Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Nora Tang and Version 1 by Heba Beshai.

Smart packaging is an emerging technology that has a great potential in solving conventional food packaging problems and in meeting the evolving packaged vegetables market needs. The advantages of using such a system lies in extending the shelf life of products, ensuring the safety and the compliance of these packages while reducing the food waste; hence, lessening the negative environmental impacts. Many new concepts were developed to serve this purpose, especially in the meat and fish industry with less focus on fruits and vegetables.

- smart packaging

- intelligent systems

- active packaging

- sensors

- indicators

1. Introduction

Food packaging was developed to serve several purposes such as limiting food loss and preserving food quality for longer periods. Its main functions can be summarized as protection from possible contaminations as it acts as a barrier, communication of the package information about brands and nutritional content, containment, and convenience to accommodate the fast-paced customer’s lifestyle [1]. However, continuous changes in customer and industry demands led to the evolution of smart packaging as an alternative to conventional packaging. An important purpose of smart packaging is to trace and preserve perishable goods as much as possible while ensuring safety, reducing food waste and environmental impact through monitoring and sensing. Generally, food loss is considered one of the main issues of concern around the world. It was found that almost one third of the food produced is wasted along the supply chain [2]. In Canada, in 2019, the estimated food loss was worth $31 billion, of which 30% was vegetables [2].

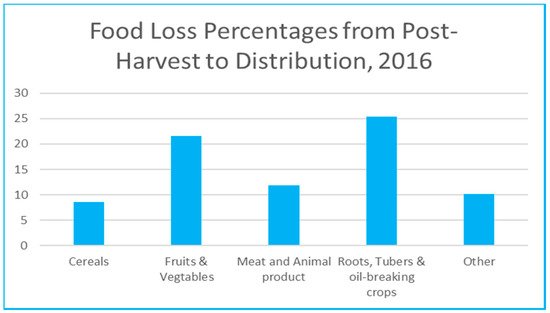

Food waste occurs along different stages in the supply chain, starting with on farm waste as a result of inadequate harvesting and handling, to losses through processing and storage, then in transportation and distribution due to the use of unsuitable facilities, and losses at the retail shops due to limited shelf-life or improper storing. Figure 1 shows percentages of food losses for different categories, from post-harvest to distribution. Fruits and vegetables are considered a major contributor after the roots, tubers, and oil-breaking corps to food wastage along the supply chain with 21.6% [3]. Apart from the ethical side of wasting food, other problems such as food contamination is an issue of concern. Many deaths over the years were linked to presence of pathogens in packaged food [4]. The economic loss and the environmental depletion of agricultural resources are also major problems that need to be addressed. All of that brought to attention the necessity to take the appropriate measures to ensure control and reduction in these wastage rates. Smart packaging presents a viable solution in such application to reduce the inefficiencies and wastage in the food supply chain [5].

Many papers were published about the use of smart systems in different food and beverage industries [6]. Some discussed their use in monitoring water quality [7,8,9,10,11][7][8][9][10][11]. Other publications focused on freshness detection and control of packaged meat and animal products [12,13,14,15][12][13][14][15]. Some others were concerned about the freshness of the produce in general [16[16][17][18][19][20],17,18,19,20], with less attention and focus to vegetables in specific. However, with the recent increase of illnesses outbreaks related to packaged vegetables [21], the need to have more research on vegetable freshness inside a package in specific became a necessity. This is to avoid food wastage while ensuring the health and safety of the public. Smart systems have a great potential in such application. Smart packaging can be used to monitor the freshness and the quality of the food inside, and also to detect the presence of substances such as Bisphenol A migrating from the plastic package itself that is used in the food and beverage industries [22]. Therefore, with the continuous improvement in smart systems technologies, the possibility of commercial use of smart packaging in the food industry is rising.

In this paper we provide a review of the state-of-the-art smart packaging systems used. Definition and classification into intelligent and active packaging systems are discussed in the first two sections. In the Section 3, we present some of the most important factors affecting vegetables inside the package. In Section 4, intelligent systems are further classified into sensors, indicators, and data carriers with various commercial top niche examples of each category briefly described. In Section 5, a comparison between different intelligent systems are summarized. In Section 6, an introduction to active packaging with a glance on different scavenging and object releasing active components is overviewed. In Section 7, challenges, outlook, and future research opportunities are discussed. In Section 8, a conclusion is provided emphasizing on the importance of smart packaging systems in evaluating freshness monitoring of vegetables.

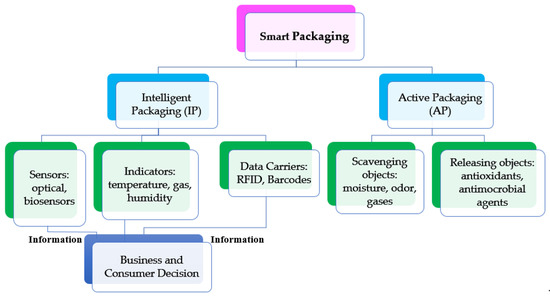

2. Classification

In the last two decades smart packaging has become popular especially because it leads the consumer and businesses to make better decisions regarding food quality. It can be further classified into two main categories: intelligent packaging (IP) to monitor the freshness and safety, and active packaging (AP) to keep or improve the quality. IP is defined as one of the packaging systems that plays an important role by providing means of sensing/indicating and communicating the information about the freshness and the safety of the consumed vegetables and aims to prolong the shelf life. This emerging packaging technology, that serves as a barrier against environmental influences such as odors, dust, micro-organisms, facilitates decision making regarding the quality of the packaged food. IP contains smart devices that are capable of tracing and monitoring the freshness of the produce. It can also store and transfer the sensed information to retailers and stakeholders to improve the technology. Intelligent packaging (IP) can be classified into three main categories: sensors, indicators, and data carrier, as shown in Figure 2. Each category can be either placed inside or on the package to provide information about each package, or to monitor the environment surrounding the packages [1,23][1][23]. In contrast, active packaging (AP) is defined as the system that incorporates active components such as scavenging or releasing objects in response to changes in package headspace to extend the shelf-life of the packaged food. AP can be further classified depending on the objects used inside the package into scavengers and releasers. Scavenging objects concern the capture of excess moisture, odors, and gases such as moisture absorbers, oxygen scavengers, and odor absorbers [23]. The releasing objects are usually emitters/generators that release objects such as antimicrobials agents, carbon dioxide emitters, and antioxidants [23].

Figure 2. Smart packaging system classification.

3. Conclusions

The smart packaging systems provide potential solutions to the conventional packaging problems such as food loss and contamination. For packaged vegetables, the most important factors to monitor as a part of freshness assessment of vegetables are the ratio of oxygen and carbon dioxide inside the package, ethylene response, pathogen presence, and temperature, which has a huge effect on pathogens growth rate, chlorophyll content, and humidity. Tracking these parameters can be done through intelligent systems such as sensors (optical, bio, gas, and humidity), indicators (TTI, gas and humidity, and freshness), or by data carriers (RFID tags and barcodes). Adjusting these parameters can be done using active packaging such as using scavenging objects (oxygen or carbon dioxide scavengers, moisture absorbers), or releasing objects (oxygen or carbon dioxide emitters, antioxidants, antimicrobials). However, the challenges facing this industry in terms of complexity of legislations and regulation, cost, privacy concerns, and sustainability of the systems used are inhibiting mass-production of such smart systems. Therefore, collaboration between the researchers, industries, regulatory agencies, and the consumers will allow for further development of smart packaging systems.References

- Han, J.; Ruiz-Garcia, L.; Qian, J.; Yang, X. Food packaging: A comprehensive review and future trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877.

- Food Waste in Canada. Available online: https://lovefoodhatewaste.ca/about/food-waste/ (accessed on 21 March 2020).

- The State of Food and Agriculture. Available online: http://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 21 March 2020).

- Behravesh, C.B.; Jones, T.F.; Vugia, D.J.; Long, C.; Marcus, R.; Smith, K.; Thomas, S.; Zansky, S.; Fullerton, K.E.; Henao, O.L.; et al. FoodNet Working Group, Deaths Associated With Bacterial Pathogens Transmitted Commonly Through Food: Foodborne Diseases Active Surveillance Network (FoodNet), 1996–2005. J. Infect. Dis. 2011, 204, 263–267.

- Taking Stock: Reducing Food Loss and Waste in Canada. Available online: https://www.canada.ca/en/environment-climate-change/services/managing-reducing-waste/food-loss-waste/taking-stock.html#toc4 (accessed on 21 March 2020).

- Plimmer, J. Augmenting and securing the consumer brand experience through smart and intelligent packaging for food, beverages and other fast-moving consumer goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods Markets, Materials and Technologies, 1st ed.; Farmer, N., Ed.; Woodhead Publishing Series in Food Science; Technology and Nutrition: Philadelphia, PA, USA, 2013; pp. 35–57.

- Jin, H.; Qin, Y.; Pan, S.; Alam, A.U.; Dong, S.; Ghosh, R.; Deen, M.J. Open-Source Low-Cost Wireless Potentiometric Instrument for pH Determination Experiments. J. Chem. Educ. 2018, 95, 326–330.

- Alam, A.U.; Clyne, D.; Jin, H.; Hu, N.X.; Deen, M.J. Fully Integrated, Simple, and Low-Cost Electrochemical Sensor Array for in Situ Water Quality Monitoring. Acs Sens. 2020, 5, 412–422.

- Alam, A.U.; Howlader, M.M.; Hu, N.X.; Deen, M.J. Electrochemical sensing of lead in drinking water using β-cyclodextrin-modified MWCNTs. Sens. Actuat. B Chem. 2019, 296, 126632.

- Qin, Y.; Alam, A.U.; Pan, S.; Howlader, M.M.; Ghosh, R.; Hu, N.X.; Deen, M.J. Integrated water quality monitoring system with pH, free chlorine, and temperature sensors. Sens. Actuat. B Chem. 2018, 255, 781–790.

- Alam, A.U.; Qin, Y.; Howlader, M.M.; Hu, N.X.; Deen, M.J. Electrochemical sensing of acetaminophen using multi-walled carbon nanotube and β-cyclodextrin. Sens. Actuat. B Chem. 2018, 254, 896–909.

- Gallocchio, F.; Cibin, V.; Biancotto, G.; Roccato, A.; Muzzolon, O.; Carmen, L.; Simone, B.; Manodori, L.; Fabrizi, A.; Patuzzi, I. Testing nano-silver food packaging to evaluate silver migration and food spoilage bacteria on chicken meat. Food Addit. Contam. Part A 2016, 33, 1063–1071.

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview of existing solutions. J. Food Sci. Technol. 2015, 52, 3947–3964.

- Solomon, M.B.; Eastridge, J.S.; Paroczay, E.W.; Williams, J.L.; Shackell, G.H.; Dodds, K.G. Animal Biotechnology for the Enhancement of Meat Quality. In Meat Biotechnology, 1st ed; Tolrá, F., Ed.; Springer Science +Business Media LLC: New York, NY, USA, 2008; pp. 2–91.

- Holman, B.W.B.; Kerry, J.P.; Hopkins, D.L. A review of patents for the smart packaging of meat and muscle-based food products, Bentham science. Recent Patents Food Nutr. Agric. 2018, 9, 3–13.

- Beaudry, R.; Scully, A.D.; Horsham, M.A. MAP as a basis for active packaging. Active packaging for fruits and vegetables. In Intelligent and Active Packaging for Fruits and Vegetables, 1st ed.; Wilson, C.L., Ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 31–72.

- Beaudry, R.M. Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biol. Technol. 1999, 16, 293–303.

- Zhen-guo, L.; Yu, L.; Jian-guo, D.; Rong-jiang, X.; Mei-zhen, Z. Effect of low oxygen and high carbon dioxide on the levels of ethylene and 1-aminocyclopropane-1-carboxylic acid in ripening apple fruits. J. Plant Growth Regul. 1983, 2, 81–87.

- Shirazi, A.; Cameron, A.C. Controlling relative humidity in modified atmosphere packages of tomato fruit. Hortscience 1992, 27, 336–339.

- Pant, A.F.; Thielmann, J.; Kuswandi, B. Active Packaging of Fresh and Fresh-cut Fruit and Vegetables. Intelligent Packaging Applications for Fruits and Vegetables. In Innovative Packaging of Fruits and Vegetables: Strategies for Safety and Quality Maintenance, 1st ed.; Siddiqui, M.W., Rahman, M.S., Wani, A.A., Eds.; CRC Press: Boca Raton, FL, USA, 2007; pp. 49–104.

- Callejón, R.M.; Rodríguez-Naranjo, M.I.; Úbeda, C.; Hornedo-Ortega, R.; García, M.C.; Garcia-Parrilla, M.C.; Troncoso, A.M. Reported foodborne outbreaks due to fresh produce in the United States and european union: Trends and causes. Foodborne Pathog. Dis. 2015, 12, 32–38.

- Alam, A.U.; Deen, M.J. Bisphenol A Electrochemical Sensor Using Graphene Oxide and β-Cyclodextrin-Functionalized Multi-Walled Carbon Nanotubes. Anal. Chem. 2020, 92, 5532–5539.

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent packaging: Concepts and applications. J. Food Sci. 2005, 70, R1–R10.

More