines with Integral Blades that are 108 m long. The radius of the rotor is 111 m. As we enter the 2020s, recycling will become increasingly important. Nowadays, about 90% of the entire mass of wind turbines is recyclable, and the wind energy sector uses about 2.5 million tons of composite material worldwide [4][16]. Furthermore, by 2023, about 14,000 blades (weighing 40,000–60,000 tons) will be decommissioned. The wind industry prioritizes the recycling of these obsolete blades [4][16]. For disassembly, collecting, transportation, waste disposal, and restructuring of composite materials into production chains, this challenge requires both logistical and technical solutions [4][16].5. Construction and Infrastructure

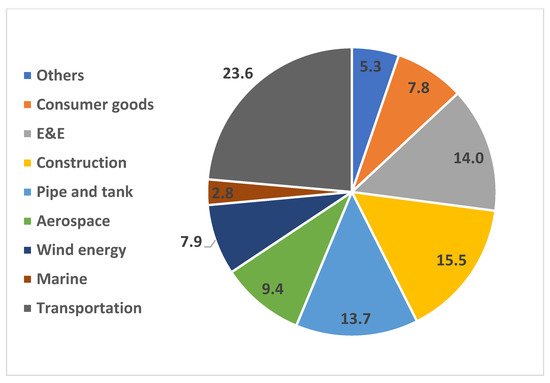

Perhaps the most intriguing application of sophisticated composite materials so far is a functional bridge on the state highway system. Hollow carbon composite tubes and lightweight concrete were employed in its construction. ACMs are excellent for seismic retrofitting because of their flexibility and ease of application. They are now a valuable resource for retrofitting and improving processes in forensic engineering. Glass and carbon fibers are most commonly used in epoxy resin matrixes [23][18]. Additionally, after wind turbines, WPCBs are one of the fastest-growing worldwide waste sources, accounting for a major portion of overall electronic waste and containing 27.4–45.55 wt% GF. Owing to the existence of hazardous metals and organic substances, as well as GFs, the recovery of WPCBs to retrieve GFs is a difficult procedure [7,22][19][17]. Composite material recycling will become more important in the 2020s and beyond as efforts are made to cut down on pollution and fulfill demand. Figure 2 shows the global composite materials’ market size distribution by application in 2020. Among composite materials, fiber-reinforced composites (FRC) are the most widely utilized [24,25,26,27,28][20][21][22][23][24]. The remarkable material characteristics of CFRC and GFRC make them particularly useful in this regard [29,30,31,32][25][26][27][28]. FRC materials are attractive as a replacement for steel and other materials due to their low weight, high strength, durability, and form flexibility. CF and GF, with polyester matrix resin as components, were used to create modern FRC materials in the early 1950s. They’re commonly utilized in the construction of boats, automobiles, and storage tanks [30][26]. The international market for composite materials is growing and is estimated to exceed $96 billion in 2020, up 40% from 2014. Carbon and glass fibers are the most common materials; CFRC and GFRC products account for $57 billion and $30 billion, respectively, of the $96 billion [2][5]. The FRC industry’s expansion has boosted both productivity and consumption. However, it has also resulted in a large number of EOL materials. The struggle to preserve and recycle EOL scrap FRC has become a major barrier to the sustainability of a circular economy. In the past, the industry rushed to use these materials without understanding how to properly dispose of them. For decades, the two most common disposal techniques used by the composite industry were landfill and incineration. The drawbacks of these techniques have led to increased environmental awareness, resulting in the search for sustainable disposal methods and strategies to avoid trash accumulation [33,34,35,36,37,38,39][29][30][31][32][33][34][35]. Over the past few years, several studies have analyzed market demand for various composites, as well as the associated quantity of accumulating waste, in order to minimize the unavoidable negative effects. The market for fiber-reinforced polymer composites (FRPC) in the United States was about $12 billion in 2020, with a yearly growth rate of 6.6% [40,41][36][37]. To meet such a high need for virgin carbon fiber (vCF) and virgin glass fiber (vGF), the accumulating CFRC and GFRC waste must be recycled effectively, to minimize environmental consequences while also meeting the demand [42][38]. However, converting CFRP and GFRP into useful resources is a difficult problem that threatens the future of the fiber-based industry [43,44,45,46][39][40][41][42]. As a result, the treatment and recycling of FRC materials such as CFRC/GFRC within environmental constraints, government regulations, manufacturing costs, resource management, and economic opportunity are all critical worldwide problems. The present research demonstrated the influence of the pyrolysis technique as a rising and feasible technology for FRC recycling. This research will help to systematize technological knowledge of CFRC/GFRC recycling processes such as pyrolysis.References

- The International Air Transport Association (IATA). Helping Aircraft Decommissioning. 2020. Available online: https://www.iata.org/en/programs/environment/aircraft-decommissioning/ (accessed on 11 August 2021).

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68.

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28.

- Chen, T.; Kazerooni, D.; Ju, L.; Okonski, D.A.; Baird, D.G. Development of Recyclable and High-Performance In Situ Hybrid TLCP/Glass Fiber Composites. J. Compos. Sci. 2020, 4, 125.

- Amaechi, C.V.; Odijie, A.C.; Orok, E.O.; Ye, J. Economic aspects of fiber reinforced polymer composite recycling. Encycl. Renew. Sustain. Mater. 2020, 2, 377–397.

- Amaechi, C.V.; Agbomerie, C.O.; Sotayo, A.; Wang, F.; Hou, X.; Ye, J. Recycling of Renewable Composite Materials in the Offshore Industry. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019.

- Gagani, A.I.; Krauklis, A.E.; Echtermeyer, A.T. Orthotropic fluid diffusion in composite marine structures. Experimental procedure, analytical and numerical modelling of plates, rods and pipes. Compos. Part A Appl. Sci. Manuf. 2018, 115, 196–205.

- Rocha, I.B.C.M.; Parente, E., Jr.; Melo, A.M.C. A hybrid shared/distributed memory parallel genetic algorithm for optimization of laminate composites. Compos. Struct. 2014, 107, 288–297.

- Gagani, A.; Krauklis, A.; Echtermeyer, A.T. Anisotropic fluid diffusion in carbon fiber reinforced composite rods: Experimental, analytical and numerical study. Mar. Struct. 2018, 59, 47–59.

- Starkova, O.; Aniskevich, A. Modelling of moisture sorption by CFRP rebars with vinylester matrix. Adv. Compos. Lett. 2004, 13, 096369350401300603.

- Gagani, A.I.; Krauklis, A.E.; Sæter, E.; Vedvik, N.P.; Echtermeyer, A.T. A novel method for testing and determining ILSS for marine and offshore composites. Compos. Struct. 2019, 220, 431–440.

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26.

- Jayalakshmi, C.G.; Inamdar, A.; Anand, A.; Kandasubramanian, B. Polymer matrix composites as broadband radar absorbing structures for stealth aircrafts. J. Appl. Polym. Sci. 2019, 136, 47241.

- Marsh, G. What’s to be done with ‘spent’wind turbine blades? Renew. Energy Focus 2017, 22, 20–23.

- Belton, P. What Happens to All the Old Wind Turbines? BBC News: Business. 22 February 2020. Available online: https://www.bbc.com/news/business-51325101 (accessed on 11 May 2021).

- WindEurope–Cefic–EuCIA. Accelerating Wind Turbine Blade Circularity. White Paper. 2020. Available online: https://windeurope.org/wp-content/uploads/files/about-wind/reports/WindEurope-Accelerating-wind-turbine-bladecircularity.pdf (accessed on 11 August 2021).

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240.

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Roldán, A.; Gallego, A. Monitoring of carbon fiber-reinforced old timber beams via strain and multi resonant acoustic emission sensors. Sensors 2018, 18, 1224.

- Liu, Y.; Farnsworth, M.; Tiwari, A. A review of optimisation techniques used in the composite recycling area: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2017, 140, 1775–1781.

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2014, 48, 593–608.

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99.

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges, and possibilities in a circular economy. Renew Sustain. Energy Rev. 2018, 97, 165–176.

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050. Resour. Conserv. Recycl. 2017, 125, 264–272.

- Erden, S.; Ho, K. Fiber-reinforced composites. In Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: John Solston, UK, 2017; pp. 51–79.

- Pimenta, S.; Pinho, S.T. Recycling carbon fiber reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392.

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263.

- Yao, S.; Jin, F.; Rhee, K.Y.; Hui, D.; Park, S. Recent advances in carbon fiber-reinforced thermoplastic composites: A review. Compos. B Eng. 2018, 142, 241–250.

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317.

- Hadi, P.; Ning, C.; Ouyang, W.; Xu, M.; Lin, C.S.; McKay, G. Toward environmentally benign utilization of nonmetallic fraction of waste printed circuit boards as modifier and precursor. Waste Manag. 2015, 35, 236–246.

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An eco-audit comparison. J. Clean. Prod. 2019, 212, 1268–1281.

- Pillain, B.; Loubet, P.; Pestalozzi, F.; Woidasky, J.; Erriguible, A.; Aymonier, C.; Sonnemann, G. Positioning supercritical solvolysis among innovative recycling and current waste management scenarios for carbon fiber reinforced plastics thanks to comparative life cycle assessment. J. Supercrit. Fluids 2019, 154, 104607.

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460.

- Prinçaud, M.; Aymonier, C.; Loppinet-Serani, A.; Perry, N.; Sonnemann, G. Environmental feasibility of the recycling of carbon fibers from CFRPs by solvolysis using supercritical water. ACS Sustain. Chem. Eng. 2014, 2, 1498–1502.

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.M.; da Silva Moris, V.A.; de Paiva JM, F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess 2017, 23, 1825–1838.

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99.

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129.

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing life cycle energy and global warming potential of carbon fiber composite recycling technologies and waste management options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865.

- Moriyama, A.; Hasegawa, T.; Nagaya, C.; Hamada, K.; Himaki, T.; Murakami, M.; Horie, M.; Takahashi, J.; Iwahashi, H.; Moritomi, H. Assessment of harmfulness and biological effect of carbon fiber dust generated during new carbon fiber recycling method. J. Hazard. Mater. 2019, 378, 120777.

- Roberts, T. Rapid growth forecast for carbon fiber market. Reinf. Plast. 2007, 51, 10–13.

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012.

- Rodrigues, G.G.M.; de Paiva, J.M.F.; do Carmo, J.B.; Botaro, V.R. Recycling of carbon fibers inserted in composite of DGEBA epoxy matrix by thermal degradation. Polym. Degrad. Stab. 2014, 109, 50–58.

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215.

More