The Fourth Industrial Revolution drives industries from traditional manufacturing to the smart manufacturing approach. In this transformation, existing equipment, processes, or devices are retrofitted with some sensors and other cyber-physical systems (CPS), and adapted towards digital production, which is a blend of critical enabling technologies. In the current scenario of Industry 4.0, industries are shaping themselves towards the development of customized and cost-effective processes to satisfy customer needs with the aid of a digital twin framework, which enables the user to monitor, simulate, control, optimize, and identify defects and trends within, ongoing process, and reduces the chances of human prone errors.

- digital twin

- industry 4.0

- Proknow-C

- artificial intelligence

- machine learning

- deep learning

1. Introduction

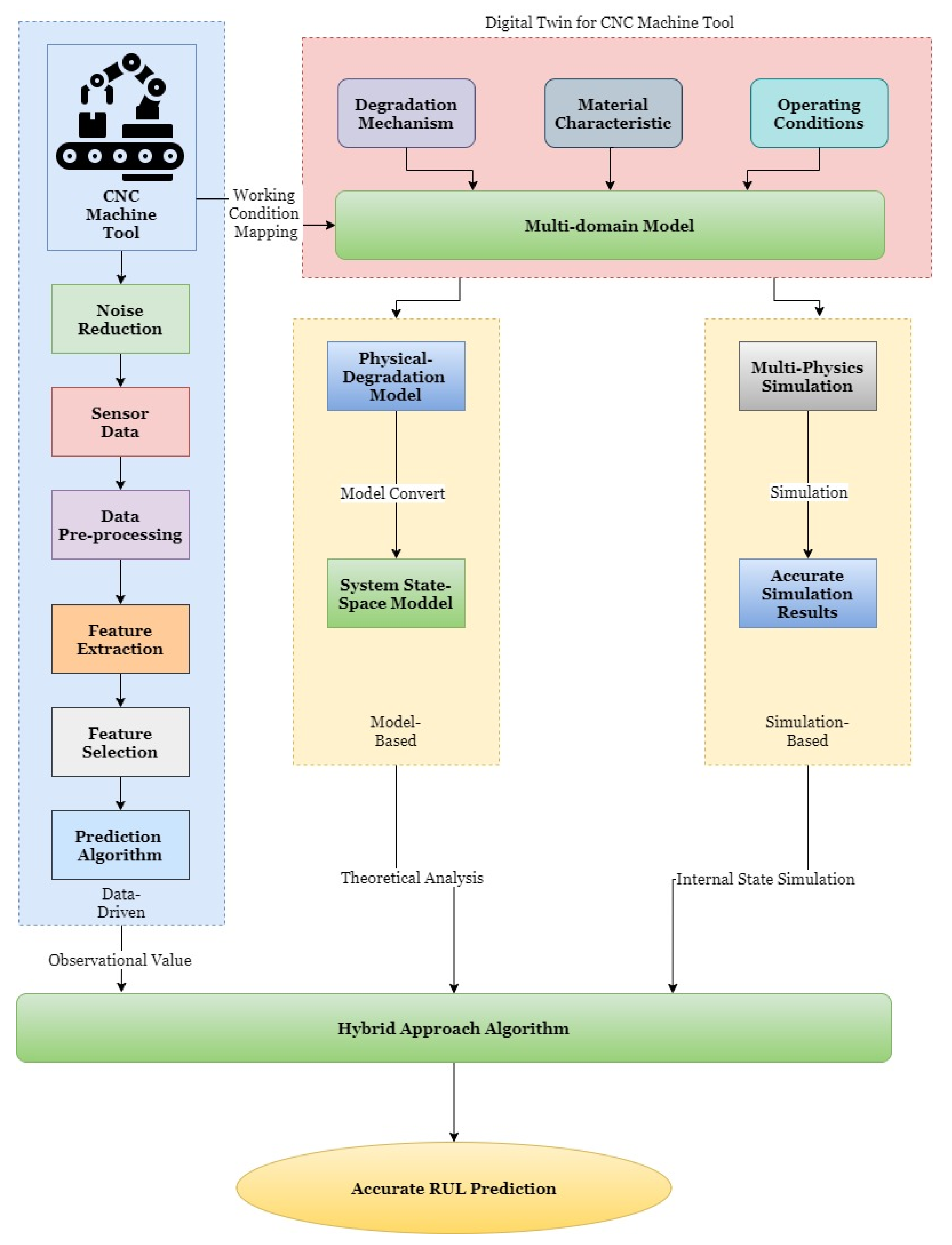

2. Case Study: Hybrid Predictive Maintenance of CNC Tool Using Digital Twin

References

- Paritala, P.; Manchikatla, S.; Yarlagadda, P. Digital Manufacturing- Applications Past, Current, and Future Trends. Procedia Eng. 2017, 174, 982–991.

- Benotsmane, R.; Kovács, G.; Dudás, L. Economic, social impacts and operation of smart factories in Industry 4.0 focusing on simulation and artificial intelligence of collaborating robots. Soc. Sci. 2019, 8, 143.

- Leng, J.; Liu, Q.; Ye, S.; Jing, J.; Wang, Y.; Zhang, C.; Zhang, D.; Chen, X. Digital twin-driven rapid reconfiguration of the automated manufacturing system via an open architecture model. Robot. Comput. Integr. Manuf. 2020, 63, 101895.

- Markets and Markets. Smart Manufacturing Market by Enabling Technology, Information Technology, Industry, and Region | COVID-19 Impact Analysis|MarketsandMarketsTM. 2020. Available online: https://www.marketsandmarkets.com/Market-Reports/smart-manufacturing-market-105448439.html?gclid=Cj0KCQjwzZj2BRDVARIsABs3l9LqNjw2gircZUP8sh_4EJw0WOKqqOQHpDNwK2ZOw8r_xCaLk2Jr2CQaAtXtEALw_wcB (accessed on 6 July 2021).

- Aimienrovbiye, G. Maintenance impact on Production Profitability: A Case Study. 2010, p. 69. Available online: https://www.diva-portal.org/smash/get/diva2:327878/FULLTEXT01.pdf (accessed on 6 July 2021).

- Tucci, M.; Rapaccini, M.; De Carlo, F.; Borgia, O. New Maintenance Opportunities in Legacy Plants; IFAC: Szczecin, Poland, 2008; Volume 41, ISBN 9783902661401.

- Krar, S. The Importance of Maintenance. 2014. Available online: https://www.automationmag.com/images/stories/LWTech-files/94%20Intelligent%20Systems.pdf (accessed on 8 June 2020).

- Manufacturing Machinery Maintenance _ NIST. National Institute of Standards and Technology U.S. Department of Commerce. 2020. Available online: https://www.nist.gov/el/applied-economics-office/manufacturing/topics-manufacturing/manufacturing-machinery-maintenance#:~:text=Oneoftheapplicationsof,andApplicationforManufacturingOperations (accessed on 6 July 2021).

- Smith, A.; Hinchcliffe, G. Preventive Maintenance—Definition and Structure. In RCM Gateway to World Class Maintenance; Elsevier: Amsterdam, The Netherlands, 2004; pp. 19–37. ISBN 9780750674614.

- Vilarinho, S.; Lopes, I.; Oliveira, J.A. Preventive Maintenance Decisions through Maintenance Optimization Models: A Case Study. Procedia Manuf. 2017, 11, 1170–1177.

- Swanson, L. Linking maintenance strategies to performance. Int. J. Prod. Econ. 2001, 70, 237–244.

- Nita Ali, K.; Sun, M.; Petley, G.; Barrett, P. Improving the business process of reactive maintenance projects. Facilities 2002, 20, 251–261.

- Kahraman, C.; Onar, S.Ç. Intelligent Techniques in Engineering Management Theory and Applications; Springer International Publishing: Basel, Switzerland, 2015; Volume 87, ISBN 978-3-319-17905-6.

- Amihai, I.; Gitzel, R.; Kotriwala, A.M.; Pareschi, D.; Subbiah, S.; Sosale, G. An industrial case study using vibration data and machine learning to predict asset health. In Proceedings of the 2018 IEEE 20th Conference on Business Informatics (CBI), Vienna, Austria, 11–14 July 2018; Volume 1, pp. 178–185.

- Man, J.; Zhou, Q. Prediction of hard failures with stochastic degradation signals using Wiener process and proportional hazards model. Comput. Ind. Eng. 2018, 125, 480–489.

- Schroeder, T. Benefits of Predictive Maintenance in Manufacturing. Excellence Blog. 2017. Available online: https://blog.softexpert.com/en/the-benefits-of-predictive-maintenance/ (accessed on 7 July 2021).

- Upkeep Maintenance Management. Maintenance Statistics: Predictive & Preventive, Labor & Costs. 2021. Available online: https://www.onupkeep.com/learning/maintenance-metrics/maintenance-statistics (accessed on 7 July 2021).

- Vavra, B. Plant Engineering _ 2018 Maintenance Survey_ Playing Offense and Defense. 2018. Available online: https://www.plantengineering.com/articles/2018-maintenance-survey-playing-offense-and-defense/ (accessed on 7 July 2021).

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316.

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661.

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z.; et al. Five-dimension digital twin model and its ten applications. Jisuanji Jicheng Zhizao Xitong/Comput. Integr. Manuf. Syst. CIMS 2019, 25, 1–18.

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971.

- Ashtari Talkhestani, B.; Weyrich, M. Digital Twin of manufacturing systems: A case study on increasing the efficiency of reconfiguration. At-Automatisierungstechnik 2020, 68, 435–444.

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593.

- Markets and Markets. Digital Twin Market by Technology, Type, Application, Industry|COVID-19 Impact Analysis | MarketsandMarketsTM. 2020. Available online: https://www.marketsandmarkets.com/Market-Reports/digital-twin-market-225269522.html?gclid=EAIaIQobChMIl8GUtO3c7wIVEuh3Ch2zWgfrEAAYAiAAEgIUTfD_BwE (accessed on 7 July 2021).

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. Integr. Manuf. 2020, 65, 101974.