There is an increasing number of people that sufferhealth problems from the consumption of wheat and other cereals that contain gluten as well as all their derived products. They can experience different health conditions such as celiac disease, non-celiac gluten sensitivity (NCGS), wheat allergy or irritable bowel syndrome. Celiac disease is a specific immune response that is caused after consumption of gluten present in wheat, rye, barley and related grains from genetically predisposed patients. On the other hand, wheat allergy is triggered by the consumption of insoluble gliadins of wheat that react with immunoglobulin E (IgE) causing allergy symptoms that could be life-threatening. Contrary to celiac disease, wheat allergy is not reported to cause permanent damage to the gastrointestinal system. For celiac patients and those diagnosed with wheat allergy, the only treatment is to adhere to a very strict diet that does not contain gluten or a wheat-free diet, respectively. Gluten-free products have come into the market in order to alleviate health problems such as celiac disease.

- gluten-free bread

- plant proteins

- animal proteins

- microalgae

1. Plant-Based Gluten-Free Protein

Many studies found in the recent literature report the use in a gluten-free bread recipe of highly concentrated protein sources of plant origin (

). The use of these sources intends to improve not only bread quality but also its nutritive values. Using protein-rich sources of plant origin has gained interest due to the limitation of animal origin counterparts due to their allergenic character. Generally, the gluten-free flours of plant origin differ in the content and quality of protein. Wu et al. [1] prepared breads from a range of gluten (white wheat, wholemeal wheat, spelt and rye) and gluten-free (lupin, buckwheat, chickpea, amaranth) flours standardized at 10% protein with maize starch. They observed differences in the proportions of essential amino acids (0.31–0.35 and 0.34–0.41 for gluten and gluten-free flours, respectively) with lysine and arginine showing much higher levels in gluten-free flours compared to glutenous flours, whereas the opposite was observed for proline. Low levels of proline in gluten-free flours were considered responsible for the lower rising capacity during proofing.

Different high protein sources of vegetable origin reported in recent published literature to improve gluten-free bread.

| Source | Concentration (% in the Starchy Flour Mixture) | Control Bread | Literature |

|---|

| Gluten-free cereals | |||

| rice protein | 30% | 100% maize starch | [13][2] |

| rice protein | 5%, 10% | 50% rice flour: 50% maize starch | [14][3] |

| rice bran protein concentrate | 2%, 4% | 100% rice flour | [15][4] |

| Zein | 15% | 15% vital wheat gluten: 85% rice starch | [16][5] |

| Zein | 15% | 100% wheat flour, 100% starch from: rice, maize, potato | [17][6] |

| Zein | 2.5%, 5%, 10% | 100% wheat flour, ~88% maize starch: ~12% potato starch | [18][7] |

| Legumes | |||

| Pea protein | 30% | 100% maize starch | [13][2] |

| Pea protein | 5%, 10% | 50% rice flour: 50% maize starch | [14][3] |

| Pea protein | ~10% | 80% maize starch: 20% potato starch | [19][8] |

| Pea protein | 2% | 100% potato starch | [20][9] |

| Lupin protein | ~10% | 80% maize starch: 20% potato starch | [19][8] |

| Lupin protein | 2% | 100% potato starch | [20][9] |

| Soy protein | ~10% | 80% maize starch: 20% potato starch | [19][8] |

| Soy protein | 2%, 4%, 6% | 100% rice flour | [21][10] |

| Soy protein | 4% | 100% rice flour | [22][11] |

| Soy protein | 2% | 100% potato starch | [20][9] |

| Oil seeds | |||

| Rapeseed protein | 6%, 9%, 12%, 15% | 80% corn starch: 20% potato starch | [23][12] |

| Rapeseed protein | 6%, 9%, 12%, 15% | 80% corn starch: 20% potato starch | [24][13] |

| Canola protein extract | 3%, 6%, 9% | 100% wheat flour, 100% rice flour | [25][14] |

| Sunflower protein | 5%, 10%, 20% | 70% rice flour: 30% maize starch | [26][15] |

| Tubers | |||

| Potato protein | 2%, 6%, 10% | 80% maize starch: 20% potato starch | [27][16] |

| Potato protein | 2% | 100% potato starch | [20][9] |

In recent years, different plant-based high protein isolates have been used for gluten-free bread preparation (

). Rice flour is considered as the most suitable among the cereal flours for the production of gluten-free bread because it is considered hypoallergenic and has high digestibility besides a bland taste and white colour that do not affect the final bread quality. Derived from rice flour, rice protein isolate is used as a safe source of protein in gluten-free bread production [2]. On the other hand, rice bran protein concentrate obtained from rice bran that is a by-product of rice production is also considered a non-allergenic protein. It is utilized for increasing the protein content of gluten-free bread [4]. It is isolated from rice bran via an alkaline-acid extraction technique resulting in 68% protein on a dry basis. Zein, a protein from another non-gluten cereal, maize, was used to provide extensibility to starch-based doughs [5][6] and firmness to the bread crumb comparable to wheat breads [7].

Besides non-gluten cereals, proteins from legumes have attained the interest of researchers due to their adequate protein profile. Although being high in lysine, they are deficient in amino acids methionine, cystine and cysteine [17].

Soy protein isolate is obtained by extraction from the soy bean, and is of high biological value due to high amounts of the essential amino acids lysine and methionine [18]. It has the ability to alter water absorption of the dough mixture and thereby impacts its rheology. Moreover, soy protein isolates have high foaming capacities, as well as high foam stability [9]. Contradictory results are reported in the literature about the resulted bread volume and crumb structure [9][11]. Horstmann, Foschia and Arendt [9] report that soy-protein-enriched bread (2% on potato starch) produces bread with a low volume and a dense crumb structure and a low consumer acceptance score, whereas Masure, Wouters, Fierens and Delcour [11] showed that the addition of soy (4% on rice flour) produced bread with a similar volume of that of the control bread made of rice flour and in a homogeneous crumb structure with very large gas cells.

Lupin protein represents another protein-rich source gaining interest in gluten-free bread production [8]. It was noted that the extraction method used to obtain lupin protein concentrates/isolates plays a significant role in the functional qualities of lupin proteins, including their chemical composition, emulsification, rheology and thermal properties [19].

Pea protein, an extract from pea seeds, has become a popular product in the food industry due to its well-balanced amino acid profile rich in the essential amino acid lysine [20]. According to Horstmann, Foschia and Arendt [9], the emulsifying capacity of legume isolates decreases in the following order: soy > lupin > pea, whereas emulsifying stability decreases in the order: lupin protein > soy protein > pea protein.

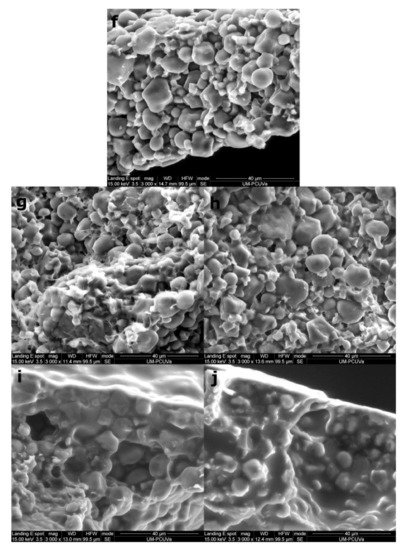

A highly concentrated protein of legume origin is being used recently not only to equilibrate the amino acid profile of gluten-free bread but also to strengthen the protein matrix in these breads. Micrographs in

reveal the matrix created in the gluten-free breads with different protein sources. Compared to the control bread made of rice flour and maize starch (

f), cross-sectional photographs of gluten-free bread with added rice and pea protein (

g and h, respectively) show a higher number of small filaments connected to starch granules. These filaments are more evident for rice protein and represent protein molecules that link starch granules [3]. Incorporation of rice protein until 10% increases the specific volume of the gluten-free bread whereas when added 5% of pea proteins, there is not observed any difference with the control. Any further increase (10%) decreased the specific volume of the bread [3]. In their study, Ziobro, Juszczak, Witczak and Korus [8] observed that the pea and soy protein addition at 10% level has a negative effect on bread volume, whereas lupine protein showed similar values with control bread (maize and potato starch). The crumb structure of pea, soy and lupine breads was more porous and has more large pores than control bread. Nevertheless, lupine is considered a better option due to the lower hardness of crumb than pea and soy.

Micrographs of crust cross-section at 3000× magnification. Images correspond to breads supplemented with 10% protein and control sample: Control (50% rice flour: 50% maize starch) (

), Rice protein 10% (

), Pea protein 10% (

), Egg white powder 10% (

), Whey protein 10% (

) [3].

The incorporation of legume proteins produces gluten-free breads with darker crumb and crust [2]. Among proteins of vegetal origin added to gluten-free bread, pea protein decreases the luminosity of the bread crust to a greater extent than rice, due to the higher lysine content that reacts with carbohydrates producing more coloured products during the Maillard reaction [2]. Although different flavours are produced during the baking of breads there are not all considered attractive to the consumers, it was observed that the acceptability of panellist decreases in the following range: lupine protein, pea protein, soy protein.

Different regulatory authorities such as European [21], Australian and New Zealand [22] legislation consider rapeseed protein isolate (containing 96% on dry basis protein) as a novel food ingredient for use in food products, whereas the US FDA gives GRAS status [23]. Its inclusion in the gluten-free bread recipe provides not only valuable amino acids but also affects the pasting characteristics of starch and modifies rheological characteristics of dough [13] as well as improves quality characteristics, sensory attributes and storage of gluten-free bread [12]. Levels of addition higher than 9% resulted in higher bread volume and lower hardness of the breads during storage compared to control bread. In another study, when canola proteins were added to a white rice flour bread recipe up to 6% resulted in an improvement of the technological properties of the dough and the resulted bread [14].

Sunflower protein concentrate represents another source of protein. Containing more than 75% proteins, it is obtained by extraction from the cake that remains after oil extraction from the seeds. Its high water-holding capacity decreased bread hardness during the storage, whereas the dark colour decreased the brightness of the bread making them more attractive to the panellist due to the similarity with whole flour [15].

Potato protein is extracted from the remains after the removal of starch [24]. The nutritional quality of potato protein is considered high in quality because it contains a high proportion of lysine, approaching the quality of proteins in eggs [25]. This isolate (>90% protein dry base) was employed by Witczak, Juszczak, Ziobro and Korus [16] for the production of gluten-free bread.

2. Animal-Based Gluten-Free Protein

Among the high protein sources of animal origin, those based on milk and eggs are widely used to increase the protein content and improve amino acids’ profile in gluten-free breads. These characteristics made these sources highly popular for gluten-free breads in the recent scientific literature (

). Proteins of animal origin have good solubility, high emulsifying and foaming capacity and high stability. This fact is observed in surface photographs (

) where a film is visible covering the starch granules in the case when egg white powder and whey protein were used. There is observed a very distinct difference when compared to the control bread or to breads with rice and pea protein isolates [3]. Animal proteins such as whey protein and egg white powder were found to decrease the crispness in the crust of gluten-free breads [3]. The type of protein added affects the crust colour since it reacts with the carbohydrates triggering Maillard reactions. In general, when protein sources of animal-origin are added to a gluten-free recipe, they decrease the luminosity of crust, producing breads with a darker and more reddish crust than the control bread [2][8][26]. There are differences in the decrease in luminosity among the different protein sources, with whey protein yielding a darker crust than egg white powder due to the high lysine content that this protein contains and the importance it has in the Maillard reaction [3]. In the literature, there are reported contradictory results for the crust and crumb colour, possibly due to the differences in the level of proteins added [2][4][8][26]. Generally, the higher the protein addition level, the darker the colour [26].

Different high protein sources of animal origin in recent published literature to improve gluten-free bread.

| Source | Concentration (% of Starchy Flour Mixture) | Control Bread | Literature |

|---|

| Dairy | |||

| whey protein | 10%, 20%, 30% | 100% wheat flour, 50% cassava starch: 50% chickpea flour |

[37][26] |

| whey protein | 30% | 100% maize starch | [13][2] |

| whey protein | 5%, 10% | 50% rice flour: 50% maize starch | [14][3] |

| whey protein | 2%, 4%, 6% | 100% rice flour | [21][10] |

| whey protein | 12% * | 50% quinoaflour: 50% (maize starch, potato starch, modified maize starch, modified potato starch) | [38][27] |

| Eggs | |||

| egg white powder | 30% | 100% maize starch | [13][2] |

| egg white powder | 5%, 10% | 50% rice flour: 50% maize starch | [14][3] |

| egg white powder | 2%, 4% | 100% rice flour | [15][4] |

| egg white powder | ~10% | 80% maize starch: 20% potato starch | [19][8] |

| egg white powder | 5%, 10%, 15% | Commercial gluten-free flour (mixture of garbanzo bean flour, potato starch, tapioca flour, whole grain sorghum flour and fava bean flour) | [39][28] |

| egg white powder | 4% | 100% rice flour | [22][11] |

| Other animal sources | |||

| collagen | ~10% | 80% maize starch: 20% potato starch | [19][8] |

The volume and the texture parameters of the breads with added animal protein content vary depending on the protein type and the level of addition [2][4][8][27][28]. For example, Ziobro, Juszczak, Witczak and Korus [8] report an increase in the specific volume of breads when 10% albumin was added. Contrarily, Phongthai, D’Amico, Schoenlechner and Rawdkuen [4] report an increase in the specific volume of bread when the level increases to 2% and then a decrease for a further increase to 4%, whereas Sahagún and Gómez [2] report a decrease at the 30% addition level. A comparison is difficult since in the above studies, the egg protein source was added in different flour mixtures, and different levels of hydration were applied resulting in different dough systems. The same is valid for the texture and the structure of these breads. Moreover, the composition of the high protein source can affect the quality of the bread. Han, Romero, Nishijima, Ichimura, Handa, Xu and Zhang [28] compared two egg white sources of similar composition but differing in water solubility and reported that the powder with more water-soluble protein aggregates was associated with larger improvement in bread quality. On the other hand, Masure, Wouters, Fierens and Delcour [11] reported that regular egg white powder and dry heated egg white powder produced similar bread loaf volume, but regular egg white showed lower firmness during storage than the dry heated counterpart. Another factor that must be taken into consideration is the basic flour mixture used to prepare the gluten-free bread. In their study, Aprodu and Banu [27] observed that the type of starch also affects the efficiency of whey protein on thermo-mechanical properties, specific volume and firmness of the bread crumb.

Collagen is reported as more effective than albumin to reduce the hardness and prevents staling of gluten-free breads [8]. Generally, the hardness of the crumb is increased with increasing protein concentration [26], suggesting the need for optimization of the level of protein enrichment.

3. Sea Microorganisms- and Insect-Based Proteins

Another protein source used for the preparation of gluten-free breads can be obtained from algae, seaweed and insects (

). Seaweeds or macroalgae are complex multicellular organisms that grow in salt and marine environments, and most of them can be used for direct human nutrition.

Different high protein sources from algae and insects reported in recent published literature to enrich gluten-free breads.

| Source | Concentration (% of Starchy Flour Mixture) | Control Bread | Literature |

|---|

| Algae | |||

| Chlorella powder (Chlorella sorokiniana) | 2.1%, 4.2% | 25% rice flour: 58.3% maize starch: 16.7% pea flour | [40][29] |

| Microalgae powder (Nannochloropsis gaditana L2; Chlamydomonas sp. EL5) | 1%, 3% | 31% rice flour: 46% buckwheat: 23% potato starch | [41][30] |

| Spirulina (strain LEB -18) | 1–4% | 100% rice flour | [42][31] |

| Brown algae powder (Ascophyllum nodosum) | 2%, 4%, 6%, 8%, 10% | 45% white rice flour: 45% maize flour: 10% millet flour | [43][32] |

| Insects | |||

| Cricket powder (Acheta domesticus) | 2%, 6%, 10% | 80% maize starch: 20% potato starch | [44][33] |

| Cricket powder (Acheta domesticus) | 5.5% | 80% maize flour: 20% rice flour | [45][34] |

| Cricket powder (Gryllus assimilis) | 10%, 20% | 70% rice flour: 30% maize starch | [46][35] |

Microalgae are considered as a rich source of protein of high quality (rich profile of essential amino acids), besides other bioactive compounds (e.g., polyunsaturated fatty acids, carotenoids, vitamins) [36]. Becker [36] in his review reports that the protein content of different algae that can be used in the food industry varies 6–71% of the dry matter, but most of them contain more than 28%. In addition, the amino-acid profile of microalgae protein is considered well-balanced and comparable with that recommended by WHO/FAO and that of eggs and soybean [36]. Some varieties of macroalgal species have been used to obtain bioactive peptides that exert beneficial health effects beyond those benefits associated with basic nutritional values [37].

Among microalgae, Chlorella species were reported to have a high amount of protein in combination with an adequate amount of essential amino acids, especially higher levels of the essential amino acids lysine and tryptophane, in order to provide adequate nutrition [38]. Besides protein, they contain in high amounts carbohydrates (8–64%) and lipids (2–22%) [36]. In order to minimize production cost, instead of refined protein, the industry tries to promote the use of algal biomass as a whole in powder form and not as a protein isolate. The use of these powders was reported to alter sensory characteristics of the bread such as colour, aroma and flavour as well as texture [29][30]. Breads enriched with C. sorokiniana were characterised by low luminosity and a deep green colour [29]. Similarly, other authors observed a decrease in bread luminosity and an increase in green and yellow colour when two other microalgae were used as the species, observing differences that are due to both species and level of addition [30]. Changes in dough and bread colour are due to the presence of pigments (mainly chlorophyll) in microalgal biomass.

In their study, Khemiri, Khelifi, Nunes, Ferreira, Gouveia, Smaali and Raymundo [30] evaluated the effect of the incorporation of two different microalgae (

and

sp. EL5) on the dough properties. They suggest that for levels 1% and 3%, there was no need to adjust the water content and observed that dough mixing curves of microalgae-added doughs were similar to that of the control. The incorporation of microalgae increased dough development time and stability of the doughs, but differences were noticed based on microalgae strains and the level of addition. On the other hand, texture parameters (firmness, adhesiveness and cohesiveness) of the doughs were not affected by microalgae addition. Contrarily, the addition of microalgae significantly increased the firmness and adhesiveness of the gluten-free bread crumb as microalgal biomass incorporation increased, but without producing significant changes in bread cohesiveness. These changes were considered positive by the authors since it helped to strengthen the texture of the gluten-free bread by reinforcing the protein structure of the bread and reduce the brittleness that characterizes gluten-free breads [30]. In another study, breads with microalgae

at a higher level of addition (4.2%) showed increased crumb porosity in comparison with the control bread. This behaviour was attributed to the high protein and lipid contents present in the powder [29]. Generally, besides the odour, taste and texture, panellists appreciated the intense green colour of the 3% supplemented bread scoring higher than the control [30].

Dough and bread pH is a parameter of great importance since it determines the growth kinetic of yeasts/microorganisms during fermentation, and the final bread pH is linked with bread taste and storage but often is not reported. The addition of microalgal biomass increased the pH of the gluten-free dough with values varying from 5.77 in control to 6.05 and 6.01 for

sp. EL5 and

L2, respectively, when the microalgae were added at 3% [30]. Similarly, Różyło, Hameed Hassoon, Gawlik-Dziki, Siastała and Dziki [32] observed an increase in the pH of dough that ranged from 5.05 in control dough to 5.2 in the dough with 10% brown algae added. These values differ due to the different initial mixture used to prepare the gluten-free bread as well as the composition and level of the microalgae added. The addition of brown algae increased the bread volume [32]. The authors suggested that algae components are hydrated, swelled and gelatinized at a slower rate compared to the control flour mixture. Moreover, they report that it was due to the algal protein enrichment that improved the rheological properties of dough and increased the gas retention capacity of the dough that resulted in higher bread volume. Since algae contain pigments, their addition decreased the lightness of bread crumb. The brown algae addition decreased bread firmness and the staling rate, whereas the bread elasticity was increased with algae addition. Nevertheless, sensory tests demonstrated that the addition of much less amount (2%) of brown algae can lead to an acceptable gluten-free bread.

References

- Wu, T.; Taylor, C.; Nebl, T.; Ng, K.; Bennett, L.E. Effects of chemical composition and baking on in vitro digestibility of proteins in breads made from selected gluten-containing and gluten-free flours. Food Chem. 2017, 233, 514–524.

- Sahagún, M.; Gómez, M. Assessing Influence of Protein Source on Characteristics of Gluten-Free Breads Optimising their Hydration Level. Food Bioproc. Technol. 2018, 11, 1686–1694.

- Pico, J.; Reguilón, M.P.; Bernal, J.; Gómez, M. Effect of rice, pea, egg white and whey proteins on crust quality of rice flour-corn starch based gluten-free breads. J. Cereal Sci. 2019, 86, 92–101.

- Phongthai, S.; D’Amico, S.; Schoenlechner, R.; Rawdkuen, S. Comparative study of rice bran protein concentrate and egg albumin on gluten-free bread properties. J. Cereal Sci. 2016, 72, 38–45.

- Federici, E.; Selling, G.W.; Campanella, O.H.; Jones, O.G. Thermal treatment of dry zein to improve rheological properties in gluten-free dough. Food Hydrocol. 2021, 115, 106629.

- Federici, E.; Jones, O.G.; Selling, G.W.; Tagliasco, M.; Campanella, O.H. Effect of zein extrusion and starch type on the rheological behavior of gluten-free dough. J. Cereal Sci. 2020, 91, 102866.

- Berta, M.; Koelewijn, I.; Öhgren, C.; Stading, M. Effect of zein protein and hydroxypropyl methylcellulose on the texture of model gluten-free bread. J. Texture Stud. 2019, 50, 341–349.

- Ziobro, R.; Juszczak, L.; Witczak, M.; Korus, J. Non-gluten proteins as structure forming agents in gluten free bread. J. Food Sci. Technol. 2016, 53, 571–580.

- Horstmann, S.W.; Foschia, M.; Arendt, E.K. Correlation analysis of protein quality characteristics with gluten-free bread properties. Food Funct. 2017, 8, 2465–2474.

- Srikanlaya, C.; Therdthai, N.; Ritthiruangdej, P.; Zhou, W. Effect of hydroxypropyl methylcellulose, whey protein concentrate and soy protein isolate enrichment on characteristics of gluten-free rice dough and bread. Int. J. Food Sci. Technol. 2018, 53, 1760–1770.

- Masure, H.G.; Wouters, A.G.B.; Fierens, E.; Delcour, J.A. Impact of egg white and soy proteins on structure formation and crumb firming in gluten-free breads. Food Hydrocol. 2019, 95, 406–417.

- Korus, J.; Chmielewska, A.; Witczak, M.; Ziobro, R.; Juszczak, L. Rapeseed protein as a novel ingredient of gluten-free bread. Eur. Food Res. Technol. 2021, 247, 2015–2025.

- Witczak, M.; Chmielewska, A.; Ziobro, R.; Korus, J.; Juszczak, L. Rapeseed protein as a novel ingredient of gluten-free dough: Rheological and thermal properties. Food Hydrocol. 2021, 118, 106813.

- Salah, K.; Olkhovatov, E.A.; Aïder, M. Effect of canola proteins on rice flour bread and mathematical modelling of the baking process. J. Food Sci. Technol. 2019, 56, 3744–3753.

- Zorzi, C.Z.; Garske, R.P.; Flôres, S.H.; Thys, R.C.S. Sunflower protein concentrate: A possible and beneficial ingredient for gluten-free bread. Innovat. Food Sci. Emerg. Technol. 2020, 66, 102539.

- Witczak, T.; Juszczak, L.; Ziobro, R.; Korus, J. Rheology of gluten-free dough and physical characteristics of bread with potato protein. J. Food Proc. Eng. 2017, 40, e12491.

- Farzana, W.; Khalil, I.A. Protein quality of tropical food legumes. J. Sci. Technol. 1999, 23, 13–19.

- Iqbal, A.; Khalil, I.A.; Ateeq, N.; Sayyar Khan, M. Nutritional quality of important food legumes. Food Chem. 2006, 97, 331–335.

- Lo, B.; Kasapis, S.; Farahnaky, A. Lupin protein: Isolation and techno-functional properties, a review. Food Hydrocoll. 2021, 112, 106318.

- Nunes, M.C.; Raymundo, A.; Sousa, I. Rheological behaviour and microstructure of pea protein/kappa-carrageenan/starch gels with different setting conditions. Food Hydrocol. 2006, 20, 106–113.

- E.U. Commission Implementing Decision of 1 July 2014 authorising the placing on the market of rapeseed protein as a novel food ingredient under Regulation (EC) No 258/97 of the European Parliament and of the Council. Off. J. Eur. Union 2014, L196, 27.

- FSANZ—Food Standards Australia New Zealand. Approval Report–Application A1175. Rapeseed Protein Isolate as a Novel Food. 15 December 2020. p. 34. Available online: https://www.foodstandards.gov.au/code/applications/Documents/A1175%20Approval%20Report.pdf (accessed on 1 June 2021).

- FDA. GRAS Notice No. GRN 000683 Canola Protein Isolate. Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/index.cfm?set=GRASNotices&id=683&sort=GRN_No&order=DESC&startrow=1&type=advanced&search=%C2%A4Canola%20protein%C2%A4%C2%A4 (accessed on 1 June 2021).

- Waglay, A.; Karboune, S.; Alli, I. Potato protein isolates: Recovery and characterization of their properties. Food Chem. 2014, 142, 373–382.

- Santos, J.; Calero, N.; Guerrero, A.; Muñoz, J. Relationship of rheological and microstructural properties with physical stability of potato protein-based emulsions stabilized by guar gum. Food Hydrocol. 2015, 44, 109–114.

- Komeroski, M.R.; Homem, R.V.; Schmidt, H.d.O.; Rockett, F.C.; de Lira, L.; Vitória da Farias, D.; Kist, T.L.; Doneda, D.; Rios, A.d.O.; Ruffo de Oliveira, V. Effect of whey protein and mixed flours on the quality parameters of gluten-free breads. Int. J. Gastron. Food Sci. 2021, 24, 100361.

- Han, A.; Romero, H.M.; Nishijima, N.; Ichimura, T.; Handa, A.; Xu, C.; Zhang, Y. Effect of egg white solids on the rheological properties and bread making performance of gluten-free batter. Food Hydrocol. 2019, 87, 287–296.

- Aprodu, I.; Banu, I. Effect of starch and dairy proteins on the gluten free bread formulation based on quinoa. J. Food Meas. Charact. 2021, 15, 2264–2274.

- Diprat, A.B.; Silveira Thys, R.C.; Rodrigues, E.; Rech, R. Chlorella sorokiniana: A new alternative source of carotenoids and proteins for gluten-free bread. LWT 2020, 134, 109974.

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I.; Raymundo, A. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998.

- Selmo, M.S.; Salas-Mellado, M.M. Technological quality of bread from rice flour with Spirulina. Int. Food Res. J. 2014, 21, 1523–1528.

- Różyło, R.; Hameed Hassoon, W.; Gawlik-Dziki, U.; Siastała, M.; Dziki, D. Study on the physical and antioxidant properties of gluten-free bread with brown algae. CyTA J. Food 2017, 15, 196–203.

- Kowalczewski, P.Ł.; Gumienna, M.; Rybicka, I.; Górna, B.; Sarbak, P.; Dziedzic, K.; Kmiecik, D. Nutritional value and biological activity of gluten-free bread enriched with cricket powder. Molecules 2021, 26, 1184.

- Nissen, L.; Samaei, S.P.; Babini, E.; Gianotti, A. Gluten free sourdough bread enriched with cricket flour for protein fortification: Antioxidant improvement and Volatilome characterization. Food Chem. 2020, 333, 127410.

- Da Rosa Machado, C.; Thys, R.C.S. Cricket powder (Gryllus assimilis) as a new alternative protein source for gluten-free breads. Innov. Food Sci. Emerg. Technol. 2019, 56, 102180.

- Becker, E.W. Micro-algae as a source of protein. Biotechnol. Adv. 2007, 25, 207–210.

- Aneiros, A.; Garateix, A. Bioactive peptides from marine sources: Pharmacological properties and isolation procedures. J. Chromatogr. B 2004, 803, 41–53.

- Viegas, C.V.; Hachemi, I.; Mäki-Arvela, P.; Smeds, A.; Aho, A.; Freitas, S.P.; da Silva Gorgônio, C.M.; Carbonetti, G.; Peurla, M.; Paranko, J.; et al. Algal products beyond lipids: Comprehensive characterization of different products in direct saponification of green alga Chlorella sp. Algal Res. 2015, 11, 156–164.